06 GTAW Stainless Steel

Diunggah oleh

Muhammad Fitransyah Syamsuar PutraDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

06 GTAW Stainless Steel

Diunggah oleh

Muhammad Fitransyah Syamsuar PutraHak Cipta:

Format Tersedia

PT.

MONTIS ENERGY

, Alamat Pusat:SentralSenayan 2 Lantai 16 unit 216A. JL. Asia Afrika No.8 KelGelora, Kec. Tanah Abang

Jakarta Pusat. 10270

Fax : 62-21-2924-1980 : 62-21-2924-1996 Telephone

: customersupport@montisenergy.com Email

: http://www.montisenergy.comWebsite

Page 1 of 2

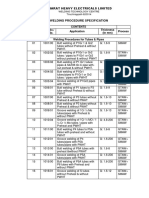

WELDING PROCEDURE SPECIFICATION (WPS)

(Section IX, ASME Boiler and Pressure Vessel Code)

Company Name PT. Montis Energy By : PT. Montis Energy

Welding Procedure Specification No. 06-WPS-ASME-ME-2016 Date Supporting PQR No. (s) : 06-PQR-ASME-ME-2016 Date

Revision No. 0

Welding Process (es) GTAW Type(s) Manual

(Automatic, Manual, Machine, or Semi-Auto)

JOINTS (QW-402) Details Joint

Joint Design As Per Details Joint

Root Spacing As Per Details Joint

Backing (Yes) √ ( No) √

Backing Material (Type) Yes

(Refer to both backing and retainers)

Metal Nonfusing Metal

Nonmetallic Other (Weld Metal)

Sketches, Production Drawings, Weld Symbols or Written Description

shoul show the general arrangement of the parts to be welded. Where

applicable, the root spacing and details of weld groove may be specified.

(At the option of the Mfgr., sketches may be attached to illustrate joint design,

weld layers and bead sequence, e.g., for notch toughness procedures, for

multiple process procedures, etc.) or See Applicable Drawing & Weld Map

* BASE METALS (QW-403)

P-No. 8 Group No. 1 to P-No. 1 Group No. 1

OR

Specification and type / grade or UNS Number -

to Specification and type / grade or UNS Number -

OR

Chem. Analysis and Mech. Prop. -

to Chem. Analysis and Mech. Prop. -

Thickness Range :

Base Metal : Thickness Groove 1.5 mm to 14.22 mm Fillet All Sizes & All Diameters

Diameter Groove All Sizes Fillet All Sizes

Maximum Pass Thickness ≤ 1/2 in. (13mm) (Yes) √ (No)

Other

* FILLER METALS (QW-404) GTAW

Spec. No. (SFA) 5.9

AWS No. (Class) ER 309L

F-No. 6

A-No. 8

Size of Filler Metal(s)/Electrode(s) 1.6 mm to 4 mm including

Filler Metal Product Form (Solid/Metal or Flux Cored) Solid

Flux/Wire Classification N.A

Alloy Flux N.A

± Filler None

± Flux None

Consumable Insert None

Alloy Element N.A

Supplemental Filler Metal N.A

Flux Designation or Trade Name N.A

t Deposit/Weld Metal

Thickness Range :

Groove : Max 14.22 mm

Fillet : All Sizes & All Diameters

Flux Type N.A

Recrushed Slag N.A

Other None

PT. MONTIS ENERGY

, Alamat Pusat:SentralSenayan 2 Lantai 16 unit 216A. JL. Asia Afrika No.8 KelGelora, Kec. Tanah Abang

Jakarta Pusat. 10270

Fax : 62-21-2924-1980 : 62-21-2924-1996 Telephone

: customersupport@montisenergy.comEmail

: http://www.montisenergy.comWebsite

Page 2 of 2

WPS No.: 03-WPS-ASME-ME-2016 Rev.: 0

POSITION (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove All Temperature Range None

Welding Progression : Uphill √ Downhill - Time Range None

Position(s) of Fillet All Other None

Other None

GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temperature, Minimum 10 ° C Gas (es) (Mixture) Flow Rate

Interpass Temperature, Maximum 200 ° C Shielding Argon 99.99% 5 - 25 lpm

Preheat Maintenance N.A Trailing None None None

Other None Backing Argon 99.99% 5 - 25 lpm

(Continuous or special heating where applicable should be recorded) Other None None None

ELECTRICAL CHARACTERISTICS (QW-409)

Other

Filler Metal

Wire Feed

Energy or Power or (e.g., Remarks,

Weld Layer Current Type Amps Speed Travel Speed

Process Heat Input Volts (Range), V Comments, Hot Wire

(s) and Polarity (Range), A (Range), (Range), mm/min

(Range), J/mm Addition, Technique,

Classification Diameter mm/min

Torch Angle, Etc.)

(mm)

As Required GTAW ER 309 1.6 DCEN 35 - 60 N.A 140 - 1008 10 - 14 50 - 150 -

As Required GTAW ER 309 2.0 DCEN 60 - 90 N.A 288 - 1512 12 - 14 50 - 150 -

As Required GTAW ER 309 2.4 DCEN 90 - 120 N.A 432 - 2016 12 - 14 50 - 150 -

As Required GTAW ER 309 3.2 DCEN 120 - 150 N.A 480 - 3240 10 - 18 50 - 150 -

As Required GTAW ER 309 4.0 DCEN 150 - 200 N.A 600 - 4320 10 - 18 50 - 150 -

(Amps and volts, or power or energy range, should be recorded for each electrode size, position, and thickness, etc)

Current AC or DC : DC Polarity : EN

Amperage : As Table Above Voltage : As Table Above

± Pulsing : None

Tungsten Electrode : Dia. 1.6 - 3.0 mm Tungsten 2% Thoriated (WT20), AWS Class EWTH-2

Pure Tungsten, 2 % Thoriated, etc

Mode of Transfer : N.A

Globular, Spray, Pulsed Spray Transfer to Short Circuiting Transfer or Vice Versa

Other : None

TECHNIQUE (QW-410)

String or Weave : String or Weave

Orifice, Nozzle, or Gas Cup Size : 6 mm - 24 mm

Method of Cleaning : Brushing, Grinding or Gouging (if required)

Method of Back Gouging : Grinding or Gouging (if required)

Oscillation : None

Tube to Work Distance : N.A

Multiple or Single Pass (Per Side) : Multiple

Multiple or Single Electrode(s) : Single

Closed to Out of Chamber Welding : None

Melt-in to Key Hole : N.A

Electrode Spacing : None

Peening : None

Thermal Process : None

Other : Used Stainless Brush for Cleaning and Keep Away The Base Metal from Galvanized Steel

Prepared by, Review & Approved by, KEMENAKERTRANS RI

Doni Winarno Bagus Pratama

Welding Engineer QA/QC Manager

PT. MONTIS ENERGY

, Alamat Pusat:SentralSenayan 2 Lantai 16 unit 216A. JL. Asia Afrika No.8 KelGelora, Kec. Tanah Abang

Jakarta Pusat. 10270

Fax : 62-21-2924-1980 : 62-21-2924-1996 Telephone

: customersupport@montisenergy.comEmail

: http://www.montisenergy.comWebsite

Page 1 of 2

PROCEDURE QUALIFICATION RECORD (PQR)

( Section IX, ASME Boiler and Pressure Vessel Code)

Record Actual Conditions Used to Weld Test Coupon

Procedure Qualification Record No 06-PQR-ASME-ME-2016 Rev. :0 Date

WPS No 06-WPS-ASME-ME-2016 Rev. :0

Welding Process (es) GTAW

Types (Manual, Machine, Automatic, Semi-Auto) Manual

JOINTS (QW-402)

Groove Design of Test Coupon

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal or process used)

BASE METALS (QW 403) POSTWELD HEAT TREATMENT (QW-407)

Material Spec SA 312 Tp 304L to SA 106 Gr. B Temperature None

Type or Grade, or UNS Number - Time None

P-No 8 Group No. 1 To P-No. 1 Group No. 1 Other None

Thickness of Test Coupon 7.11 mm

Diameter of Test Coupon 168.28 mm GAS (QW-408)

Maximum Pass Thickness GTAW = 3 mm Precent Composition

Other None Gas (es) (Mixture) Flow Rate

Shielding Ar 99.99% None 15 lpm

FILLER METALS (QW - 404) GTAW Trailing None None None

SFA Specification 5.9 Backing None None None

AWS Classification ER 309L Other None None None

Filler Metal F-No 6

Weld Metal Analysis A-No. 8 ELECTRICAL CHARACTERISTICS (QW-409)

Size of Filler Metal 2.4 mm Current DC

Filler Metal Product Form Solid Polarity EN

Supplemental Filler Metal N.A Amps. 90 - 120 A Volts 12 - 14 V

Electrode Flux Classification N.A Tungsten Electrode Size Dia. 2.4 mm EWTH-2

± Flux None Mode of Metal Tranfer for GMAW (FCAW) N.A

± Filler None Heat Input Max. 2016 J/mm

Recrushed Slag N.A Other None

Alloy Flux N.A

Alloy Element N.A

Consumable Insert None TECHNIQUE (QW-410)

Flux Type N.A Travel Speed 50 - 150 mm/min

Consumable Trade Name Huatong String or Weave Bead Weave Bead

Weld Metal Thickness 8 mm Oscillation None

Other None Multiple or Single Pass (per side) Multiple Pass

Multiple or Single Electrode(s) Single Electrode

POSITION (QW-405) Method of Cleaning Grinding & Brushing

Position of Groove : 5G Method of Back Gouging None

Weld Progression (Uphill, Downhill) : Uphill Tube to Work Distance N.A

Position of Fillet : None Closed to Out off Chamber Welding None

Other None Melt-in to Keyhole N.A

Electrode Spacing None

PREHEAT (QW-406) ± Peening None

Preheat Temperature 32 ⁰C (Ambient Temperature) Other : None

Interpass Temperature 200 ⁰C

Other None

PT. MONTIS ENERGY

, Alamat Pusat:SentralSenayan 2 Lantai 16 unit 216A. JL. Asia Afrika No.8 KelGelora, Kec. Tanah Abang

Jakarta Pusat. 10270

Fax : 62-21-2924-1980 : 62-21-2924-1996 Telephone

: customersupport@montisenergy.comEmail

: http://www.montisenergy.comWebsite

Page 2 of 2

PQR No. 06-PQR-ASME-ME-2016 Rev.: 0

Tension Test (QW-150)

Ultimate Ultimate Type of

Speciment Width Thickness Unit Stress

Area Total Load Failure and

No. (mm) (mm)

(kN) (N/mm2) Location

T1 19.48 7.11 138.50 72.71 525 Ductile and Base Metal

T2 19.56 7.15 139.85 71.33 510 Ductile and Base Metal

Guided-Bend Tests (QW-160)

Type and Figure No. Result

FB 1 (Face Bend) Accepted

FB 2 (Face Bend) Accepted

RB 1 (Root Bend) Accepted

RB 2 (Root Bend) Accepted

Toughness Tests (QW-170)

Speciment Notch Speciment Test Impact Values

Drop Weigh Break (Y/N)

No. Location Size Temperature ft-Ib or J % Shear Mils (in) or mm

None None None None None None None None

None None None None None None None None

Visual Examination of Completed Weld

Result : Accepted No. Report :

Volumetric Examination

Type of Test : Radiographic Test Result : Accepted

Film or specimens evaluated by : Fitransyah Company :

Fillet-Weld Test (QW-180)

Result - Satisfactory : Yes - No - Penetration into Parent Metal : Yes - No -

Macro - Results -

Other Test

Type of Test None

Deposit Analysis None

Other None

Welder's Name Afri. S Clock No. - Stamp No. ME 01

Test conducted by : PT. Hi-Test Laboratory Test No. HT/JKT/0516/0021

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

Date May 23, 2016

Manufacturer

PT. Montis Energy Approved by, KEMENAKERTRANS RI

Doni Winarno Bagus Pratama

Welding Engineer QA/QC Manager

(Detail of record of tests are illustrative only and may be modified to conform to the type and number of tests required by the Code.)

Anda mungkin juga menyukai

- P45 To P45 PQR CertifiedDokumen7 halamanP45 To P45 PQR CertifiedBala SingamBelum ada peringkat

- Ilcs-Smaw-D1.3-Deck (G) WPSDokumen3 halamanIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Aws d1.5 PQRDokumen2 halamanAws d1.5 PQRjacquesmayolBelum ada peringkat

- Welding Procedure Qualification Record: Shipyard LogoDokumen4 halamanWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- 2019 Product Catalog WebDokumen104 halaman2019 Product Catalog WebIan Niko100% (1)

- Alu WpsDokumen4 halamanAlu WpsdselvakuuBelum ada peringkat

- Surface Tension Transfer (STT) Pipe WeldingDokumen3 halamanSurface Tension Transfer (STT) Pipe WeldingahmedBelum ada peringkat

- 004 Gtaw P5aDokumen16 halaman004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Joints (Qw-402) DetailsDokumen3 halamanJoints (Qw-402) DetailsNaqqash SajidBelum ada peringkat

- Welding Procedure Specification (WPS)Dokumen2 halamanWelding Procedure Specification (WPS)Abdulmecit YetisBelum ada peringkat

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Dokumen2 halamanASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- 169 Gtaw Zug Asme (Fefri 5g) WPQDokumen4 halaman169 Gtaw Zug Asme (Fefri 5g) WPQMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Gta+sma PQRDokumen3 halamanGta+sma PQRRahul MoottolikandyBelum ada peringkat

- WPS SampleDokumen182 halamanWPS Sampleaymenfr23Belum ada peringkat

- WPS BhelDokumen2 halamanWPS BhelpradhankruhsnaBelum ada peringkat

- WPS - 023Dokumen10 halamanWPS - 023MAT-LION0% (1)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDokumen1 halamanWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavBelum ada peringkat

- WPS 19Dokumen15 halamanWPS 19Avishek Gupta100% (1)

- HHHHHHHHJJJJJJ: O O O ODokumen1 halamanHHHHHHHHJJJJJJ: O O O OAli MoosaviBelum ada peringkat

- Format WPQDokumen2 halamanFormat WPQAkash Singh TomarBelum ada peringkat

- WPS & PQRDokumen24 halamanWPS & PQRtulasirao.nammiBelum ada peringkat

- List Mechanical Procedure Qualification Test (API 1104) 2018 (CEPU)Dokumen5 halamanList Mechanical Procedure Qualification Test (API 1104) 2018 (CEPU)Muhammad Iqbal SpBelum ada peringkat

- Okan Ggcpdebottlenecking Project: Welding Procedure Specification FOR Pipe To FlangeDokumen4 halamanOkan Ggcpdebottlenecking Project: Welding Procedure Specification FOR Pipe To FlangeNilesh KabadeBelum ada peringkat

- Mechanical Test 1Dokumen21 halamanMechanical Test 1Manoranjan sharmaBelum ada peringkat

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDokumen5 halamanWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriBelum ada peringkat

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDokumen4 halaman170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Dokumen1 halamanWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- 202 1sp 0 Saw Cs CsDokumen8 halaman202 1sp 0 Saw Cs CskrishimaBelum ada peringkat

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Dokumen8 halamanQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanBelum ada peringkat

- 161 Gmaw Zug Asme (Beni Kantona 3g) WPQDokumen2 halaman161 Gmaw Zug Asme (Beni Kantona 3g) WPQMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- API Welding ProcedureDokumen2 halamanAPI Welding ProcedureSamarakoon BandaBelum ada peringkat

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDokumen1 halamanWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Dokumen2 halaman(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDokumen1 halamanPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraBelum ada peringkat

- Acceptable Grade of Plate Material (API 650)Dokumen1 halamanAcceptable Grade of Plate Material (API 650)juantamad02Belum ada peringkat

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDokumen11 halamanEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaBelum ada peringkat

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDokumen5 halamanQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- WPQ Format - SMAWDokumen3 halamanWPQ Format - SMAWBalkishan DyavanapellyBelum ada peringkat

- SMAW DuniDokumen4 halamanSMAW DuniMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Welding Procedure SpecificationDokumen27 halamanWelding Procedure SpecificationGopakumar K100% (2)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDokumen4 halaman163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Manual Joints (QW - 402) : Page 1 of 12Dokumen12 halamanManual Joints (QW - 402) : Page 1 of 12miteshpatel191Belum ada peringkat

- WPS Format For ASME IX - PQR-AllDokumen3 halamanWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Duties of The RWCDokumen3 halamanDuties of The RWCbluegalago100% (1)

- WPS - 021Dokumen13 halamanWPS - 021MAT-LIONBelum ada peringkat

- WPS 316 L PDFDokumen4 halamanWPS 316 L PDFIrinaBelum ada peringkat

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Dokumen3 halamanWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielBelum ada peringkat

- QW-484A (WPQ) GTAW 4MM FilletDokumen2 halamanQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPS API1104 A516 GR 70Dokumen1 halamanWPS API1104 A516 GR 70Erick HoganBelum ada peringkat

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDokumen9 halaman2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanBelum ada peringkat

- ASME IX Sample WPS GTAW SMAWDokumen1 halamanASME IX Sample WPS GTAW SMAWDeepak ShrivastavBelum ada peringkat

- Asme PQR DemoDokumen3 halamanAsme PQR DemoMuthusamy AyyanapillaiBelum ada peringkat

- QW 482 WPSDokumen2 halamanQW 482 WPSsmit patelBelum ada peringkat

- WPS - 006Dokumen13 halamanWPS - 006MAT-LIONBelum ada peringkat

- Company Name Key Information Questions Answers File Reference Reviews & ApprovalsDokumen7 halamanCompany Name Key Information Questions Answers File Reference Reviews & ApprovalsMAT-LIONBelum ada peringkat

- WPS - D1.1Dokumen1 halamanWPS - D1.1Nam_HitechBelum ada peringkat

- Wps Mma PipeDokumen2 halamanWps Mma PipeDimitris NikouBelum ada peringkat

- Wps Hzi SMAWDokumen18 halamanWps Hzi SMAWMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Pwps Asme Gtaw & SmawDokumen2 halamanPwps Asme Gtaw & SmawMuhammad Fitransyah Syamsuar Putra100% (1)

- PWPS - 3G FCAWDokumen2 halamanPWPS - 3G FCAWasrafiBelum ada peringkat

- Hydrostatic Water Filling Test ProcedureDokumen1 halamanHydrostatic Water Filling Test ProcedureMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Employee Hours Worked Last Three YearsDokumen1 halamanEmployee Hours Worked Last Three YearsMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Program K3 2023Dokumen2 halamanProgram K3 2023Muhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Program K3 2023Dokumen2 halamanProgram K3 2023Muhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Vii CertificateDokumen1 halamanVii CertificateMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Tanda TerimaDokumen2 halamanTanda TerimaMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT BridonDokumen1 halamanPT BridonMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Fit-Up Inspection ReportDokumen1 halamanFit-Up Inspection ReportMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- III EngineeringDokumen1 halamanIII EngineeringMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Transmittal FormDokumen90 halamanTransmittal FormMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Laporan PiketDokumen12 halamanLaporan PiketMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Lifting Lug Calculation G1-5Dokumen3 halamanLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Manufacturing Data Record IndexDokumen2 halamanManufacturing Data Record IndexMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT BridonDokumen1 halamanPT BridonMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PQR PT Bse WPS 07Dokumen2 halamanPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT DjabesmenDokumen1 halamanPT DjabesmenMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Transmittal FormDokumen90 halamanTransmittal FormMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT DjabesmenDokumen1 halamanPT DjabesmenMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT PrysmianDokumen1 halamanPT PrysmianMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT DjabesmenDokumen1 halamanPT DjabesmenMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Method Statement For Prediction Weld Shrinkage On StructuralDokumen4 halamanMethod Statement For Prediction Weld Shrinkage On StructuralMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Design Intermittent WeldingDokumen5 halamanDesign Intermittent WeldingMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- CSDCDokumen2 halamanCSDCMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT DjabesmenDokumen1 halamanPT DjabesmenMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- PT DjabesmenDokumen1 halamanPT DjabesmenMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Lifting Lug Calculation G1-5Dokumen3 halamanLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Dokumen3 halamanLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Dokumen3 halamanLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Dokumen3 halamanLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Dokumen3 halamanLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Project Analysis - M5 - MotorwayDokumen6 halamanProject Analysis - M5 - MotorwayMuhammad Haroon ArshadBelum ada peringkat

- WoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsDokumen3 halamanWoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsPR.comBelum ada peringkat

- Sustainable Strategic Management BarbosaDokumen11 halamanSustainable Strategic Management BarbosapurwawardhaniBelum ada peringkat

- Module 5Dokumen14 halamanModule 5shin roseBelum ada peringkat

- FIGMADokumen22 halamanFIGMACessBelum ada peringkat

- 12 Logarithm Approximate FloatingDokumen6 halaman12 Logarithm Approximate FloatingPhilippe Englert VelhaBelum ada peringkat

- VTB Datasheet PDFDokumen24 halamanVTB Datasheet PDFNikola DulgiarovBelum ada peringkat

- High Speed Power TransferDokumen33 halamanHigh Speed Power TransferJAYKUMAR SINGHBelum ada peringkat

- What Is Urban PlanningDokumen33 halamanWhat Is Urban PlanningDivine Grace FernandoBelum ada peringkat

- Abdominal Migraine and HomoeopathyDokumen17 halamanAbdominal Migraine and HomoeopathyDr. Rajneesh Kumar Sharma MD HomBelum ada peringkat

- HPSC HCS Exam 2021: Important DatesDokumen6 halamanHPSC HCS Exam 2021: Important DatesTejaswi SaxenaBelum ada peringkat

- 1en 02 PDFDokumen96 halaman1en 02 PDFAndrey100% (2)

- C103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratoriesDokumen19 halamanC103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratorieshuidhyiuodghBelum ada peringkat

- ING C1 CO JUN2016 CorrectorDokumen6 halamanING C1 CO JUN2016 CorrectoraciameBelum ada peringkat

- Using Your Digital Assets On Q-GlobalDokumen3 halamanUsing Your Digital Assets On Q-GlobalRemik BuczekBelum ada peringkat

- DADTCO Presentation PDFDokumen34 halamanDADTCO Presentation PDFIngeniería Industrias Alimentarias Itsm100% (1)

- X Lube Bushes PDFDokumen8 halamanX Lube Bushes PDFDavid TurnerBelum ada peringkat

- CBC DrivingDokumen74 halamanCBC DrivingElonah Jean ConstantinoBelum ada peringkat

- Intercultural Personhood and Identity NegotiationDokumen13 halamanIntercultural Personhood and Identity NegotiationJoão HorrBelum ada peringkat

- Chemical & Biological Depopulation (By Water Floridation and Food Additives or Preservatives) PDFDokumen178 halamanChemical & Biological Depopulation (By Water Floridation and Food Additives or Preservatives) PDFsogunmola100% (2)

- An Introduction To Routine and Special StainingDokumen13 halamanAn Introduction To Routine and Special StainingBadiu ElenaBelum ada peringkat

- Project Report For Tunnel ExcavationDokumen19 halamanProject Report For Tunnel ExcavationAbhishek Sarkar50% (2)

- PID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDokumen7 halamanPID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDenisBelum ada peringkat

- M2252D PS PDFDokumen36 halamanM2252D PS PDFCarmen da SilvaBelum ada peringkat

- Chrysler CDS System - Bulletin2Dokumen6 halamanChrysler CDS System - Bulletin2Martin Boiani100% (1)

- Hackerearth Online Judge: Prepared By: Mohamed AymanDokumen21 halamanHackerearth Online Judge: Prepared By: Mohamed AymanPawan NaniBelum ada peringkat

- A-1660 11TH Trimester From Mcdowell To Vodafone Interpretation of Tax Law in Cases. OriginalDokumen18 halamanA-1660 11TH Trimester From Mcdowell To Vodafone Interpretation of Tax Law in Cases. OriginalPrasun TiwariBelum ada peringkat

- Nbme NotesDokumen3 halamanNbme NotesShariq AkramBelum ada peringkat

- Free ConvectionDokumen4 halamanFree ConvectionLuthfy AditiarBelum ada peringkat

- Richardson ResumeDokumen3 halamanRichardson Resumeapi-549248694Belum ada peringkat