IP-7900 Installation Manual

Diunggah oleh

Empresa AS APHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

IP-7900 Installation Manual

Diunggah oleh

Empresa AS APHak Cipta:

Format Tersedia

SIIT CONFIDENTIAL

IP-7900

Solvent Ink Color Inkjet Printer

Installation Manual

U00112843101

Seiko I Infotech Inc.

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

U00112843100 September 2008

U00112843101 February 2009

Copyright by Seiko I Infotech Inc., 2009

All right reserved.

The contents of this document may be subject to change without previous notice.

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Preface

The IP-7900 Color Ink Jet Printer Installation Manual describes how to install the IP-7900

Color Ink Jet Printer (simply called the printer below).

Installation is important for the printer's proper operation with the same performance as

confirmed at the predelivery test at the customer's site. Engineers should be familiarize

themselves with the printer and install it at the correct location using the correct

procedure and check it properly.

This manual covers unpacking, moving to the installation site, installation, assembly,

cable connection and operation check, which should be carried out after the printer is

delivered and unloaded in the customer's premises.

Before starting installation, take the time to read the Safety Precautions and Notes on

Installation and Handling, which are written on the following pages.

This manual consists of the following sections:

Section 1 Describes the steps for installation, details of each step, required manpower

and related sections. In addition, this section lists required tools. Familiarize

yourself with the flow of installation.

Section 2 Details installation requirements. Before starting installation, check that the

site chosen by the user meets these requirements.

Section 3 Shows the system configuration, appearance and names of components.

Section 4 Describes the procedures for unpacking, moving, installing, connecting, and

checking the printer.

Section 5 Describes the procedures for moving and relocating the printer.

When using the printer, see also the following documents:

● IP-7900 User’s Guide

● IP-7900 Maintenance Manual

● IP-7900 Packing Specification

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Safety Precautions

WARNINGS

• Use the power supply voltage specified on the nameplate.

DO NOT plug several devices into one electrical outlet as this might result in fire or

electric shock.

• DO NOT allow metal or liquids to touch the internal parts of the printer.

Doing so may cause fire, electric shock, or other accidents.

• DO NOT disconnect or connect the power cable with wet hands.

Doing so may lead to electric shock.

• Make sure the printer is well grounded. If it is not grounded, a short circuit may cause

fire or electrical shock.

• DO NOT disassemble or remodel the printer.

DO NOT repair the printer by yourself. Doing so may cause fire, electric shock or other

accidents.

• DO NOT remove the fixed covers of the printer because they contain high-voltage and

extremely hot parts. Careless removal might result in an electric shock or burn.

• DO NOT damage, break, process, or heat the power cable.

If it is damaged, replace it with a new one.

Using a damaged power cable may cause fire or electric shock.

• NEVER use the printer in a place of extreme humidity or any place where it can

possibly be splashed by any liquids.

If any liquids get into the printer, it could lead to fire, electric shock, or other serious

accidents.

• Turn the printer off and unplug the power cable immediately during a thunder storm.

WARNINGS

Power OFF the printer and unplug the power cable from the power outlet in any of the

following cases:

• When putting your hands inside the printer.

• Smoke, strange noise or smells erupt from the printer.

• A piece of metal or any liquid touches the internal parts or slot of the printer.

• An error requiring service from a service center occurs.

Avoid ink ingestion or splashes on skin or in eyes. Keep ink bottles out of the reach of

children. If ink is swallowed by mistake, do not try to vomit, but seek medical attention

immediately.

ii

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

CAUTIONS

In order to ensure the safe operation of the printer heed all of the cautions and warnings

contained throughout this manual.

• DO NOT put any paper rolls on an unstable table or a tilted surface as they could fall

leading to an injury.

• Handle the paper rolls with care because they are very heavy. If you drop them, it could

lead to personal injury.

• Hold the electric cable by the plug when connecting and disconnecting it.

Failing to do so may cause the cable to fray or break which could lead to electric shock

and/or fire.

• Cap the waste ink bottle tightly to prevent leakage before discarding it.

• DO NOT get ink on your skin or clothes. Wash off any ink with immediately with soapy

water.

• When replacing the ink cartridge, place a sheet of paper under the bottle to prevent

spillage and work in a well-ventilated area.

iii

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Notes on installation and handling

Pay attention to the following items to make full and proper use of the printer.

Notes on installation and storage

1. Do not install the printer in an area where it is directly exposed to sunlight orstrong

light source.

2. Do not install the printer in an area where it will receive vibration, dust or water.

3. Do not install the printer in an area where ventilation is poor.

4. Do not install the printer in an area where it directly receives air from airconditioners,

heaters or ventilators.

5. Use the printer in an area conforming to the specified operating conditions.

6. The printer should be installed on a level plane. It should not be tiltedduring

transportation. If the printer is not installed on a level surface, the printquality may

deteriorate or the printer may fail. Be sure to lock casters to preventmovement of

the printer.

7. There must be sufficient spaces for maintenance around the printer: left space:

40cm; right space: 40 cm; front space: 100 cm; rear space: 100 cm.These spaces

are also required to ventilate the printer.

8. Install the printer in the place where a warp in the floor will not be caused by

theweight of 450 kg.

9. Avoid the installation in a place where condensation may occur inside of theprinter.

In the case of condensation, leave the printer as it is until the

condensationdisappears. If it is used when condensation occurs, the printer may fail

or may notprint properly.

10. The printer weighs about 450 kg (excluding media and accessories). When

anypower equipment, such as fork-lift truck, is not used to move or transport

it,handle by eight people. Otherwise, it may cause injury.

Precautions on the power supply

1. Install the printer near an electrical outlet which should be easily accessible.

2. Do not provide power to the printer through the same power line as for

noise-generating devices, such as a motor.

3. Connect the power cable to an electrical outlet. Do not put many loads on one

electrical outlet.

iv

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Handling precautions

1. Turn the power OFF, wait for at least ten seconds, and turn the power on again.

2. Do not place anything on top of the printer. Do not rest your elbow on the printer.

3. Open and close the top cover gently with both hands from the front of the printer.

4. Before connecting or disconnecting the interface connector, turn the printer OFF.

5. Do not wipe the cover surface with benzene or paint thinner. The coating maycome

off or deteriorate.Wipe the cover clean with a soft cloth. If the cover is very dirty, use

a clothmoistened with a neutral detergent.

6. Do not touch the ink-jet head surface.

Precautions on consumables

1. Always use the recommended consumables (paper, ink, etc.). Failure to follow this

instruction may cause poor print quality or a breakdown.

Downloaded from www.Manualslib.com manuals search engine

Table of Contents

Section 1 Installation Overview

1.1 Installation Overview ................................................... 1-1

1.2 Required Tools ........................................................... 1-2

1.3 Package Size ............................................................. 1-3

Section 2 Installation Site Check

2.1 Temperature and Humidity ........................................... 2-1

2.2 Installation Floor ........................................................ 2-2

2.3 Installation Space ....................................................... 2-3

2.4 Transfer Space ........................................................... 2-4

2.5 Power Supply Requirements ........................................ 2-5

Section 3 Printer Configuration and Names of Components

3.1 Standard Components ................................................. 3-1

3.1.1 Basic components ............................................................. 3-1

3.1.2 I t e m s b u n d l e d i n t h e p r i n t e r pa c k a g e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

3.1.3 Accessories ...................................................................... 3-3

3.2 Options ...................................................................... 3-4

3.3 Consumables ............................................................. 3-5

Section 4 Unpacking, Transportation and Installation

4.1 Transferring to an Unpacking Area ................................ 4-2

4.1.1 U n pa c k i n g a r e a s e l e c t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

4.1.2 Tr a n s f e r m e t h o d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

4.2 Unpacking .................................................................. 4-4

4.2.1 U n pa c k i n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

4.2.2 U n l o a d i n g p r i n t e r f r o m pa l l e t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

4.3 Transferring to an Installation Area and Assembling Printer

Parts ........................................................................ 4-10

4.3.1 F i x i n g p r i n t e r a n d a s s e m b l i n g p r i n t e r pa r t s . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1 0

4.3.2 Assembling roll feed unit and take-up reel unit .................... 4-18

4.3.3 I n s t a l l i n g wa s t e i n k b o t t l e a n d i n k pa c k s . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2 6

4.3.4 Removing carriage cushioning materials............................. 4-31

4.3.5 F i l l i n g wi p e r c l e a n i n g l i q u i d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3 5

4.3.6 Filling spittoon absorber liquid .......................................... 4-36

4.3.7 Installing media .............................................................. 4-37

4.3.8 St r a i g h t e n i n g m e d i a f e e d d i r e c t i o n b y a d j u s t i n g t a k e - u p s c r o l l e r

height ............................................................................ 4-37

4.4 Connecting Power Cables and Turning on .................... 4-39

4.5 Filling an Initial Ink .................................................... 4-43

CONTENTS-1

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Table of Contents

4.6 Checking Printer Operation ......................................... 4-45

4.6.1 S e t t i n g pa r a m e t e r s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4 5

4.6.2 Adjusting sensors for roll feed unit and take-up reel unit ...... 4-45

4.6.3 C h e c k i n g p r i n t e r o p e r a t i o n wi t h o u t c o n n e c t i n g t o h o s t c o m p u t e r 4 - 4 9

4.6.4 C o n n e c t i n g wi t h h o s t c o m p u t e r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5 3

4.6.5 Confirming system operation............................................. 4-54

4.7 Completing installation ............................................... 4-55

Section 5 Moving and Relocating

5.1 Moving a Printer ......................................................... 5-1

5.1.1 M o v i n g a p r i n t e r wi t h c a s t e r s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

5.1.2 M o v i n g a p r i n t e r wi t h c r a n e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

5.2 Relocating a Printer .................................................... 5-2

5.2.1 Purging inks ..................................................................... 5-2

5.2.2 P o we r i n g o ff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

5.2.3 Fixing carriage .................................................................. 5-2

5.2.4 R e m o v i n g wa s t e i n k b o t t l e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

5.2.5 Installing cushioning materials and fittings ........................... 5-3

5.2.6 Unlocking casters and releasing the adjustable leveling feet ... 5-3

CONTENTS-2

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 1 Installation Overview

1.1 Installation Overview

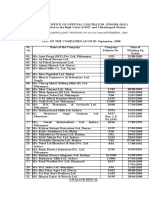

Table 1-1 lists the steps for installation and required manpower.

Table 1-1 Installation Overview

Required

Step Action

manpower

1 To transfer to unpacking Move the printer to an unpacking area. 2*

area

2 To unpack Remove the printer from the carton and 4

check the content against the packing list.

3 To move to installation Move the printer to the installation site. 2*

site

4 To install Install the printer, components, and 2

accessories, then connect the power cable.

5 To set parameters Set the parameters for printing and data 1

transmission.

6 To check printer Check the print quality. 1

operation

7 To connect interface Connect the interface cable. 1

cable

8 To check printer By connecting the printer with the host 1

operation computer, check the system performance in

advance, and secure that the system

operates properly.

* Eight persons are required to lift the printer. (Main body weight: about 600 kg; Packaged weight:

about 900 kg)

To move or transport the printer, use a forklift truck or a cart, containing long-fork, with the carrying

capacity, 1.5t or more. Check the route for carrying in advance, and secure a sufficient number of

operators.

1-1

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 1 Installation Overview

1.2 Required Tools

Table 1-2 lists the tools required for installation.

Table 1-2 Main Tools

Item Qty Remarks

Cutting pliers 1 To cut PP-band and insulation lock tie

Cutter 1 To unpack

Philips screwdriver JIS B 4633 (2) 1 To loosen screws holding the printer

Philips screwdriver (1: 250mm) 1 To adjust print head for image quality

improvement

Philips screwdriver (2: 250mm) 1 To adjust print head for image quality

improvement

Normal screwdriver 45x50 JIS B 4609 1 To loosen screws holding the printer

Normal screwdriver (1: 250mm) 1 To adjust print head for image quality

improvement

Wrench 13mm 2 To unpack

Hexagon wrench M4 1 To assemble cooling fan and sheet metal

Hexagon wrench M8 1 To remove metal pedestals

Hexagon wrench M3 1 To adjust carriage height for image quality

improvement

Hexagon wrench M5 1 To parallel carriage to platen for image quality

improvement

Hexagon wrench M6 1 To parallel carriage to platen for image quality

improvement

Socket wrench 9.5mm squared 1 To loosen stand reinforcement plate

Adjustable end wrench 1

Wrench 1

Torque screwdriver 1 To tighten carriage covers 49N (5kgf)

Level 1 To install the printer horizontally

1-2

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 1 Installation Overview

1.3 Package Size

Table 1-3 Package Size

Package size 約 4300(W)x1100(D)x1820(H)

Package weight 約 900kg

Pallet Material: Iron, Weight: Approx. 147kg

Pallet size 4300 (W) x 1100 (D) x 250 (H)

1-3

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 2 Installation Site Check

Before installation, check the environmental conditions below including power supply.

2.1 Temperature and Humidity

The conditions for the installation site are shown below.

(1) Keep the air condition constant.

Table 2-1 lists the temperature and humidity at the installation site.

Table 2-1 Environmental Conditions

Item Conditions/Remarks

Temperature Operating: 15 to 30 °C

Non-operating: 5 to 35 °C

To guarantee print quality: 20 to 25 °C

Relative humidity Operating: 30 to 70% RH

(without condensation) Non-operating: 10 to 80% RH

Print quality guarantee: 40 to 60% RH

Temperature gradient Operating: ±10 °C/h or less

(without condensation) Non-operating: ±20 °C/h or less

Operating temperature and Operate the printer under the temperature and humidity below.

humidity range Temperature: 15℃ to 30℃

Humidity: 30% to 70%RH

To obtain better print quality, operate the printer within the

temperature 20 to 25 °C (68 to 77℉).

(2) Do not subject the printer to mechanical vibration.

(3) Avoid dusty place. Keep the air clean.

(4) Do not expose the printer to the direct sunlight. Confirm that the printer is not exposed

the afternoon sunlight.

(5) Do not expose the printer to the air exhausted from ventilation outlet.

(6) Provide adequate ventilation.

2-1

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 2 Installation Site Check

2.2 Installation Floor

The adequate space around the printer for supplies replacement and print processing is required when

operating and repairing.

The floor of the installation site should meet the following requirements:

(1) The floor should be level.

The floor should be level to distribute a load on the leveling feet evenly and keep the printer

horizontal. (Measure and check the levelness with a level at the center of the printer’s BEAM.)

As the pallet has casters, avoid obstructions in the path to move it on casters.

(2) The floor should have sufficient strength to hold the weight of the printer.

The floor strength to support the casters is shown below.

● Printer weight 600kg (excluding media and consumable parts)

● Load on a caster 150kg (excluding media and consumable parts)

The caster position subjected to the load are shown in Figure 2-1.

The part painted in gray indicates the roll feed/take-up reel unit.

4125.5

524 2906.1

424

3106.6

8-φ65

1379.2

723

369

4-φ75

FRONT

(単位: mm)

Figure 2-1 Caster Positions

2-2

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 2 Installation Site Check

2.3 Installation Space

At installing the printer, a sufficient space around the printer must be secured to:

- Replace the frequently used part

- Output the drawings

- Provide adequate ventilation

- Repair printer and replace components

The space required for the installation and maintenance (excluding media setting) is shown in Figure

2-2.

NOTE

The figure below shows the space for installation only. To unload the printer from the pallet

with slope, secure the space width 9.0m or more. For more details, refer to “Section 4

Unpacking, Transportation, and Installation.”

1,000

400 400

Front

1,000

Height: 2,200

(Unit: mm)

Figure 2-2 Installation/Maintenance Space

2-3

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 2 Installation Site Check

2.4 Transfer Space

Note that they are the dimensions of the printer just unpacked and not assembled.

Secure the printer’s transfer space based on the printer’s dimensions below.

(Unit: mm)

Figure 2-3 Printer Dimensions for Transfer Space

2-4

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 2 Installation Site Check

2.5 Power Supply Requirements

The requirements to connect the printer’s power cable are shown below.

(1) Power supply specifications

The power supply specifications for the printer are as follows:

Verify that the power supply at the site meets the following specifications.

● Power consumption

Printer power supply operating: 1440W or less

Printer power supply idle: 100W or less

Heater power supply operating:

200V input voltage: 2000W or less

240V input voltage: 2880W or less

Heater power supply idle: 5W or less

● Input power voltage for printer power supply and heater power supply

Rated voltage: 200 to 240VAC

(Input voltage range: 180 to 260VAC)

● Input power frequency for printer power supply and heater power supply

Rated frequency: 50/60Hz

(Input frequency range: 50/60±1Hz)

● Instantaneous interruption for printer power supply and heater power supply

20msec or more

● Inrush current for printer power supply and heater power supply

35A or less

● Leakage current for printer power supply and heater power supply

3.5mA or less (IEC950,UL1950,CSA950)

1.0mA or less (Electrical Appliance and Material

Safety Law)

● Insulation resistance for printer power supply and heater power supply

10MΩ (500VDC) or more

2-5

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 2 Installation Site Check

● Withstand voltage for printer power supply and heater power supply

1.5kVAC for one minute

● Calorific power 15552000J/H or less

● Grounding for printer power supply and heater power supply

Class D grounding (3rd grounding)

CAUTION

To prevent induction noise, apply an exclusive ground cable. Do not connect it together

with the power cable.

2-6

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 2 Installation Site Check

(2) AC outlet

The shape of the plug and plug outlet are as follows.

Apply the receptacle suitable for the plug.

1)For Japan

Figure 2-4 JIS C8303 3P 15A 250V Shape of plug and outlet

2)For Europe

Unit:mm

Figure 2-5 Plug shape for Europe (STANDARD SHEET V II)

2-7

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 2 Installation Site Check

3)For North America

Unit:mm

Figure 2-6 Plug shape for North America (NEMA 250V-20A)

2-8

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 3 Printer Configuration and

Names of Components

This section shows the printer configuration and the names of components as a basic knowledge

required for the operations described in “Section 4 Unpacking, Transportation and Installation” and the

subsequent section.

The printer consists of three major components below.

● Standard components (basic components, items bundled in the printer package, and

accessories)

● Options

● Consumables

While the standard main unit components (printer, bundled items, and accessories) are common to all

configurations, options and consumables depend on the customer specification.

The configuration and the names of the components are shown below.

3.1 Standard Components

3.1.1 Basic components

- Roll feed unit

- Take-up reel unit

- Front paper guide

- Media drying fan

- Subcartridge cover

- Scroller (x2)

- Tension bar guideTension bar(x1)

- Tension bar holder

- Rubber spacerA,B,C

- Paper tube flange(x2)

- Take-up flange(x2)

- Securing ring(x2)

3-1

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 3 Printer Configuration and Names of Components

3.1.2 Items bundled in the printer package

Scroller

<2 PCS> Tension bar

(with flange 2 PCS)

(with no flange 1PC)

<3PCS>

Supply side frange (with screw) Supply side frange / fixing ring

<1 set> <1 set>

Roll media (for adjustment) Waste ink bottle 64-inch paper tube

<1PC> P6-109 (for take-up reel unit)

<1 bottle> <1PC>

Paper tube flange Rubber spacer A Rubber spacer B Rubber spacerC

<2 PCS> <1 PC> <1 PC> <1 PC>

Phillips

Paper setting gauge screwdriver

<1 PC>

Pullout handle of scroller

<1 PC>

3-2

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 3 Printer Configuration and Names of Components

3.1.3 Accessories

Power cable USB2.0 cable

<2PCS> <1PC>

Ink tray Subcartridge Dummy pack

IP7-123 <1 set> <8PCS>

<8PCS> Y(IP7-111) :2 PCS

M(IP7-112) :2 PCS

C(IP7-113) :2 PCS

K(IP7-114) :2 PCS

Lc(IP7-115) :1 PCS

Lm(IP7-116) :1 PCS

Gy(IP7-117) :1 PCS

Lgy(IP7-118) :1 PCS

Daily maintenance kit IP7-130 Wiper cleaning liquid set Wiper cleaning liquid

<1 set> IP7-131 extraction set

<1 set>

- Cap cleaning liquid : 300 ml -Wiper cleaning liquid ((200ml):3 bottles

- Wiper cleaning liquid : 200 ml

- Spittoon absorber liquid : 100 ml

- Cleaning roller : 30 PCS

- Cleaning swab : 10 PCS

- Dripper : 10 PCS

- Tweezers : 1 PC

- Cleaning stick : 1 PC

- Spittoon case : 1 PC

- Gloves : 30 pairs User’s Guide Spittoon absorber

- Bag : 1 PC IP7-132

<1 set>

- Spittoon absorber liquid(100 ml)

: 3 bottles

3-3

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 3 Printer Configuration and Names of Components

3.2 Options

● Exhaust attachment (IP-177) 2

● PS RIP(PhotoPrint 6 Standard SIIT Edition)(IP-550) 1

● PS RIP(PhotoPrint 6 Server SIIT Edition)(IP-551) 1

● Mesh printing kit(IP7-011) 1

● Footswitch 1

● Scroller 1

● Color exchange set (IP7-122) <1 set>

・Cleaning liquid pack 4

・Dummy subcartridge 4

3-4

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 3 Printer Configuration and Names of Components

3.3 Consumables

Daily maintenance kit IP7-130 Subcartridge (8 colors)

<1 set> <1 set>

Y(IP7-111) :2 PCS

- Cap cleaning liquid : 300 ml M(IP7-112) :2 PCS

- Wiper cleaning liquid : 200 ml C(IP7-113) :2 PCS

- Spittoon absorber liquid : 100 ml K(IP7-114) :2 PCS

- Cleaning roller : 30 PCS Lc(IP7-115) :1 PCS

- Cleaning swab : 10 PCS Lm(IP7-116) :1 PCS

- Dripper : 10 PCS Gy(IP7-117) :1 PCS

- Tweezers : 1 PC Lgy(IP7-118) :1 PCS

- Cleaning stick : 1 PC

- Spittoon case : 1 PC

- Gloves : 30 pairs

- Bag : 1 PC

Cleaning liquid kit IP7-136 Storage liquid kit IP7-137 Cap cleaning liquid set

<1 set> <1 set> IP7-134

- Cleaning liquid pack : 8 PCS - Storage liquid pack : 8 PCS <1 set>

- Dummy subcartridge : 8 PCS - Dummy subcartridge : 8 PCS Cap cleaning liquid (300 ml) : 3 bottles

Wiper cleaning liquid set Cleaning swab Spittoon absorber liquid

IP7-131 IP6-147 IP7-132

<1 set> <300 PCS> <1 set>

- Wiper cleaning liquid (200 ml) : 3 bottles -Spittoon absorber liquid(100 ml) :3bottles

3-5

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 3 Printer Configuration and Names of Components

Ink pack (8 colors) Waste ink bottle

Ink tray

Y(IP7-101), M(P7-102), C(IP7-103), IP6-109

IP7-123

K(IP7-104), Lc(IP7-105), Lm(IP7-106), <1 bottle>

<8 PCS>

Gy(IP7-107), Lgy(IP7-108),

Cleaning roller set

IP5-121

Head cleaning kit < 90 PCS>

Cleaning stick

IP7-125

IP5-120

<1PC>

(with one cleaning roller)

Wiper blade

IP7-133 Absorbent sheet Absorbent sponge

IP7-124 IP7-127

<1 roll> <10PCS>

Spittoon case set IP7-126 Color exchange set Glove set

- Spittoon case IP7-122 IP7-138

- Bag <100 pairs>

Wiper cleaning liquid

IP7-135

<1PC>

3-6

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and

Installation

Install the printer with the following steps:

(1) To decide unpacking area and to transfer the printer to the unpacking area:

See the section 4.1

(2) To unpack: See the section 4.2.

(3) To transfer the printer to the area to be installed: See the section 4.3.

(4) To supply the power: See the section 4.4.

(5) To fill initial ink: See the section 4.5.

(6) To confirm the printer operation See the section 4.6.

(7) To complete the installation See the section 4.7.

CAUTIONS

Temperature’s sudden changes may cause condensation inside the printer and printer

failure.

When the outside temperature differs considerably from the room temperature, warm up

the printer before starting installation by leaving the carton containing the printer with the

steps below.

• Leave the printer at an intermediate temperature between the room temperature and

the outside temperature for about one hour.

• Leave the printer at the room temperature for two hours or more.

2.

4-1

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.1 Transferring to an Unpacking Area

4.1.1 Unpacking area selection

Take the following precautions when selecting an unpacking area:

(1) Minimize the transfer distance from the unpacking area to the installation area. Note that the

printer performance is affected by vibration and shock, since it is a precision piece of

equipment.

(2) Secure the unpacking area large enough to temporarily store packing materials and

accessories to be installed.

Unpacking area

Slope Printer carton

2.5m

Unloading direction Printer

9.0m

*Unload the printer from either the capping unit side or the wiping unit side.

Figure 4-1 Unpacking Area

(3) Since unpacking makes noise, carefully choose the unpacking area so that it does not affect

the other works done nearby.

(4) Before unloading the printer, identify the printer’s direction. Note that SII’s logo label is

attached to the carton’s side panel corresponding to the printer’s front face.

4-2

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.1.2 Transfer method

(1) Preparation for transfer

Check the transfer route carefully, and confirm that no obstruction is found on the way.

(2) Transfer

Move the printer with casters since its gross weight is approx. 600kg. If the carton must be

lifted, note that eight persons are required.

(3) Precautions on transfer

● Be sure to follow the safety precautions if the carton is moved without casters.

● Keep the printer horizontal during transportation.

● Be careful not to damage any existing facilities when moving the printer.

Barycentric position

Pallet

4-3

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.2 Unpacking

After unloading, unpack and remove the printer from the package and check its components.

4.2.1 Unpacking

1. Cut the PP-band and remove the

plastic cover.

2. Remove the top cover.

3. Remove the side panels

corresponding to the printer’s front and

rear.

4-4

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4. Remove the eight 13mm bolts securing

the iron frame’s top part, and top iron

frame.

NOTE

• Hold the iron frame firmly to prevent it

from falling down when the upper

nuts are removed.

• Remove carefully not to drop the

nuts.

5. Remove the ten 13mm bolts securing

the iron frame and remove the all iron

frame in the side faces.

6. Remove the side panels

corresponding to the printer’s right and

left.

Side panels

7. Remove the plastic sheet covering the

printer. Plastic cover

Pallet

4-5

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

8. Cut the PP-bands fixing the bundled

packages, and take out them.

Scroller

F-PG (front paper guide)

Slope

Scroller-Support(Feed)

● TakeUp-Drive-Unit

● Scroller-Support(TakeUp)

Feed-Drive-Unit

Drying fan

Media for adjustment at installation

● BEAM(Frame)FEED

● BEAM(Frame)TAKE-UP

4-6

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

9. Inspect the packed items.

Inspect that neither lack nor damage is

found. If it is found, contact our

dealer.

NOTE

• For the details of the packed items,

refer to the Packing Specifications.

• Do not leave the waste and the

packing items at the customer’s site.

Be sure to take back with you.

4-7

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.2.2 Unloading printer from pallet

1. With a hexagon wrench, remove the

four bolts securing the printer’s stand

to the pallet. Hexagon socket head screw

Then remove the angle’s two upper

screws with a 6mm hexagon wrench,

and the two lower bolts with a 13mm

socket wrench.

NOTE Angle

• Unload the printer from either the

capping unit side or the wiping unit

side.

13mm bolts

• Do not loosen the angle’s bolts at the

opposite side.

2. Raise the printer by inserting a slope

under the caster and pushing it deeper.

Slope

With keeping the printer raised,

remove the fixing angle. Then

remove the slopes by lightly kicking

them.

NOTE

The procedure above requires at least

three persons: one to press each slope,

and one to remove the fixing angle.

4-8

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

3. Before removing the other side’s angle,

hold the printer in the opposite side so

that it would not move.

NOTE

As one side’s angle was already

removed, support the printer’s corner not

to move it.

4. By repeating the steps 1 and 2,

remove the other side’s angle.

5. Fix the slopes by inserting the slopes’

hooks in the iron frame stand’s holes.

6. Take off the printer along the slope.

7. To the installation area transfer the

printer covered with the protection

materials.

4-9

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.3 Transferring to an Installation Area and

Assembling Printer Parts

After taking off the printer from the pallet, move the printer to the user-specified location

and install it with the following steps.

4.3.1 Fixing printer and assembling printer parts

1. Hold the caster’s wheel at the printer’s

front side by pushing the caster’s

stopper down as the photo shows.

Stopper

Caster wheel

2. Set the adjustable leveling feet to the

four positions of the printer’s leg part.

Adjustable leveling foot

3. By rotating the adjustable leveling feet,

adjust the printer to be horizontal.

NOTE

Be sure to perform this adjustment to

prevent printer’s malfunction or damage.

Note that the adjustable leveling foot is

an important part to support a large mass

of media on the roll feed unit and the

take-up reel unit.

Adjustable leveling foot

4-10

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4. Remove the printer’s all packing

materials: polyethylene wrap, tapes,

PP-bands, and Bubble Wrap.

NOTE Protection for

transportation

At this step do not remove the protection

materials inside the carriage.

Polyethylene wrap

GRIT-Roller

protection

Protection

PP-bands

Protection Protection

5. Remove the ANGLE(STAND)HV at the

four positions of the printer’s leg part.

Note that each ANGLE(STAND)HV is

fixed with four M5x10 screws.

NOTE

Keep the screws removed at this step,

as they are reused to fix the angles for

Feed-Drive-Unit, Scroller-Support(Feed),

TakeUp-Drive-Unit, and ANGLE(STAND)HV for

Scroller-Support(TakeUp). transportation

4 - 11

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

6. Assemble the

BRACKET(PG-F-MountR).

<Fixing torque>

M4×8: 1.5Nm

M5×10: 2.5Nm

BRACKET(PG-F-MountR)

One M5×10 screw

One M4×8 screw

Two M4×8 screws

At this assembly, pass the interlock

switch cable through the hole shown

in the right figure.

7. Insert the cable into the

BRACKET(PG-F-MountR) connector.

4-12

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

8. Assemble the

BRACKET(PG-F-MountL).

<Fixing torque>

M4×8: 1.5Nm

M5×10: 2.5Nm

BRACKET(PG-F-MountL)

One M5×10 screw

One M4×8 screw

Two M4×8 screws

At this assembly, pass the interlock

switch cable through the hole shown

in the right figure.

4-13

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

9. Assemble the BRACKET(PGF-Cen) to

the three positions. Note that each

BRACKET(PGF-Cen) is fixed with four

screws.

ねじ 4 本(M4×8)

BRACKET(PGF-Cen)

10. Remove the GUIDE-CUTTER(104)

temporarily attached to the fixing

position of the

FRONT-PG-ASSY(104).

GUIDE-CUTTER(104)

11. Set the FRONT-PG-ASSY(104) to its

fixing position by inserting the screws

into the sheet metal’s holes. Then fix

the GUIDE-CUTTER(104) between

the printer and the

FRONT-PG-ASSY(104) with 12 M4x12

screws.

Screw positions of GUIDE-CUTTER(104)

GUIDE-CUTTER(104)

GUIDE-CUTTER(104)

FRONT-PG-ASSY(104) 4-14

FRONT-PG-ASSY(104)

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

12. Tighten the 10 M5x10 screws at the

FRONT-PG-ASSY(104) bottom face.

Screw positions at FRONT-PG-ASSY(104) bottom face

13. Put your hands from the

FRONT-PG-ASSY(104)’s bottom part,

and connect the all connectors

between the FRONT-PG-ASSY(104)

and the printer.

4-15

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

14. Set the four LID(PG-Under) to the

FRONT-PG-ASSY(104)’s bottom part.

Note that each LID(PG-Under) is fixed

with four screws.

M4×8

LID(PG-Under)

LID(PG-Under) setting positions

15. Fix the HOOK-TB at the five positions

with lake blue painted screws.

HOOK-TB (tension bar hook)

4-16

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

16. Fix the TRAY(BOTTLE)HV with four

4x8 screws, and insert the waste ink

tube with cap so that the cap’s button

is set on the TRAY(BOTTLE)HV’s

protruding slip.

DT-3 4X8

17. Assemble the drying fan with one

screw each for right and left and one Painted screw

painted screw.

Screws Drying fan

18. Insert the drying fan connector.

Connector

Then apply a nylon clip on the cable,

and fix it with a screw.

Drying fan

19. Set the PIPE(PG-GARD) in the

groove.

PIPE(PG-GARD)

4-17

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.3.2 Assembling roll feed unit and take-up reel unit

The roll feed unit and the take-up reel unit are assembled with the procedure below.

(1) Fix the Feed-Drive-Unit and the Scroller-Support(Feed) to the BEAM(Frame)FEED.

(2) Fix the TakeUp-Drive-Unit and the Scroller-Support(TakeUp) to the

BEAM(Frame)TAKE-UP.

(3) Assemble the BEAM(Frame)FEED via angle to the printer’s rear face, that is,

media-supply side.

(4) Assemble the BEAM(Frame)TAKE-UP via angle to the printer’s front face, that is,

media-takeup side.

Note that the assemble is difficult when the angle is attached the to Feed-Drive-Unit or

the TakeUp-Drive-Unit in advance. So first fix the Feed-Drive-Unit side angle and

TakeUp-Drive-Unit side angle to the printer, then assemble each BEAM to the printer. For

details, refer to the procedure on the following pages.

Overview to Assemble Roll Feed Unit and Take-Up Reel Unit

Feed-Drive-Unit TakeUp-Drive-Unit

BEAM(Frame)FEED

Scroller-Support(Feed) TensionBar-Guide-Kotei

BEAM(Frame)TAKE-UP

Sensor

TensionBar-Guide(TU)HV

Printer’s front side

Scroller-Support(TakeUp)

4-18

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

<Screw positions in lever side>

1. Assemble the Feed-Drive-Unit to the

BEAM(Frame)FEED with four M8x20

Feed-Drive-Unit

hex socket head bolts with spring and

flat washers and two M5x10 screws.

NOTE

Do not fix Angle(RF) at this step.

M8X20 hex socket head bolt with

spring and flat washers

<Screw positions in rear side>

BEAM(Frame)FEED

M5X10

2. Assemble the Scroller-Support(Feed)

to the BEAM(Frame)FEED with four

M8x20 hexagon socket head bolts and

two M5x10 screws.

Scroller-Support(Feed)

<Screw positions>

BEAM(Frame)FEED

M8X20 hex socket

M5X10 head bolt with spring

and flat washers

4-19

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

3. With four M5x10 screws assemble the

Angle(LF) to the

Scroller-Support(Feed) which was

fixed to the BEAM(Frame)FEED in the

previous step.

Scroller-Support(Feed)

Angle(LF)

4. Assemble the TakeUp-Drive-Unit to the

BEAM(Frame)TAKE-UP with four

M8x20 hexagon socket head bolts and

two M5x10 screws.

NOTE

Do not fix Angle(RT) at this step.

<Screw positions>

M8X20 hex socket

head bolt with spring

and flat washers

Do not fix

Angle(RT) at this

step.

M5X10

4-20

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

5. Assemble the <Screw positions>

Scroller-Support(TakeUp) to the TensionBar-Guide(TU)HV

BEAM(Frame)TAKE-UP with four

M8x20 hexagon socket head bolts and

two M5x10 screws.

M8X20 hex socket head bolt

with spring and flat washers

M5X10

If the BEAM(Frame)TAKE-UP is kept

to be raised up with some tool, at this BEAM(Frame)TAKE-UP

step slide and insert the

TensionBar-Guide(TU)HV to the

BEAM(Frame)TAKE-UP without

removing the screws.

If not, assemble the

TensionBar-Guide(TU)HV by removing

the screws at the following step.

Tool

TensionBar-Guide(TU)HV

6. With four M5x10 screws assemble the

Angle(LT) to the

Scroller-Support(TakeUp) which was

fixed to the BEAM(Frame)TAKE-UP in

the previous step.

Scroller-Support(TakeUp)

Angle(LT)

7. Assemble the sensor to the center of Sensor position

the BEAM(Frame)TAKE-UP shown in

the figure, and connect the connector.

Connector

4-21

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

8. Assemble the BEAM(Frame)FEED

with the Feed-Drive-Unit and the

Scroller-Support(Feed) fixed to the

printer.

a) Press the Angle(RF) against the

printer, and fix it with two M5x10

screws.

b) From the Feed-Drive-Unit side,

insert the BEAM(Frame)FEED to

the printer. Then insert the

Scroller-Support(Feed).

2.

1.

c) Assemble the Feed-Drive-Unit

and the Angle(RF) with two

M5x10 screws.

4-22

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

d) Assemble the Angle(LF) in the

Scroller-Support(Feed) side and

the printer with two M5x10 screws.

Scroller-Support(Feed)

9. Just like repeating the procedure to

assemble the BEAM(Frame)FEED to

the printer, assemble the

BEAM(Frame)TAKE-UP with the

TakeUp-Drive-Unit and the

Scroller-Support(TakeUp) fixed to the

to the printer.

a) Press the Angle(RT) against the

printer, and fix it with two M5x10

screws.

b) From the TakeUp-Drive-Unit side,

insert the BEAM(Frame)TAKE-UP

to the printer. Then insert the

Scroller-Support(TakeUp).

2.

1.

c) Assemble the TakeUp-Drive-Unit

and the Angle(RT) with two M5x10

screws.

d) Assemble the Angle(LT) in the

Scroller-Support(TakeUp) side

and the printer with two M5x10

screws.

4-23

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

BEAM(Frame)TAKE-UP

10. Assemble the

TensionBar-Guide(TU)HV, when it was

not assembled at the step 5.

Knob

TensionBar-Guide(TU)HV

a) Remove the four screws, shown in

the Photo, of the

TensionBar-Guide(TU)HV.

b) Assemble the part A shown in

the right Photo to the

BEAM(Frame)TAKE-UP’s groove

with the four screws removed at

the previous step.

c) Slide the

TensionBar-Guide(TU)HV to the

left side, and tight the knob lightly.

4-24

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

11. Assemble the TensionBar-Guide-Kotei

to the TakeUp-Drive-Unit with the three

screws, one M5x10 and two 4x8. Then

connect the sensor connector.

This screw fixes TensionBar-Guide-Kotei

and BEARING SUPPORT-B.

12. Connect the all connectors from

TakeUp-Drive-Unit to the printer.

Connect the sensor's connectors:

connector tagged as "TU" to the upper

sensor, and tagged as "TL" to the

lower sensor.

4-25

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.3.3 Installing waste ink bottle and ink packs

■ SAFETY PRECAUTIONS FOR WASTE INK BOTTLE

WARNINGS

• The ink used for the printer contains petroleum solvent. Since the ink is flammable,

NEVER place the waste ink near open flame.

• DO NOT swallow the waste ink and avoid contact with eye. It will cause respiratory

distress and can harm the eye.

• DO NOT get the waste ink on your skin or clothes. Wash off any ink immediately with

soapy water.

CAUTIONS

• DO NOT attempt to disassemble the waste ink bottle.

• Cap the waste ink bottle tightly to prevent leakage before discharging it. Then put the

bottle into a plastic bag and dispose it as hazardous waste. Observe local regulations

for disposal of waste ink bottles.

NOTES

• Install the waste ink bottle correctly and securely. If not, the waste ink amount cannot

be detected correctly, which cause a spillage.

• Never leave the printer without installing waste ink bottle. When it is removed for

replacement, be sure to install a new one.

• At replacement, support the waste ink bottle with your both hands to prevent leakage.

NEVER tip or turn over the bottle.

4-26

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

■ SAFETY PRECAUTIONS FOR INK PACK

WARNINGS

• The ink used for the printer contains petroleum solvent. Since the ink is flammable,

NEVER place the ink pack near open flame.

• DO NOT swallow ink and avoid contact with eye. It will cause respiratory distress and

can harm the eye. Keep the ink packs out of the reach of the children.

• DO NOT get the ink on your skin or clothes. Wash off any ink immediately with soapy

water.

CAUTIONS

• DO NOT attempt to disassemble ink packs.

• Put a used ink pack into a plastic bag and dispose it as hazardous waste. Observe

local regulations for disposal of used ink packs.

NOTES

• Always use the recommended ink. Failure to do this may cause poor print quality or

printer damage that may invalidate your warranty.

• The ink’s storage life is 12 months from the manufacturing date.

• DO NOT shake an ink pack before use.

• Never leave the printer without installing ink packs for eight colors. When they are

removed for replacement, be sure to install new ones.

• DO NOT use ink past the date of expiration as this may cause poor print quality or

printer damage that may invalidate your warranty.

• Store ink in a dark and cool place. NEVER store ink in a high temperature or direct

sunlight. Ink change characteristic if exposed to direct sunlight.

4-27

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

Install the waste ink bottle and ink pack according to the following procedures.

Be sure to install the waste ink bottle before installing the ink packs.

1. Remove the cap of the waste ink bottle.

2. Upward slide the lever of the waste ink

bottle applied part, and set the waste

ink bottle.

3. Slide the lever downward.

NOTE

Install the waste ink bottle correctly and

securely. If not, the waste ink amount

cannot be detected correctly, which

cause a spillage or may stain the floor

with spilled ink.

4. Open the ink box cover by pressing its

knob.

4-28

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

1.

5. Set the dummy pack to the ink tray.

Hook the two holes at the dummy

pack’s bottom part over the ink tray’s

two protrusions. Then insert the

dummy pack’s top plate into the ink

tray slit until you hear the joint click.

2.

6. With a dropper, apply the cap cleaning

liquid to the ink tray's spout holes.

NOTE

Do not omit this step, or the ink may leak

from the spout hole.

Spout hole

7. Insert the ink tray into the slot of the ink

box.

NOTES

• Insert the ink tray all the way seated.

• Be sure to insert the dummy pack

into the correct slot. Note that the

slot positions are designated

depending on the colors.

8. Close the ink box cover.

4-29

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

9. Remove the eight drip-proof tubes

connected to the upper ink supply pins

of the subcartridge attaching part.

Drip-proof tube

10. Attach the subcartridge cover, and fix it

by rotating the two painted screws.

NOTE

At this step do not set the subcartridge.

Note that the subcartridge cover is fixed

without setting a subcartridge.

4-30

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.3.4 Removing carriage cushioning materials

1. Detach the all covers to remove the

carriage cushioning materials.

a) Open the COVER (HV)FMR. By COVER (HV)FMR

pressing the claw, remove the

COVER (HV)FTR from the

COVER (HV)FTR.

Claw

COVER (HV)FTR

b) Remove the COVER (HV)FBR-R

with three screws.

COVER (HV)FBR-R

c) Remove the COVER (HV)FTR

with two screws.

COVER (HV)FTR

4-31

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

d) Remove nine screws fixing the

COVER(HV104)YRR. Note that

four screws are set at the top face,

three on the rear face, and two on

the bottom front part.

Note

Apply 35mm Philips screwdriver.

COVER(HV104)YRR

e) Tilt the COVER(HV104)YRR.

Then remove it by lifting upward.

f) Remove the

COVER(HV104)YRR-B with five

screws on the printer’s rear face.

COVER(HV104)YRR-B

4-32

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

2. Remove the Cover(CarriageUpper)

with two screws. Cover(CarriageUpper)

3. Remove the Cover (CarriageUnder)

ASSY with six screws: four on the rear

face and two on the front face. Then

remove the fan cable, too. Cover (CarriageUnder) ASSY

4. Remove carriage cushioning materials

shown in the figures. Carriage fixing polystyrene foam on printer’s

rear side

CLAMP(Carriage-HeadBase)

Block(HeadBase)

AnglePlate(HeadBase)

4-33

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

5. Fix the Cover(CarriageUnder) ASSY

and the Cover(CarriageUpper)

removed in the previous procedure.

<Fixing torque>

0.78 Nm

4-34

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.3.5 Filling wiper cleaning liquid

1. Open the front cover and the wiper

cover.

2. Confirm that the cleaning liquid filling

hole is at the wiper unit top panel’s

bottom right part. Fill the wiper

cleaning liquid from the filling hole.

Visually check that:

- The wiper cleaning liquid

surface is higher than the “x”

mark’s top edge.

- The wiper cleaning liquid

surface is NOT higher than the

“o” mark’s top edge.

NOTE

Explain the daily maintenance below to

the users:

- To check visually the wiper

cleaning liquid surface position

- To fill wiper cleaning liquid

3. Close the wiper cover and the front

cover.

4-35

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.3.6 Filling spittoon absorber liquid

1. Using a dripper, drizzle the spittoon

case with the spittoon absorber liquid

so that the whole spittoon case surface Spittoon case

is fully wet.

First, drizzle the top surface

evenly with the spittoon absorber

liquid.

2. After the whole surface is wet, fill the

spittoon case with the spittoon

absorber liquid. Confirm that the top of

the protrusions shown in the Photo is

submerged by the agent.

Protrusions

4-36

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.3.7 Installing media

Install media to the printer.

For the procedure, refer to the IP-7900 User’s Guide, “Section 2 Basic Operation”: “Roll

media installation procedure” of “Media installation and removal.”

4.3.8 Straightening media feed direction by adjusting take-up

scroller height

To straightening the media feed direction, parallelize the take-up scroller to the

FRONT-PG-ASSY(104) by adjusting the take-up scroller height.

1. Tie a string at the tape measure case.

Make a loop with the other end of the

string, and let the take-up scroller

through the loop.

Hook the tape measure top’s L-shaped

part on the platen’s media supply side.

2. In the capping side, measure the

distance between the platen’s media

supply side and the take-up scroller.

Tape measure

4-37

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

3. In the wiping side, measure the

distance between the platen’s media

supply side and the take-up scroller.

Tape measure

4. Loosen the two fixing screws at the

side face of the

Scroller-Support(TakeUp). Height adjustment bolt

5. By rotating the height adjustment bolt,

adjust take-up scroller’s wiping-side

height to be the same as its

capping-side height.

Note that the difference between the Fixing screws

wiping-side height and the

capping-side height must be within

1mm.

6. After the adjustment, tighten the two

screws loosened at the step 4.

4-38

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.4 Connecting Power Cables and Turning on

Notes

• Note that the printer contains two 200V power systems.

• Connect only the power cables attached to the printer.

• Before connecting the power cable, check that the power cable conforms to the

regional AC power specification.

• Be sure to clamp the power codes. If not, the power code may be caught by the

scrollers, which may cause an electrification or a printer damage.

• After turning on the printer power switch and the heater power switch, be sure to turn

on or off only with the power switch on the printer’s operation panel.

Printer power inlet

7. Insert the two power cables attached Heater power inlet

into the printer power inlet and the

heater power inlet of the printer.

8. Turn ON the printer power switch, and Printer power switch

then heater power switch.

Heater power switch

4-39

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

9. Turn ON the power switch on the

operation panel.

When the switch is turned ON, a

power-on self-diagnostic test is Booting up…

performed and the following message

appears on the operation panel’s LCD.

Notes

INITIALIZING...

• Explain to the users that except for PLEASE WAIT

emergency the printer power must be

turned OFF only while “PRINT” is

indicated on the LCD. If the power is

turned OFF during “INITIALIZING”

or “CLEANING,” ink drooling or print

head damage may occur, or even the

parameter settings may be lost.

• If an error is detected during the

self-diagnostic test at power on, an

error message appears on the LCD.

Solve the problem following the error

message.

• Note that the operation cannot be

reversed after completing with the

procedure below. To change the

setting, shut down the printer, and

restart the operation.

a) With and keys #LANGUAGE

select the language to be

*ENGLISH

displayed on the operation panel,

and press key.

・ENGLISH

・FRANCAIS

・ITALIANO

・DEUTSCH

・ESPANOL

・PORTUGUeS

・JAPANESE

4-40

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

b) Press key. #LANGUAGE

*ENGLISH OK?

c) With and keys #TIME ZONE (GMT+)

select the time zone of the country

where the printer is operated. *YY/MM/DD HH:MM +00

d) Press key. #TIME ZONE (GMT+)

*YY/MM/DD HH:MM +12

e) Press key.

#TIME ZONE (GMT+)

*YY/MM/DD HH:MM +OK?

f) With and keys #LENGTH UNITS

select the unit of the length.

*INCH

g) Press key. #LENGTH UNITS

*MILLIMETER

h) Press key. #LENGTH UNITS

>MILLIMETER OK?

i) With and keys #TEMPERATURE UNITS

select the unit of the temperature.

*FAHRENHEIT

j) Press key. #TEMPERATURE UNITS

*CENTIGRADE

k) Press key. #TEMPERATURE UNITS

>CENTIGRADE OK?

4-41

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

l) With and keys

#NO. OF INK COLORS

select the ink color mode, 4-color

or 8-color. *8 COLORS

m) Press key. #NO. OF INK COLORS

*8 COLORS OK?

INITIALIZING...

PLEASE WAIT

10. After the initialization, the right OPEN SUBCART COVER

message is indicated.

CCC LOAD SUBCART

After confirming the message above

appears, with a dropper, apply the cap

cleaning liquid to the subcartridge's

two spout holes.

Note

Do not omit this step, or the ink may leak

from the spout hole.

Spout hole

11. Set the subcartridges.

PRINTER READY

ROLL:XXXX/YYYYYY

4-42

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.5 Filling an Initial Ink

The initial ink filling is required only when the printer is installed for the first time.

Notes

• Do not release the pressure control knob, nor open the front cover.

• When the ink filling is suspended by some reason such as ink running out or pressure

control knob error, do not continue the ink filling operation. If it is continued, waste ink

may overflow from the waste ink bottle.

When it is suspended, terminate the ink filling with the either of the two operations

below.

1. Set a new subcartridge and start the ink filling again.

2. Supply the ink from the ink pack. For the procedure,

refer to "Supplying ink from ink pack" described in "4.7 Completing Installation."

1. Press key on the

operation panel to enter offline mode.

2. Repeat pressing key until ∧REWIND FORM FEED ∨

"PH.MAIN" menu is displayed.

<PH.REC PH.MAIN>

3. Press key to select "INK #CAP CLEANING

SYSTEM OPT" menu. >

4. Press key to select "INK #INK SYSTEM OPT

SYSTEM OPT" menu, and press >STORE INK SYS

key.

#INK SYSTEM OPT

5. Press key to select "INITIAL *INITIAL CHARGE

CHARGE".

6. Press key. #INK SYSTEM OPT

*BOTTLE OK?

7. Confirm that a waste ink bottle was OPEN

installed, and press key.

SUBCARTRIDGE COVER

8. Remove the subcartridge cover. LOAD SUBCARTRIDGE

LOAD CCC SLOT

4-43

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

9. Set the subcartridges. CLOSE

SUBCARTRIDGE COVER

10. Set the subcartridge cover. OPEN

INK COVER

11. Open the ink box cover. LOAD

DUMMY INKPACK

12. Set the dummy ink packs. CLOSE

INK COVER

13. Close the ink box cover. START INK CHARGING

*BOTTLE OK?

14. Confirm that a waste ink bottle was CHARGING INK

installed, and press key. PLEASE WAIT XXX

Subcartridges and ink delivery system #INK SYSTEM OPT

below the subcartridges are filled with

ink. Then normal cleaning operation is *INITIAL CHARGE

completed.

4-44

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.6 Checking Printer Operation

4.6.1 Setting parameters

After turning the printer on, set parameters according to the user’s operating environment

referring to IP-7900 User’s Guide, “Section 3 Menu operation on the operation panel”:

“Explanation of each menu operation”

4.6.2 Adjusting sensors for roll feed unit and take-up reel unit

After turning on the printer and setting the parameters, adjust the light sensors below.

Sensors in the printer’s roll feed unit side

- Two light-emitting units on the drive unit’s side face

- Two light-receiving units on the beam.

Sensors in the printer’s take-up reel unit side

- One light-emitting units on the beam

- Two light-receiving unit on the drive unit’s side face

(1) Adjusting supply-side media end sensor

Adjust the supply-side media end sensor’s light-emitting direction with the procedure

below.

1. Remove the cover of the supply-side

media end sensor’s light-emitting units.

2. Remove the connector of the

supply-side media slack sensor’s

light-emitting unit. Note that the media

slack sensor position is lower than the

media end sensor.

3. By rotating the pan-head machine

screws, adjust the upper and lower

lighting-receiving units to the positions

to receive the emitted lights. Note that

at the correct position the red LED is

ON.

4. Gradually tighten the adjusting screw

until the media slack sensor’s

light-receiving unit does not receive

the emitted light. Note that the media

4-45

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

slack sensor position is lower than the

media end sensor.

5. Tighten the adjusting screw

additionally by XXX(T.B.D)turns.

6. Confirm that the media end sensor’s

light-receiving unit receives the emitted Screw to adjust the media end

light. Note that the media end sensor is sensor's light-emitting unit direction

upper than the media slack sensor.

Then put the connector removed at the

step 2 back in place. Media end sensor's light emitting

unit

Media slack sensor’s light

7. Put the cover back in place. emitting unit

Media end sensor’s light-receiving

unit (The LED goes on when the

step 3 is completed.)

Media slack sensor’s light-receiving

unit (The LED goes on when the

step 4 is completed.)

(2) Adjusting supply-side media slack sensor

Check the media slack sensor position, and adjust it just as repeating the procedure to

adjust the media end sensor.

4-46

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

(3) Adjusting takeup-side media slack sensor

Takeup-side media slack sensor detects the media slack at the high limit position and the

low limit position. Adjust the sensor’s light-receiving direction with the procedure below.

1. Remove the cover of the takeup-side

media slack sensor’s light-receiving

unit.

2. Loosen the adjusting screw of the

light-receiving unit.

3. Gradually tighten the adjusting screw

until the sensor fixing sheet metal is

loosened. Then tighten the screw by

one turn.

4. Fix the light emitting unit at the lowest

fixing position.

5. By selecting “MAINTENANCE MODE,”

“SENSORS,” and “TUR SENSORS”

with the operation panel, confirm that

the emitted light is received by the high

limit light-receiving unit and the low

limit light-receiving unit.

6. If the light is not received, tighten the

adjusting screw gradually until the light

is received.

7. Fix the light-emitting unit at the highest

fixing position.

8. By selecting “MAINTENANCE MODE,”

“SENSORS,” and “TUR SENSORS”

with the operation panel, confirm that

the emitted light is received by the high

limit light-receiving unit and the low

limit light-receiving unit.

9. If the light is not received, tighten the

adjusting screw gradually until the light

is received.

10. Repeat the steps 4 to 9 until both the

high limit light-receiving unit and the

low limit light-receiving unit correctly

4-47

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

receive the emitted light if the

light-emitting unit is fixed at the highest

position or the lowest position.

11. Fix the light-emitting unit at the second

position from the top.

NOTE

The upper and lower adjusting screws at the sensor fixing sheet metal do not require

adjustment.

Media slack upper limit sensor’s

light-receiving unit

Media slack lower limit sensor’s

light-receiving unit

Media slack sensor’s

light-emitting unit

4-48

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.6.3 Checking printer operation without connecting to host

computer

Print the patterns below to check the printer operation.

● Nozzle check pattern

● Mechanical check pattern (to check the nozzle position and the print head tilt)

(1) Printing nozzle check pattern

1. Press key on the

operation panel to enter offline mode.

2. Press the , , MAINTENANCE MODE

, and keys in PASSWORD?

sequence.

(When the key was

pressed, the buzzer sounds to notify

the user that the pressed key is invalid;

however, after this, the user can shift to

the password entry state.)

3. Press the , ,

, and keys in sequence.

4. Repeat the key until ∧PRINTER SETUP∨

"ADJUST" menu is displayed. <ADJUST HEATER>

5. Press the key to select #TEST PRINTS

"ADJUST" menu. >NOZZLE PRINT

4-49

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

6. Press key to select "TEST

PRINTS".

7. Press key to select "CHECK #TEST PRINTS

NOZZLE".

>CHECK NOZZLE

8. Press key. #TEST PRINTS

*OK?

9. By pressing key, print the

#TEST PRINTS

nozzle check pattern.

*EXECUTING

Print output

M K C Y direction

Lg Lc GY Lm

10. With magnifier (x10) inspect the whole

print, and confirm that no nozzleout is

found on the pattern in each color.

If a problem is found, solve it with

adjustment referring to “Maintenance

Manual.”

4-50

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

(2) Printing mechanical check pattern

By selecting “CHECK MECHANICAL” with the procedure below, the print patterns to

check the print head tilt and nozzle position are printed at the same time.

1. Enter the maintenance mode.

(See the previous item.)

2. Repeat pressing key until

∧PRINTER SETUP∨

"ADJUST" menu is displayed.

<ADJUST HEATER>

3. Press key to select "ADJUST"

#TEST PRINTS

menu.l

>NOZZLE PRINT

4. Press key to select "TEST

PRINTS".

5. Repeat key until "CHECK #TEST PRINTS

MECHANICAL" is diaplayed.

>CHECK MECHANICAL

6. Press key. #TEST PRINTS

*OK?

7. Press key. #TEST PRINTS

*EXECUTING

8. Check the printed patterns. When no

problem is found with the patterns, no

adjustment is required.

If any problem is found with the

patterns, adjust the print head phase

and tilt. Repeat the steps 1 to 8 until no

problem is found with the patterns.

4-51

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

d)

a)

e)

b)

a)

f)

c)

b)

c)

Print head tilt check pattern with eight colors Nozzle position check pattern with eight colors

<Tilt check and adjustment> <Nozzle position check and adjustment>

a): Printed at the first swath d): Printed to check front-side print head

b): Printed at the second swath: e): Printed to check dual lines :

c): Printed at the third swath f): Printed to check rear-side print head

a) and b) overlap each other with 9.0mm.

b) and c) overlap each other with 9.0mm.

The print head tilt will causes the two vertical lines

while they should be one vertical lines. So adjust

the print head tilt so that the two vertical lines At the part e), confirm that no misalignment is

overlap to be one straight line. found with K and Gy lines.

At the part d), confirm that no misalignment is

[NG] [OK] found with K line and each of C, M, and Y lines.

At the part f), confirm that no misalignment is found

with Gy and each of Lc, Lm, and Lgy.

Adjust the phase by setting the tool at Gy print

head so that Gy line pattern matches K line

pattern.

4-52

Downloaded from www.Manualslib.com manuals search engine

SIIT CONFIDENTIAL

Section 4 Unpacking, Transportation and Installation

4.6.4 Connecting with host computer

NOTES

• For USB connection, apply USB2.0 cable.

• For hub connection, apply hubs supporting USB2.0.

• For USB connection, apply the USB-certified cables and hubs. The products to be

connected to the USB system must also be USB-certified. Failure to use the

USB-certified products may lead a printer malfunction.

• Apply the cable of 5m or less in length. When the connection exceeds 5m, apply hubs.

At the hub cascade connection, five cascades are the maximum number. The

connection with a cable exceeding 5m or without hub cascade connection may lead a

printer malfunction.