Aux Transformer Test

Diunggah oleh

Engr Fahimuddin QureshiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aux Transformer Test

Diunggah oleh

Engr Fahimuddin QureshiHak Cipta:

Format Tersedia

Commissioning Service Department

Commissioning Standard Test Formats

Description: AUXILIARY TRANSFORMER TEST Record No.:

Bay no.: Drawing ref.: Sheet: 1 of 4

Contractor: Contract no.: Substation No :

1. NAME PLATE DETAILS

Sl. no. :

Make :

Power Capacity :

Voltage Rating :

Vector Group :

% Impedance at Nominal Tap:

Normal Tap :

Frequency : 60 HZ

Primary Current :

Secondary Current :

NO. of Taps :

2. MECHANICAL CHECK AND VISUAL INSPECTION

Item Description Remarks

1 Inspect For Physical Damage/Defects

2 Check Nameplates data against contract specifications

Check colour, earthing, painting, external damage, oil leakage, wheel

3

stopper, cable connection and bolt tightness. etc

Check all Position of the off load tap - changer with its indications and

4

alarms

5 Check all devices are labeled correctly as per drawing

3. Insulation Resistance & Polarization Index Test

Insulation Checked With 5kV MEGGER

Time HV-LV HV- Earth. LV- Earth. Remarks

30 Sec.

1 min

2min

3 min

4 min

5 min

6 min

7 min

8 min

9 min

10 min

P.I.

NOTE: Polarization Index = IR Value at 10 min. / IR Value at 1 min

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: AUXILIARY TRANSFORMER TEST Record No.:

Bay no.: Drawing ref.: Sheet: 2 of 4

Contractor: Contract no.: Substation No :

4. WINDING RESISTANCE TEST

Amb Temp.: ⁰C

4.1. HV Winding

Measured Value (Ohm) Mean Value Factory

HV side Mean Value @ 75°C Remarks

Tap Position @

(ohm) (ohm)

75°C(ohm)

R-Y Y-B B-R

1

2

3

4

5

4.2. LV Winding

Mean Value @ Factory Test

r–yn y–bn b–rn Mean Remark

75°C Value @ 75°C

Temperature correction formula:

R @ 75°C = (235 + 75 / 235 + Tm) x Rm

Where, Rm = Measured value of resistance

Tm = Temp. During measurement

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: AUXILIARY TRANSFORMER TEST Record No.:

Bay no.: Drawing ref.: Sheet: 3 of 4

Contractor: Contract no.: Substation No :

5. MAGNETIZING CURRENT

Condition:

1. three phase voltages applied on HV side, by keeping LV side open.

2. Current measurement carried at HV terminals.

Applied Voltage @ Primary Winding Magnetizing Current in m A at Primary

TAP

(V) Winding

No.

R-Y Y-B B-R IR IY IB

1

2

3

4

5

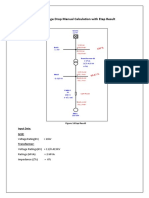

6. VECTOR GROUP:

Tap No.

Connect (R) to (r)

Apply 3 Phase balance supply to HV side.

Drawing:

Measured voltages following

R Y B N r y b

R × × × × × × ×

Y × × × × × ×

B × × × × ×

N × × × ×

r × × ×

y × ×

b ×

n ×

Result: Vector Group _________

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Commissioning Service Department

Commissioning Standard Test Formats

Description: AUXILIARY TRANSFORMER TEST Record No.:

Bay no.: Drawing ref.: Sheet: 4 of 4

Contractor: Contract no.: Substation No :

7. CALIBRATION OF OIL TEMPERATURE SENSORS

Start Temp. Reading: OTI = °C

Item Standard Thermometer Reading (°C) Main TR. OTI Reading (°C)

1

2

3

4

5

8. RATIO TEST

primary Sec Calc. R - Phase Y - Phase B - Phase

Tap Volts Volts Ratio Measured %E Measured % E Measured %E

1

2

3

4

5

9. INSULATING OIL DIELECTRIC STRENGTH TEST

According to IEC 156, Electrode Gap is set at 2.5 mm and for transformers in service with

maximum operating voltage up to 36kV the minimum breakdown voltage is to be 40kV.

Number of Trials Breakdown Voltage (KV) Remarks

Sample 1 Sample 2

Average Reading.

Remarks

Tested by: ENG. Witnessed by: ENG.

Signature & Date: Signature & Date:

Anda mungkin juga menyukai

- Site Acceptance Test Report For 33Kv Cable: Project: Construction of 306 Villas - Al SaadDokumen3 halamanSite Acceptance Test Report For 33Kv Cable: Project: Construction of 306 Villas - Al SaadJayaprakash M PBelum ada peringkat

- 1.6 Kva Transformer Testing ReportDokumen5 halaman1.6 Kva Transformer Testing ReportVikrant DeshmukhBelum ada peringkat

- 416e Diagrama ElectricoDokumen24 halaman416e Diagrama ElectricoElvis Gonzalez Huerta83% (6)

- Aether Gravity TechnologyDokumen328 halamanAether Gravity Technologyrossix1100% (2)

- Ref615 - Oc Ef Relay TestDokumen8 halamanRef615 - Oc Ef Relay TestMeghavahinaBelum ada peringkat

- TR Differential Ret670Dokumen19 halamanTR Differential Ret670Mahdi AlamriBelum ada peringkat

- General Data and InformationDokumen5 halamanGeneral Data and InformationSunil SinghBelum ada peringkat

- Site Testing Pre Commissioning PDFDokumen2 halamanSite Testing Pre Commissioning PDFadi nugrohoBelum ada peringkat

- Circuit Breaker - For SwitchayrdDokumen9 halamanCircuit Breaker - For SwitchayrdSindhuKumarBelum ada peringkat

- REF615 Over Current Test FormatDokumen8 halamanREF615 Over Current Test FormatEssam AjamiBelum ada peringkat

- Power Transformer - For SwitchayrdDokumen20 halamanPower Transformer - For SwitchayrdSindhuKumarBelum ada peringkat

- ISA Introduction To The Test of Protection RelaysDokumen23 halamanISA Introduction To The Test of Protection RelaysCata CatalinBelum ada peringkat

- CB Test ReportDokumen2 halamanCB Test ReportLingga SuhadhaBelum ada peringkat

- 132 Testing - Power TransformerDokumen3 halaman132 Testing - Power TransformerSantosh GairheBelum ada peringkat

- Grounding Resistance MeasurementsDokumen13 halamanGrounding Resistance MeasurementskishansaiBelum ada peringkat

- Functional Test of Thermal Overload ProtectionDokumen1 halamanFunctional Test of Thermal Overload ProtectionMihai BancuBelum ada peringkat

- Site Acceptance Test Report For 11Kv Cable: Project Equipment Client Date Contractor Location Testing CompanyDokumen3 halamanSite Acceptance Test Report For 11Kv Cable: Project Equipment Client Date Contractor Location Testing CompanyGajendran SriramBelum ada peringkat

- Xr350-Tcsr by ReyrolleDokumen3 halamanXr350-Tcsr by ReyrolleGunta RavitejaBelum ada peringkat

- Tested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureDokumen2 halamanTested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureRK KBelum ada peringkat

- Pre-Commissioning Test Report For Numerical Relay: ProjectDokumen3 halamanPre-Commissioning Test Report For Numerical Relay: ProjectHari haranBelum ada peringkat

- MV Cable Hi-Pot Test ShetDokumen1 halamanMV Cable Hi-Pot Test ShetAhmad Dagamseh100% (1)

- T&CDokumen13 halamanT&CAbdurRahmanFBelum ada peringkat

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDokumen2 halamanTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun AhsanBelum ada peringkat

- 4.various Tests Part 1Dokumen53 halaman4.various Tests Part 1Rohit JoshiBelum ada peringkat

- QA/QC CHECKLIST: Installation of M.V SwitchgearDokumen2 halamanQA/QC CHECKLIST: Installation of M.V SwitchgearehteshamBelum ada peringkat

- Distance Protection Relay of LineDokumen11 halamanDistance Protection Relay of LineYahya DarBelum ada peringkat

- 1 - Hi Pot Test Procedure For SwitchyardDokumen6 halaman1 - Hi Pot Test Procedure For Switchyardbayu dewanto100% (1)

- Volt::Ch: Voltech Engineers Pvt. LTDDokumen32 halamanVolt::Ch: Voltech Engineers Pvt. LTDstalin63100% (1)

- Itp For Commissioning Procedure For LV Switchgear SystemDokumen4 halamanItp For Commissioning Procedure For LV Switchgear SystemSulimanBelum ada peringkat

- Potential TransformerDokumen8 halamanPotential TransformerSyed AbbasBelum ada peringkat

- RET 650 REPORT - 132kV CRPDokumen6 halamanRET 650 REPORT - 132kV CRPAbhishek RajputBelum ada peringkat

- DC Faultr Location FinderDokumen26 halamanDC Faultr Location Findergaurang1111Belum ada peringkat

- Final END To END Test MAIN 1 FormatDokumen69 halamanFinal END To END Test MAIN 1 FormatVAJIRAVEL NAGALINGAM50% (2)

- Dgt801b Gen - Unit ADokumen30 halamanDgt801b Gen - Unit ASamraddh TiwariBelum ada peringkat

- 1.a Power TransformerDokumen28 halaman1.a Power TransformerAnkur SinhaBelum ada peringkat

- Site Test Report: Under Ground Cables Precommissioning Test SheetDokumen1 halamanSite Test Report: Under Ground Cables Precommissioning Test SheetNaser MahamidBelum ada peringkat

- Baur PGK25 Cable Test Set User ManualDokumen1 halamanBaur PGK25 Cable Test Set User ManualKuyan LesmanaBelum ada peringkat

- Test Report For Motor Protection Relay-Sel 710: DATE: 21.06.2018Dokumen3 halamanTest Report For Motor Protection Relay-Sel 710: DATE: 21.06.2018Jayam kondanBelum ada peringkat

- P 220 Testing ProcedureDokumen8 halamanP 220 Testing ProcedureRanjit Rjt100% (3)

- Tan Delta Test For TransformerDokumen3 halamanTan Delta Test For Transformermayur3dhandeBelum ada peringkat

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDokumen2 halaman86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanBelum ada peringkat

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDokumen6 halamanCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDinesh PitchaivelBelum ada peringkat

- J03 - TRF 2 Oc-Ef & Sbef Relay TestDokumen6 halamanJ03 - TRF 2 Oc-Ef & Sbef Relay TestSaran Saravanan100% (1)

- Testing Procedure For Transformer Differential Protection Relay Using Conventional KitDokumen14 halamanTesting Procedure For Transformer Differential Protection Relay Using Conventional KitRavi MehroliyaBelum ada peringkat

- 132KV VT Test Report-Jumsouth Ss by PatrixDokumen3 halaman132KV VT Test Report-Jumsouth Ss by Patrixharihara_675292894Belum ada peringkat

- Uss 105Dokumen12 halamanUss 105Soumya BhowmickBelum ada peringkat

- 230 KV Power Cable Test ProcedureDokumen1 halaman230 KV Power Cable Test ProcedureAshiqur Rahman ZituBelum ada peringkat

- Dry Type Traformer 1mvaDokumen4 halamanDry Type Traformer 1mvaidrisBelum ada peringkat

- Test Report For Motor Protection Relay-Sel 710: DATE: 21.06.2018Dokumen3 halamanTest Report For Motor Protection Relay-Sel 710: DATE: 21.06.2018Jayam kondanBelum ada peringkat

- Bus Bar Test Report PDFDokumen3 halamanBus Bar Test Report PDFArif AhmedBelum ada peringkat

- CT Secondary InjectionDokumen2 halamanCT Secondary InjectionHumayun AhsanBelum ada peringkat

- Site Acceptance Test Report For MV Panel - J01: MV Switchgear Functional TestsDokumen2 halamanSite Acceptance Test Report For MV Panel - J01: MV Switchgear Functional TestsGajendran SriramBelum ada peringkat

- Test Report For: CT Primary Injection TestDokumen4 halamanTest Report For: CT Primary Injection TestAhmed FathyBelum ada peringkat

- Siemens 7sd5Dokumen20 halamanSiemens 7sd5Omer Nawaz Malik100% (1)

- Trafo-1 Test ReportDokumen16 halamanTrafo-1 Test ReportramBelum ada peringkat

- Transformer Name Plate DataDokumen3 halamanTransformer Name Plate DataSaad NasirBelum ada peringkat

- Transformer WorkshopDokumen44 halamanTransformer Workshopniyaz100% (3)

- LT Fault Level CalculationDokumen2 halamanLT Fault Level Calculationmazumdar_satyajitBelum ada peringkat

- Shunt Reactor TestDokumen10 halamanShunt Reactor TestEngr Imtiaz Hussain GilaniBelum ada peringkat

- Maintenence Report PSS Full YearDokumen8 halamanMaintenence Report PSS Full YearAmr ElkadyBelum ada peringkat

- 132kv VT TestDokumen2 halaman132kv VT TestTota KamelBelum ada peringkat

- Time Synchronization of Relays at NTDC Grid Stations-1Dokumen1 halamanTime Synchronization of Relays at NTDC Grid Stations-1Engr Fahimuddin QureshiBelum ada peringkat

- Push - Pull Converter - 5 - B - H - Cruve - Transformer - Design - UpdatedDokumen24 halamanPush - Pull Converter - 5 - B - H - Cruve - Transformer - Design - UpdatedEngr Fahimuddin QureshiBelum ada peringkat

- Flux Imbalances in Push Pull ConverterDokumen5 halamanFlux Imbalances in Push Pull ConverterEngr Fahimuddin QureshiBelum ada peringkat

- Push - Pull Converter - 4 - Wavforms - Voltage - StressDokumen18 halamanPush - Pull Converter - 4 - Wavforms - Voltage - StressEngr Fahimuddin QureshiBelum ada peringkat

- Effect of Z Tolerance and - Z Variation On Short CircuitDokumen3 halamanEffect of Z Tolerance and - Z Variation On Short CircuitEngr Fahimuddin QureshiBelum ada peringkat

- Interpretation of Gases Generated in Mineral OilDokumen32 halamanInterpretation of Gases Generated in Mineral OilEngr Fahimuddin QureshiBelum ada peringkat

- Distance Protection (Zone 2 Consideration)Dokumen1 halamanDistance Protection (Zone 2 Consideration)Engr Fahimuddin QureshiBelum ada peringkat

- Mho Relay 2 PDFDokumen8 halamanMho Relay 2 PDFArion BaboolalBelum ada peringkat

- Cable Voltage Drop CalculationDokumen3 halamanCable Voltage Drop CalculationEngr Fahimuddin QureshiBelum ada peringkat

- HVDC Links in System OperationsDokumen81 halamanHVDC Links in System OperationsUtopia BogdanBelum ada peringkat

- Conference 101719Dokumen3 halamanConference 101719Engr Fahimuddin QureshiBelum ada peringkat

- CT Sizing - CT Over Dimensioning FactorDokumen19 halamanCT Sizing - CT Over Dimensioning FactorEngr Fahimuddin QureshiBelum ada peringkat

- Homework 5Dokumen4 halamanHomework 5Engr Fahimuddin QureshiBelum ada peringkat

- Diagnostics of Winding Deformation in A Single-PhaDokumen4 halamanDiagnostics of Winding Deformation in A Single-PhaEngr Fahimuddin QureshiBelum ada peringkat

- OSHA Safety ManualDokumen278 halamanOSHA Safety ManualEngr Fahimuddin QureshiBelum ada peringkat

- 2018 04 16 Tertiary Winding in Transformers PRCDokumen17 halaman2018 04 16 Tertiary Winding in Transformers PRCSaurav Kafle100% (1)

- Investigation of A Transferred Voltage Surge Trbusic 19IPST033Dokumen5 halamanInvestigation of A Transferred Voltage Surge Trbusic 19IPST033Engr Fahimuddin QureshiBelum ada peringkat

- Article Download 1Dokumen6 halamanArticle Download 1Engr Fahimuddin QureshiBelum ada peringkat

- Performance Analysis of Distance Relay On Shunt - Series Facts-CompDokumen106 halamanPerformance Analysis of Distance Relay On Shunt - Series Facts-CompEngr Fahimuddin QureshiBelum ada peringkat

- Csa - Cia - MalikDokumen26 halamanCsa - Cia - MalikEngr Fahimuddin QureshiBelum ada peringkat

- Short Circuit Study 11Dokumen5 halamanShort Circuit Study 11Engr Fahimuddin QureshiBelum ada peringkat

- AuthorproofspringerDokumen19 halamanAuthorproofspringerEngr Fahimuddin QureshiBelum ada peringkat

- Short Circuit Study 11Dokumen5 halamanShort Circuit Study 11Engr Fahimuddin QureshiBelum ada peringkat

- Cable Schedule For Low Impedance Bus Bar Protection PanelDokumen4 halamanCable Schedule For Low Impedance Bus Bar Protection PanelEngr Fahimuddin QureshiBelum ada peringkat

- Who Is Telling The Truth FinalDokumen41 halamanWho Is Telling The Truth FinalEngr Fahimuddin Qureshi100% (1)

- Case StudyDokumen8 halamanCase StudyEngr Fahimuddin QureshiBelum ada peringkat

- What To Do If Your Team Is Underperforming ABP Fahimuddin QureshiDokumen41 halamanWhat To Do If Your Team Is Underperforming ABP Fahimuddin QureshiEngr Fahimuddin QureshiBelum ada peringkat

- Article Base Presentation Final 1Dokumen26 halamanArticle Base Presentation Final 1Engr Fahimuddin QureshiBelum ada peringkat

- CSA Report Fahim FinalDokumen9 halamanCSA Report Fahim FinalEngr Fahimuddin QureshiBelum ada peringkat

- Ex 12 HLOOKUPDokumen2 halamanEx 12 HLOOKUPEngr Fahimuddin QureshiBelum ada peringkat

- ELEC2507 SummerCourse PA Assigned Problems Summer2021Dokumen1 halamanELEC2507 SummerCourse PA Assigned Problems Summer2021Ambar MendezBelum ada peringkat

- SR2/SR3 Series: 3-Phase, Detachable/Integrated Heatsink Type SSRDokumen8 halamanSR2/SR3 Series: 3-Phase, Detachable/Integrated Heatsink Type SSRaldo peñaBelum ada peringkat

- 20TL / 33TL: Three-Phase TL Inverters With The Maximum Efficiency at The Best PriceDokumen4 halaman20TL / 33TL: Three-Phase TL Inverters With The Maximum Efficiency at The Best PriceMarcelo SilvaBelum ada peringkat

- An Enhanced Droop Control Method For Accurate Load Sharing and Voltage Improvement of Isolated and Interconnected DC MicrogridsDokumen11 halamanAn Enhanced Droop Control Method For Accurate Load Sharing and Voltage Improvement of Isolated and Interconnected DC MicrogridsRiad TifaBelum ada peringkat

- Vfm40 Description: Ac-Dc Power Supply: SeriesDokumen4 halamanVfm40 Description: Ac-Dc Power Supply: SeriesElviraBelum ada peringkat

- CO2 Laser - OrganizedDokumen4 halamanCO2 Laser - OrganizedEE Sachin18Belum ada peringkat

- Electric DrivesDokumen91 halamanElectric DrivesS.m. FerdousBelum ada peringkat

- Legrand - Light Sensitive Switch SCNDokumen1 halamanLegrand - Light Sensitive Switch SCNberliani navitasBelum ada peringkat

- Set ADokumen5 halamanSet AgregBelum ada peringkat

- Spacelogic VBB/VBS: NoticeDokumen4 halamanSpacelogic VBB/VBS: Noticehamza alhassanBelum ada peringkat

- Power Flow Control in A Transmission Line Through UPFCDokumen5 halamanPower Flow Control in A Transmission Line Through UPFCMmillion AlemayehuBelum ada peringkat

- MAR N I N I: J Oy Vector Ano Scalar Tic Intensities Generated 8Y An Infin Tely Lo G COLDokumen34 halamanMAR N I N I: J Oy Vector Ano Scalar Tic Intensities Generated 8Y An Infin Tely Lo G COLchadj1060Belum ada peringkat

- MainDokumen30 halamanMainmgitecetechBelum ada peringkat

- c4.4 Sistema ElectricoDokumen7 halamanc4.4 Sistema ElectricoAngelica VergaraBelum ada peringkat

- Major PPT Batch 6Dokumen19 halamanMajor PPT Batch 6starboyBelum ada peringkat

- Ats 100 A Model KSS-KSPDokumen12 halamanAts 100 A Model KSS-KSPhenryvargas238565Belum ada peringkat

- Power SupplyDokumen165 halamanPower SupplyMohamed AbdelhameedBelum ada peringkat

- Eee 11 15Dokumen5 halamanEee 11 15aswakrishBelum ada peringkat

- Ec8701 Ame Unit-2 NotesDokumen174 halamanEc8701 Ame Unit-2 Notesajaykarthicsp.ece2020Belum ada peringkat

- Master TripDokumen2 halamanMaster TripTanveer Ul HaqBelum ada peringkat

- Priya 456Dokumen54 halamanPriya 456Priya GadirajuBelum ada peringkat

- Elexia FP2 RELAY Axicom D3016Dokumen4 halamanElexia FP2 RELAY Axicom D3016Коресендович ЮрийBelum ada peringkat

- Boss GE-10 Service NotesDokumen5 halamanBoss GE-10 Service NotesIncubusKissBelum ada peringkat

- L (Na) 02031eng-F (1712) 17a PDFDokumen390 halamanL (Na) 02031eng-F (1712) 17a PDFFerdi Bayu0% (1)

- Server Supply DPS-800GB A EngDokumen1 halamanServer Supply DPS-800GB A EngЛеонид ДорфманBelum ada peringkat

- Ayantika Khanra UG23Dokumen42 halamanAyantika Khanra UG23Anisha GoenkaBelum ada peringkat

- Output Filter Design Guide - MG90N502Dokumen47 halamanOutput Filter Design Guide - MG90N502DavorBelum ada peringkat

- JustAccepted EML 12 109Dokumen22 halamanJustAccepted EML 12 109Shridhar MathadBelum ada peringkat