Omgoing Stability Testing - Innovations - in - Pharmaceutical - Technology

Diunggah oleh

Juan RojasJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Omgoing Stability Testing - Innovations - in - Pharmaceutical - Technology

Diunggah oleh

Juan RojasHak Cipta:

Format Tersedia

IPT 28 2009 12/3/09 13:56 Page 78

Ingredients, Formulations & Finishing

Ongoing Stability Testing: Requirements,

Solutions and Potential Pitfalls

By Sven Oliver Kruse EU GMP Guidelines require ongoing stability testing for the market-life

at Diapharm Analytics of all medicinal products – but with sensible and skilled planning of the

GmbH

test protocol, it is possible for expenditure, and hence production costs,

to be kept to a minimum.

All medicinal products on the market must be licence. Technical Agreements for third-party analysis

monitored in a continuous programme in order to (which define responsibilities on both sides) must be

demonstrate stability and quality over their entire thoroughly revised under theses premises or must take

market life. Laboratory analysis is a cost factor that still account of it when they are first drawn up. The Qualified

offers room for manoeuvre in many companies, and Person employed by the manufacturing or contracting

with improved study design, the burden of ongoing company must ensure that the tests are carried out in

stability tests can be reduced. In the realisation of more accordance with GMP requirements by means of an audit.

efficient stability testing, however, it is important to be It should be kept in mind that ongoing stability

aware of the potential pitfalls. testing differs from other stability tests in its regulatory

and legal background (see Table 1) (2,3). However, these

BACKGROUND requirements only apply to licensed medicinal products

The revised version of Chapter 1 of the EU GMP which are currently on the market.

Guidelines (1) came into force in 2006; item 1.5 makes

the annual Product Quality Review (PQR) compulsory REQUIREMENTS FOR ONGOING

for all licensed products. This continuous revision of the STABILITY TESTING

consistency and validity of the entire manufacturing The categorical requirements of the GMP Guidelines for

process also includes a stability-monitoring programme ongoing stability testing are that:

as listed under sub-item vii. These ongoing stability tests

are specified in Chapter 6 of the EU GMP Guidelines, ! All medicinal products/formulations have to be

which were updated in the same year. tested, with no exception, in principle, for

Areas of quality control which previously formed only homeopathic products, herbals, and so on

part of R&D are now included in official GMP inspections. ! All finished products and, where appropriate, bulk

This is the case, for example, with the qualification of special products have to be tested (for example, when

equipment for stability testing, such as controlled storage stored or transported for prolonged periods).

cabinets. Standard operating procedures (SOPs) for dealing Excipients and active substances are not taken into

with out-of-specification results, not only for batch release account here

but also during stability testing, and for evaluating out-of- ! Requirements apply in principle to every product

trend results have to be implemented. in every dosage and pack size or (primary)

External laboratories contracted to carry out ongoing packaging type/package

stability testing must be included in the manufacturing ! Tests have to be carried out continuously, usually

one batch a year

Table 1: Summary of the different types of stability testing

(exemplarily for a new registration of a human medicinal product)

! Studies have to be carried out under long-term

Study type R&D study Follow-up (commitment) study On-going study

conditions (for example, 25°C and 60 per cent

Time point Before registration After submission of the dossier After registration and marketing relative humidity) continuously over the period

Aim of the study Setting shelf-life, storage Verify registration data Proof that conditions are of the labelled shelf life

conditions and specifications still valid

Background Registration procedures, Registration procedures, EU-GMP guideline

guidelines for stability testing guidelines for stability Tests following storage under intermediate and accelerated

(for example, ICH) testing (for example, ICH)

Extent Two pilot- or production-scale batches Production-scale, three Continuous; one batch conditions should only be carried out if supplementary

of the finished project. If ‘critical’, batches of the finished product – per year

for example when known as unstable, – each product

information is required at an early stage. In principle, all

three batches – each strength decisions which affect the test protocol, the frequency of

– each package

Competent authority Regulatory agency (for example, Regulatory agency (for example, National GMP surveillance –

testing and the choice of test samples should be product-

BfArM and MHRA) BfArM and MHRA) regulatory agency or health authority

based, targeted and founded on a risk analysis (see Table 2).

78 Innovations in Pharmaceutical Technology

IPT 28 2009 12/3/09 13:56 Page 79

Ongoing studies are intended to prove that, over the Table 2: Selection of stability-limiting parameters. Decision should

period of its labelled shelf life and under ‘real life be made on the basis of existing data

Less critical parameters More critical and essential parameters

conditions’, the product remains of the quality defined in

the authorisation/registration documents. Stability Capsules and tablets Organoleptic and physical tests, uniformity of mass and content, Assay and impurities

disintegration and dissolution, microbiological quality

studies done for registration solely provide a ‘snap-shot’.

Liquids (for oral use) Organoleptic tests, uniformity of dosage, density, pH-value, Assay and impurities

Adverse effects such as changes in manufacture and the preservation, microbiological quality

supply chain (even those not on a variation level) should Sterile solutions Organoleptic tests, uniformity of dosage, density, Assay, impurities, sterility

(Ophthalmica, Parenteralia) pH-value, preservation and particles

be identified by ongoing studies. However, this

procedure also implies that the test protocol can be

Table 3: Protocol with reduced frequency of testing for an ongoing study (solid formulation):

adjusted at any time to the current situation. The T = Test, (T) = Test optional, o = designated testing, dossier (2), (3) omitted

stability protocol does not necessarily have to comply Test t0 t3 t6 t9 t12 t18 t24 t36 t48 t60

with the ICH stability testing guidelines. Organoleptic T (T) (T) (T) (T) (T) (T) (T) (T) T

Mass uniformity T o o o o o o o o T

Resistance to crushing T o o o (T) o (T) (T) (T) T

POTENTIAL SAVINGS

Dissolution test T o o o T o T T T T

– REALISATION AND PITFALLS Identity T - - - - - - - - -

Item 6.28 of the EU GMP Guidelines specifically states that Assay T o o o T o T T T T

the protocol for the ongoing stability programme may differ Purity T o o o T o T T T T

Microbiological quality T - - - T - o o o T

from that of the initial long-term stability protocol (3),

25ºC/60% rh T (T) (T) (T) T (T) T T T T

giving a reduction in the frequency of testing as an example. 30ºC/65% rh - - o o o - - - - -

If it has been shown that a test parameter is not critical, for 40ºC/75% rh - o o - - - - - - -

example during the course of commitment (follow-up)

studies or later in ongoing studies that have already been generated in follow-up studies can also be used for

performed, the frequency of testing may be reduced. review, as mentioned in sub-item vii in the PQR.

A given example shows that, overall, there is a possible Conversely, however, this means that tests must cover the

reduction in the required frequency of testing of about full protocol in the dossier. Savings, such as those

50 per cent or even more (see Table 3). It should be discussed above, are hardly possible in this case.

noted that at the end of the shelf life, all the test If it was agreed in the post-marketing commitment that,

parameters should be checked again (in this case t60), in after launch, one batch per year would be tested for three

order to prove stability over the entire storage life. years for the follow-up study, then the additional (ongoing)

If the product is manufactured in different strengths tests could be saved for three years. As usual, analyses for the

(same API with similar matrix) and pack sizes, the release of a product batch can also be used as starting values

‘bracketing’ recommendations can be applied (4). If there for ongoing studies, but possible differences in the

are more than two sizes for any parameter, this provides for specifications have to be observed. Thus, further ongoing

only the extremes to be tested (see Table 4). This example testing does not start until a year after the start of storage.

shows the requirements in the guidance. Assuming an It is also recommended that production and hence

identical bulk product, then if the exemplary product starting dates should, if possible, be in the same period of

above is packed in blister packs of 10 tablets, each with the calendar year. As a result, in subsequent years there

identical primary packaging material, the effect of will be further synergies as a result of parallel testing.

secondary packaging – for example, different secondary

packaging for different foreign markets – does not have to STEPS AFTER TESTING

be taken into account. Testing of only one pack size would Suitable data analysis procedures that allow not only

therefore be sufficient. The same applies to multi-dose retrospective but also prospective evaluation have to be

containers, where only the most sensitive size of container established. The EU GMP Guidelines require that, at the

would have to be tested on a ‘worst case scenario’ basis. individual test times, it must be stated whether it can be

In the latter (ideal) example, the number of tests could assumed that, for example, the active substance content

be reduced from nine to two, with corresponding cost-

savings. However, consideration of the individual case is Table 4: Example of bracketing,

(T = Test; o = Test omitted), solid formulation

always important. It may be necessary, for example, for the

Strength

first batches to be tested in accordance with the full protocol

50mg 75mg 100mg

in order to provide sufficient data for trend analyses.

20 tablets T o T

The combination of ongoing studies with follow-up

50 tablets o o o

(commitment) studies is often discussed. It should be

100 tablets T o T

emphasised here that, in principle, the data that are

Innovations in Pharmaceutical Technology 79

IPT 28 2009 12/3/09 13:56 Page 80

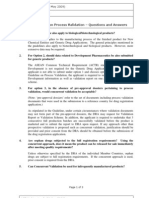

Regulatory affairs After the implementation of corrective actions, the

subsequent production batch should be reviewed by an

Drug safety Production ongoing study in addition to the normal yearly round of

testing. The test parameters must be agreed on the basis

QP

of the individual situation.

Legal department QC laboratory

(PQR)

TEAMWORK

As with PQR in general, ongoing stability testing

Marketing authorisation holder

requires the intensive exchange of information between

the responsible persons and relevant specialist

Figure 1: is likely to remain within the specified limits as testing departments (see Figure 1). Responsibilities must be

Interactions continues. Here, statistical methods of regression and clearly laid down, and if external service providers are

between specialist

departments and

confidence interval analysis can be useful, although they involved, appropriate technical agreements must be

external service should be used with caution. drawn up which define these responsibilities.

providers The results of ongoing stability testing have to be The involvement of an external service provider may

summarised in a report. All current results have to be be beneficial to the marketing authorisation holder;

compared with data from previous tests, for example expensive implementation of an in-house system can be

from follow-up studies, and trend analyses have to be avoided by employing the existing system of the service

carried out (if applicable). The results have to be company. Investments and fixed costs are not increased,

incorporated and discussed in the relevant PQR. and the marketing authorisation holder can concentrate

It must also be noted that the manufacturing on its core competences such as marketing. Outsourcing

department (internal or contract manufacturer) and the all other functions is, in principle, possible (5).

Qualified Person responsible for market release have to be

notified of the results of the ongoing stability studies. CONCLUSION

An appropriate SOP should specify what should be done The message to take away from this review is that

in the case of out-of-specification (OOS) results and expenditure, and hence production costs, can be

significant negative trends. If verified, they must be reported minimised by sensible and skilled planning of the test

to the supervisory authorities. Further considerations protocol for ongoing stability testing.

should also be taken into account here, for example:

Note

! A review of sensitive or relevant areas in production Thanks to Annemarie Jasper, PhD, and Christian Rieke

should be undertaken to try to identify the cause for their helpful support.

and possible transmission to other batches/products

! A critical review of the labelled stability and, if References

necessary a recall of the affected product batch must

be considered 1. EU Guidelines to Good Manufacturing Practice

! Measures to avoid errors should be discussed and Medicinal Products for Human and Veterinary Use,

implemented (corrective and protective actions, http://ec.europa.eu/enterprise/pharmaceuticals/

(CAPA)). In justified cases, other specialist personnel eudralex/vol4_en.htm

such as the Qualified Person for Pharmacovigilance 2. Guideline on Stability Testing: Stability of Existing

will need to be involved Active Substances and Related Finished Products

(CPMP/QWP/122/02, rev 1)

Sven Oliver Kruse, PhD, is Managing Director at Diapharm, 3. Note for Guidance on Stability Testing

responsible for the service laboratory Diapharm Analytics GmbH of New Drug Substances and Products

in Oldenburg (Germany). He entered the company in 2001 (CPMP/ICH/2736/99 corr)

and accompanied the transition from a scientific institute to a 4. Note for Guidance on Bracketing and Matrixing

service laboratory. He is also a Qualified Person for the

Designs for Stability Testing of Drug Substances

company. Sven is a member of the Pharmaceutical-Technical

Committee and the working parties ‘Validation’ and ‘PQR/On- and Drug Products (CPMP/ICH/4104/00 adopted

going Stability’ at the German Medicines Manufacturers’ Association (BAH). He 2002 / ICH Q1D)

studied Pharmacy at the University of Münster (Germany) where he received his 5. Sandner and Klöpf, Outsourcing in der

PhD in the field of phytochemistry research and analysis. He is also a member of Pharmaindustrie, Teil 1, Pharm Ind, 68, Nr 7,

the Society of Medicinal Plant Research, the Society of Phytotherapy and the

pp825-828, Teil 2, Pharm Ind, 68, Nr. 8,

German Pharmaceutical Society. Email: sven.kruse@diapharm.com

pp932-936, 2006

80 Innovations in Pharmaceutical Technology

Anda mungkin juga menyukai

- Guide to Pharmaceutical Quality Control Lab InspectionsDokumen16 halamanGuide to Pharmaceutical Quality Control Lab Inspectionssubrata1Belum ada peringkat

- WHOPIR LPR 04-06dec2019Dokumen13 halamanWHOPIR LPR 04-06dec20196E.57Pawar RushiBelum ada peringkat

- Ich Guideline q7 Good Manufacturing Practice Active Pharmaceutical Ingredients Questions Answers - enDokumen37 halamanIch Guideline q7 Good Manufacturing Practice Active Pharmaceutical Ingredients Questions Answers - ensatishBelum ada peringkat

- Risk Based Environmental Monitoring (Em) and em Data Management and TrendingDokumen65 halamanRisk Based Environmental Monitoring (Em) and em Data Management and TrendingIsabelle PlourdeBelum ada peringkat

- 2013-09-18 USP Stability 1 RegulationsDokumen68 halaman2013-09-18 USP Stability 1 RegulationssreekanthsharmaBelum ada peringkat

- FST 658 FPD Product Development PDFDokumen80 halamanFST 658 FPD Product Development PDFAzrin HalizaBelum ada peringkat

- QBD Approach To Dissolution Through Understanding of The Release Mechanisms and Critical in Vivo ParametersDokumen61 halamanQBD Approach To Dissolution Through Understanding of The Release Mechanisms and Critical in Vivo Parametersvg_vvgBelum ada peringkat

- 2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFDokumen4 halaman2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFVishal SomaniBelum ada peringkat

- Avoiding Errors With The Batch Release ProcessDokumen11 halamanAvoiding Errors With The Batch Release ProcessAnthony CollierBelum ada peringkat

- What Is 21 CFR Part 11Dokumen26 halamanWhat Is 21 CFR Part 11chemtabBelum ada peringkat

- ASEAN Guideline On Process Validation - Q& ADokumen3 halamanASEAN Guideline On Process Validation - Q& AMuqeet KazmiBelum ada peringkat

- ICH Quality Guidelines: An Implementation GuideDari EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleBelum ada peringkat

- REVERSE LAMINAR AIR FLOW UNIT SPECIFICATIONSDokumen8 halamanREVERSE LAMINAR AIR FLOW UNIT SPECIFICATIONSAndreas StathatosBelum ada peringkat

- Good Manufacturing Practice GMP Guidelines Eudralex Volume 4Dokumen12 halamanGood Manufacturing Practice GMP Guidelines Eudralex Volume 4Editor IJTSRDBelum ada peringkat

- Basic Aspects of Process Validation of Solid Oral Dosage FormsDokumen15 halamanBasic Aspects of Process Validation of Solid Oral Dosage FormsAbeer TamimiBelum ada peringkat

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Dokumen8 halamanHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104iloveit52252Belum ada peringkat

- SOP For Reduce Testing For Raw MaterialDokumen3 halamanSOP For Reduce Testing For Raw MaterialMubarak Patel100% (1)

- Quality control tests for pharmaceutical tablets according to pharmacopoeiasDokumen7 halamanQuality control tests for pharmaceutical tablets according to pharmacopoeiasMaheshBelum ada peringkat

- Handling Out of Specification ResultsDokumen8 halamanHandling Out of Specification ResultsPavana KharwalBelum ada peringkat

- ICH Topic Q 6 BDokumen17 halamanICH Topic Q 6 BAprianaRohmanBelum ada peringkat

- Variation GuidelineDokumen33 halamanVariation GuidelineBo RatchadapornBelum ada peringkat

- G OwningDokumen6 halamanG Owningk.p.100% (1)

- 01 LC Vibratory Sifter 01Dokumen2 halaman01 LC Vibratory Sifter 01Ravi YadavBelum ada peringkat

- Clean Rooms and Controlled Areas (Sterile Area Classification) - Pharmaceutical GuidelinesDokumen9 halamanClean Rooms and Controlled Areas (Sterile Area Classification) - Pharmaceutical GuidelinesASHOK KUMAR LENKA100% (1)

- Guidelines For The Stability Testing of PharmaceuticalsDokumen43 halamanGuidelines For The Stability Testing of PharmaceuticalsSrinivas ReddyBelum ada peringkat

- (Operations Management) - McDonald's AnalysisDokumen36 halaman(Operations Management) - McDonald's AnalysisVineet Harit100% (1)

- TP0602 0505Dokumen8 halamanTP0602 0505nsk79in@gmail.comBelum ada peringkat

- Elsanhouty Pharma Hold Time Study NotesDokumen6 halamanElsanhouty Pharma Hold Time Study NotesHuỳnh Ngọc SángBelum ada peringkat

- Microbiological Best Lab Practices & Environmental MonitoringDokumen26 halamanMicrobiological Best Lab Practices & Environmental MonitoringNurul Hardiyanthi SadikinBelum ada peringkat

- TRS961 - Annex7 WHO Tech TransferDokumen25 halamanTRS961 - Annex7 WHO Tech TransferkrasataBelum ada peringkat

- Hold Time Study SOP Indian Pharma 1Dokumen3 halamanHold Time Study SOP Indian Pharma 1ziadddBelum ada peringkat

- Retail-Foods Riyadh Saudi-Arabia 12-8-2012Dokumen15 halamanRetail-Foods Riyadh Saudi-Arabia 12-8-2012knabpshoBelum ada peringkat

- 41 (1) In-Process Revision - 1790 - Visual Inspection of InjectionsDokumen10 halaman41 (1) In-Process Revision - 1790 - Visual Inspection of InjectionsBudy WijiyantoBelum ada peringkat

- WareHouse Management GuideDokumen36 halamanWareHouse Management GuideVadnala Sidhartha100% (1)

- Sop For Bio-BurdenDokumen5 halamanSop For Bio-BurdenMusyoka UrbanusBelum ada peringkat

- Pharmaceutical Quality Management System (QMS) Questions and AnswersDari EverandPharmaceutical Quality Management System (QMS) Questions and AnswersBelum ada peringkat

- ASTM F1980 Thermoalterung Von VerpackungenDokumen6 halamanASTM F1980 Thermoalterung Von VerpackungenRicha RohillaBelum ada peringkat

- Ongoing Stability Testing Requirements, Solutions and Potential PitfallsDokumen3 halamanOngoing Stability Testing Requirements, Solutions and Potential PitfallssamxuBelum ada peringkat

- USP-NF 1251 Weighing On An Analytical BalanceDokumen6 halamanUSP-NF 1251 Weighing On An Analytical BalanceMinh LêBelum ada peringkat

- Documentation Required For Periodic GMP Compliance Inspection Annex 1 JPDokumen5 halamanDocumentation Required For Periodic GMP Compliance Inspection Annex 1 JPspam_discardBelum ada peringkat

- Canada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1Dokumen34 halamanCanada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1atulbsBelum ada peringkat

- Simultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFDokumen7 halamanSimultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFNájla KassabBelum ada peringkat

- How To Ensure Trouble-Free HPLC System OperationDokumen3 halamanHow To Ensure Trouble-Free HPLC System OperationKavisa GhoshBelum ada peringkat

- VP-08-107 - Protocol For Hold Time of Softgel EquipmentsDokumen7 halamanVP-08-107 - Protocol For Hold Time of Softgel EquipmentsprakashBelum ada peringkat

- 2 6 Sampling WHO GuidelinesDokumen22 halaman2 6 Sampling WHO GuidelinesPepeArandaBelum ada peringkat

- HoldTime 01Dokumen4 halamanHoldTime 01Anonymous GPLMks1pBelum ada peringkat

- Methods For Identifying Out of Trends in Ongoing StabilityDokumen10 halamanMethods For Identifying Out of Trends in Ongoing StabilityPiruzi MaghlakelidzeBelum ada peringkat

- The APIC Audit Programme Version 6Dokumen18 halamanThe APIC Audit Programme Version 6Ngoc Sang HuynhBelum ada peringkat

- Guideline On Stability Testing For Applications For Variations To A Marketing AuthorisationDokumen8 halamanGuideline On Stability Testing For Applications For Variations To A Marketing Authorisation刘朝阳Belum ada peringkat

- Omcl Management of Environmental Conditions Paphomcl1686r6Dokumen8 halamanOmcl Management of Environmental Conditions Paphomcl1686r6Hans LeupoldBelum ada peringkat

- Put Your Continued Process VerificationDokumen9 halamanPut Your Continued Process VerificationMinh LeBelum ada peringkat

- SOP For Karl Fisher Titration-Sophie - RadwanDokumen3 halamanSOP For Karl Fisher Titration-Sophie - RadwanzhobeysBelum ada peringkat

- CalibrationDokumen5 halamanCalibrationMonika KshBelum ada peringkat

- Verification of Compendial MethodDokumen2 halamanVerification of Compendial MethodshdphBelum ada peringkat

- Amlodipine and Celecoxib Tablets PDFDokumen38 halamanAmlodipine and Celecoxib Tablets PDFNarongchai PongpanBelum ada peringkat

- OOSDokumen14 halamanOOSqfbfabyholaBelum ada peringkat

- Honey Analysis by HPLCDokumen3 halamanHoney Analysis by HPLCOmar BinshehabBelum ada peringkat

- Seminar (Photostability)Dokumen12 halamanSeminar (Photostability)Mr. HIMANSHU PALIWALBelum ada peringkat

- USP Verification of Comp en Dial Procedures CVG CADokumen23 halamanUSP Verification of Comp en Dial Procedures CVG CAWilliamWang19Belum ada peringkat

- Deviation Report Guidance in Pharma in Engineering DepartmentDokumen24 halamanDeviation Report Guidance in Pharma in Engineering DepartmentShiva Sai BuraBelum ada peringkat

- 4 Egac SystemDokumen55 halaman4 Egac SystemWaleed El-azabBelum ada peringkat

- Periodic or Skip Testing in Pharmaceutical Industry Us and Europe Perspective 2153 2435.1000283 PDFDokumen5 halamanPeriodic or Skip Testing in Pharmaceutical Industry Us and Europe Perspective 2153 2435.1000283 PDFpakdomoBelum ada peringkat

- Meclizine HCLDokumen10 halamanMeclizine HCLChEng_Belum ada peringkat

- 1-6 Establishing Impurity SpecificationsDokumen52 halaman1-6 Establishing Impurity SpecificationsDivyesh PatelBelum ada peringkat

- Validation of Analytical Procedures Paphomcl 13-82-2rDokumen9 halamanValidation of Analytical Procedures Paphomcl 13-82-2rantonellodelreBelum ada peringkat

- Drug Exci Pie NT InteractionsDokumen0 halamanDrug Exci Pie NT InteractionsyuppierajBelum ada peringkat

- Required HLB For Oils and LipidsDokumen2 halamanRequired HLB For Oils and Lipidsevelina martono0% (1)

- Animal Models Abstract Booklet 20110915Dokumen29 halamanAnimal Models Abstract Booklet 20110915Juan RojasBelum ada peringkat

- DLS Terms Defined MalvernDokumen6 halamanDLS Terms Defined Malverncuongtran_siegenBelum ada peringkat

- The New Pathophysiology of CoronaryDokumen9 halamanThe New Pathophysiology of CoronarySebastian RomeroBelum ada peringkat

- NYCO Aeronautics & Defence Lubricants CatalogueDokumen70 halamanNYCO Aeronautics & Defence Lubricants CatalogueFremy Daniel Salazar Guedez100% (1)

- BUSM2479 Digital EntrepreneurshipDokumen10 halamanBUSM2479 Digital EntrepreneurshipHuỳnh Ngọc TuyềnBelum ada peringkat

- PREMIUM JEJU FOOD PRODUCTSDokumen12 halamanPREMIUM JEJU FOOD PRODUCTSSaddam BousbataBelum ada peringkat

- Medications Disposal and Waste ManagementDokumen7 halamanMedications Disposal and Waste ManagementMohamed KhaledBelum ada peringkat

- Cake Industry in IndiaDokumen15 halamanCake Industry in IndiaGenesian Nikhilesh Pillay50% (2)

- IATG 07.20 Surveillance and in Service Proof V.2Dokumen27 halamanIATG 07.20 Surveillance and in Service Proof V.2deepu1wBelum ada peringkat

- s058 - Résine D'accrochageDokumen1 halamans058 - Résine D'accrochageBen Abdallah BecemBelum ada peringkat

- Hempadur XP 87550: Product Characteristics Product DataDokumen3 halamanHempadur XP 87550: Product Characteristics Product DataOmar Marghani SalmaBelum ada peringkat

- Nitofill WS60Dokumen3 halamanNitofill WS60talatzahoorBelum ada peringkat

- Carboguard 888 PDSDokumen3 halamanCarboguard 888 PDSCane CirpoBelum ada peringkat

- TDS Brushbond IndiaDokumen2 halamanTDS Brushbond IndiapankajsinghBelum ada peringkat

- Case Study FoodDokumen4 halamanCase Study FoodKarynne Bernardine Gerona SiclotBelum ada peringkat

- Obat ExpiredDokumen5 halamanObat ExpiredKarvina KusumaBelum ada peringkat

- Forced-Air Cooling Systems For Fresh Ontario Fruits and VegetablesDokumen12 halamanForced-Air Cooling Systems For Fresh Ontario Fruits and Vegetableseroz2805Belum ada peringkat

- Guidance Note 18 Determination of Product Shelf Life PDFDokumen56 halamanGuidance Note 18 Determination of Product Shelf Life PDFHiếu LêBelum ada peringkat

- Fosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsDokumen3 halamanFosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsJohnBelum ada peringkat

- Instructions AllerSnap Rapid Protein Residue TestDokumen1 halamanInstructions AllerSnap Rapid Protein Residue TestBerry CheraBelum ada peringkat

- Monginis CakeDokumen11 halamanMonginis CakeLalit PandhareBelum ada peringkat

- Hempalin Enamel 52140: Product CharacteristicsDokumen3 halamanHempalin Enamel 52140: Product CharacteristicsMohamed FarhanBelum ada peringkat

- Assessment 1 4020 1Dokumen25 halamanAssessment 1 4020 1Magar Thapa lalitBelum ada peringkat

- FSIS Product Categorization GuideDokumen12 halamanFSIS Product Categorization Guideimran24Belum ada peringkat

- CXG 061eDokumen28 halamanCXG 061eKarizma Joy Arrocena SagsagatBelum ada peringkat

- AIBT - SITXINV006-Assessment 2 - Learner WorkbookDokumen19 halamanAIBT - SITXINV006-Assessment 2 - Learner WorkbookSukh RanaBelum ada peringkat

- N-Zorbit 2144 DG - enDokumen3 halamanN-Zorbit 2144 DG - enfernando guzman garciaBelum ada peringkat