TechTips - Vol3 - Iss3 - Inadequate Lube PT 1 of 3 PDF

Diunggah oleh

grupa2904Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TechTips - Vol3 - Iss3 - Inadequate Lube PT 1 of 3 PDF

Diunggah oleh

grupa2904Hak Cipta:

Format Tersedia

SOLUTIONS FOR THE

AUTOMOTIVE INDUSTRY

VOLUME 3 • ISSUE 3

Maximizing bearing performance and life remains an objective throughout The Timken Company, from design teams

and manufacturing associates to our field sales team and distributors. TechTips help you install and maintain Timken®

bearings, seals and components to maximize their life and performance and the systems in which they operate. For

more information regarding Timken automotive products and services, visit www.timken.com or contact your local

Timken distributor.

Part 1 of a 3-Part Series

INADEQUATE GREASE LUBRICATION IN BEARINGS:

OVERFILLING AND UNDERFILLING

The life of a Timken® bearing depends to a great extent on the oxidation (breakdown) rate of the grease sharply increases

proper lubrication of the bearing. Lubricants aid in carrying – doubling every 18º F.

away heat, protecting bearing surfaces from corrosion and

*NOTE: During initial start-up, it is common for a properly lu-

reducing friction.

bricated bearing to purge a small amount of grease. A slight

Statistics show that nearly 50 percent of all bearing dam- grease purge is often recommended by original equipment

age can be attributed to inadequate lubrication. Although a manufacturers, as it acts as a barrier seal to help keep out

very broad term, inadequate lubrication can be classified into external debris contamination (Fig. 1). Always follow origi-

eight basic categories: 1) overfilling, 2) underfilling, 3) incor- nal equipment manufacturers’ recommendations regarding

rect grease, 4) mixing greases, 5) incorrect lubrication sys- grease purging and correct replenishment amounts.

tems and intervals, 6) worn-out grease, 7) water contamina-

An overfilled bearing may also purge grease during initial

tion, and 8) debris contamination.

start-up. However, over time and as temperature rises, ex-

The following offers a quick reference to two of these eight cess grease will continue to purge from an overfilled bearing

basic categories: overfilling and underfilling. and have a darkened color (Fig. 2).

Fig. 1- ‘Clean’ grease slight-

Overfilling ly purging (leaking) from a

Overfilling a bearing with too much grease can cause excess bearing during initial start-

churning of the grease during operation and high tempera- up is generally acceptable.

tures, resulting in overheating and excess grease purging* The grease is wet and even-

(leaking). Overheating occurs because the heat generated ly purged. If this slight purge

cannot dissipate correctly, continually building until damage is not causing any problems, leave it alone as it is an effective

occurs. As the operating temperature of the bearing rises, the barrier seal.

Fig. 2- A petri dish containing Effects of Inadequate Grease Lubrication

heavily oxidized grease, which in Bearings

purged from an overfilled bear-

ing. Grease undergoing heavy

oxidation often has a very dis-

tinguishable black color and Ball bearing inner race (above)

burned odor. In addition, it and outer race (below) burn-

gets stiffer in composition. up: metal-to metal contact

from breakdown of lubricant

Underfilling film.

Underfilling a bearing with grease can also have adverse con-

sequences. As in overfilling, heat can be generated but for

different reasons. When the grease amount is low, a grease

starvation condition may be created, causing heat generation

Tapered roller bearing cone

or excessive metal wear during operation. If a bearing sud-

large rib face deformation:

denly becomes noisy and/or the temperature increases, ex-

Metal flow from excessive

cessive wear may be taking place.

heat generation.

Fig. 3 - Grease removed from

Cylindrical bearing outer race

an underfilled bearing show-

and rollers with peeling and

ing shiny bearing metal debris.

moderate wear due to under-

filling of lubricant.

WARNING:

• Proper maintenance and handling practices are critical. Failure to follow installation instructions and

maintain proper lubrication can result in equipment failure, creating a risk of serious bodily harm.

• Never spin a bearing with compressed air. The rollers may be forcefully expelled creating a risk of serious bodily harm.

TechTips is not intended to substitute for the specific recommendations of your equipment suppliers.

Timken® is the registered trademark of

The Timken Company.

www.timken.com

© 2005 The Timken Company

Printed In the U.S.A.

70M-04-05-7 Order No. 7713

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Shades Eq Gloss Large Shade ChartDokumen2 halamanShades Eq Gloss Large Shade ChartmeganBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Acute Leukemia The Scientist's Perspective and ChallengeDokumen438 halamanAcute Leukemia The Scientist's Perspective and ChallengemedskyqqBelum ada peringkat

- RENK Slide Bearings Type EDokumen20 halamanRENK Slide Bearings Type Eagnostic0750% (2)

- Renk Slide Bearings Foot Mounted ER EG 34-45 SizesDokumen8 halamanRenk Slide Bearings Foot Mounted ER EG 34-45 Sizesgrupa2904Belum ada peringkat

- Renk Slide Bearings Type EFDokumen6 halamanRenk Slide Bearings Type EFgrupa2904100% (1)

- Credit Risk ManagementDokumen64 halamanCredit Risk Managementcherry_nu100% (12)

- My Activities in Module 2Dokumen7 halamanMy Activities in Module 2Devine Gabat100% (6)

- Ariete Multi Vapor Compact 4146Dokumen2 halamanAriete Multi Vapor Compact 4146grupa2904Belum ada peringkat

- Irb Ball Joints 2016Dokumen1.245 halamanIrb Ball Joints 2016Paulo Antonio Mora RojasBelum ada peringkat

- Irb Needle Roller Bearings 2016Dokumen6 halamanIrb Needle Roller Bearings 2016grupa2904Belum ada peringkat

- GBC About News Jun2011 r5Dokumen6 halamanGBC About News Jun2011 r5grupa2904Belum ada peringkat

- Why Choose Rexnord?: Valuable ExpertiseDokumen4 halamanWhy Choose Rexnord?: Valuable Expertisegrupa2904Belum ada peringkat

- BR5 015 Link Belt S Series Intermediate Duty Ball Bearings FAQs Product SheetDokumen4 halamanBR5 015 Link Belt S Series Intermediate Duty Ball Bearings FAQs Product Sheetgrupa2904Belum ada peringkat

- Inch Series Ball BearingsDokumen1 halamanInch Series Ball Bearingsgrupa2904Belum ada peringkat

- Renk Slide Bearings Type HGDokumen4 halamanRenk Slide Bearings Type HGgrupa2904Belum ada peringkat

- SKF Tih220m ManualDokumen116 halamanSKF Tih220m Manualgrupa2904Belum ada peringkat

- Why Choose Rexnord?: Valuable ExpertiseDokumen4 halamanWhy Choose Rexnord?: Valuable Expertisegrupa2904Belum ada peringkat

- BR5 013 Link Belt Klean Gard Ball Bearings FAQs Product SheetDokumen4 halamanBR5 013 Link Belt Klean Gard Ball Bearings FAQs Product Sheetgrupa2904Belum ada peringkat

- BR5 014 Link Belt S, W Series Intermediate Duty Ball Bearings Product SheetDokumen2 halamanBR5 014 Link Belt S, W Series Intermediate Duty Ball Bearings Product Sheetgrupa2904Belum ada peringkat

- Slide Bearings Type E Series EF PDFDokumen6 halamanSlide Bearings Type E Series EF PDFharosalesvBelum ada peringkat

- 1046311Dokumen6 halaman1046311Jose Antonio VazquezBelum ada peringkat

- Slide Bearing For Electricar Machines BrochureDokumen6 halamanSlide Bearing For Electricar Machines BrochureGabriel BolívarBelum ada peringkat

- Renk Slide Bearings Type GDokumen6 halamanRenk Slide Bearings Type Ggrupa2904Belum ada peringkat

- 3/14/2012 Quote Tabulation (09/12/2011) Page 1 of 1Dokumen1 halaman3/14/2012 Quote Tabulation (09/12/2011) Page 1 of 1grupa2904Belum ada peringkat

- NTN Linear Ball BushingsDokumen84 halamanNTN Linear Ball Bushingsgrupa2904Belum ada peringkat

- Link Pumps Equipment Datasheet: Pump Number: PCE736Dokumen2 halamanLink Pumps Equipment Datasheet: Pump Number: PCE736grupa2904Belum ada peringkat

- NTN Linear ModulesDokumen136 halamanNTN Linear Modulesgrupa2904Belum ada peringkat

- SKF Standard Jaw Pullers TMMP MRODokumen2 halamanSKF Standard Jaw Pullers TMMP MROgrupa2904Belum ada peringkat

- SKF Standard Jaw Pullers TMMP MRODokumen2 halamanSKF Standard Jaw Pullers TMMP MROgrupa2904Belum ada peringkat

- NTN Linear Axis RangeDokumen2 halamanNTN Linear Axis Rangegrupa2904Belum ada peringkat

- NTN Linear Axis NewsDokumen54 halamanNTN Linear Axis Newsgrupa2904Belum ada peringkat

- NTN Wireless Linear Measuring SystemDokumen12 halamanNTN Wireless Linear Measuring Systemgrupa2904Belum ada peringkat

- Timken Dial IndicatorDokumen2 halamanTimken Dial Indicatorgrupa2904Belum ada peringkat

- Timken Induction Heater VHIN900Dokumen2 halamanTimken Induction Heater VHIN900grupa2904Belum ada peringkat

- Eco EssayDokumen3 halamanEco EssaymanthanBelum ada peringkat

- Modular ResumeDokumen1 halamanModular ResumeedisontBelum ada peringkat

- Florida Gov. Ron DeSantis Provides Update As Hurricane Ian Prompts EvDokumen1 halamanFlorida Gov. Ron DeSantis Provides Update As Hurricane Ian Prompts Evedwinbramosmac.comBelum ada peringkat

- Yojananov 2021Dokumen67 halamanYojananov 2021JackBelum ada peringkat

- DISTRICT CENSUS HANDBOOK North GoaDokumen190 halamanDISTRICT CENSUS HANDBOOK North Goants1020Belum ada peringkat

- So Tim Penilik N10 16 Desember 2022 Finish-1Dokumen163 halamanSo Tim Penilik N10 16 Desember 2022 Finish-1Muhammad EkiBelum ada peringkat

- Gifted Black Females Attending Predominantly White Schools Compressed 1 CompressedDokumen488 halamanGifted Black Females Attending Predominantly White Schools Compressed 1 Compressedapi-718408484Belum ada peringkat

- Vignyapan 18-04-2024Dokumen16 halamanVignyapan 18-04-2024adil1787Belum ada peringkat

- Sinamics g120 BrochureDokumen16 halamanSinamics g120 BrochuremihacraciunBelum ada peringkat

- USA Nozzle 01Dokumen2 halamanUSA Nozzle 01Justin MercadoBelum ada peringkat

- Knitting in Satellite AntennaDokumen4 halamanKnitting in Satellite AntennaBhaswati PandaBelum ada peringkat

- British Birds 10 LondDokumen376 halamanBritish Birds 10 Londcassy98Belum ada peringkat

- The Global Entrepreneurship and Development Index 2014 For Web1 PDFDokumen249 halamanThe Global Entrepreneurship and Development Index 2014 For Web1 PDFAlex Yuri Rodriguez100% (1)

- Mehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Dokumen294 halamanMehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Alexandra KoehlerBelum ada peringkat

- Module 4 How To Make Self-Rescue Evacuation Maps?Dokumen85 halamanModule 4 How To Make Self-Rescue Evacuation Maps?RejieBelum ada peringkat

- Altura Architect & Interior Design BriefDokumen56 halamanAltura Architect & Interior Design BriefDave WongBelum ada peringkat

- Image Hosting SitesDokumen16 halamanImage Hosting SitesstudentBelum ada peringkat

- BBO2020Dokumen41 halamanBBO2020qiuBelum ada peringkat

- 30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Dokumen64 halaman30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Trần MaiBelum ada peringkat

- APRStt Implementation Notes PDFDokumen36 halamanAPRStt Implementation Notes PDFCT2IWWBelum ada peringkat

- Corporate Valuation WhartonDokumen6 halamanCorporate Valuation Whartonebrahimnejad64Belum ada peringkat

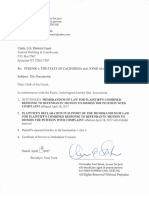

- STRUNK V THE STATE OF CALIFORNIA Etal. NYND 16-cv-1496 (BKS / DJS) OSC WITH TRO Filed 12-15-2016 For 3 Judge Court Electoral College ChallengeDokumen1.683 halamanSTRUNK V THE STATE OF CALIFORNIA Etal. NYND 16-cv-1496 (BKS / DJS) OSC WITH TRO Filed 12-15-2016 For 3 Judge Court Electoral College ChallengeChristopher Earl Strunk100% (1)

- Quarter 4 Week 1 EnglishDokumen62 halamanQuarter 4 Week 1 EnglishJanine Jordan Canlas-BacaniBelum ada peringkat

- Demand Determinants EEMDokumen22 halamanDemand Determinants EEMPrabha KaranBelum ada peringkat

- Datalogic tl46 A Manual - 230104 - 140343Dokumen2 halamanDatalogic tl46 A Manual - 230104 - 140343Emmanuel Baldenegro PadillaBelum ada peringkat

- Andromeda: Druid 3 Warborn06Dokumen5 halamanAndromeda: Druid 3 Warborn06AlanBelum ada peringkat