Lenton Coupler Instruction Manual 2004 PDF

Diunggah oleh

Hsaam HsaamJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Lenton Coupler Instruction Manual 2004 PDF

Diunggah oleh

Hsaam HsaamHak Cipta:

Format Tersedia

reinforcing bar splicing

COUPLER INSTRUCTION MANUAL

copyright © 2004 Erico BV EBV - 039700 - CRP1 - GB

0 CONTENTS

0. CONTENTS

PAR SUBJECT PAGE

0. CONTENTS 0-1

1. LENTON COUPLER TYPE OVERVIEW 1-1

2. TORQUE WRENCHES 2-1

2.1. Available types 2-1

2.2. Calibration 2-2

3. INSTALLATION OF COUPLERS 3-1

3.1. LENTON coupler type A12 3-1

3.2. LENTON coupler type P13 3-2

3.3. LENTON coupler type P14 3-3

3.4. LENTON coupler type P15 3-4

3.5. LENTON P13-P15 coupler combination 3-5

3.6. LENTON coupler type S13 3-6

3.7. LENTON coupler type D14 3-7

3.8. LENTON coupler type C12 3-8

We reserve the right to make any alterations to the information contained in this brochure which we WHETHER EXPRESSED OR IMPLIED, (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

consider to be either necessary or advantageous. This brochure is designed to provide only preliminary in FITNESS), SHALL EXIST IN CONNECTION WITH THE SALE OR USE OF ANY ERICO PRODUCT.

information on the products and is not a contract. The Company does not accept any liability for loss or 4. All instructions must be completely followed to ensure proper and safe operation.

damage arising from failure to follow its instructions to products not agreed by it.

The buyer and/or installer is responsible for:

WARNING a. Application in conformance to all governing codes.

1. These products shall be used only as illustrated and recommended in product instruction sheets b. The integrity of structures to which the products are attached, including their capability of safely

(additional instruction sheets are available at www.erico.com). Misuse or misapplication may cause accepting the loads imposed, as evaluated by a qualified engineer.

failure resulting in possible property damage or bodily c. Using appropriate industry standard hardware as noted above.

injury. SAFETY WARNING:

2. These products must be used only in the manner depicted in the illustrations that accompany them SAFETY INSTRUCTIONS: All governing codes and regulations and those required by the job site must

and must not exceed load ratings. be observed. Always use appropriate safety equipment such as eye protection, hard hat, and gloves as

3. Failure to observe these specifications may cause product malfunction resulting in property damage or appropriate to the application.

bodily injury. ERICO products at the time of shipment are warranted to conform to any applicable written

description furnished to the Buyer by ERICO, and to be free from defects in material and workmanship. CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH and LENTON are registered trademarks of

NO OTHER WARRANTY, ERICO International Corporation.

copyright © 2004 ERICO. Inc. 0-1

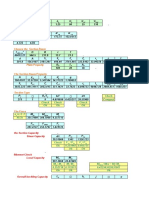

1 LENTON COUPLER TYPE OVERVIEW

1. LENTON COUPLER TYPE OVERVIEW

LENTON coupler type A12 EL - .. - A12

A12

Coupler type A12 for use in situations where one or both of the bars to be joined are

free to turn.

LENTON coupler type P13 EL - .. - P13

Connection onto a bent bar or a bar that cannot be rotated and has limited P13

movement in axial direction.

LENTON coupler type P14 EL - .. - P14

Connection onto a bent bar or a bar that cannot be rotated. P14

LENTON coupler type P15 EL - .. - P15

The P15 is constructed in a way that avoids a fixed pitch relationship between one end

of the coupler and the other. This feature, used in combination with the adjustability of

the P13, facilitates the forming of a ‘closer’ suitable for column erection or precision P15

coupling of elements with multiples of bars to be joined over a short span.

LENTON coupler type D14 EL - .. - D14

The D14 coupler provides an anchor- or stop nut.

LENTON coupler type S13 EL - .. - S13

D14

The S13 couplers provide a full strength joint between a reinforcing bar and a metric

threaded bolt.

LENTON coupler type C12 EL - .. - C12 S13

The C12 coupler is made for joining reinforcing bars to structural steel sections or

plates. The coupler is made from a weldable steel and formed with a ‘J’ groove to

facilitate a full-penetration weld.

For more detailed information, see LENTON catalogue. C12

copyright © 2004 Erico BV en 1-1

2 TORQUE WRENCHES

2. TORQUE WRENCHES

Type Range kg A max B C D E F max T max Part No.

2.1. Available types Nm

LENTON torque wrenches are manufactured to perform within the tolerance limits of 275 Ø 10-28 2.5 630 25 175 75 40 60 275 148010

ISO standard no. 6789. 850 Ø 24-57 3.0 825 30 210 90 45 90 350 148030

Table 1.2 Dimensions Torque wrench

To set torque value required

1. Depress ‘tongue’ inside end of handgrip - this will release the scale lock.

2. Slide scale by pushing red knob in required direction until correct value is on ‘set’

position.

3. Release tongue to lock the new setting.

In practice it is found that installers tend to overshoot the click of the torque wrench

witch results in a degree of over tightening. The values of torque recommended take

this into consideration (see table 1.1).

Bar size Ø mm 10-12 14 16 18 20 22 24-28 30 32-36 38-57

torque setting

+ 20 % Nm 40 80 120 150 180 220 270 300 300 350

- 20 %

Table 1.1 Torque setting Table

Fig. 2.1

Torque wrenches Type 275 / 850

copyright © 2004 Erico BV en 2-1

2 TORQUE WRENCHES

2.2. Calibration

Each LENTON torque wrench is checked to ensure correct operations and has its

own serial number and calibration certificate.

Recalibration of the torque wrench is the responsibility of the user. It is

recommended to recalibrate the torque wrench at least once a year.

Calibration check apparatus is available to order.

Art.No. 148050 Calibrator Torque wrench Fig. 2.2

Art.No. 148060 Adaptor Torque wrench Fig. 2.3 Fig. 2.2

Calibrator torque wrench

The calibration tolerance is +/- 10% of the set value. If the wrench performance is

outside this range the wrench must not be used anymore. For further information,

please contact ERICO.

Fig. 2.3

Adaptor torque wrench

copyright © 2004 Erico BV en 2-2

3 INSTALLATION OF COUPLERS

3. INSTALLATION OF COUPLERS

All threads should be clean and free from oil or grease. Screw the parts together by

hand - approximately four and a half turns are required - after which the tightening

should be completed using the LENTON torque wrench set at the appropriate value

taken from the torque setting table 1.1, or from the label on the wrench.

The torque values recommended have been selected to provide uniformity of

installation and positive restraint against effects of vibration during concrete placing.

These values should not be exceeded. Each LENTON torque wrench is checked to

ensure correct operation and has its own serial number and calibration certificate.

Recalibration is responsibility of the user.

3.1. LENTON coupler type A12

STEP 1 1

Ensure coupler is tightened onto first bar. Use Prescribed torque according to

table 1.1.

STEP 2 2

(Coupler can be in concrete or not)

Ensure second bar is tightened into the coupler. Use Prescribed torque according

to table 1.1.

copyright © 2004 Erico BV en 3-1

3 INSTALLATION OF COUPLERS

3.2. LENTON coupler type P13

1a

Either step 1A or 1B will be applicable

STEP 1a

Ensure coupler is fully screwed together and tightened onto first bar.

Use Prescribed torque according to table 1.1 for all steps.

1b

STEP 1b

st

When female coupler part is cast in 1 concrete section, fully re-assemble the

coupler with male part and lock nut.

STEP 2

Bring cage or other bar into fix position and ensure gap between coupler and bar 2

is not greater than extension possibility of the coupler (see LENTON catalogue).

STEP 3

Screw out male part to meet the taper thread of the ongoing bar.

3

STEP 4

Tighten male part fully onto ongoing bar.

4

STEP 5

Spin back lock-nut and fully tighten against body of coupler. Ensure limit groove is

not fully visible above lock-nut.

IMPORTANT NOTE: 5

P13 and P14 couplers have a limited amount of allowable extension and

so are manufactured with easy seen groove cut into the thread of the

male part. After full assembly of the coupler this groove should not be

fully visible above the lock-nut. If the groove is fully clear above the lock-

nut it indicates that there is insufficient thread engagement to ensure full

design strength of the coupler. This feature makes inspection of the

completed joint very simple and very positive.

copyright © 2004 Erico BV en 3-2

3 INSTALLATION OF COUPLERS

3.3. LENTON coupler type P14 1a

Either step 1A or 1B will be applicable.

STEP 1a

Ensure coupler is fully screwed into female and tighten female onto first bar.

Use Prescribed torque according to table 1.1 for all steps. 1b

STEP 1b

st

When female coupler part is cast in 1 concrete section, fully re-assemble the

coupler with male part and lock nut.

2

STEP 2

Insert LENTON taper threaded bent bar into mouth of coupler as far as it will go.

STEP 3

Screw male part out of female and onto taper threaded bar.

3

STEP 4

Tighten male part fully onto bent bar and spin lock-nut back to coupler body.

4

STEP 5

Fully tighten lock-nut against coupler body after setting bent bar to required

position. Ensure limit groove is not fully visible above the lock-nut.

IMPORTANT NOTE:

P13 and P14 couplers have a limited amount of allowable extension and 5

so are manufactured with easy seen groove cut into the thread of the

male part. After full assembly of the coupler this groove should not be

fully visible above the lock-nut. If the groove is fully clear above the lock-

nut it indicates that there is insufficient thread engagement to ensure full

design strength of the coupler. This feature makes inspection of the

completed joint very simple and very positive.

copyright © 2004 Erico BV en 3-3

3 INSTALLATION OF COUPLERS

3.4. LENTON coupler type P15

STEP 1

1

Fully tighten body of coupler to first bar and remove male parts.

Use Prescribed torque according to table 1.1 for all steps.

STEP 2 2

Slide locking ferrule onto ongoing bar and tighten insert-end fully onto ongoing

bar.

STEP 3

3

Push insert-end into body and screw in locking ferrule.

STEP 4 4

Fully tighten locking ferrule into body after placing ongoing bar into required

position.

copyright © 2004 Erico BV en 3-4

3 INSTALLATION OF COUPLERS

3.5. LENTON P13 - P15 coupler combination

Used to connect bars across access ways or between fixed elements including

precast column erection. (Female coupler parts may also not be cast in concrete).

STEP 1

Expose couplers. 1

STEP 2

Install male part of P13 and offer joining bar with P15 parts mounted.

Use torque according to table 1.1 for all steps. 2

STEP 3

Screw in ferrule loosely.

3

STEP 4

Screw out P13 male to engage bar and tighten using 2 wrenches.

4

STEP 5

Screw P13 male out - by hand - until bar is set fully into P15.

Tighten ferrule fully. 5

STEP 6

Run back lock-nut of P13 and tighten fully.

6

copyright © 2004 Erico BV en 3-5

3 INSTALLATION OF COUPLERS

3.6. LENTON coupler type S13

1

STEP 1

Ensure coupler is tightened onto the bar. Use Prescribed torque according to

table 1.1.

STEP 2 2

Fix metric bolt with/without construction element into coupler. Minimum insertion

depth of bolt for full strength connection can be found in LENTON catalogue.

copyright © 2004 Erico BV en 3-6

3 INSTALLATION OF COUPLERS

3.7. LENTON coupler type D14

STEP 1

1

Ensure coupler is tightened onto the bar with the Prescribed torque according to

table 1.1.

copyright © 2004 Erico BV en 3-7

3 INSTALLATION OF COUPLERS

3.8. LENTON coupler type C12

1

STEP 1

The coupler is made from a weldable steel and formed with a ‘J’ groove to

facilitate a full-penetration weld. Welding should be carried out by a skilled welder

and the recommendations of the local Welding Institute and relevant Standards

should be followed. When necessary for protection, please fit plastic plug

afterwards.

STEP 2

2

Ensure bar is tightened into coupler with the prescribed torque according to table 1.1.

copyright © 2004 Erico BV en 3-8

Anda mungkin juga menyukai

- Code of Practice For Design of Concrete Bridges - bs-5400-Part-5-PDF-freeDokumen40 halamanCode of Practice For Design of Concrete Bridges - bs-5400-Part-5-PDF-freeHsaam HsaamBelum ada peringkat

- Guidebook On Non-Destructive Testing of Concrete Structures: Training Course Series No. 17Dokumen242 halamanGuidebook On Non-Destructive Testing of Concrete Structures: Training Course Series No. 17Harish LambadiBelum ada peringkat

- Astm-D3689 07 PDFDokumen13 halamanAstm-D3689 07 PDFreivin27Belum ada peringkat

- RCC13 Punching ShearDokumen10 halamanRCC13 Punching ShearPremasiri KarunarathnaBelum ada peringkat

- Spreadsheets To BS 8110: Type L (M) H (MM) BW (MM) HF (MM) BF (MM)Dokumen17 halamanSpreadsheets To BS 8110: Type L (M) H (MM) BW (MM) HF (MM) BF (MM)Hsaam HsaamBelum ada peringkat

- BS 8002 (2015) Code of Practice For Retaining StructuresDokumen104 halamanBS 8002 (2015) Code of Practice For Retaining Structuresrichardhenrylamb100% (3)

- A 53 - A 53M - 02Dokumen22 halamanA 53 - A 53M - 02Sourav RobinBelum ada peringkat

- تحليل البلاطات المصمتة0Dokumen8 halamanتحليل البلاطات المصمتة0Hsaam HsaamBelum ada peringkat

- Isolated Footing DesignDokumen7 halamanIsolated Footing DesignChristopher Joshua MartinezBelum ada peringkat

- Spreadsheets To BS 8110: Flight 5Dokumen3 halamanSpreadsheets To BS 8110: Flight 5MILACEL GAMIDOBelum ada peringkat

- RCC94 Two-Way Slabs (Tables)Dokumen4 halamanRCC94 Two-Way Slabs (Tables)Zayyan RomjonBelum ada peringkat

- Basement WallDokumen14 halamanBasement WallmakakkBelum ada peringkat

- PAD FOUNDATION DESIGN To BS 81101997Dokumen16 halamanPAD FOUNDATION DESIGN To BS 81101997nelsonhugo100% (1)

- Spreadsheets To BS 8110: Advisory Group 3rd Floor Slab RMW 43 CHG - R68 1 5aDokumen22 halamanSpreadsheets To BS 8110: Advisory Group 3rd Floor Slab RMW 43 CHG - R68 1 5aHsaam HsaamBelum ada peringkat

- STAIR FLIGHTS AND LANDINGS To BS 81101997Dokumen4 halamanSTAIR FLIGHTS AND LANDINGS To BS 81101997Imran KhanBelum ada peringkat

- R SteelDokumen7 halamanR SteelHsaam HsaamBelum ada peringkat

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 18-Feb-2021 101 CHG - R68Dokumen10 halamanSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 18-Feb-2021 101 CHG - R68Hsaam HsaamBelum ada peringkat

- Shear ForceDokumen18 halamanShear ForceHsaam HsaamBelum ada peringkat

- Tow RibsDokumen2 halamanTow RibsHsaam HsaamBelum ada peringkat

- FootingDokumen7 halamanFootingHsaam HsaamBelum ada peringkat

- Chick 1 Chick 2 Check Ok Ok P N.Ok: Thickness Check Flange CheckDokumen4 halamanChick 1 Chick 2 Check Ok Ok P N.Ok: Thickness Check Flange CheckHsaam HsaamBelum ada peringkat

- طريقة استخدام ملفات الإكسلDokumen9 halamanطريقة استخدام ملفات الإكسلHsaam HsaamBelum ada peringkat

- Input Data: Check Compact Check Check Check Ok Ok OkDokumen4 halamanInput Data: Check Compact Check Check Check Ok Ok OkHsaam HsaamBelum ada peringkat

- Slender ColumnDokumen2 halamanSlender ColumnHsaam HsaamBelum ada peringkat

- TankDokumen4 halamanTankHsaam HsaamBelum ada peringkat

- Second RenforcementDokumen1 halamanSecond RenforcementHsaam HsaamBelum ada peringkat

- Ribs LoadDokumen4 halamanRibs LoadHsaam HsaamBelum ada peringkat

- Crane Beam 0Dokumen8 halamanCrane Beam 0Hsaam HsaamBelum ada peringkat

- Corbels, BracketsDokumen1 halamanCorbels, BracketsHsaam HsaamBelum ada peringkat

- Chanal Culmon DesignDokumen1 halamanChanal Culmon DesignHsaam HsaamBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- A Proposed Methodology For Quantifying The Environmental Impacts of Structural Elements of Standard Bridge DesignsDokumen7 halamanA Proposed Methodology For Quantifying The Environmental Impacts of Structural Elements of Standard Bridge Designsandyoreta6332Belum ada peringkat

- Electrical Manhole and Handhole Design GuideDokumen8 halamanElectrical Manhole and Handhole Design Guidelilama45-1100% (1)

- Polystyrene Blocks: Uses, Benefits, and Availability in Ozamiz CityDokumen5 halamanPolystyrene Blocks: Uses, Benefits, and Availability in Ozamiz CityClaudine PansacalaBelum ada peringkat

- REINFORCING STEEL AND MESHDokumen24 halamanREINFORCING STEEL AND MESHThilan Senarathne100% (1)

- Repairs of D-Wall Exposed ReinforcementDokumen7 halamanRepairs of D-Wall Exposed Reinforcement陈勇Belum ada peringkat

- Bda - 4 CaltransDokumen20 halamanBda - 4 CaltransalbertoxinaBelum ada peringkat

- Is 456 2000-Withamend-3Dokumen137 halamanIs 456 2000-Withamend-3Muhammad HasanBelum ada peringkat

- Method Statement For Construction of Compound WallDokumen12 halamanMethod Statement For Construction of Compound Walljones71% (7)

- ACI-439.3R-91 Mechanical Connections of Reinforcing BarsDokumen16 halamanACI-439.3R-91 Mechanical Connections of Reinforcing BarsMichi AGBelum ada peringkat

- IJM IBS Sales & Marketing Team Presentation 200330 - CompressedDokumen41 halamanIJM IBS Sales & Marketing Team Presentation 200330 - CompressedCalvin NgBelum ada peringkat

- Civil/Structural Calculation SheetDokumen19 halamanCivil/Structural Calculation Sheetfbaxter22Belum ada peringkat

- Bongabon Plan MpsDokumen29 halamanBongabon Plan Mpsdarren gonzalesBelum ada peringkat

- PWD-E041-CNS-WKP-CNL-0000-00003-00 Rev3Dokumen13 halamanPWD-E041-CNS-WKP-CNL-0000-00003-00 Rev3Stroom LimitedBelum ada peringkat

- BS en 14487-2-2006Dokumen20 halamanBS en 14487-2-2006Thanh Hai QB50% (2)

- cOVER BLOCKSDokumen4 halamancOVER BLOCKSPrashant Mankar100% (1)

- Bunker BookDokumen58 halamanBunker BookMichaelrs80100% (1)

- Dubai Municipality Test G+12 & Unlimites - MajdDokumen19 halamanDubai Municipality Test G+12 & Unlimites - Majdmajd el chami75% (4)

- Overstrength Factor Calculation Procedure - ACI 318-08 (R) - Overstrength Factor - R - Part-2Dokumen5 halamanOverstrength Factor Calculation Procedure - ACI 318-08 (R) - Overstrength Factor - R - Part-2Adam Michael GreenBelum ada peringkat

- Ce 412 (Uap)Dokumen269 halamanCe 412 (Uap)Abdul MukitBelum ada peringkat

- NZS 4298:1998 Materials and Workmanship For Earth Buildings: Skip To Main Content Skip To Primary NavigationDokumen10 halamanNZS 4298:1998 Materials and Workmanship For Earth Buildings: Skip To Main Content Skip To Primary NavigationRui TerrasBelum ada peringkat

- Lesson 5.1 - Shear Strength in BeamsDokumen12 halamanLesson 5.1 - Shear Strength in BeamsManibog April MaeBelum ada peringkat

- Abaqus 1-Way RCC SlabDokumen10 halamanAbaqus 1-Way RCC SlabmitnathBelum ada peringkat

- Lab+Flyer NABL NaviMum+R4+-+PDokumen4 halamanLab+Flyer NABL NaviMum+R4+-+Pganesh.pg. GaniBelum ada peringkat

- Waffle SlabDokumen14 halamanWaffle SlabHuzefaMalikBelum ada peringkat

- Design and Construction of Confined Masonry Houses in IndonesiaDokumen20 halamanDesign and Construction of Confined Masonry Houses in IndonesiaRAIMUNDO SUHERDINBelum ada peringkat

- BoQ Local Clinic Additional BuidlingsDokumen26 halamanBoQ Local Clinic Additional BuidlingsswazsurvBelum ada peringkat

- Staircase CalculationsDokumen9 halamanStaircase Calculationsali jamiil100% (1)

- Concrete Frame Design: ACI 318-14 Column Section DesignDokumen2 halamanConcrete Frame Design: ACI 318-14 Column Section Designျမတ္ သူ ေအာင္Belum ada peringkat

- Corbel Design Reinforced ConcreteDokumen8 halamanCorbel Design Reinforced ConcreteAlexBelum ada peringkat