Form 85 Unilets Conduit Outlet Bodies, Covers and Gaskets: Applications

Diunggah oleh

soayJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Form 85 Unilets Conduit Outlet Bodies, Covers and Gaskets: Applications

Diunggah oleh

soayHak Cipta:

Format Tersedia

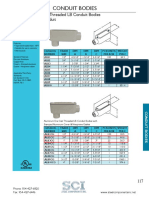

Form 85™ Unilets™ Conduit Outlet Bodies, Covers and Gaskets

For use with Rigid Steel, Rigid Aluminum, IMC, and EMT Conduit.

NEC/CEC — Suitable for use in the following

Hazardous Locations:

Class I, Division 2 per NEC 501.10(B)(4)

Applications

• Serve as pulling fittings.

• Make bends in conduit system.

• Provide openings for splicing.

• Connect and change direction of conduit runs.

• Allow connections for branch runs.

• Permit access to conductors for maintenance.

Features

• Roomy interiors: more wiring space.

• Smooth, rounded integral bushings in hubs protect conductor Conduit Body with Stamped Aluminum Cover. 2” Type C shown.

insulation.

• Accurately tapped, tapered threads for tight, rigid joints and

excellent ground continuity.

• Form 85 copperfree aluminum Unilets™ are lightweight, self-

oxidizing, self-renewing and offer a high corrosion resistance.

• Lightweight aluminum facilitates shipping, handling and

installing.

• Sizes with flat-back design ideal where fitting is mounted flat

against surface.

• 1/2" to 3" blank covers are domed for extra wiring space.

• Raintight when a cover and gasket are installed.

Standard Materials

• Bodies: copperfree (max. 4/10 of 1%) aluminum

— 1/2” thru 2”: pressure cast

— 2-1/2” thru 4”: sand cast

COMMERCIAL AND INDUSTRIAL FITTINGS: CONDUIT BODIES

• Blank covers: malleable iron, steel or aluminum

• Cover screws: stainless steel

• Gaskets: neoprene or composition fiber

Standard Finishes Typical Form 85 Conduit Bodies with Setscrews.

• Aluminum bodies: epoxy powder coat For use with Electrical Metallic Tubing (EMT).

• Stamped aluminum covers: natural finish

• Cast aluminum covers: epoxy powder coat

Options

• PVC coating available on all threaded bodies and select covers.

Add suffix -PVC to catalog number.

NEC/CEC Certifications and Compliances

• UL Standards: 514A, 514B

• UL Listed: E2527

• CSA Standard: C22.2 No. 18.3

• CSA Certified: 065183

• NEMA Standard: FB-1

Related Products

• For explosionproof conduit outlet bodies and boxes, see

Enclosures and Junction Boxes in Protection and Control of

Electrical Apparatus and Circuits Catalog.

Visit our website at www.emerson.com or contact us at (800) 621-1506. 43

© February 2017

Form 85™ Unilets™ Conduit Outlet Bodies, Covers and Gaskets

Threaded Type for use with Rigid Metal Conduit and IMC; Setscrew Type for use with Electrical Metallic Tubing (EMT).

NEC/CEC — Suitable for use in the following

Hazardous Locations:

Class I, Division 2 per NEC 501.10(B)(4)

Appleton™ Form 85™ Conduit Bodies: Threaded/SetScrew Type

LB LL

Hub Size Threaded Setscrew Threaded Setscrew

(Inches) Max. Wire Fill Type Type Max. Wire Fill Type Type

1/2 LB-50A LB-50TA LL-50A LL-50TA

3/4 (3) # 6 LB-75A LB-75TA (3) # 6 LL-75A LL-75TA

1 (3) # 4 LB-100A LB-100TA (3) # 4 LL-100A LL-100TA

1-1/4 (3) # 2 LB-125A LB-125TA (3) # 2 LL-125A LL-125TA

1-1/2 (3) # 1/0 LB-150A LB-150TA (3) # 1 LL-150A LL-150TA

2 (3) # 4/0 LB-200A LB-200TA (3) # 2/0 LL-200A LL-200TA

2-1/2 (3) 300 LB-250A — (3) 300 LL-250A —

3 (3) 400 LB-300A — (3) 350 LL-300A —

3-1/2 (3) 500 LB-350A — (3) 350 LL-350A —

4 (3) 500 LB-400A — (3) 350 LL-400A —

COMMERCIAL AND INDUSTRIAL FITTINGS: CONDUIT BODIES

TB X

Hub Size Threaded Setscrew Threaded Setscrew

(Inches) Max. Wire Fill Type Type Max. Wire Fill Type Type

1/2 TB-50A — X-50A —

3/4 (3) # 6 TB-75A — (3) # 6 X-75A —

1 (3) # 6 TB-100A — (3) # 4 X-100A —

1-1/4 (3) # 6 TB-125A — — — —

1-1/2 (3) # 4 TB-150A — — — —

2 (3) # 1/0 TB-200A — — — —

2-1/2 — — — — — —

3 — — — — — —

3-1/2 — — — — — —

4 — — — — — —

Back Style for Form 85 Unilet Conduit Body Sizes (Inches)

Unilet Body Flat Back Round Back

C, LB, LL, LR, T 1/2 – 2 2-1/2 – 4

TB 1-1/4, 1-1/2 1/2, 3/4, 1, 2

E, X 1/2 – 1 –

Refer to following page for Wiring Capacity Table.

All 1/2” Max Wire Fill Calculations per the NEC - Annex C - Table C8.

Visit our website at www.emerson.com or contact us at (800) 621-1506. 45

© February 2017

Form 85™ Unilets™ Conduit Outlet Bodies, Covers and Gaskets

Covers Furnished with Stainless Steel Fastening Screws.

NEC/CEC — Suitable for use in the following

Hazardous Locations:

Class I, Division 2 per NEC 501.10(B)(4)

Covers and Gaskets

Body Size (Inches) Blank Stamped Aluminum Blank Cast Aluminum Neoprene Composition Fiber

Domed: 1/2” - 3” Flat: 1/2” - 2”

Tear out inner section

Flat: 3-1/2” - 6” Domed: 2-1/2” - 4” to convert to “open type” gasket.

1/2 K50-A K50-CA GK50-N GK50-V

3/4 K75-A K75-CA GK75-N GK75-V

1 K100-A K100-CA GK100-N GK100-V

1-1/4 K125-150-A K125-150-CA GK125-150-N GK125-150-V

1-1/2 K125-150-A K125-150-CA GK125-150-N GK125-150-V

2 K200-A K200-CA GK200-N GK200-V

2-1/2 K250-300-A K250-300-CA GK250-300-N GK-250-300-V

3 K250-300-A K250-300-CA GK250-300-N GK-250-300-V

3-1/2 K350-400-A K350-400-CA GK350-400-N GK-350-400-V

4 K350-400-A K350-400-CA GK350-400-N GK-350-400-V

COMMERCIAL AND INDUSTRIAL FITTINGS: CONDUIT BODIES

Wiring Capacity: Combine Body and Cover Capacities for Total Usable Capacity per NEC 314.16(A)

Hub Size Capacity — dm3 (in3)

(Inches) C E LB LL LR LRL T TA TB X Stamped Cover Cast Cover

0.07 0.07 0.07 0.07 0.07 0.10 0.07 0.01 0.00

1/2 — —

(4.00) (4.00) (4.00) (4.00) (4.00) (6.00) (4.00) (0.50) (0.00)

0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.01 0.00

3/4 — —

(7.00) (7.00) (7.00) (7.00) (7.00) (7.00) (7.00) (0.80 (0.30)

0.19 0.19 0.19 0.19 0.19 0.21 0.19 1.00 0.01

1 — —

(11.80) (11.80) (11.80) (11.80) (11.80) (13.00) (11.80) (25.4) (0.50)

0.57 0.57 0.57 0.57 0.57 0.04 0.01

1-1/4 — — — —

(34.80) (34.80) (34.80) (34.80) (35.00) (2.50) (0.80)

0.57 0.57 0.57 0.57 0.57 0.04 0.01

1-1/2 — — — —

(35.00) (35.00) (35.00) (35.00) (34.50) (2.50) (0.80)

1.15 1.15 1.15 1.15 1.16 0.11 0.02

2 — — — —

(70.00) (70.00) (70.00) (70.00) (71.00) (6.50) (1.00)

2.34 2.28 3568.7 2.39 0.29 0.49

2-1/2 — — — — —

(143.00) (139.00) (140.50) (146.00) (18.00) (30.00)

2.95 2.90 2.87 3.03 0.29 0.49

3 — — — — —

(180.00) (177.00) (175.00) (185.00) (18.00) (30.00)

4.97 4.92 4.92 5.15 0.82

3-1/2 — — — — — —

(303.00) (300.00) (300.00) (314.00) (50.00)

5.57 5.41 5.41 5.65 0.82

4 — — — — — —

(340.00) (330.00) (330.00) (345.00) (50.00)

Add suffix -PVC to catalog number.

46 Visit our website at www.emerson.com or contact us at (800) 621-1506.

© February 2017

Aluminum Conduit Bodies, Covers and Gaskets

For Rigid Conduit & IMC.

NEC/CEC — Suitable for use in the following

Hazardous Locations:

Class I, Division 2 per NEC 501.10(B)(4)

Applications

• To provide access to conductors for pulling, splicing,

maintenance and future changes/upgrades.

• Allows connection of straight conduit runs, branch conduit runs

and 90° bends.

Features

• Tapered threaded hubs (NPT).

• Raintight when used with gasketed covers.

Type LB-A

• Internal volume and maximum wire clearly marked on castings.

Standard Materials

• Bodies: copperfree (max. 4/10 of 1%) aluminum

— 1/2” thru 2”: pressure cast

— 2-1/2” thru 4”: sand cast

• Blank covers: malleable iron, steel or aluminum

• Cover screws: stainless steel

• Gaskets: neoprene or composition fiber

Standard Finishes

• Aluminum bodies: epoxy powder coat

• Stamped aluminum covers: natural finish Type T-A

• Cast aluminum covers: epoxy powder coat

NEC/CEC Certifications and Compliances

• UL Standards: 514A

• UL Listed: E-18095w

COMMERCIAL AND INDUSTRIAL FITTINGS: CONDUIT BODIES

• CSA Standard: C22.2 No. 18

• CSA Certified: 009795

• NEMA Standard: FB-1, FB-2.10

Type LL-A

Type LR-A

Type C-A

50 Visit our website at www.emerson.com or contact us at (800) 621-1506.

© February 2017

Aluminum Conduit Bodies, Covers and Gaskets

For Rigid Conduit & IMC.

NEC/CEC — Suitable for use in the following

Hazardous Locations:

Class I, Division 2 per NEC 501.10(B)(4)

Aluminum Conduit Bodies

Diecast Sandcast

Hub Size

(Inches) Max. Wire Fill C-A

1/2 C-50A —

3/4 (3) # 6 C-75A —

1 (3) # 4 C-100A —

1-1/4 (3) # 2 C-125A —

1-1/2 (3) # 1/0 C-150A —

2 (3) # 3/0 C-200A —

2-1/2 (3) 300 — C-250A

3 (3) 300 — C-300A

3-1/2 (3) 350 — C-350A

4 (3) 350 — C-400A

COMMERCIAL AND INDUSTRIAL FITTINGS: CONDUIT BODIES

Sandcast

Hub Size

(Inches) Max. Wire Fill TB-A Max. Wire Fill X-A

1/2 TB-50A X-50A

3/4 (3) # 6 TB-75A (3) # 6 X-75A

1 (3) # 6 TB-100A (3) # 4 X-100A

1-1/4 (3) # 6 TB-125A — X-125A

1-1/2 (3) # 4 TB-150A — X-150A

2 (3) # 1/0 TB-200A — X-200A

2-1/2 — — — —

3 — — — —

3-1/2 — — — —

4 — — — —

All 1/2” Max Wire Fill Calculations per the NEC - Annex C - Table C8.

52 Visit our website at www.emerson.com or contact us at (800) 621-1506.

© February 2017

Aluminum Conduit Bodies, Covers and Gaskets

For Rigid Conduit & IMC.

NEC/CEC — Suitable for use in the following

Hazardous Locations:

Class I, Division 2 per NEC 501.10(B)(4)

Dimensions in Millimeters (Inches)

Types C, T, TB, X Types LB, LL, LR

Hub Size Dimensions In Millimeters (Inches)

(Inches) A B C D E F G H J L M N P

Pressure Cast

100.1 33.3 35.1 120.7 65.0 50.8 52.3 88.9 109.5 16.0 28.7 79.8 26.7

1/2

(3.94) (1.31) (1.38) (4.75) (2.56) (2.00) (2.06) (3.50) (4.31) (0.63) (1.13) (3.14) (1.05)

COMMERCIAL AND INDUSTRIAL FITTINGS: CONDUIT BODIES

117.6 39.6 41.4 143.0 76.2 57.2 62.0 104.9 130.3 19.1 35.1 96.0 32.3

3/4

(4.63) (1.56) (1.63) (5.63) (3.00) (2.25) (2.44) (4.13) (5.13) (0.75) (1.38) (3.78) (1.27)

136.7 46.0 47.8 169.9 88.9 66.8 71.4 124.0 152.4 23.9 42.9 114.3 38.6

1

(5.38) (1.81) (1.88) (6.69) (3.50) (2.63) (2.81) (4.88) (6.00) (0.94) (1.69) (4.50) (1.52)

182.6 63.5 69.9 217.4 88.9 98.6 166.6 200.2 26.9 54.1 152.4 57.2

1-1/4 —

(7.19) (2.50) (2.75) (8.56) (3.50) (3.88) (6.56) (7.88) (1.06) (2.13) (6.00) (2.25)

182.6 63.5 69.9 217.4 88.9 96.8 163.6 200.2 30.2 60.5 152.4 57.2

1-1/2 —

(7.19) (2.50) (2.75) (8.56) (3.50) (3.81) (6.44) (7.88) (1.19) (2.38) (6.00) (2.25)

241.3 79.5 87.4 274.6 106.4 115.8 211.1 258.8 38.1 74.7 204.7 69.9

2 —

(9.50) (3.13) (3.44) (10.81) (4.19) (4.56) (8.31) (10.19) (1.50) (2.94) (8.06) (2.75)

Sand Cast

311.2 109.5 98.6 384.3 146.1 133.4 301.8 347.7 46.0 85.9 270.0 93.7

2-1/2 —

(12.25) (4.31) (3.88) (15.13) (5.75) (5.25) (11.88) (13.69) (1.81) (3.38) (10.63) (3.69)

311.2 109.5 117.6 384.3 146.1 152.4 293.6 347.7 55.6 104.9 270.0 93.7

3 —

(12.25) (4.31) (4.63) (15.13) (5.75) (6.00) (11.56) (13.69) (2.19) (4.13) (10.63) (3.69)

378.0 139.7 131.8 460.5 181.1 173.0 355.6 419.1 63.5 120.7 333.5 124.0

3-1/2 —

(14.88) (5.50) (5.19) (18.13) (7.13) (6.81) (14.00) (16.50) (2.50) (4.75) (13.13) (4.88)

378.0 139.7 141.2 460.5 181.1 182.6 349.3 419.1 69.9 130.3 333.5 124.0

4 —

(14.88) (5.50) (5.56) (18.13) (7.13) (7.19) (13.75) (16.50) (2.75) (5.13) (13.13) (4.88)

54 Visit our website at www.emerson.com or contact us at (800) 621-1506.

© February 2017

Anda mungkin juga menyukai

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- Type Sct50 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestDokumen6 halamanType Sct50 Cable Trunking: Standard Length: 2.4M, Other Lengths Such As 3M Available Upon RequestHAFIZBelum ada peringkat

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Catalog Appleton Fm7 Conduit Outlet Bodies en 588966Dokumen7 halamanCatalog Appleton Fm7 Conduit Outlet Bodies en 588966Alexis Rodrigo Tapia EstrellaBelum ada peringkat

- Grounding and Lightning SpecificationDokumen33 halamanGrounding and Lightning Specificationsatang M.F.LBelum ada peringkat

- Star Jan 2007 Parts CatalogDokumen50 halamanStar Jan 2007 Parts Catalogrichda1Belum ada peringkat

- Bonney Forge WFI Recommended Flexolet, Pipet, and Weldolet Weld ProfilesDokumen17 halamanBonney Forge WFI Recommended Flexolet, Pipet, and Weldolet Weld ProfilesozkanhasanBelum ada peringkat

- Homac T&B Multi-LugsDokumen3 halamanHomac T&B Multi-LugsallfloridaBelum ada peringkat

- LBD and LBDN Pulling Fittings: Features Standard FinishesDokumen1 halamanLBD and LBDN Pulling Fittings: Features Standard FinishesRaúl RangelBelum ada peringkat

- NICOPRESS Electrical PowerDokumen1 halamanNICOPRESS Electrical PowerAsima Jaya TamaBelum ada peringkat

- Catalog Appleton PLG Close Up Plugs BR Reducers en Us 190422Dokumen2 halamanCatalog Appleton PLG Close Up Plugs BR Reducers en Us 190422maygomezBelum ada peringkat

- catalog-appleton-fm8-conduit-outlet-bodies-en-588968Dokumen6 halamancatalog-appleton-fm8-conduit-outlet-bodies-en-588968Kiatbandit ChitsongboonBelum ada peringkat

- Er-63 1Dokumen3 halamanEr-63 1Dibyendu ChakrabortyBelum ada peringkat

- 64 9826 Tweco Fluxcore GunDokumen4 halaman64 9826 Tweco Fluxcore GunSamuel ManducaBelum ada peringkat

- Applications:: Integral Gasket CoversDokumen6 halamanApplications:: Integral Gasket CoversVíctor elkinBelum ada peringkat

- Style TC-TB-TP - Catalog PagesDokumen2 halamanStyle TC-TB-TP - Catalog PagesdrBelum ada peringkat

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDokumen8 halamanGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexBelum ada peringkat

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDokumen8 halamanGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexBelum ada peringkat

- Gaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsDokumen8 halamanGaugeable Alloy 400/R-405 Mechanically Attached Pipe and Tube FittingsAlexBelum ada peringkat

- CableterminationsDokumen2 halamanCableterminationsheri fauziBelum ada peringkat

- Reduccion Bushing MadisonDokumen1 halamanReduccion Bushing Madisonluiszc2988Belum ada peringkat

- Wiring AccessoriesDokumen56 halamanWiring AccessoriesKrizia De PeraltaBelum ada peringkat

- Valvula de Bola 20-BP BS - WNDokumen2 halamanValvula de Bola 20-BP BS - WNAna FigueroaBelum ada peringkat

- CH Condulets Form 5 PDFDokumen4 halamanCH Condulets Form 5 PDFDruen Delgado MirandaBelum ada peringkat

- Multiple Connection Terminal Blocks: CX2.5/4/2B CX2.5/3/1BDokumen1 halamanMultiple Connection Terminal Blocks: CX2.5/4/2B CX2.5/3/1BsamBelum ada peringkat

- st50APLTONE01235 275 276Dokumen2 halamanst50APLTONE01235 275 276soayBelum ada peringkat

- STB Insulated ConnectorsDokumen3 halamanSTB Insulated ConnectorsPablo Jeremias Campos VenegasBelum ada peringkat

- Type 50 and 51 Temporary Strainer BrochureDokumen6 halamanType 50 and 51 Temporary Strainer BrochureAlireza HakamiBelum ada peringkat

- Wheatley Series 822 Check Valves FlyerDokumen2 halamanWheatley Series 822 Check Valves FlyerLorena DávilaBelum ada peringkat

- Crouse Hinds Form5 Catalog PageDokumen4 halamanCrouse Hinds Form5 Catalog PageMarcos UrielBelum ada peringkat

- 230kV Aluminum Bolted Cable Couplers PDFDokumen5 halaman230kV Aluminum Bolted Cable Couplers PDFCarloBelum ada peringkat

- Tmax Accessory Guide 8Dokumen1 halamanTmax Accessory Guide 8haillBelum ada peringkat

- Cast Carbon Steel (WCB) : Class 150, 300 Flanged 1/2'' - 6'' and Class 600 Flanged 1/2'' - 4''Dokumen1 halamanCast Carbon Steel (WCB) : Class 150, 300 Flanged 1/2'' - 6'' and Class 600 Flanged 1/2'' - 4''Miguel LopezBelum ada peringkat

- Appendix C. Conduit and Tubing Fill Tables For Conductors and Fixture Wires of The Same SizeDokumen1 halamanAppendix C. Conduit and Tubing Fill Tables For Conductors and Fixture Wires of The Same SizeONG, Chester Z.Belum ada peringkat

- Norwolf Calibrador de Tension de Pernos AST CaliboreDokumen4 halamanNorwolf Calibrador de Tension de Pernos AST CaliborejorgeBelum ada peringkat

- Compression Connectors: Zinc Die Cast Zinc Die Cast / Insulated Throat - 105°CDokumen14 halamanCompression Connectors: Zinc Die Cast Zinc Die Cast / Insulated Throat - 105°CLes De JesusBelum ada peringkat

- TYPES AYP, AYPO 018 C&I - FullLRDokumen2 halamanTYPES AYP, AYPO 018 C&I - FullLRIrving GuatemalaBelum ada peringkat

- Applications:: Suffix DescriptionDokumen4 halamanApplications:: Suffix DescriptionAlex CarreraBelum ada peringkat

- Thomson Roundrail 1BC SpecsheetDokumen2 halamanThomson Roundrail 1BC SpecsheetElectromateBelum ada peringkat

- 1A1Dokumen148 halaman1A1Mayraniz MedelBelum ada peringkat

- Absorber tower flanges and nozzles MTODokumen3 halamanAbsorber tower flanges and nozzles MTOhgag selimBelum ada peringkat

- CONDULET APPLETONDokumen6 halamanCONDULET APPLETONPablo Jeremias Campos VenegasBelum ada peringkat

- Liquidtight Broch DEC06Dokumen8 halamanLiquidtight Broch DEC06Anonymous OnzJpzBelum ada peringkat

- Cast iron air vents for pressures up to 300 PSIDokumen2 halamanCast iron air vents for pressures up to 300 PSIRakhmad sugih hartonoBelum ada peringkat

- 2010 BurndyDokumen99 halaman2010 BurndycarloscaduBelum ada peringkat

- BURNDY Conectores MecanicosDokumen58 halamanBURNDY Conectores MecanicosRafael RuizBelum ada peringkat

- Premolded cable termination for indoor and outdoor use up to 36 kVDokumen6 halamanPremolded cable termination for indoor and outdoor use up to 36 kVIsaac CroquerBelum ada peringkat

- Appleton Clavijas y Receptaculos EGS-egs-aee23-cut-sheetDokumen7 halamanAppleton Clavijas y Receptaculos EGS-egs-aee23-cut-sheetMantenimiento TullboxBelum ada peringkat

- RB Reducing Bushings: Explosionproof, Dust-IgnitionproofDokumen1 halamanRB Reducing Bushings: Explosionproof, Dust-IgnitionproofJaaffer AliBelum ada peringkat

- SCH-00-J-7000 Inst. Cable Schedule Rev - 3Dokumen28 halamanSCH-00-J-7000 Inst. Cable Schedule Rev - 3Kishore KrishnaBelum ada peringkat

- c21014 PDFDokumen2 halamanc21014 PDFKhaled A MarashliBelum ada peringkat

- Axial Flow Check ValveDokumen2 halamanAxial Flow Check ValveProject MarsysBelum ada peringkat

- HT Condulets Aluminio RMCDokumen4 halamanHT Condulets Aluminio RMCDavidBelum ada peringkat

- Minerae00024 53Dokumen1 halamanMinerae00024 53soayBelum ada peringkat

- CatalogDokumen46 halamanCataloglangtu2011Belum ada peringkat

- BS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01Dokumen4 halamanBS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01skodgeBelum ada peringkat

- Lincolnweld 960Dokumen2 halamanLincolnweld 960pratik charkhawalaBelum ada peringkat

- Drill Pipe & Casing Tongs: Product CatalogDokumen12 halamanDrill Pipe & Casing Tongs: Product CatalogAnonymous fBIEWgmRzBelum ada peringkat

- Quick Release Couplings TEMA European Interchange (39Dokumen1 halamanQuick Release Couplings TEMA European Interchange (39rweidlingBelum ada peringkat

- Magnum ProDokumen6 halamanMagnum ProJuan Jose Ramos CortesBelum ada peringkat

- 2090 CSWM1DF 14aa05 PDFDokumen132 halaman2090 CSWM1DF 14aa05 PDFsoayBelum ada peringkat

- Ec Ca100 - en PDokumen412 halamanEc Ca100 - en PGustavo Lama ValdiviaBelum ada peringkat

- 1 SMC-3Dokumen18 halaman1 SMC-3soayBelum ada peringkat

- Catalog PDFDokumen226 halamanCatalog PDFAndika Arihta Pasaribu100% (1)

- 42mrr 5000Dokumen9 halaman42mrr 5000soayBelum ada peringkat

- 1 Metal Thobete68234 c14 c16Dokumen2 halaman1 Metal Thobete68234 c14 c16soayBelum ada peringkat

- A 117Dokumen226 halamanA 117soayBelum ada peringkat

- st50APLTONE01235 275 276Dokumen2 halamanst50APLTONE01235 275 276soayBelum ada peringkat

- 42g td001 - en p.pd1Dokumen10 halaman42g td001 - en p.pd1soayBelum ada peringkat

- A117 Ca902 - en PDokumen266 halamanA117 Ca902 - en PsixtossBelum ada peringkat

- 1 Graceport Component - D4Dokumen1 halaman1 Graceport Component - D4soayBelum ada peringkat

- 800T Contact Block RatingsDokumen1 halaman800T Contact Block RatingssoayBelum ada peringkat

- Allen Bradley 598-BS933Dokumen6 halamanAllen Bradley 598-BS933soayBelum ada peringkat

- 1585J M4TBJM 1 PDFDokumen1 halaman1585J M4TBJM 1 PDFsoayBelum ada peringkat

- rb7550 APLTONE01221 - 669Dokumen1 halamanrb7550 APLTONE01221 - 669soayBelum ada peringkat

- Color-Keyed Connectors: Color-Keyed Special Lugs For Special Problems - Angled, Shaped and Flared The Way You Need ThemDokumen5 halamanColor-Keyed Connectors: Color-Keyed Special Lugs For Special Problems - Angled, Shaped and Flared The Way You Need ThemsoayBelum ada peringkat

- Sta-Kon Rings, Forks and Locking Forks: Ring TerminalsDokumen2 halamanSta-Kon Rings, Forks and Locking Forks: Ring TerminalssoayBelum ada peringkat

- Allen Bradley 42BA S2LNAC A2Dokumen3 halamanAllen Bradley 42BA S2LNAC A2soayBelum ada peringkat

- 141tb THOBETE68451 - E34 - E35Dokumen2 halaman141tb THOBETE68451 - E34 - E35soayBelum ada peringkat

- HazardDokumen44 halamanHazardsoayBelum ada peringkat

- Hol-Sealers™ Hole Seals: Accessories 1Dokumen4 halamanHol-Sealers™ Hole Seals: Accessories 1soayBelum ada peringkat

- 9324-Qr001 - En-P Studio 5000 Logix Designer Ordering GuideDokumen4 halaman9324-Qr001 - En-P Studio 5000 Logix Designer Ordering Guidesmith_raBelum ada peringkat

- 1 Apltone01279 - 313 - 314Dokumen2 halaman1 Apltone01279 - 313 - 314soayBelum ada peringkat

- 9324-Qr001 - En-P Studio 5000 Logix Designer Ordering GuideDokumen4 halaman9324-Qr001 - En-P Studio 5000 Logix Designer Ordering Guidesmith_raBelum ada peringkat

- 1 Hubkele08539 - V27 - V28Dokumen2 halaman1 Hubkele08539 - V27 - V28soayBelum ada peringkat

- Apltone01221 683Dokumen1 halamanApltone01221 683soayBelum ada peringkat

- Lhdotte02353 C11Dokumen1 halamanLhdotte02353 C11soayBelum ada peringkat

- Eds Switch AppletonDokumen9 halamanEds Switch AppletonsoayBelum ada peringkat

- EDS Factory Sealed Tumbler Switches: Explosionproof, Dust-IgnitionproofDokumen6 halamanEDS Factory Sealed Tumbler Switches: Explosionproof, Dust-IgnitionproofsoayBelum ada peringkat

- Table III Load Criteria Uniform Bearing On Soil Type "C": Notes For Load TablesDokumen1 halamanTable III Load Criteria Uniform Bearing On Soil Type "C": Notes For Load TablesDhina karanBelum ada peringkat

- MAN-02-00067-RD 24 V Power Station ManualDokumen3 halamanMAN-02-00067-RD 24 V Power Station ManualAnonymous xMpBefLBelum ada peringkat

- DIY Filament Extruder Kit v2 - Store of WH HuangDokumen5 halamanDIY Filament Extruder Kit v2 - Store of WH Huangeduardo toscanoBelum ada peringkat

- Lightning Arresters and Insulation CoordinationDokumen25 halamanLightning Arresters and Insulation CoordinationGITAM UNIVERISTYBelum ada peringkat

- Group 2 PDFDokumen19 halamanGroup 2 PDFJoshua OrdeñizaBelum ada peringkat

- Octane Number of Gasoline PDFDokumen2 halamanOctane Number of Gasoline PDFJamesBelum ada peringkat

- Thermal Power PlantDokumen13 halamanThermal Power PlantSanat KumarBelum ada peringkat

- Volume and Temperature Correctors Operating InstructionsDokumen49 halamanVolume and Temperature Correctors Operating InstructionsArsalan KhanBelum ada peringkat

- Energy Conscious Architecture - Edge AmsterdamDokumen7 halamanEnergy Conscious Architecture - Edge AmsterdamPriyanjita AdhikariBelum ada peringkat

- Chilled Beams in Heating: Design Criteria and Case StudyDokumen8 halamanChilled Beams in Heating: Design Criteria and Case StudyarjantinBelum ada peringkat

- Hydra Info2Dokumen22 halamanHydra Info2קארין קצבBelum ada peringkat

- UK DynaSand C0209Dokumen2 halamanUK DynaSand C0209Mee DepoBelum ada peringkat

- Jindal SteelDokumen8 halamanJindal SteelVishal HBelum ada peringkat

- Bomba de Cebado DespieceDokumen2 halamanBomba de Cebado DespiecehenotharenasBelum ada peringkat

- Aircraft Performance I PDFDokumen18 halamanAircraft Performance I PDFJJBelum ada peringkat

- DW95 Series Dishwasher Program and Fault Troubleshooting GuideDokumen56 halamanDW95 Series Dishwasher Program and Fault Troubleshooting GuidepksertzenBelum ada peringkat

- Vehicle MainDokumen89 halamanVehicle MainmgitecetechBelum ada peringkat

- ET5152 - Design of Embedded SystemsDokumen12 halamanET5152 - Design of Embedded Systemsantoabi100% (1)

- Plastering and PointingDokumen3 halamanPlastering and PointingRanajit BiswasBelum ada peringkat

- Microstructure and Mechanical Properties of X80/X100 Grade Plates and PipesDokumen6 halamanMicrostructure and Mechanical Properties of X80/X100 Grade Plates and PipesallswellelleBelum ada peringkat

- Agepan EducationDokumen100 halamanAgepan EducationsswinforBelum ada peringkat

- JED Magazine 2011-06Dokumen85 halamanJED Magazine 2011-06Park Sung100% (1)

- Terry Towel BanglaeshDokumen12 halamanTerry Towel BanglaeshAisha ThaBelum ada peringkat

- M.M.A. Welding ElectrodeDokumen1 halamanM.M.A. Welding ElectrodecwiksjBelum ada peringkat

- SEBoK v. 1.9.1 PDFDokumen1.035 halamanSEBoK v. 1.9.1 PDFprasoft100% (1)

- Design Gates for Hydropower ProjectsDokumen55 halamanDesign Gates for Hydropower ProjectsDangol RupeshBelum ada peringkat

- Escavadora John Deere 120CDokumen553 halamanEscavadora John Deere 120CGilberto Torres83% (6)

- Vermicomposting From Gondia Municipal Solid WasteDokumen7 halamanVermicomposting From Gondia Municipal Solid WasteInternational Journal of Innovations in Engineering and ScienceBelum ada peringkat

- 14 Ultra Manhole For Underground Sewerage SystemDokumen6 halaman14 Ultra Manhole For Underground Sewerage SystemNikita KadamBelum ada peringkat