MBI5026

Diunggah oleh

Racer RacerHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MBI5026

Diunggah oleh

Racer RacerHak Cipta:

Format Tersedia

Datasheet MBI5026

Macroblock

16-bit Constant Current LED Sink Driver

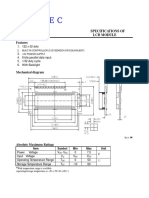

Features Dual In-Line Package

I5016CNS

MBI5016CNS

z 16 constant-current output channels

z Constant output current invariant to load voltage change

z Excellent output current accuracy:

between channels: <±3% (max.), and

CN: P-DIP24-300-2.54

between ICs: <±6% (max.)

GN: P-DIP24-300-2.54

z Output current adjusted through an external resistor

CNS: SP-DIP24-300-1.78

z Constant output current range: 5-90 mA GNS: SP-DIP24-300-1.78

z Fast response of output current, OE (min.): 200 ns

z 25MHz clock frequency Small Outline

I5016CFPackage

z Schmitt trigger input

z 5V supply voltage

z Optional for “Pb-free & Green” Package

CD: SOP24-300-1.27

GD: SOP24-300-1.27

CF: SOP24-300-1.00

Current Accuracy GF: SOP24-300-1.00

Conditions

Between Channels Between ICs

< ±3% < ±6% IOUT = 10 ~ 60 mA Shrink BI5016CP

SOP

CP\CPA: SSOP24-150-0.64

GP\GPA: SSOP24-150-0.64

Product Description

MBI5026 is designed for LED displays. As an enhancement of its predecessor, MBI5016, MBI5026 exploits

PrecisionDrive™ technology to enhance its output characteristics. MBI5026 contains a serial buffer and data

latches which convert serial input data into parallel output format. At MBI5026 output stage, sixteen regulated

current ports are designed to provide uniform and constant current sinks for driving LEDs within a large range of VF

variations.

MBI5026 provides users with great flexibility and device performance while using MBI5026 in their system design

for LED display applications, e.g. LED panels. Users may adjust the output current from 5 mA to 90 mA through an

external resistor, Rext, which gives users flexibility in controlling the light intensity of LEDs. MBI5026 guarantees to

endure maximum 17V at the output port. The high clock frequency, 25 MHz, also satisfies the system requirements

of high volume data transmission.

Macroblock, Inc. 2005

Floor 6-4, No.18, Pu-Ting Rd., Hsinchu, Taiwan 30077, ROC.

TEL: +886-3-579-0068, FAX: +886-3-579-7534 E-mail: info@mblock.com.tw

-1- April 2005, VA.02

MBI5026 16-bit Constant Current LED Sink Driver

Block Diagram

OUT0 OUT1 OUT14 OUT15

R-EXT IO Regulator

VDD

OE 16-bit Output Driver

16

LE 16-bit Output Latch

GND 16

SDI 16-bit Shift Register SDO

CLK

Terminal Description Pin Configuration

Pin Name Function

Ground terminal for control logic and current GND 1 24 VDD

GND SDI 2 23 R-EXT

sink

CLK 3 22 SDO

SDI Serial-data input to the shift register LE 4 21 OE

OUT0 5 20 OUT15

Clock input terminal for data shift on rising OUT1 6 19 OUT14

CLK OUT2 7 18 OUT13

edge

OUT3 8 17 OUT12

Data strobe input terminal OUT4 9 16 OUT11

OUT5 10 15 OUT10

LE Serial data is transferred to the output latch OUT6 11 14 OUT9

when LE is high. The data is latched when OUT7 12 13 OUT8

LE goes low.

MBI5026CN\CNS\CD\CF\CP\

OUT0 ~ OUT15 Constant current output terminals GN\GNS\GD\GF\GP

Output enable terminal OUT14 1 24 OUT13

OUT15 2 23 OUT12

OE When OE (active) low, the output drivers

OE 3 22 OUT11

are enabled; when OE high, all output SDO 4 21 OUT10

drivers are turned OFF (blanked). R-EXT 5 20 OUT9

VDD 6 19 OUT8

Serial-data output to the following SDI of GND 7 18 OUT7

SDO

next driver IC SDI 8 17 OUT6

CLK 9 16 OUT5

Input terminal used to connect an external LE 10 15 OUT4

R-EXT resistor for setting up output current for all OUT0 11 14 OUT3

output channels OUT1 12 13 OUT2

VDD 5V supply voltage terminal MBI5026CPA\GPA

April 2005, VA.02

-2-

MBI5026 16-bit Constant Current LED Sink Driver

Equivalent Circuits of Inputs and Outputs

OE terminal LE terminal

VDD VDD

IN IN

CLK, SDI terminal SDO terminal

VDD VDD

IN OUT

April 2005, VA.02

-3-

MBI5026 16-bit Constant Current LED Sink Driver

Timing Diagram

N=0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

CLK

SDI

LE

OE

OFF

OUT0 ON

OFF

OUT1

ON

OFF

OUT2

ON

OFF

OUT3 ON

OFF

OUT15 ON

SDO

: don’t care

Truth Table

CLK LE OE SDI OUT 0 … OUT 7 … OUT15 SDO

H L Dn Dn ….. Dn - 7 …. Dn - 15 Dn-15

L L Dn+1 No Change Dn-14

H L Dn+2 Dn + 2 …. Dn - 5 …. Dn - 13 Dn-13

X L Dn+3 Dn + 2 …. Dn - 5 …. Dn - 13 Dn-13

X H Dn+3 Off Dn-13

April 2005, VA.02

-4-

MBI5026 16-bit Constant Current LED Sink Driver

Maximum Ratings

Characteristic Symbol Rating Unit

Supply Voltage VDD 0~7.0 V

Input Voltage VIN -0.4~VDD + 0.4 V

Output Current IOUT +90 mA

Output Voltage VDS -0.5~+17.0 V

Clock Frequency FCLK 25 MHz

GND Terminal Current IGND 1440 mA

CN GN 1.80 2.00

CNS GNS 1.50 1.61

Power Dissipation CD GD 2.01 2.19

PD W

(On PCB, Ta=25°C) CF GF 1.69 1.91

CP GP 1.38 1.46

CPA GPA 1.38 1.46

CN GN 55.52 49.9

CNS GNS 66.74 62.28

Thermal Resistance CD GD 49.81 45.69

Rth(j-a) °C/W

(On PCB, Ta=25°C) CF GF 59.01 52.38

CP GP 72.43 68.48

CPA GPA 72.43 68.48

Operating Temperature Topr -40~+85 °C

Storage Temperature Tstg -55~+150 °C

April 2005, VA.02

-5-

MBI5026 16-bit Constant Current LED Sink Driver

Electrical Characteristics

Characteristic Symbol Condition Min. Typ. Max. Unit

Supply Voltage VDD - 4.5 5.0 5.5 V

Output Voltage VDS OUT0 ~ OUT15 - - 17.0 V

IOUT DC Test Circuit 5 - 90 mA

Output Current IOH SDO - - -1.0 mA

IOL SDO - - 1.0 mA

“H” level VIH Ta = -40~85ºC 0.8*VDD - VDD V

Input Voltage

“L” level VIL Ta = -40~85ºC GND - 0.3*VDD V

Output Leakage Current IOH VOH=17.0V - - 0.5 µA

VOL IOL=+1.0mA - - 0.4 V

Output Voltage SDO

VOH IOH=-1.0mA 4.6 - - V

Output Current 1 IOUT1 VDS=0.6V Rext=720 Ω - 26.25 - mA

IOL=26.25mA

Current Skew dIOUT1 Rext=720 Ω - ±1 ±3 %

VDS=0.6V

Output Current 2 IOUT2 VDS=0.8V Rext=360 Ω - 52.5 - mA

IOL=52.5mA

Current Skew dIOUT2 Rext=360 Ω - ±1 ±3 %

VDS=0.8V

Output Current vs.

%/dVDS VDS within 1.0V and 3.0V - ±0.1 - %/V

Output Voltage Regulation

Output Current vs.

%/dVDD VDD within 4.5V and 5.5V - ±1 - %/V

Supply Voltage Regulation

Pull-up Resistor RIN(up) OE 250 500 800 KΩ

Pull-down Resistor RIN(down) LE 250 500 800 KΩ

IDD(off) 1 Rext=Open, OUT0 ~ OUT15 =Off - 6 6.8

“OFF” IDD(off) 2 Rext=720 Ω, OUT0 ~ OUT15 =Off - 8.8 9.6

Supply

IDD(off) 3 Rext=360 Ω, OUT0 ~ OUT15 =Off - 12.4 13.2 mA

Current

IDD(on) 1 Rext=720 Ω, OUT0 ~ OUT15 =On - 8.8 10.8

“ON”

IDD(on) 2 Rext=360 Ω, OUT0 ~ OUT15 =On - 12.3 15.3

Test Circuit for Electrical Characteristics

IDD

IOUT

VDD

OE

..

OUT0

IIH,IIL

CLK ..

LE OUT15

SDI

SDO

R - EXT GND

VIH, VIL

Iref

April 2005, VA.02

-6-

MBI5026 16-bit Constant Current LED Sink Driver

Switching Characteristics

Characteristic Symbol Condition Min. Typ. Max. Unit

CLK - OUTn tpLH1 - 100 150 ns

Propagation Delay Time LE - OUTn tpLH2 - 100 150 ns

(“L” to “H”) tpLH3 - 50 150 ns

OE - OUTn

CLK - SDO tpLH 15 20 - ns

VDD=5.0 V

CLK - OUTn tpHL1 - 50 100 ns

VDS=0.8 V

Propagation Delay Time LE - OUTn tpHL2 VIH=VDD - 50 100 ns

(“H” to “L”) VIL=GND

OE - OUTn tpHL3 Rext=300 Ω - 20 100 ns

CLK - SDO tpHL VL=4.0 V 15 20 - ns

RL=52 Ω

CLK tw(CLK) CL=10 pF 20 - - ns

Pulse Width LE tw(L) 20 - - ns

OE tw(OE) 200 - - ns

Hold Time for LE th(L) 5 - - ns

Setup Time for LE tsu(L) 5 - - ns

Hold Time for SDI th(D) 10 - - ns

Setup Time for SDI tsu(D) 5 - - ns

Cascade

Clock Frequency FCLK - - 25.0 MHz

Operation

Maximum CLK Rise Time tr** - - 500 ns

Maximum CLK Fall Time tf** - - 500 ns

Output Rise Time of Vout (turn off) tor - 70 200 ns

Output Fall Time of Vout (turn on) tof - 40 120 ns

**If the devices are connected in cascade and tr or tf is large, it may be critical to achieve the timing required for

data transfer between two cascaded devices.

Test Circuit for Switching Characteristics

IDD

IOUT

VDD

VIH, VIL

OE

..

OUT0

Function

Generator

CLK

.

LE OUT15

RL

SDI

SDO CL

R - EXT GND

Logic input

waveform VL

VIH = 5V CL

Iref

VIL = 0V

tr = tf = 10 ns

April 2005, VA.02

-7-

MBI5026 16-bit Constant Current LED Sink Driver

Timing Waveform

tW(CLK)

50% 50% 50%

CLK

tsu(D) th(D)

SDI 50% 50%

SDO 50%

tpLH, tpHL tW(L)

LE 50% 50%

th(L) tsu(L)

OE LOW = OUTPUTS ENABLED

HIGH = OUTPUT OFF

OUTn 50%

LOW = OUTPUT ON

tpLH1, tpHL1

tpLH2, tpHL2

tW(OE)

OE 50% 50%

tpHL3 tpLH3

90% 90%

OUTn 50% 50%

10% 10%

tof tor

April 2005, VA.02

-8-

MBI5026 16-bit Constant Current LED Sink Driver

Application Information

Constant Current

In LED display application, MBI5026 provides nearly no variations in current from channel to channel and from IC

to IC. This can be achieved by:

1) The maximum current variation between channels is less than ±3%, and that between ICs is less than ±6%.

2) In addition, the current characteristic of output stage is flat and users can refer to the figure as shown below. The

output current can be kept constant regardless of the variations of LED forward voltages (VF). This performs as

a perfection of load regulation.

100.00

90.00

80.00

70.00

60.00

Iout (mA)

50.00

40.00

30.00

20.00

10.00

0.00

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2 1.3 1.4 1.5 2 2.5

VDS (V)

Adjusting Output Current

The output current of each channel (IOUT) is set by an external resistor, Rext. The relationship between Iout and Rext is

shown in the following figure.

100

90

80

70

IOUT (mA)

60

50

40 VDS = 1.0V

30

20

10

0

0 500 1000 1500 2000 2500 3000 3500

Rext

Resistance of the external resistor, Rext, in Ω

Also, the output current can be calculated from the equation:

VR-EXT = 1.26V;IOUT = (VR-EXT / Rext ) x 15

where Rext is the resistance of the external resistor connected to R-EXT terminal and VR-EXT is the voltage of R-EXT

terminal. The magnitude of current (as a function of Rext) is around 52.5mA at 360Ω and 26.25mA at 720Ω.

April 2005, VA.02

-9-

MBI5026 16-bit Constant Current LED Sink Driver

Soldering Process of “Pb-free & Green” Package Plating*

Macroblock has defines "Pb-Free & Green" to mean semiconductor products that are compatible with the current

RoHS requirements and selected 100% pure tin (Sn) to provide forward and backward compatibility with both the

current industry-standard SnPb-based soldering processes and higher-temperature Pb-free processes. Pure tin is

widely accepted by customers and suppliers of electronic devices in Europe, Asia and the US as the lead-free

surface finish of choice to replace tin-lead. Also, it is backward compatible to standard 215ºC to 240ºC reflow

processes which adopt tin/lead (SnPb) solder paste. However, in the whole Pb-free soldering processes and

materials, 100% pure tin (Sn), will all require up to 260oC for proper soldering on boards, referring to J-STD-020B

as shown below.

Temperature (℃)

300

255℃ 260℃+0℃

-5℃

250 245℃±5℃

240℃

217℃

30s max

200

Ramp-down

Average ramp-up

6℃/s (max)

rate= 0.7℃/s

150 100s max

Peak Temperature 245℃~260℃< 10s

100

Average ramp-up

rate = 0.4℃/s Average ramp-up

50 rate= 3.3℃/s

25

0 50 100 150 200 250 300

Time (sec)

----Maximum peak temperature

Recommended reflow profile Acc.J-STD-020B

*Note1: For details, please refer to Macroblock’s “Policy on Pb-free & Green Package”.

April 2005, VA.02

- 10 -

MBI5026 16-bit Constant Current LED Sink Driver

Package Power Dissipation (PD)

The maximum allowable package power dissipation is determined as PD(max) = (Tj – Ta) / Rth(j-a). When 16 output

channels are turned on simultaneously, the actual package power dissipation is PD(act) = (IDD x VDD) + (IOUT x Duty

x VDS x 16). Therefore, to keep PD(act) ≤ PD(max), the allowable maximum output current as a function of duty cycle

is:

IOUT = { [ (Tj – Ta) / Rth(j-a) ] – (IDD x VDD) } / VDS / Duty / 16,

where Tj = 150°C.

Iout vs. Duty Cycle at Rth = 55.52 (°C/W)

Iout vs. Duty Cycle at Rth = 59.01 (°C/W)

100

100

90 90

80 80

70 70

Iout(mA)

60

Iout(mA)

60

50 50

40 40

30 30

20 20

10 10

0 0 5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

Duty Cycle Duty Cycle

CN\GN type package CF\GF type package

Iout

Iout vs.

vs. Duty CycleatatRth

Duty Cycle Rth = 72.43

= 66.74 (°C/W)

(°C/W) Iout vs. Duty Cycle at Rth = 72.43 (°C/W)

100 100 100

90 90 90

80 80 80

Iout(mA)

70 70

Iout(mA)

70

60 60 60

Iout(mA)

50 50 50

40 40 40

30 30 30

20 20 20

10 10 10

0 0 0

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

5%

100%

Duty Cycle Duty Cycle

Duty Cycle

CNS\GNS type package CP\CPA\GP\GPA type package

Iout vs. Duty Cycle at Rth = 49.81 (°C/W)

100

90

80 Condition : Iout = 90mA,VDS = 1.0V,16 output channels

70

active

Iout(mA)

60

50

Device Type Rth(j-a)(°C/W) Note

40 CN GN 55.52 49.90

30 CNS GNS 66.74 62.28 Ta = 25℃

Ta = 55℃

20

CD GD 49.81 45.69

10 Ta = 85℃

0

CF GF 59.01 52.38

CP\CPA GP\GPA 72.43 68.48

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

Duty Cycle

CD\GD type package

April 2005, VA.02

- 11 -

MBI5026 16-bit Constant Current LED Sink Driver

The maximum power dissipation, PD(max) = (Tj – Ta) / Rth(j-a), decreases as the ambient temperature increases.

Max. Power Dissipation at Various Ambient Temperature

2.50

2.25

Power Dissipation

2.00

1.75 CN\GN T ype: Rth= 53.82

CNS\GNS T ype: Rth= 66.74

1.50

CD\GD T ype: Rth= 49.81

1.25 CF\GF Type: Rth= 59.01

CP\GP T ype: Rth= 72.43

1.00

CPA\GPA T ype: Rth= 72.43

0.75

0.50

10 20 30 40 50 60 70 80 90

Ambient Temperature

Load Supply Voltage (VLED)

MBI5026 are designed to operate with VDS ranging from 0.4V to 1.0V considering the package power dissipating

limits. VDS may be higher enough to make PD(act) > PD(max) when VLED = 5V and VDS = VLED –VF, in which VLED is the

load supply voltage. In this case, it is recommended to use the lowest possible supply voltage or to set an external

voltage reducer, VDROP.

A voltage reducer lets VDS = (VLED –VF) – VDROP.

Resistors or Zener diode can be used in the applications as shown in the following figures.

Voltage Supply Voltage Supply

VDrop VDrop

VLED VLED

VF VDS VF VDS

MBI5026 MBI5026

Switching Noise Reduction

LED driver ICs are frequently used in switch-mode applications which always behave with switching noise due to

the parasitic inductance on PCB. To eliminate switching noise, refer to “Application Note for 8-bit and 16-bit LED

Drivers- Overshoot”.

April 2005, VA.02

- 12 -

MBI5026 16-bit Constant Current LED Sink Driver

Package Outline

MBI5026CN\GN Outline Drawing

MBI5026CNS\GNS Outline Drawing

April 2005, VA.02

- 13 -

MBI5026 16-bit Constant Current LED Sink Driver

MBI5026CD\GD Outline Drawing

MBI5026CF\GF Outline Drawing

April 2005, VA.02

- 14 -

MBI5026 16-bit Constant Current LED Sink Driver

MBI5026CP\CPA\GP\GPA Outline Drawing

Note: The unit for the outline drawing is mm.

Product Top-mark Information

The first row of printing Part number

MBIXXXX ○ ○○ ● ID number The second row of printing

Or XXXXXXXX ○

MBIXXXX ○ ○

Manufacture

Device Version Code

Code

Product No. Package Code

Process Code

C: General type

G: Green and Pb-free

Product Revision History

Datasheet version Device version code

VA.00 Not defined

VA.01 A

VA.02 A

Product Ordering Information

Part Number Package Type Weight (g) Part Number “Pb-free & Green” Weight (g)

Package Type

MBI5026CN P-DIP24-300-2.54 1.628 MBI5026GN P-DIP24-300-2.54 1.628

MBI5026CNS SP-DIP24-300-1.78 1.11 MBI5026GNS SP-DIP24-300-1.78 1.11

MBI5026CD SOP24-300-1.27 0.617 MBI5026GD SOP24-300-1.27 0.617

MBI5026CF SOP24-300-1.00 0.28 MBI5026GF SOP24-300-1.00 0.28

MBI5026CP SSOP24-150-0.64 0.11 MBI5026GP SSOP24-150-0.64 0.11

MBI5026CPA SSOP24-150-0.64 0.11 MBI5026GPA SSOP24-150-0.64 0.11

April 2005, VA.02

- 15 -

MBI5026 16-bit Constant Current LED Sink Driver

Disclaimer

Macroblock reserves the right to make changes, corrections, modifications, and improvements to their products and

documents or discontinue any product or service without notice. Customers are advised to consult their sales

representative for the latest product information before ordering. All products are sold subject to the terms and

conditions supplied at the time of order acknowledgement, including those pertaining to warranty, patent

infringement, and limitation of liability.

Macroblock’s products are not designed to be used as components in device intended to support or sustain life or

in military applications. Use of Macroblock’s products in components intended for surgical implant into the body, or

other applications in which failure of Macroblock’s products could create a situation where personal death or injury

may occur, is not authorized without the express written approval of the President of Macroblock. Macroblock will

not be held liable for any damages or claims resulting from the use of its products in medical and military

applications.

All text, images, logos and information contained on this document is the intellectual property of Macoblock.

Unauthorized reproduction, duplication, extraction, use or disclosure of the above mentioned intellectual property

will be deemed as infringement.

April 2005, VA.02

- 16 -

Anda mungkin juga menyukai

- Injection Pump Calibration Data: Assy No.: 106671-0224Dokumen4 halamanInjection Pump Calibration Data: Assy No.: 106671-0224Elson DorigonBelum ada peringkat

- AxialDokumen67 halamanAxialAnonymous 6vrljIBelum ada peringkat

- 9 Power TrainDokumen146 halaman9 Power TraineduamaBelum ada peringkat

- Pajero Sports Workshop-Service Manual 1999Dokumen934 halamanPajero Sports Workshop-Service Manual 1999kiran_rm200693% (15)

- Lighting DesignDokumen178 halamanLighting DesignEderson Vertuan100% (3)

- Macroblock: 16-Bit Constant Current LED Sink DriverDokumen15 halamanMacroblock: 16-Bit Constant Current LED Sink Driverysa897Belum ada peringkat

- MBI5027Dokumen25 halamanMBI5027Hugo LoureiroBelum ada peringkat

- PCB Component MBI ICDokumen22 halamanPCB Component MBI ICAmit BhatiaBelum ada peringkat

- SEIPRA Girouette AV Minibus - MBI5168Dokumen15 halamanSEIPRA Girouette AV Minibus - MBI5168Smec KEOLISBelum ada peringkat

- Icn2038s ChiponeDokumen18 halamanIcn2038s ChiponeRoberto PasicBelum ada peringkat

- MBI5025Dokumen13 halamanMBI5025Claudio Miguel Trindade VazBelum ada peringkat

- Infineon Tle7230r Ds v03 04 enDokumen15 halamanInfineon Tle7230r Ds v03 04 enياسين الطنفوريBelum ada peringkat

- DatasheetDokumen16 halamanDatasheetAndres GuerreroBelum ada peringkat

- 7 A H-Bridge For DC-Motor Applications TLE 6209 R: 1 1.1 FeaturesDokumen29 halaman7 A H-Bridge For DC-Motor Applications TLE 6209 R: 1 1.1 Featureswtn2013Belum ada peringkat

- Infineon TLE6209R DS v03 02 enDokumen30 halamanInfineon TLE6209R DS v03 02 enRoger SegoBelum ada peringkat

- Starchips Starchips Starchips Starchips: TechnologyDokumen15 halamanStarchips Starchips Starchips Starchips: TechnologyXFact0r100% (1)

- CDP-100 Electronic Keyboard Technical ManualDokumen23 halamanCDP-100 Electronic Keyboard Technical ManualMao527kingBelum ada peringkat

- MBI6024 Datasheet VA.00-EnDokumen39 halamanMBI6024 Datasheet VA.00-Enastral projectBelum ada peringkat

- Kuman 3.5 Inch Touch Screen DatasheetDokumen15 halamanKuman 3.5 Inch Touch Screen DatasheetMarcGarciaBelum ada peringkat

- DatasheetDokumen23 halamanDatasheetAfif ArdiyansahBelum ada peringkat

- IDBS07 and IDBM07 Wiring Manual: February 2008Dokumen16 halamanIDBS07 and IDBM07 Wiring Manual: February 2008phankhoa83-1Belum ada peringkat

- TMPA 8823-5VA4 Service Manual: IC Functions and I2C Bus ControlDokumen16 halamanTMPA 8823-5VA4 Service Manual: IC Functions and I2C Bus ControlAndy AnsahBelum ada peringkat

- LPD6803Dokumen13 halamanLPD6803Deyabu DesignBelum ada peringkat

- SK9822 ShijiDokumen12 halamanSK9822 Shijinicares718Belum ada peringkat

- LCBTHT 6Dokumen16 halamanLCBTHT 6hermesBelum ada peringkat

- 7 X 5 Video Matrix Switch TDA 6920: 1 1.1 FeaturesDokumen21 halaman7 X 5 Video Matrix Switch TDA 6920: 1 1.1 FeaturesMPIMLACBelum ada peringkat

- CNC SERVO ADJUSTMENT GUIDEDokumen120 halamanCNC SERVO ADJUSTMENT GUIDEAlisson cruzBelum ada peringkat

- MBI5040 Preliminary Datasheet VA.00-EnDokumen33 halamanMBI5040 Preliminary Datasheet VA.00-EnEnéas BaroneBelum ada peringkat

- Manual de Servicio Lider 25 29 y 34 TMPA8859Dokumen14 halamanManual de Servicio Lider 25 29 y 34 TMPA8859Joel Roberto MolinaBelum ada peringkat

- S1d15200doa or EquivalentDokumen10 halamanS1d15200doa or EquivalentArduinoBeto RojasBelum ada peringkat

- TW3 Datasheet B2enDokumen26 halamanTW3 Datasheet B2enxinwubianBelum ada peringkat

- 170 3 092971 MB40528Dokumen14 halaman170 3 092971 MB40528Umum Cupang CupangBelum ada peringkat

- Ob2262 Usado em Fonte Proview MLT 198aDokumen13 halamanOb2262 Usado em Fonte Proview MLT 198aHeron Cesar VieiraBelum ada peringkat

- Max 6971Dokumen12 halamanMax 6971Goutham EzhilarasuBelum ada peringkat

- Ym12864p-Dalian Good Display PDFDokumen10 halamanYm12864p-Dalian Good Display PDFEvgeniyBelum ada peringkat

- Ob2262 Ver2.0 Datasheet PDFDokumen13 halamanOb2262 Ver2.0 Datasheet PDFjesus cautivoBelum ada peringkat

- Ob2262 Datasheet PDFDokumen13 halamanOb2262 Datasheet PDFjesus cautivoBelum ada peringkat

- General Description: EMI Filter Ac in DC OutDokumen13 halamanGeneral Description: EMI Filter Ac in DC Outjesus cautivoBelum ada peringkat

- LCD Module Specification: Model: LG128642-BMDWH6VDokumen20 halamanLCD Module Specification: Model: LG128642-BMDWH6VStuxnetBelum ada peringkat

- WF101GTYAPLNG0Dokumen7 halamanWF101GTYAPLNG0Jorge ArijaBelum ada peringkat

- STP16CP05: Low Voltage 16-Bit Constant Current LED Sink DriverDokumen30 halamanSTP16CP05: Low Voltage 16-Bit Constant Current LED Sink DriverWilson Yecit OrtizBelum ada peringkat

- Precision Digital-to-Analog Converters: SEA DFAE Training Dec 2004Dokumen38 halamanPrecision Digital-to-Analog Converters: SEA DFAE Training Dec 2004wildmonkey88Belum ada peringkat

- Pin Configurations and Definitions for the SAE 81C90/91 MicrocontrollerDokumen3 halamanPin Configurations and Definitions for the SAE 81C90/91 MicrocontrollerchawkigenieBelum ada peringkat

- Skhi 22B DatasheetDokumen9 halamanSkhi 22B DatasheetRakesh RoyBelum ada peringkat

- Dmos Dual Full Bridge Driver: Multipower BCD TechnologyDokumen11 halamanDmos Dual Full Bridge Driver: Multipower BCD TechnologyChristian BiancoBelum ada peringkat

- Sanyo TVS-2542MDokumen15 halamanSanyo TVS-2542MMartin Antonio Bautista CastilloBelum ada peringkat

- Aeg-Dvd4535 Service ManualDokumen25 halamanAeg-Dvd4535 Service ManualSerp19720% (1)

- Series Expansion BD Board: User ManualDokumen13 halamanSeries Expansion BD Board: User ManualSantiago Machado CruzBelum ada peringkat

- Fujitsu mb1502Dokumen15 halamanFujitsu mb1502haha2012Belum ada peringkat

- BD94062FDokumen35 halamanBD94062FMazalan HectorBelum ada peringkat

- E101RGD1280LBAM350-CDokumen18 halamanE101RGD1280LBAM350-CKeys SyekBelum ada peringkat

- Casio PX-700 PDFDokumen29 halamanCasio PX-700 PDFboroda2410100% (2)

- Shenzhen Sunmoon Micro SM2255E - C881537Dokumen12 halamanShenzhen Sunmoon Micro SM2255E - C881537Technical sidhuBelum ada peringkat

- TB62747AFG, TB62747AFNG: 16-Output Constant Current LED DriverDokumen20 halamanTB62747AFG, TB62747AFNG: 16-Output Constant Current LED DriverSaša DinčićBelum ada peringkat

- TA1310BN: TentativeDokumen102 halamanTA1310BN: TentativeBilly Dela PeñaBelum ada peringkat

- DC/DC Converter IC For Charging Li-Ion BatteryDokumen33 halamanDC/DC Converter IC For Charging Li-Ion BatteryMaikol DominguezBelum ada peringkat

- Tle 62326 Low Side SwitchDokumen19 halamanTle 62326 Low Side SwitchDiego CaceresBelum ada peringkat

- Mitsubishi 10Gb/s optical modulator driverDokumen8 halamanMitsubishi 10Gb/s optical modulator driverdaantic_uniBelum ada peringkat

- iom-200-data-sheet-4921240366-ukDokumen9 halamaniom-200-data-sheet-4921240366-ukAhmed AbdullahBelum ada peringkat

- Mitsubishi 8-Bit 12-Channel DAC with Buffer AmplifiersDokumen6 halamanMitsubishi 8-Bit 12-Channel DAC with Buffer Amplifiersagus2kBelum ada peringkat

- CMT 7432 PDFDokumen6 halamanCMT 7432 PDFaulia sarahBelum ada peringkat

- R1162x SERIES: 3-Mode 150ma Ldo Regulator OutlineDokumen32 halamanR1162x SERIES: 3-Mode 150ma Ldo Regulator OutlineZak zsBelum ada peringkat

- BD37543FSDokumen41 halamanBD37543FSfeni.alonso.gtzBelum ada peringkat

- CNC Plasma&Flame Cutting Control System Manual: (Model: 2100)Dokumen84 halamanCNC Plasma&Flame Cutting Control System Manual: (Model: 2100)Racer RacerBelum ada peringkat

- XPTHC-Portable300 Arc Voltage Torch Height ControllerDokumen8 halamanXPTHC-Portable300 Arc Voltage Torch Height ControllerRacer RacerBelum ada peringkat

- ULN200x, ULQ200x High-Voltage, High-Current Darlington Transistor ArraysDokumen34 halamanULN200x, ULQ200x High-Voltage, High-Current Darlington Transistor ArraysvincentavantBelum ada peringkat

- Bascavr PDFDokumen883 halamanBascavr PDFRacer RacerBelum ada peringkat

- CNC Plasma Cutting THC Controller GuideDokumen25 halamanCNC Plasma Cutting THC Controller GuideRacer RacerBelum ada peringkat

- DS1307 PDFDokumen14 halamanDS1307 PDFtestzopBelum ada peringkat

- Moc 3041Dokumen6 halamanMoc 3041Ingeniero JesusBelum ada peringkat

- sn74ls245 PDFDokumen28 halamansn74ls245 PDFRacer RacerBelum ada peringkat

- Datasheet dm114 PDFDokumen17 halamanDatasheet dm114 PDFRacer RacerBelum ada peringkat

- Moc 3020Dokumen7 halamanMoc 3020Alexandre PennaBelum ada peringkat

- W005M W10M: FeaturesDokumen3 halamanW005M W10M: FeaturesCarlos SouzaBelum ada peringkat

- FHDokumen22 halamanFHshhmmmBelum ada peringkat

- 1011 Sol 1Dokumen20 halaman1011 Sol 1Racer RacerBelum ada peringkat

- Hurricane Tech Data Sheet 1027Dokumen1 halamanHurricane Tech Data Sheet 1027Ravinesh SinghBelum ada peringkat

- Genio E550g User ManualDokumen140 halamanGenio E550g User ManualAlbert LugoBelum ada peringkat

- 17428Dokumen34 halaman17428Amit GhadeBelum ada peringkat

- ANSI CodesDokumen12 halamanANSI CodesmgkvprBelum ada peringkat

- MSA M1 SCBA LeafletDokumen5 halamanMSA M1 SCBA LeafletForum PompieriiBelum ada peringkat

- Sun SPARC Enterprise T5120 and T5220Dokumen55 halamanSun SPARC Enterprise T5120 and T5220Abhimanyu BiswasBelum ada peringkat

- Index ChillDokumen95 halamanIndex Chillreezqee100% (1)

- Emergency Valve PartsDokumen1 halamanEmergency Valve PartsNico PatawaranBelum ada peringkat

- User Manual: 3.6KW/5.6KW Solar Inverter / ChargerDokumen82 halamanUser Manual: 3.6KW/5.6KW Solar Inverter / ChargerStLisBelum ada peringkat

- Sealed Lead-Acid Battery: SpecificationDokumen2 halamanSealed Lead-Acid Battery: Specificationapi-170472102Belum ada peringkat

- 2017 BMW R Ninet Scrambler 71662Dokumen163 halaman2017 BMW R Ninet Scrambler 71662Anas KhanBelum ada peringkat

- DFZ430Dokumen14 halamanDFZ430termoking domBelum ada peringkat

- WEG Hydrogenerators Gh20 14824113 Manual EnglishDokumen51 halamanWEG Hydrogenerators Gh20 14824113 Manual EnglishGuilherme RosaBelum ada peringkat

- Cooper ElectronicDokumen128 halamanCooper ElectronicRadio Parts100% (1)

- ST10 Family: Advanced 16-Bit Microcontroller SolutionsDokumen2 halamanST10 Family: Advanced 16-Bit Microcontroller Solutionsleuchimed mouhBelum ada peringkat

- Prospecto SPS D BH3000Dokumen4 halamanProspecto SPS D BH3000Marcos Zimmermann100% (1)

- Evolution of Intel Microprocessors PDFDokumen2 halamanEvolution of Intel Microprocessors PDFErikaBelum ada peringkat

- 2014 Comtran Cable Catalog RSDokumen48 halaman2014 Comtran Cable Catalog RSHashimAmrBelum ada peringkat

- ZF TERRAPOWER TPT 20 transmission overviewDokumen2 halamanZF TERRAPOWER TPT 20 transmission overviewMiguelBelum ada peringkat

- Firefly Royu Wiring Devices Price List March 2016Dokumen2 halamanFirefly Royu Wiring Devices Price List March 2016Alvin Lagasca100% (1)

- Rečnik Srpsko-EngleskiDokumen9 halamanRečnik Srpsko-EngleskisreckoBelum ada peringkat

- Test Water Pump Pressure 16H Motor GraderDokumen2 halamanTest Water Pump Pressure 16H Motor GraderDouglas GomesBelum ada peringkat

- XH320 Operations Manual Rev J (Eng)Dokumen370 halamanXH320 Operations Manual Rev J (Eng)Goran BogdanoskiBelum ada peringkat

- Operator Protective Guards level 2Dokumen7 halamanOperator Protective Guards level 2Irfan SaeedBelum ada peringkat

- DRV MasterDrives Compact PLUS InvertersDokumen12 halamanDRV MasterDrives Compact PLUS InvertersLateef AlmusaBelum ada peringkat