Annex-D Equipment BSMarE PH

Diunggah oleh

Lorenzo Romero Dela CruzDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Annex-D Equipment BSMarE PH

Diunggah oleh

Lorenzo Romero Dela CruzHak Cipta:

Format Tersedia

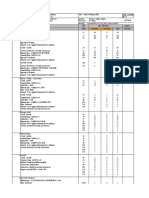

Bachelor of Science in Marine Annex D

Engineering CMO No. 67, S. 2017

Revision No: 00

Revision Date: 00

Minimum Required Equipment

RECOMMENDED MINIMUM EQUIPMENT, MATERIALS, CHEMICALS AND

TEACHING AIDS GOVERNING THE OPERATION OF THE BACHELOR OF

SCIENCE IN MARINE ENGINEERING PROGRAM. HOWEVER, THE EXACT

NUMBER SHOULD CONFORM TO THE CARRYING CAPACITY OF THE

INSTITUTION. THE TASK MAINTENANCE REPAIR COLUMN ARE USED FOR

HANDS ON EXERCIS ES AND FAMILIARIZATION OF EQUIPMENT, WHEREAS

THE SYSTEM INTEGRATION, OPERATION AND FAULT FINDING COLUMN ARE

EQUIPMENT NECESSARY TO ADDRESS THE DEFINED INTENDED LEARNING

OUTCOMES OF COURSES.

Task Maintenance and Repair System

Integration,

Course

Key Area Quantity Operation

Equipment Required and Fault

Finding

1. Mach 1 Mechanical Workshop

Mach 2 1.1. Work benches fitted with vise on 6 sets

Mach 3 each end

1.2. Gas welding equipment 6 sets

accessories and PPE 1 torch

/cubicle

1.3. Electric, arc welding equipment, 6 sets

accessories and PPE 1 machine

/cubicle

1.4. Pedestal grinder 3 units

1.5. drilling machine (approx. 35 mm 3 units

min. Diameter drill capacity)

1.6. Electric power hand drill with at 6 units

least 10 mm diameter drilling

capacity

1.7. Electric power hand 4 units

grinder/cutter

1.8. Metal cutting shear (snip) 6 sets

1.9. Anvil 6 pcs

1.10. Inside and outside steel vernier 6 pcs

caliper

1.11. Inside and outside micrometers 6 pcs

1.12. Depth gauge caliper 6 pcs

1.13. Dial micrometer with magnetic 4 sets

base

1.14. Steel ruler 6 pcs

1.15. Flat Chisel 12 pcs

1.16. Cross-out chisel 12 pcs

Annex D BSMarE Page 1 of 7

Task Maintenance and Repair System

Integration,

Course

Key Area Quantity Operation

Equipment Required and Fault

Finding

1.17. Diamond point chisel 12 pcs

1.18. Round nose chisel 12 pcs

1.19. Center punch, 60 mm 12 pcs

1.20. Center punch, 90mm 12 pcs

1.21. Hacksaw 6 pcs

1.22. Tap and dies 6 pcs

1.23. Die nuts 6 pcs

1.24. Wrench, socket type, 10mm to 6 sets

24mm

1.25. Wrench, open type (metric), 10 6 sets

mm to 24mm

1.26. Combination Wrench, open- 6 sets

close type (metric), 10 mm to

24mm

1.27. Double-cut rough files 12 pcs

1.28. Second-cut smooth files 12 pcs

1.29. Single-cut smooth files 12 pcs

1.30. Second cut files 12 pcs

1.30. Second cut files 12 pcs

1.31. Machinist’s combination set 12 pcs

1.32. Try square (steel) 12 pcs

1.33. Protractor (steel) 12 pcs

1.34. Dividers (steel) 12 pcs

1.35. Sledge hammer (various sizes, 6 pcs

steel/wooden)

1.36. Ball peen hammer 12 pcs

1.37. Straight peen hammer (various 12 pcs

sizes)

1.38. Tongs (various sizes) 12 pcs

1.39. Pliers, mechanical (various 12 pcs

sizes)

1.40. Screw driver, Philips, various 12 pcs

sizes

1.41. Screw driver, flat, various sizes 12 pcs

1.42. Vise grip 6 pcs

1.43. Feeler gauge (metric/inches) 6 pcs

1.44. Pitch gauge 6 pcs

1.45. Drill bit, 13-25 mm, tapered 6 pcs

shank

1.46. Drill bit, 15-30 mm, cylinder 3 pcs

shank

1.47. Drift punch 6 pcs

Annex D BSMarE Page 2 of 7

Task Maintenance and Repair System

Integration,

Course

Key Area Quantity Operation

Equipment Required and Fault

Finding

1.48. Lockers for storing personal

belongings

1.49. Washing facility

1.50. Scrap disposal containers 1 in

workshop

area

1.51. 150 mm swing lathe machine 6 sets

with accessories

1.52. Shaper (350mm travel) with 1 set

accessories

1.53. Milling machine (horizontal, 1 set

vertical or universal) with

cutting tools and accessories

1.74. Hydraulic pipe bender with 1 set

accessories

1.75. Pipe wrench various sizes 2 sets

1.76. Grease gun 2 sets

1.77. Oil applicator 2 sets

1.78. Wire gauge 2 sets

1.79. Surface gauge 2 sets

1.80. Blow torch 2 sets

1.81. Reamer handset, assorted 2 sets

1.82. Torque wrench 2 sets

1.83. Pipe cutter and threading tools 2 sets

2. Marine Marine Diesel engine-complete for 1 set Marine Diesel

Diesel dismantling with the following Engine

components: (operational)

• Cylinder liner with auxiliaries

or ERS

• Fuel valve/injector

Category 3.

• Cylinder relief valve

• Air-starting valve/starting

mechanism (not all have ASV)

• Crankcase relief valve

• Jerk fuel valve pump

• Cylinder head

• Turbocharger

• Bearing shells

• Piston and connecting rod

• Engine governor

• Starting system

• Fuel and lube oil filters

Annex D BSMarE Page 3 of 7

Task Maintenance and Repair System

Integration,

Course

Key Area Quantity Operation

Equipment Required and Fault

Finding

3. Auxiliary 3.1. Reciprocating displacement 1 set All items in

Machinery pump item 3 should

be operational

or an ERS

Category 3 that

can be used for

the student to

learn and

demonstrate its

operation

3.2. Gear pump 1 set

3.3. Rotary vane pump 1 set

3.4. Screw displacement pump 1 set

3.5. Centrifugal pump 1 set

3.6. Reciprocating air driven pump 1 set

3.7. Other parts/components: 1 set each

• Gland

• Mechanical Seal

• Drain Cock

• globe valve

• gate valve

• relief valve

• quick closing valve

• change-over valve chest

• mud box (strainer)

• steam trap

• shell and tube cooler

• plate-type cooler

3.8. Reciprocating air compressor (2 1 set

stage or higher) with the

following components

• Cylinder cover

• Piston

• relief valve

• fusible plug

• suction and delivering valve

• water-space safety valve

• bursting disc

3.9. Centrifugal separator/Purifier 1 set

4. Power Plant 4.1. Boiler for demonstration only 1 set Operational

2 – Steam Boiler or ERS

Plant Category 3

4.2. Boiler water test kit 1 set

4.3. Boiler safety valves (for 1 set

dismantling)

Annex D BSMarE Page 4 of 7

Task Maintenance and Repair System

Integration,

Course

Key Area Quantity Operation

Equipment Required and Fault

Finding

5. Refrigeration 5.1 Marine Refrigeration with main 1 set Working model

components or training

module to

demonstrate

the

refrigeration

processes and

operation

5.2. Expansion Valves 4 sets

5.3. Open Type Refrigerating 1 set

Compressor (Complete)

5.4. Oil Separator 1 set

5.5. Thermostat 4 sets

5.6. Pressure switch 5 sets

5.7. Vacuum pump with service 1 set

manifold (Gas Analyzer)

6. Electro- 6.1. Test Measuring Instruments 5 of each 1.Electrical Training

Module for AC

technology circuits

- can simulate

faults for

troubleshooting

2.Electronic

Training Module

- can connect

circuits for

diodes,

transistors,

thyristors and

other

semiconductor

components

3.Motor Control

Module

- can connect 3-

phase ac direct-

on-line,

reversible and

wye-delta motor

starters

- can produce or

insert faults for

troubleshooting

4.Operational 3

phase alternator

with

synchronizing

equipment of

main switch-

board or ERS

Category 3

a. Digital Multi-tester 5 set

b. Analog Multi-tester 5 set

c. Insulation Tester 5 set

d. Analog Clamp Meter 5 set

Annex D BSMarE Page 5 of 7

Task Maintenance and Repair System

Integration,

Course

Key Area Quantity Operation

Equipment Required and Fault

Finding

e. Digital Clamp Meter 5 set

f. Live Line Tester 5 set

7. Automation 7.1 Sample of sensors and other Process

instruments as defined in the Simulator that

curriculum contains

process to be

controlled,

process

transmitter/

sensor,

controller (PID,

PI, PD),

correcting

elements/ final

control

elements

7.2. Differential Pressure Switch 1 set

7.3. Pressostat 1 set

7.4. Thermistor 1 pc

7.5. Thermocouple 1 pc

7.6. 100Ω Resistance Bulb 1 pc

7.7. U-Tube Manometer 1 pc

7.8. Transmitters (Pneumatic & 1 set each

Electric)

Classification of Machinery Simulators

Category 1 Full Mission Simulator A full mission simulator capable of simulating

all machinery operations in engine control

room and machinery spaces, by the use of

operational panels in machinery spaces.

Category 2 Multi Task Simulator A multi task simulator capable of simulating

several machinery operations in engine

control room and machinery spaces, but with

limited use of operational panels in

machinery spaces.

Category 3 Limited Task Simulator A limited task simulator capable of

simulating some machinery operations in

engine control room for procedural training.

Category 4 Special Task Simulator A special task simulator capable of

simulating operation and/or maintenance of

particular machinery equipment, and/or

defined engineering scenarios.

Annex D BSMarE Page 6 of 7

Competencies addressed by the Engine Room Simulator

STCW Category

Competence

Reference 1 2 3 4

Table A-III/1.1 Maintain safe engineering watch

Table A-III/1.3 Use internal communications systems

Operate main and auxiliary machinery and

Table A-III/1.4

associated controls

Operate fuel, lubrication, ballast and other

Table A-III/1.5 pumping systems and associated control

systems

Operate electrical, electronic and control

Table A-III/1.6

systems

Maintenance and repair of electrical and

Table A-III/1.7

electronic equipment

Table A-III/1.11 Maintain seaworthiness of the ship

NOTE:

“The listed equipment is minimal for reference of MHEI’s. Additional equipment

is required based on the Course Specifications of the courses included in the

BSMarE program. MHEI’s are required to demonstrate how Course Outcomes

are evaluated and assessed.”

Annex D BSMarE Page 7 of 7

Anda mungkin juga menyukai

- Measurement While Drilling: Signal Analysis, Optimization and DesignDari EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignBelum ada peringkat

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeDari EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticePenilaian: 4 dari 5 bintang4/5 (9)

- Engine DepartmentDokumen8 halamanEngine DepartmentShem NatullaBelum ada peringkat

- Cpo Curriculum 2014Dokumen9 halamanCpo Curriculum 2014Alagappan ThiyagarajanBelum ada peringkat

- Marine-Engineering-Facilities-and-Equipments-with-pictures - FDokumen23 halamanMarine-Engineering-Facilities-and-Equipments-with-pictures - Fvlad tanBelum ada peringkat

- List of Tools & Equipment: Electronics MechanicDokumen12 halamanList of Tools & Equipment: Electronics Mechanicbal al56Belum ada peringkat

- International Islamic University Islamabad Iqra College of Technology Department of Mechanical TechnologyDokumen9 halamanInternational Islamic University Islamabad Iqra College of Technology Department of Mechanical Technologyfahadfadi48Belum ada peringkat

- MBPP Unit 3 Removal of Turbine Rotor.Dokumen14 halamanMBPP Unit 3 Removal of Turbine Rotor.niko TanBelum ada peringkat

- Dental Lab - TechnicanDokumen6 halamanDental Lab - Technicangaurav chauhanBelum ada peringkat

- Saveetha School of Engineering Saveetha University Department of Automobile Engineering Lab RequirementsDokumen4 halamanSaveetha School of Engineering Saveetha University Department of Automobile Engineering Lab RequirementsKumaran PalaniBelum ada peringkat

- Workshop Practice 1st YearDokumen21 halamanWorkshop Practice 1st YearVIPAN KUMARBelum ada peringkat

- (Ok 9) CranioplastyDokumen6 halaman(Ok 9) CranioplastyAfif Chandra BiroeBelum ada peringkat

- m2 - U3 - Drilling, Reaming & TappingDokumen14 halamanm2 - U3 - Drilling, Reaming & TappingViệt Đặng XuânBelum ada peringkat

- Lists of Laboratory EquipmentDokumen7 halamanLists of Laboratory EquipmentjansenrosesBelum ada peringkat

- Fme6 Activity2 PDFDokumen7 halamanFme6 Activity2 PDFFred BorjaBelum ada peringkat

- MMV Tool and EquipmentDokumen10 halamanMMV Tool and Equipmentrmaryanravi4828Belum ada peringkat

- PDF 30 1Dokumen121 halamanPDF 30 1Madhusudhan DBelum ada peringkat

- Syllabus Workshop Technology (ME453)Dokumen4 halamanSyllabus Workshop Technology (ME453)BISHAL AdhikariBelum ada peringkat

- m2 U9 ScrewcuttingDokumen13 halamanm2 U9 ScrewcuttingViệt Đặng XuânBelum ada peringkat

- Complete ManualDokumen70 halamanComplete ManualAli RazaBelum ada peringkat

- Spur Gear Cutting On Universal Milling MachineDokumen8 halamanSpur Gear Cutting On Universal Milling MachineMurali SiddarthBelum ada peringkat

- Multitool GeneratorDokumen5 halamanMultitool GeneratorКирилл КалюжинBelum ada peringkat

- Laboratory Manual: Mechanical Engineering WorkshopDokumen73 halamanLaboratory Manual: Mechanical Engineering WorkshopNEELIMABelum ada peringkat

- Cure MasterDokumen64 halamanCure MasterSerkan Akşanlı100% (1)

- NO Nama Alat Spesifikasi Gambar Vol Satuan Harga JumlahDokumen5 halamanNO Nama Alat Spesifikasi Gambar Vol Satuan Harga JumlahGapoktan HarapanJayaBelum ada peringkat

- No Nama Alat Spesifikasi Jumlah: Metric General Tacho Dan Dwell Meterbensin General GeneralDokumen1 halamanNo Nama Alat Spesifikasi Jumlah: Metric General Tacho Dan Dwell Meterbensin General GeneralarifBelum ada peringkat

- CHAPTER III (Peping)Dokumen8 halamanCHAPTER III (Peping)Jhon Ciryl M. CalayBelum ada peringkat

- Machine Shop Practice - Volume II, Industrial Press, New York, 1971Dokumen2 halamanMachine Shop Practice - Volume II, Industrial Press, New York, 1971HeroBelum ada peringkat

- Muka Depan FahmiDokumen5 halamanMuka Depan Fahmiabdulthaqifhasif abdulthaqifhasifBelum ada peringkat

- 1792 Brochure LPKF Drilling Milling Routing Tools en PDFDokumen4 halaman1792 Brochure LPKF Drilling Milling Routing Tools en PDFperiodoBelum ada peringkat

- PRM Bench Mill Drill ManualDokumen56 halamanPRM Bench Mill Drill ManualMatthew MattesonBelum ada peringkat

- Basic Workshop ModuleDokumen76 halamanBasic Workshop ModuleTeklu AnbeseBelum ada peringkat

- Down Hole Assembly PDFDokumen13 halamanDown Hole Assembly PDFOvRrj AhmedBelum ada peringkat

- List of Charge Papers NO.2 2019Dokumen11 halamanList of Charge Papers NO.2 2019chanduBelum ada peringkat

- TESDA-OP-CO-03-F04 Rev. No.00-03/08/17Dokumen3 halamanTESDA-OP-CO-03-F04 Rev. No.00-03/08/17Ken FerrolinoBelum ada peringkat

- HPS KosongDokumen3 halamanHPS KosongAdy Surya LesmanaBelum ada peringkat

- CBC Plumbing NC IIDokumen92 halamanCBC Plumbing NC IIFARASAN INSTITUTE100% (1)

- m1 U4 Hole TappingDokumen16 halamanm1 U4 Hole TappingViệt Đặng XuânBelum ada peringkat

- Ypdf PDFDokumen8 halamanYpdf PDFMR SASABelum ada peringkat

- Mohamed Baksh 1036007 Assignment 3Dokumen11 halamanMohamed Baksh 1036007 Assignment 3Mohamed BakshBelum ada peringkat

- Mill Drill Bench Machine MD 20DASH25Dokumen26 halamanMill Drill Bench Machine MD 20DASH25kassa mamoBelum ada peringkat

- EMEA GB 2021 MD MTM Infrared Probing Brochure enDokumen16 halamanEMEA GB 2021 MD MTM Infrared Probing Brochure engarylikeuBelum ada peringkat

- Engineering & Technology Surat) : (C.K.Pithawala College ofDokumen23 halamanEngineering & Technology Surat) : (C.K.Pithawala College of19006 Sahel GamitBelum ada peringkat

- Pneu Module Construction Guide Rev9Dokumen19 halamanPneu Module Construction Guide Rev9zaryab khanBelum ada peringkat

- Digital Portable Hardness Tester MHT - 170Dokumen3 halamanDigital Portable Hardness Tester MHT - 170Omar ShahinBelum ada peringkat

- Tool Room Machine ListDokumen12 halamanTool Room Machine ListsachinBelum ada peringkat

- Fiber Laser Cutting MachineDokumen19 halamanFiber Laser Cutting MachineKerry SaintzBelum ada peringkat

- MYSWEETY CNC Router 3018PRO-User ManualDokumen30 halamanMYSWEETY CNC Router 3018PRO-User Manualmacaar ibrahimBelum ada peringkat

- SR540 ExperimentsDokumen1 halamanSR540 ExperimentsWalter Elias Torales SartiranaBelum ada peringkat

- MGTConstruction CatDokumen16 halamanMGTConstruction CatCesar PantaBelum ada peringkat

- DrillingDokumen28 halamanDrillingsititukiniBelum ada peringkat

- SM300 Manual A4Dokumen23 halamanSM300 Manual A4Igorruzic7Belum ada peringkat

- Pilani Campus: Practice, EDD, BITS PilaniDokumen3 halamanPilani Campus: Practice, EDD, BITS PilaniRitik GuptaBelum ada peringkat

- Spur Gear Cutting On Universal Milling MachDokumen8 halamanSpur Gear Cutting On Universal Milling MachMurali SiddarthBelum ada peringkat

- Juki DLN6390Dokumen52 halamanJuki DLN6390Raza SmartBelum ada peringkat

- English 2 Chip ContractionDokumen3 halamanEnglish 2 Chip ContractionBozkurt EkinBelum ada peringkat

- Later Process Final ReportDokumen12 halamanLater Process Final Reportapi-457642486Belum ada peringkat

- Manual de Uso Grabadora Laser - Eng-InglesDokumen47 halamanManual de Uso Grabadora Laser - Eng-Inglesir.garciadlsBelum ada peringkat

- Summary of Cutting Data For Ext. Cylindrical Surface: Material DetailsDokumen4 halamanSummary of Cutting Data For Ext. Cylindrical Surface: Material DetailsAndrei MihaiBelum ada peringkat

- Annex I Minimum Equipment and Tools RequirementsDokumen4 halamanAnnex I Minimum Equipment and Tools RequirementsCharlane GenalocBelum ada peringkat

- Borrower's SlipDokumen1 halamanBorrower's SlipLorenzo Romero Dela CruzBelum ada peringkat

- Introduction To PhilosophyDokumen8 halamanIntroduction To PhilosophyLorenzo Romero Dela CruzBelum ada peringkat

- Acknowledgement Receipt: Signature Over Printed Name: - DateDokumen1 halamanAcknowledgement Receipt: Signature Over Printed Name: - DateLorenzo Romero Dela CruzBelum ada peringkat

- Per MunicipalityDokumen122 halamanPer MunicipalityLorenzo Romero Dela CruzBelum ada peringkat

- C.0738.PP9.05P - Bulk Piping & Fittings BOQ For Process Water SupplyDokumen4 halamanC.0738.PP9.05P - Bulk Piping & Fittings BOQ For Process Water Supplyfakir mohammadBelum ada peringkat

- Metrology in Chemistry - A Public Task: Gunther DubeDokumen5 halamanMetrology in Chemistry - A Public Task: Gunther DuberubenBelum ada peringkat

- CDMA Principle - Chips & Bits & SymbolsDokumen10 halamanCDMA Principle - Chips & Bits & SymbolsGregory CapellaBelum ada peringkat

- Oracle Projects User Guide For Advanced Services Pms/DmsDokumen185 halamanOracle Projects User Guide For Advanced Services Pms/Dmshelder_tougeiroBelum ada peringkat

- Mitsubishi & Hyundai A4af3, A4bf2Dokumen18 halamanMitsubishi & Hyundai A4af3, A4bf2Alejandro Leyva100% (1)

- Fersa WHU - EN Wheel End Units CVDokumen15 halamanFersa WHU - EN Wheel End Units CVPiotr ZiąbkowskiBelum ada peringkat

- DivX FailureDokumen92 halamanDivX FailureShashidhar BhandaryBelum ada peringkat

- Sm-Volkswagen Tdi 3.0l v6 Diesel Marine Engine Service Repair ManualDokumen29 halamanSm-Volkswagen Tdi 3.0l v6 Diesel Marine Engine Service Repair ManualAlberto60% (5)

- HyperWorks 10.0 Release Notes - Solvers - RADIOSS 10Dokumen11 halamanHyperWorks 10.0 Release Notes - Solvers - RADIOSS 10bsrkaushik1Belum ada peringkat

- College of Technology and Engineering: Department of Civil Engineering Ii Year M.Tech. Ii Semester Session 2015-16Dokumen4 halamanCollege of Technology and Engineering: Department of Civil Engineering Ii Year M.Tech. Ii Semester Session 2015-16ZaidBelum ada peringkat

- Naval Aviation News - Jan 1943Dokumen52 halamanNaval Aviation News - Jan 1943CAP History LibraryBelum ada peringkat

- Raghuveer Singh CVDokumen7 halamanRaghuveer Singh CVSandeepBelum ada peringkat

- Principles of Heat Flow Modelling Stuewe08Dokumen15 halamanPrinciples of Heat Flow Modelling Stuewe08Fahmi BajryBelum ada peringkat

- Aofd2 r2Dokumen387 halamanAofd2 r2ervgBelum ada peringkat

- Chapter 1 Introduction and Basic ConceptsDokumen26 halamanChapter 1 Introduction and Basic ConceptsZafirahAhmadFauziBelum ada peringkat

- An Improved Canny Edge Detection Algorithm Based On Type-2 Fuzzy SetsDokumen5 halamanAn Improved Canny Edge Detection Algorithm Based On Type-2 Fuzzy SetsAbrhamBelum ada peringkat

- 2019 Guard House Detailed EstimateDokumen7 halaman2019 Guard House Detailed EstimateMarianne Sheena Sarah SablanBelum ada peringkat

- Awwa c604-2006Dokumen48 halamanAwwa c604-2006trieu75% (4)

- Beverage Plant - South - UF RO MBR MGF ACFDokumen2 halamanBeverage Plant - South - UF RO MBR MGF ACFAbinash PatroBelum ada peringkat

- B Dporc Unx LNX Guide PDFDokumen112 halamanB Dporc Unx LNX Guide PDFMike TareBelum ada peringkat

- O Level NotesDokumen7 halamanO Level NotesDhanBahadur100% (1)

- Sullair Air Compressor Parts CatalogDokumen96 halamanSullair Air Compressor Parts Catalogedascribd67% (6)

- Sanskruti Brochure - Updated (1) 2Dokumen10 halamanSanskruti Brochure - Updated (1) 2Gaurav RaghuvanshiBelum ada peringkat

- AIR-IQ Install GuideDokumen8 halamanAIR-IQ Install GuideJWBelum ada peringkat

- Big Data Scope and ChallengesDokumen3 halamanBig Data Scope and ChallengesIJRAERBelum ada peringkat

- Gujarat Technological University: Telecommunication Switching Systems and Networks B.E. 6 SemesterDokumen3 halamanGujarat Technological University: Telecommunication Switching Systems and Networks B.E. 6 SemesterRAMSHI CHETARIYABelum ada peringkat

- Reasons, Regulations, and Rules: A Guide To The Validation Master Plan (VMP)Dokumen6 halamanReasons, Regulations, and Rules: A Guide To The Validation Master Plan (VMP)carbouBelum ada peringkat

- BBMP User ManualDokumen135 halamanBBMP User Manualks manjuBelum ada peringkat

- Instrumentation CablesDokumen21 halamanInstrumentation Cablesapi-3713457Belum ada peringkat

- Parts Catalog G080/G367: Ricoh Group CompaniesDokumen148 halamanParts Catalog G080/G367: Ricoh Group CompaniesSerge MaciaBelum ada peringkat