Conformity of Structural Steel Products and Structures

Diunggah oleh

Stephen HicksHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Conformity of Structural Steel Products and Structures

Diunggah oleh

Stephen HicksHak Cipta:

Format Tersedia

SESOC Journal

CONFORMITY OF STRUCTURAL STEEL

PRODUCTS AND STRUCTURES

by S Hicks, HERA General Manager, stephen.hicks@hera.org.nz

1 CONFORMITY REQUIREMENTS • UK CARES (Certification Authority for Reinforcing

VERSUS CONFORMITY ASSESSMENT Steels), whom are accredited by UKAS (United

Kingdom Accreditation Service) according to

It is important that a distinction is made between

ISO Guide 65 and ISO 17021 to provide product

conformity requirements and conformity assessment,

certification of reinforcing, prestressing and structural

which are given generically below in Section 1.1 and 1.2.

steel products manufactured and supplied to BS and

1.1 CONFORMITY REQUIREMENTS EN standards.

The conformity requirements set-out in product standards • ACRS (Australasian Certification Authority for

provide: Reinforcing and Structural Steels), whom are

• The characteristics of the product that are needed to accredited by JAS-ANZ (Joint Accreditation System

provide an expected performance. of Australia and New Zealand) according to ISO/

• The measurement and test methods which specify IEC 17065 to provide product certification of

the procedure for determining the values of the reinforcing, prestressing and structural steel products

characteristics or for checking conformity to stated manufactured and supplied to AS and AS/NZS

requirements. standards.

• The required frequency of the measurements. 1.3 CONFORMITY OF STEEL PRODUCTS

1.2 CONFORMITY ASSESSMENT Manufacturers of structural steel products are required to

perform the following in EN, AS and AS/NZS standards:

Conformity assessment involves a set of processes

that show a product, service or system meets the • Initial Type Testing (ITT): the complete set of

requirements of a standard. Undergoing the conformity tests described in a standard to determine the

assessment process has a number of benefits: characteristics of samples of products representative

of the product type. The ITT provides the manufacturer

• It provides consumers and other stakeholders with

with the characteristics of the product using their

added confidence.

manufacturing, measuring and quality management

• It provides a company with a competitive edge, system (QMS) and needs to be undertaken before a

differentiating it from companies that have not product is placed on the market.

achieved certification.

• Factory Production Control (FPC): the permanent

• It helps regulators ensure that technical, health, safety internal control of production exercised by the

or environmental conditions are met. manufacturer, which provides a means by which a

The main forms of conformity assessment are testing, manufacturer ensures that the performances declared

certification, and inspection. Some examples of by him (obtained on the basis of ITT) continue to

Conformity Assessment Bodies (CABs) whom are be valid for all subsequent products. This generally

specialists in structural steel and are accredited to involves ensuring that subsequent products remain

perform these activities are: substantially the same as those submitted to ITT (i.e.

• Notified Bodies that are listed on the Nando web-site, having the same characteristics).

whom are listed as being able to certify steel products 1.3.1 HOT ROLLED STEEL PRODUCTS

manufactured to EN 10025-1 to -6 and are accredited TO EN 10025-1 TO - 6

to the appropriate AVCP system that is given in

the Construction Products Regulation to enable a Conformity requirements

manufacturer to CE mark their products (see Section Conformity requirements for ITT and FPC are presented

1.3.1). (N.B. The CE mark is an EU regulatory mark in Annex B of EN 10025-1, which applies to the products

and not a product certification mark, or quality mark). described in EN 10025-2 to EN 10025-6. Unlike AS and

AS/NZS standards, EN 10025-1 to -6 only provide the

14 Journal of the Structural Engineering Society of New Zealand Inc

SESOC Journal

mechanical and chemical conformity requirements of the Commission and the clauses within the hEN in which they

structural steel material. The geometry and geometrical are addressed; therefore, Annex ZA in a particular hEN

tolerances are given in separate standards such as EN provides a checklist for a manufacturer to CE Mark their

10029 for plate, EN 10034 for I- and H-sections, etc. product. For building products the Construction Products

Conformity assessment Regulation, or ‘CPR’ (Regulation 305/2011) resulted in

Unlike the Eurocodes which are developed by the CE Marking becoming mandatory from 1 July 2013 in the

industry (e.g. for steel design, EN 1993-1-1, EN 1994-1- European Economic Area (EEA). However, CE Marking is

1, etc.), EN standards that are prepared at the request not applicable in countries outside the EEA (28 countries)

of the European Commission (to implement European and the three EFTA states (Iceland, Liechtenstein and

legislation) are known as ‘mandated’ standards. When Norway).

‘mandated’ standards are prepared under the ‘new According to the CPR, the system of Assessment and

approach’ directives, they are known as ‘harmonized Verification of Constancy of Performance (AVCP) defines

standards’ (hENs) and are cited in the Official Journal of the degree of involvement of third-party Notified Bodies

the European Communities (OJ). in assessing the conformity of a product. There are five

Normally hENs are used for product standards and are systems of AVCP: the highest being 1+ (corresponding

immediately recognizable as they possess an informative to safety-critical products); and the lowest being System

Annex ZA, which lists the regulated requirements type 4. The tasks and responsibilities for each system are

according to a mandate issued by the European shown in Table 1.

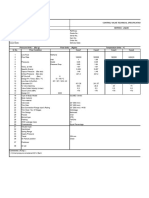

System type

1+ 1 2+ 3 4

Assessment of products performance based on testing, calculation, tabulated

X X

values or descriptive documentation

Notified Body

Tasks for the

Initial inspection of the manufacturing plant X X X X

Initial inspection of the Factory Production Control (FPC) system X X X X

Continuing surveillance of the FPC system X X X X

Audit testing X

To issue, restrict, suspend or withdraw a certificate of constancy of performance X X X X

Assessment of products performance based on testing, calculation, tabulated

manufacturer

Tasks for the

X X

values or descriptive documentation

FPC and further testing of samples X X X

FPC X X

Determination of the product-type X X X X X

Table 1 Assessment of conformity tasks according to the Construction Products Regulation

Before a product is placed on the market, a Declaration In order that a purchaser can check whether a Notified

of Performance (DoP) needs to be produced by the Body is accredited to undertake the AVCP, a list of

manufacturer, importer or distributor, thereby assuming Notified Bodies is given on the Nando (New Approach

legal responsibility of its declared performance. The DoP, Notified and Designated Organisations) Information

inter alia, identifies the hEN, the System of AVCP, the System at the following internet address: http://

Notified Body and the information required in Annex ZA of ec.europa.eu/growth/tools-databases/nando/.

the appropriate hEN. In addition, the CE Marking needs By way of an example, Appendix A presents an

to be affixed to the construction product, which indicates inspection certificate issued by Tata Steel UK for an EN

that it is consistent with its DoP. When considering steel 10025-2:S355J0+AR 203 × 203 UC 46.1 [N.B. because

construction, manufacturers, importers or distributors of of the age of the attached certificate, it refers to the CPD

structural steel products produced to EN 10025-1 to -6, (construction products regulation), which was replaced by

are required to provide a DoP to System type 2+ of AVCP. the CPR in 2011].

Volume 29 No.2 September 2016 15

SESOC Journal

By considering Item 5 in Appendix A, the license number • No document containing requirements for products,

of 0038 is given for the Notified Body (Lloyds Verification processes, services, persons, systems and bodies

Services); this can be verified by checking this license shall make conformity dependent on a quality

number on the Nando web-site. management systems standard (e.g. it shall not make

Particular note should be paid to Item 2 in Appendix A, normative reference to ISO 9001).

where EN 10025 permits an Inspection certificate Type • As opposed to EN 10025-1 and other EN product

2.2 for products where the specified minimum yield standards, there is no equivalent Annex ZA in AS and

strength for the thinnest thickness range ≤ 355 MPa and AS/NZS standards. Both standards bodies require

a specified impact energy tested at a temperature of 0°C conformity assessment to be considered in a separate

or 20°C. Conversely, when a product is used within a standard containing the specific requirements for

steel structure, the fabrication and erection standard EN assessment of conformity or for a relevant conformity

1090-2 (see Section 2) requires an Inspection document assessment scheme. Conformity assessment

3.1 for steel grade S355 JR or J0. It is recommended by standards are not encouraged by Standards Australia

the present author that an Inspection document 3.1 or and any such development is considered on a case-

3.2 is specified. by-case basis and can only proceed after approval

UK CARES is an independent, not-for-profit certification has been sought and granted from the Standards

body, established in 1983 to provide confidence to the Development and Accreditation Committee (SDAC).

users, purchasers and specifiers of constructional steels Conformity assessment

through a regime of regulation, testing and inspection (see Given that Standards Australia and Standards New

http://www.ukcares.com/). It operates for the benefit of Zealand adopt the neutrality principle, the conformity

the construction industry offering certification schemes for assessment can be made by a first-, second- or third-

companies that produce materials, components or offer party. There are currently only two third-party schemes

services, primarily to the reinforced concrete industry. for structural steel products available in Australasia, as

Although originally established to provide certification follows:

for products manufactured to BS standards, following

• The ACRS Scheme (developed from the UK CARES

the withdrawal of BS to make way for EN standards,

scheme), details of which are given in the following

CARES product certification (quality mark), in addition to

link http://www.steelcertification.com/scheme.html.

CE marking (regulatory mark), is a requirement in the UK

Unlike other CABs, ACRS has a particular specialism

for major construction specifications. Such Specification

in certifying construction steels (ACRS auditors are

for Highway Works, County Councils specifications, the

all qualified metallurgists with extensive technical

National Building Specification and the National Structural

and operational experience in steel manufacturing of

Concrete specification, to provide additional confidence

the specific products they assess). ACRS product

to users and asset-owners. (N.B. It may be possible for

conformity assessment are the requirements of AS/

UK CARES to provide assessments of manufacturers

NZS steel standards and are additional to the quality

who produce products to other standards, but this

management system assessment requirements under

might need to be considered on a case-by-case basis in

any ISO 9001 certification held by the manufacturer.

response to requests from the industry).

The ACRS Scheme is the only steel certification

1.3.2 STEEL PRODUCTS TO AS/NZS 1163, 3878, scheme currently accredited by JAS-ANZ. (N.B. It may

3679.1 AND 3679.2 be possible for UK CARES to provide assessments

of manufacturers who produce products to other

Conformity requirements standards, but this might need to be considered on a

Appendix B that is included in the 2016 edition of AS/ case-by-case basis in response to requests from the

NZS 1163, 3878 and 3679.1 has taken inspiration from industry).

EN 10025-1, Annex B in that conformity requirements for • ATIC (Australian Technical Infrastructure Committee)

ITT and FPC are given. However, Standards Australia and Scheme 10, which is generally considered to be less

Standards New Zealand strictly adhere to the following rigorous than the ACRS scheme, but can be serviced

rules : by a number of CABs. Details of ATIC Scheme 10 are

• They follow the ISO/IEC Directives, Part 2 "neutrality given in the following link: http://www.atic.net.au/

principle", such that conformity can be assessed by ATIC_conformity_assessment.html

a first-party (manufacturer or supplier), second-party

(a user or purchaser), or third-party (an independent

body).

16 Journal of the Structural Engineering Society of New Zealand Inc

SESOC Journal

2 FABRICATION AND ERECTION The different levels of quality control, management

(EXECUTION) STANDARDS FOR measures and traceability are dependent on the

execution class (EXC) of the structure from EXC1 for

STEEL STRUCTURES

low consequences of failure to EXC4 for the highest

Since 2008, the fabrication and erection of steel consequences of failure. The latest edition of the

structures (as well as reinforced concrete structures) has European design standard EN 1993-1-1 provides a

been formalized through so-called ‘execution’ standards. risk-based matrix that the designer is required to use to

Execution standards assume that the product is the enable the appropriate EXC to be specified for a particular

finished structure (whether it is a multi-storey building or a structure.

bridge), which is manufactured under factory conditions.

Different fabricators can be certified for different EXC by

To enable the safety factors used in the design standards

a Notified Body. In the UK, the main Notified Body for

to remain constant, irrespective of the consequence

fabricated structural steelwork is the Steel Construction

class of the structure (equivalent to Importance Level

Certification Scheme (see https://www.steelconstruction.

in AS/NZS 1170.0), different levels of quality control

org/steel-construction-certificate-scheme-sccs/ ). Other

and management measures are mandated in these

Notified Bodies to EN 1090-1 are given on the Nando

execution standards to provide the necessary reliability

web-site.

differentiation.

2.2 STEEL STRUCTURES FABRICATED

2.1 STEEL STRUCTURES FABRICATED

TO ISO 17607

TO EN 1090-1 AND EN 1090-2

ISO 17607 is currently under development and takes

Like EN 10025-1, EN 1090-1 possess an informative

inspiration from EN 1090-2. HERA is the Convenor of the

Annex ZA, which lists the regulated requirements

New Zealand International Review Group (IRG) for ISO/

according to a mandate issued by the European

TC 167 Steel and aluminium structures, which is the ISO

Commission and the clauses within the hEN in which

Technical Committee responsible for ISO 17607.

they are addressed; therefore, in this case, Annex ZA

provides a checklist for a fabricator to CE Mark their 2.3 STEEL STRUCTURES FABRICATED TO AS/

product. Whereas, EN 1090-2 provides the conformity NZS 5131

requirements for fabricated steelwork. In the UK CE HERA, SCNZ and ASI were responsible for the structural

marking of fabricated structural steelwork became steelwork fabrication and erection Code of Practice

mandatory on 1 July 2014. (CoP), which takes inspiration from EN 1090-2 and was

The concept for CE marking is that once the fabricator published in 2014. The contents of the CoP, together

processes the products that are CE marked by the with ISO 17607, have been used as the basis for AS/

steelmaker, CE marking is lost and the fabricator needs NZS 5131 which was published for public comment

to have the appropriate systems in place for him to on 23 March 2016. In this standard ‘Construction

apply CE marking to the finished fabricated product. Category’ is used instead of EXC. It is assumed that the

Like EN 10025-1, System type 2+ of AVCP is required implementation will follow the same format as in Europe,

in EN 1090-1 (see Table 1); this requires the fabricator to where future editions of the design standard NZS 3404/

undertake: AS 4100 will provide a risk-based matrix that the designer

is required to use to enable the appropriate construction

• Initial type-testing of the product

category to be specified.

• Factory Production Control (FPC), which includes:

For the conformity assessment of fabricators to AS/

o implementation of FPC system procedures;

NZS 5131, two schemes have been developed and are

o appointment of a responsible welding coordinator serviced by ‘Notified Bodies’ in NZ and Australia, as

(RWC); and follows:

o implementation of welding quality management • Steel Fabricator Certification (SFC) – see http://

system (WQMS) procedures. steelfabcert.co.nz/

• Further testing of samples taken at the factory in • Steelwork Compliance Australia (SCA) – see http://

accordance with the prescribed test plan. www.scacompliance.com.au/

Volume 29 No.2 September 2016 17

SESOC Journal

APPENDIX A approval to apply the CE mark to their products (e.g.

0038, Lloyds Verification Services). The CE symbol

EXAMPLE INSPECTION CERTIFICATE FOR EN has defined dimensions and if the font or size looks

10025 STEEL PRODUCTS unusual it may indicate that the certificate is false.

The relevant parts of the certificate are: 6. The unique number for the certificate confirming the

1. The name and address of the supplier / manufacturer. chemical and mechanical properties of the tested

items.

2. Identification of the Inspection certificate type (e.g.

EN10204, 3.1 or 3.2). This certificate complies with 7. The unique number for the CE marking certificate.

the requirements of EN10204 and is a Type 3.1 - 8. The identifying information for the tested material. In

which is a manufacturer's test certificate showing this case there were 12 bars from Cast 83228 and 36

actual results linked to the batch of material relevant bars from Cast 83232. All bars are 18300 mm long as

to the certificate. A Type 3.2 certificate is endorsed indicated in the Specification/Product area.

by an independent inspection authority and will 9. The mechanical properties (minimum yield, tensile

again show actual results linked to the relevant strength and elongation) of the tested items – the

batch of material. If neither type is identified on the header indicates the range of values to be achieved.

certificate then it is most probable that the certificate

10. Charpy test results indicating the toughness of the

is just a Quality Report (Certificate type 2.2) and any

steel. The results cover three tests on each cast with

information shown concerning properties / chemistry

the average value also displayed.

should be treated with care as it is only indicative of

typical results from this type of material and does not 11. Chemical analysis of the test material – one analysis

give actual test results from the batch. per cast. Results shown on the inspection certificate

should be checked against the appropriate material

3. Date of issue of the certificate.

specification/standard to confirm compliance and

4. Details of the specification and the product. This that the product is fit for the purpose for which it

certificate covers UKC 203 x 203 x 46.1 to BS EN was bought but that should not be necessary for CE

10025 – 2. The steel grade is S355, the sub grade is marked material.

J0 indicating that the Charpy impact tests were taken

12. CEV (Carbon Equivalent Value) for the cast, which is

at 0°C; +AR indicates the as-rolled delivery condition.

an indication of the weldability of the steel.

5. The CE mark and license number for the third-party

13. Signature of an approved person.

Notified Body issuing the manufacturer with the

14. Name and address of the original customer.

18 Journal of the Structural Engineering Society of New Zealand Inc

Anda mungkin juga menyukai

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationDari EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationPenilaian: 5 dari 5 bintang5/5 (1)

- Application Nr. 3 (Ultimate Limit State) : Resistance of Member Cross-SectionDokumen48 halamanApplication Nr. 3 (Ultimate Limit State) : Resistance of Member Cross-SectionVictor TvvBelum ada peringkat

- D:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)Dokumen1 halamanD:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)deepakBelum ada peringkat

- BS En-12952-2-2021Dokumen46 halamanBS En-12952-2-2021TANK INSPECTBelum ada peringkat

- DVGW G 469 EnglishDokumen27 halamanDVGW G 469 EnglishMatej ZirdumBelum ada peringkat

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Dokumen15 halamanFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaBelum ada peringkat

- E-570 Flujo DispersoDokumen7 halamanE-570 Flujo DispersoAriel TerrensBelum ada peringkat

- Asme B31.3 2020Dokumen4 halamanAsme B31.3 2020Tuugii OtgooBelum ada peringkat

- PED 2014-68-EU Guidelines EN v4Dokumen235 halamanPED 2014-68-EU Guidelines EN v4Nav TalukdarBelum ada peringkat

- 1 s2.0 S092037961000092X Main PDFDokumen6 halaman1 s2.0 S092037961000092X Main PDFevo2005_2006Belum ada peringkat

- BS en 12819-2019Dokumen34 halamanBS en 12819-2019Luís SilvaBelum ada peringkat

- Assessment of Welding ConsumablesDokumen17 halamanAssessment of Welding Consumablesmahmoud_allam3Belum ada peringkat

- En 10029Dokumen5 halamanEn 10029PHAMTOAIBelum ada peringkat

- 2019-5 TechPresentation BeachDokumen141 halaman2019-5 TechPresentation Beachaneeshta100% (1)

- EN 13480-3 Straight Pipes PDFDokumen1 halamanEN 13480-3 Straight Pipes PDFmasatusBelum ada peringkat

- Ceq, PCM and PreheatDokumen4 halamanCeq, PCM and PreheatchandakweBelum ada peringkat

- What Is NACE - MR0175 - MR0103 - en - Us - 17202Dokumen1 halamanWhat Is NACE - MR0175 - MR0103 - en - Us - 17202super51214Belum ada peringkat

- Is 210Dokumen16 halamanIs 210Debopriyo GhoshBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- API 607 Fire Test Report - Copeland - 2 Inch Class 900 Ball Valve - June 9 2017.22172258Dokumen16 halamanAPI 607 Fire Test Report - Copeland - 2 Inch Class 900 Ball Valve - June 9 2017.22172258Nilesh SargaraBelum ada peringkat

- ISO 3834-1-2021 Criteria For Selecting Quality LevelDokumen10 halamanISO 3834-1-2021 Criteria For Selecting Quality LevelPushkar GopalBelum ada peringkat

- JIS G3452 PipeDokumen0 halamanJIS G3452 PipefaridyeniBelum ada peringkat

- NipoflangeDokumen13 halamanNipoflangeAchraf BoudayaBelum ada peringkat

- Api 5l Test PressrureDokumen2 halamanApi 5l Test PressrureSıddık SarıcalarBelum ada peringkat

- Lethal ServiceDokumen24 halamanLethal Servicewylie01Belum ada peringkat

- Interface Tank Intergraph 2014Dokumen25 halamanInterface Tank Intergraph 2014Miguel EspinozaBelum ada peringkat

- Quality For WeldsDokumen9 halamanQuality For WeldsArturs StangainisBelum ada peringkat

- Knife Gate Valve - AVKCMSDokumen2 halamanKnife Gate Valve - AVKCMSjuantamad02Belum ada peringkat

- TABLE 2 Dimensions of Circular Washers: 8. Workmanship, Finish, and AppearanceDokumen1 halamanTABLE 2 Dimensions of Circular Washers: 8. Workmanship, Finish, and AppearanceGHULAM NABIBelum ada peringkat

- Flange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Dokumen2 halamanFlange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Magin Idelfonso TorreblancaBelum ada peringkat

- Subsection HDokumen111 halamanSubsection Hsafeer ahmadBelum ada peringkat

- Ilicore: 4-Ch Drive +power Controller For Portable CD D5901Dokumen16 halamanIlicore: 4-Ch Drive +power Controller For Portable CD D5901vetchboyBelum ada peringkat

- Sa 420Dokumen10 halamanSa 420Widya widyaBelum ada peringkat

- Scope PED 97 23 EGDokumen54 halamanScope PED 97 23 EGpham hoang quanBelum ada peringkat

- En10028 2Dokumen12 halamanEn10028 2Patilea Daniela100% (1)

- Soft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesDokumen4 halamanSoft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesEduardoBelum ada peringkat

- Pig Trap End Closure105671465 PDFDokumen24 halamanPig Trap End Closure105671465 PDFashishBelum ada peringkat

- List of Questions EN 13445 - 2014 PDFDokumen14 halamanList of Questions EN 13445 - 2014 PDFwindsurferke007Belum ada peringkat

- Iso 9606 4 Qualification Testing of Welders NickelDokumen26 halamanIso 9606 4 Qualification Testing of Welders NickelPeterDoner100% (1)

- ST 35.8 (Germany / DIN) : Material PropertiesDokumen3 halamanST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiBelum ada peringkat

- ASME CertificationDokumen3 halamanASME Certificationtamim2014Belum ada peringkat

- Plate Analysis: Floor and Deck SlabsDokumen20 halamanPlate Analysis: Floor and Deck SlabsDobromir DinevBelum ada peringkat

- UHV Chambers - BirnbaumDokumen16 halamanUHV Chambers - Birnbaumpique86Belum ada peringkat

- Simply Supported Rectangular PlateDokumen17 halamanSimply Supported Rectangular PlateJoshua MagatBelum ada peringkat

- Stuewe 201708 Catalogue Type-HsdDokumen25 halamanStuewe 201708 Catalogue Type-HsdJorge A VilalBelum ada peringkat

- UHV Standard ComponentsDokumen101 halamanUHV Standard Componentschipulino100% (1)

- GL Vi-9-2 e PDFDokumen20 halamanGL Vi-9-2 e PDFValli RajuBelum ada peringkat

- En 286-1Dokumen96 halamanEn 286-1Onur oskay SaatçiBelum ada peringkat

- Conical ShellsDokumen3 halamanConical ShellsEng-CalculationsBelum ada peringkat

- LiquidDokumen2 halamanLiquidsiddhesh_guessBelum ada peringkat

- Heavy-Walled (4 To 12-In. (114 To 305-mm) ) Steel Castings: Standard Reference Radiographs ForDokumen4 halamanHeavy-Walled (4 To 12-In. (114 To 305-mm) ) Steel Castings: Standard Reference Radiographs ForAvinash SilimkarBelum ada peringkat

- A276 PDFDokumen8 halamanA276 PDFsingaravelan narayanasamyBelum ada peringkat

- S275JRDokumen1 halamanS275JRpsaayoBelum ada peringkat

- 1.4404 enDokumen5 halaman1.4404 enyraju88Belum ada peringkat

- Iso 3452-5 - 2008Dokumen12 halamanIso 3452-5 - 2008jesonelite100% (1)

- Flat Ends With A Relief GrooveDokumen11 halamanFlat Ends With A Relief GrooveEng-CalculationsBelum ada peringkat

- Brank LeyDokumen6 halamanBrank LeyAhmadHamdyBelum ada peringkat

- Ac 133Dokumen7 halamanAc 133thirumalaichettiar100% (2)

- 141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFDokumen12 halaman141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFmarigusatuBelum ada peringkat

- Iecex: Conformity Assessment Solution For The Ex Field: International Electrotechnical CommissionDokumen62 halamanIecex: Conformity Assessment Solution For The Ex Field: International Electrotechnical Commissioncacalot93Belum ada peringkat

- Hicks Energy Efficiency of LSFDokumen14 halamanHicks Energy Efficiency of LSFStephen HicksBelum ada peringkat

- Ensuring Compliance of Structural Steelwork - Regardless of OriginDokumen10 halamanEnsuring Compliance of Structural Steelwork - Regardless of OriginStephen HicksBelum ada peringkat

- Hicks Presentation at The IIE Conference 2012Dokumen43 halamanHicks Presentation at The IIE Conference 2012Stephen HicksBelum ada peringkat

- The New Joint Australian and New Zealand Bridge Design Standard AS/NZS 5100 - Part 6: Steel and Composite ConstructionDokumen12 halamanThe New Joint Australian and New Zealand Bridge Design Standard AS/NZS 5100 - Part 6: Steel and Composite ConstructionStephen HicksBelum ada peringkat

- High Quality Acoustic and Vibration Performance of Lightweight Steel ConstructionsDokumen181 halamanHigh Quality Acoustic and Vibration Performance of Lightweight Steel ConstructionsStephen HicksBelum ada peringkat

- Human-Induced Vibration of Steel Structures (Hivoss)Dokumen25 halamanHuman-Induced Vibration of Steel Structures (Hivoss)Stephen Hicks0% (1)

- Large Web Openings For Service Integration in Composite FloorsDokumen121 halamanLarge Web Openings For Service Integration in Composite FloorsStephen HicksBelum ada peringkat

- High Quality Acoustic and Vibration Performance of Lightweight Steel ConstructionsDokumen181 halamanHigh Quality Acoustic and Vibration Performance of Lightweight Steel ConstructionsStephen HicksBelum ada peringkat

- CT26-Design Guide For SHS Concrete Filled ColumnDokumen72 halamanCT26-Design Guide For SHS Concrete Filled ColumnKeen LoongBelum ada peringkat

- Light Steel Frame Fire TestDokumen1 halamanLight Steel Frame Fire TestStephen HicksBelum ada peringkat

- Hempadur Zinc 17360Dokumen2 halamanHempadur Zinc 17360Krishna Vacha100% (1)

- S. Musenyi - Effectiveness of Risk Assessment As Accident Prevention Tool in Engineering ProjectsDokumen20 halamanS. Musenyi - Effectiveness of Risk Assessment As Accident Prevention Tool in Engineering ProjectsEmperorr Tau MtetwaBelum ada peringkat

- Abb ManualDokumen20 halamanAbb ManualHamilton Velandia GalloBelum ada peringkat

- Anystream428 Premium 200channel H.265 IPTV TranscoderDokumen4 halamanAnystream428 Premium 200channel H.265 IPTV TranscoderCarlos GuzmanBelum ada peringkat

- Service ManualDokumen393 halamanService ManualdudosoBelum ada peringkat

- MMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagDokumen13 halamanMMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagJan KowalskiBelum ada peringkat

- Heating For Pig ProductionpdfDokumen4 halamanHeating For Pig ProductionpdfGabriel RaicaBelum ada peringkat

- The Baldrige FrameworkDokumen1 halamanThe Baldrige FrameworkRobinson MojicaBelum ada peringkat

- IS 15658 Product ManualDokumen7 halamanIS 15658 Product ManualMohan Ram VishnoiBelum ada peringkat

- Big Dutchman Elterntierhaltung Breeder Manager EuroventParents enDokumen4 halamanBig Dutchman Elterntierhaltung Breeder Manager EuroventParents enLuis OrdoñezBelum ada peringkat

- Especificaciones de Bateria de 170 AH CD TRUE 12 - 1075 - 0512Dokumen2 halamanEspecificaciones de Bateria de 170 AH CD TRUE 12 - 1075 - 0512LUIS MANUEL MEDINA TORRESBelum ada peringkat

- Ict - HTML Lesson Plan ExampleDokumen4 halamanIct - HTML Lesson Plan ExampleKeith Borgonia Manatad78% (9)

- PB Super 1100-2 VogeleDokumen14 halamanPB Super 1100-2 VogeleRobinson GuanemeBelum ada peringkat

- Rotary Screw CompressorDokumen8 halamanRotary Screw Compressormanpreetsodhi08100% (2)

- CAN Specification Version 2 BOSCHDokumen73 halamanCAN Specification Version 2 BOSCHdigitales100% (4)

- Arduino Info SoftwareSerialRS485ExampleDokumen8 halamanArduino Info SoftwareSerialRS485ExampleindoramaBelum ada peringkat

- Vendor ManagementDokumen8 halamanVendor ManagementKs ServicesBelum ada peringkat

- 001 - Common Rail Diesel 1Dokumen25 halaman001 - Common Rail Diesel 1Encik Rafa BenitezBelum ada peringkat

- Basic Cricut File Types Explained - Color Me CraftyDokumen22 halamanBasic Cricut File Types Explained - Color Me CraftyPatricia QuintanillaBelum ada peringkat

- Test Procedure of Generator - For U#1,2,3&4 PDFDokumen14 halamanTest Procedure of Generator - For U#1,2,3&4 PDFPrince SharmaBelum ada peringkat

- Marianas Navy and Marine Corps Design and Construction StandardsDokumen135 halamanMarianas Navy and Marine Corps Design and Construction StandardsRainier Gemuel Tom100% (1)

- Superterm AceleratorDokumen12 halamanSuperterm AceleratorFernando Estrada ZapataBelum ada peringkat

- Ex Magazine PDFDokumen3 halamanEx Magazine PDFAhmadBelum ada peringkat

- Manual Operacion Cargadora Daewoo M200 V, M200 VTCDokumen200 halamanManual Operacion Cargadora Daewoo M200 V, M200 VTCJovita Uvijindia100% (2)

- Sikafloor 220 W ConductiveDokumen5 halamanSikafloor 220 W Conductivethe pilotBelum ada peringkat

- Astm f1554 Grade 36Dokumen9 halamanAstm f1554 Grade 36AngelicaBelum ada peringkat

- V1000 Manual PDFDokumen487 halamanV1000 Manual PDFMohammed SajidBelum ada peringkat

- Pressure Test ProceduresDokumen5 halamanPressure Test Procedureszaxader100% (1)

- 8002 Pacom Edge Controller DatasheetDokumen3 halaman8002 Pacom Edge Controller DatasheetJonathan Pérez Salazar50% (2)

- Power ScrewsDokumen10 halamanPower ScrewsamanggayamBelum ada peringkat