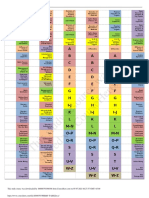

Conversion Factors and Mathematical Symbols Density of Aqueous Inorganic Solutions (With Concentrations) (1 Atm)

Diunggah oleh

Marife dela Cruz0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

62 tayangan6 halamanThis document contains information about physical and thermodynamic properties of various substances. It is divided into multiple chapters that cover topics such as vapor pressure, density, heat transfer, fluid dynamics, and mass transfer. The document appears to be a reference text that provides formulas, data, and concepts related to engineering fields involving physical and chemical changes of state.

Deskripsi Asli:

perry tabs chemical engineering

Judul Asli

Perry Tabs Printing

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document contains information about physical and thermodynamic properties of various substances. It is divided into multiple chapters that cover topics such as vapor pressure, density, heat transfer, fluid dynamics, and mass transfer. The document appears to be a reference text that provides formulas, data, and concepts related to engineering fields involving physical and chemical changes of state.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

62 tayangan6 halamanConversion Factors and Mathematical Symbols Density of Aqueous Inorganic Solutions (With Concentrations) (1 Atm)

Diunggah oleh

Marife dela CruzThis document contains information about physical and thermodynamic properties of various substances. It is divided into multiple chapters that cover topics such as vapor pressure, density, heat transfer, fluid dynamics, and mass transfer. The document appears to be a reference text that provides formulas, data, and concepts related to engineering fields involving physical and chemical changes of state.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

Physical Vapor Pressure

CHAPTER 1 CHAPTER 2 Physical

Properties of Vapor Pressure

Conversion Factors

Derived Common Common Properties of of H2O (Ice,

Physical and Elements and of Inorganic and

and Mathematical Units Conversions Constants Organic Supercooled,

Chemical Data Inorganic Organic Liquids

Symbols Compounds and Liquid)

Compounds

Vapor Density of Aqueous Solubilities of

Vapor Density of Density of Density of Densities of

Pressure of Inorganic Solutions

Aqueous Organic Inorganic Critical

Pressure of Saturated Organic (with

Solutions (with

Miscellaneous

Compounds at

Organic Concentrations) (1 Constants

Solutions Liquid Water Liquids atm) Concentrations) Materials Various Temps

Compounds

Latent Heat (Gamma)= Specific Heat Specific Heat Heat of Enthalpy

(Heats of Heat (Cp/Cv) of Formation of Hf, Gibbs, Thermodynamic Concentration

of Aqueous

Fusion and Capacity (Specific Heat Miscellaneous Inorganic Entropy, Hc Properties of Air Diagram of

Vaporization) Ratio)

Solutions Materials Compounds NaOH

Vapor Viscosity Viscosity Vapor Thermal

Thermodynamic Conductivity

Thermal Viscosity of Prandtl Diffusivity of Diffusivities

(Organic and (Organic and Conductivity

Properties of

Inorganic Inorganic

(Organic and

(Organic and Liquids Number of Pairs of Gases in Liquids

Water Inorganic

Substances) Liquids) Substances)

Inorganic Liquids) (Nomograph) Air (1 atm) (25oC)

Thermal Heat transfer by

Dimensional CHAPTER 5 Conduction Fourier’s Law 5-1, Conduction with Heat

Conductivity CHAPTER 3 Analysis and some CHAPTER 4

Dimensionless Heat and Mass Thermal One dimensional Resistances in Transfer by

of Building Mathematics Thermodynamics Conductivity, Steady Conduction 5-4 Series 5-9, 5-11

Numbers Transfer State Conduction Convection

Materials

Heat Transfer Heat Transfer Radiant

Flow through with Change of Coefficient for Heat

Natural Equations for Forced Emissive powers Energy

Nusselt’s Number tubes banks Phase, film-type Transfer by equation (E)

Convection Convection condensation condensation Interchange

equations coefficients graph

Radiation Q1,2 equation

Hydraulic Diffusivity

Diffusivity Diffusivity Hydraulic

Diameter Mass Fick’s Law 5- Correlations of HTU, NTU,

Emmisivity Correlations Correlations Diameter

Rectangular Transfer 189 Liquids (Tables z(ht)

Duct Equation of Gases 5-14, 5-15) of Solids Equation

Stoke’s Law Volumetric Mass- CHAPTER 6 Viscosity,

Transfer Fluid Equations: Fanning

Terminal Fluid and Kinematic Incompressible

Settling Velocity

Coefficients Dynamics Viscosity

Continuity, Flow

MEB 6-30 Friction, Surface

Equations (K’Ga, Particle Roughness

(k<3.3) Concepts Formulas Bernoulli

KLa) 5-313, 5-314 Dynamics

Fanning

Frictional Frictional loss Mach Equation for Terminal Terminal/Free

Friction, Compressible Dimensionless Settling Velocity,

Loss in Pipes for fittings and Number Compressible Settling Spherical particles

Reynolds, 6-32 Flow Groups

6-89 valves Equation Fluids 6-114 Velocity 6-228, 6-229

– 6-39

Stokes’ Law CHAPTER 7 Rate CHAPTER 8

Michaelis

(k<3.3) 6-232, Half-life 7- Process

Newton’s Law

Reaction constant Reactors Menten Kinetics Process Thermometers

Measurements

4-90 171

(k>4.4) 6-234 Kinetics Equation 7-7 Control

Process CHAPTER 9 Accounting, Estimation of Manufacturing

Capital Cost Cost Indices

Controllers Valves Control and Process Ledgers, cost by – Operating

Estimation Table 9-9 Expenses

Plant Safety Economics Journals capacity 9-1

Straight Line CHAPTER 10 Velocity for

Depreciation, MARR, Net Glossary for Incompressible and Volumetric

Interest Transport and Measurement

Declining Balance Profitability Present Worth Process Compressible Flow Rate

Method 9-10, 9- Formulas Storage of of Flow Fluids in Pitot

9-19, 9-21 Economics 10-12

11 Fluids Tubes 10-13, 10-14

Velocity ratio Discharge Discharge Open Channel

Differential

Coefficient of Coefficient of Area Meters Rectangular and

vs Reynolds Head Meters Coefficient Coefficient Volume Expansion Volume Expansion

Pressure

for Head Meters for Head Meters (Rotameters) Triangular Notch

Number Fig. Flowmeters 10-22 NRe>30000 Fig NRe<30000 Fig Weirs 10-39, 10-

10 -13 10-15 10-16 of gases 10-23 Fig 10-18 10-37, 10-37 40

Pump Adiabatic

NPSH, Pump Performance Piping System

Pumps and Head for Adiabatic Process Plant

Selection Fig Curves Figs. 10- Affinity Laws Compressors Components ,

Compressors 38, 10-39, 10-41, Compressors Calculations Piping

10-24 Joints, Valves

10-56, 10-58 10-73

Design of Storage and LMTD

Properties of Piping Storage of Pressure CHAPTER 11 Overall HTC

Process Vessels Correction

Piping Storage of

Heat-Transfer Factors for Heat

Steel Pipe Systems Gases Vessels 11-1 – 11-4

Systems Liquids Equipment Exchangers

Calculation of Shell and Tube

Overall HTCs Number of Tube Coefficient of

Shell Side Heat Heat

Tables 11-3 – Passes 11-74 - Refrigeration Performance Refrigerants Evaporators

Geometrical Exchangers 11-75

Exchangers

Parameters 11-8 Costing 11-84 -11-87

Arrangement CHAPTER 12 Thermodynamic

Psychrometry,

Saturation Psychrometric Psychrometric Properties of

Psychrometry Psychrometric

BPR of Evaporative Terminologies

Vapor Pressure Equation (Twb is Charts Figs. 12-1 Saturated Air Calculations

Evaporators Cooling, and Solids 12-4 known) 12-11 – 12-4

Drying (RH=100)

Evaporative K (Vapor-Liquid

Clausius- Liquid – Vapor De Priester

Cooling – Drying CHAPTER 13 Distillation Equilibrium ratio) Equilibrium

Clapeyron Equilibrium

13-1, Relative

Charts Fig

Cooling Terminologies Distillation Principles Data Curves

Towers Equation Volatility 13-2 13-9

Single- Stage Isothermal Flash Bubble Point q (thermal

Raoult’s Law McCabe Rectifying Line

Antoine Antoine Equilibrium Distillation and Dew Point condition of the

K Value 13- Equations 13-

Thiele Equation 13-

feed), Feed Line

Equation Constants Flash Equations 13-

11 12, 13-13 Method 21 Equation 13-28

Equations 15, 13-16

Murphree Plate Fenske Petroleum and

Simulation of

Efficiency 13-29, Underwood Kremser Degrees of Distillation Enhanced Complex Mixture

Fenske Equation

Distillation Distillation, Lab

API Gravity

Gilliland Equation Freedom Systems Distillation

13-31, 13-32 Method Processes Distillation Tests

Catalytic Cracking Rayleigh CHAPTER 14 Gas

Design of Gas

Crude Oil Unit, Delayed Batch Equipment for Absorption, HOG, NOG,

coking Unit Figs. Equation Distillation, Gas Absorption KGa Values

Distillation Distillation Absorption, Phase Stripping hT

13-108 13-109 F/W 13-126 Dispersion, and Phase Systems

Separation Definitions

Comparison of

Entrainment Robbins’ Generalized FLGFlow

Tray Common Tray Pressure equation Total Packed Pressure Drop Parameter

Flooding Correlation

Columns types, Tray Drop Pressure Drop Columns Correlation for Trays 14-

Spacing Fig 14-34 14-145 14-140 141

GPDC Random Gilliland and

Packings Fig. 14- Mass Transfer Wetted Sherwood Mist vs. CHAPTER 15

Packing Phase Phase Liquid-Liquid Extraction,

55, Structured Coefficient Wall/ Falling Equation for Spray and Other Liquid-Liquid

Packings Fig. 14- Factors Wetted Wall Dispersion Separation operations and

Fig 14-73 Film Column Definition Equipment

56 Columns 14-171

Separation Factor

Properties of Partition ratio Solvent

Liquid-liquid Extraction 15-14, Minimum Phase Partition

mass fraction,

a Desirable Number of

Partition Ratio and Maximum Screening

Extraction Factor 15-11 Solvent-Feed diagrams Ratio Data

Solvent Stages 15-2, 15-3 Ratio 15-15, 15-15

Methods

Flooding Mass Transfer Power Number

Kremser Equipment

Calculation Ap and for Crawford- Data for Mass Transfer Mass Transfer vs. Impeller

Equation 15- Liquid-liquid Reynolds

Methods Packings Wilke Packed Data for Plates Data for Trays

48 Extraction Correlation Columns Number

Equipment CHAPTER 16 Physical Physical Properties Rate and

Liquid-liquid Adsorption of Ion Exchange Batch Process

Properties of Materials, Sorption Dispersion Chromatography Equipment

Phase and Ion Adsorption Cycles

Separation Adsorbents Equilibrium Factors

Exchange

CHAPTER 17 Fluidized Bed Uses of Dust Efficiency of Some US

Gas-Solid Systems, Gas- Solids gravity

Fluidized Collection Scrubbers Patented Filters

Operation and Types of Separations setting

beds equipment Scrubbers

Equipment Solids chamber 17-1

Average CHAPTER 18 Classification Impeller Power Mixing of Power

Atmospheric Liquid-Solid System for Mixing Viscous Power Number vs

Reynolds Consumption

Dust Operation and mixing Equipment Fluids, Pastes Number Reynolds

Concentration Number 18-1 of Impellers

Equipment Processes and Doughs Number

s

Crystallizer Selection of a

Crystallization Phase Habit Equipment Number of Clarifiers,

Costs, Leaching Thickeners

from Solution Diagrams Modifiers Crystallization Stages 18-45 Parameters

Leaching Process

Area for Inclined Typical Thickener Thickener Continuous Percent Constant

Filtration Theory Minimum Cake

Plate Clarifiers 18- and Clarifier Filtration Batch Pressure

51, Total Design Criteria Costs, (Hagen-Poiseuille

Equations 18-55

Thickness for Remaining Filtration 18-70

Equation 18-54) Discharge Filtration

Clarification Area and Parameter Filtration – 18-59 18-68 – 18-73

Centripetal

Constant Rate Filter Fabric Acceleration,

Cake Porosity 18- Power

Filtration 87 – 18-89, Total

Filtration 18-74 – Filter Media Materials, Filter Prices Centrifuges Centrifugal

Solids Recovery

Consumption

18-76 Equipment Acceleration 18-78,

18-96 – 18-98

Filter Aids 18-79 18-90,18-93

Terminal Velocity Industrial Batch Continuous Concepts Residence

Sedimentation Filtration CHAPTER 19

Centrifuges 18-

Sedimenting Filtering Filtering Expression and Reactor Time of

Centrifuges

Rate 18-119a Reactors

103 Centrifuges Centrifuges Types Reactors

KGa for KGa for

Single Phase Fluid-Solid Fluid-Fluid Moving Bed, Fluid-Fluid

Fixed Bed Kiln Intalox Raschig Rings

Reactors Reactors Reactor Fluidized Bed Reactors

(Absorption) (Absorption

CHAPTER 20 Supercritical

Alternative

Reactor Solid Multiphase Reactor Alternative Crystallization Fluid Membrane

Solid/Liquid

Types Reactors Reactors Types Separation from Melt Separation Separation

Processes Processes Separations

Selection of

Reverse Gas CHAPTER 21

Separation Size Biochemical Particle Size

Osmosis, Microfiltration Separation Pervaporation Solid-Solid

Factor Spectrum Separation Analysis

Nanofiltration Membranes Operations

Processes

Pressure Drop Kick’s,

across Initial fixed Ergun’s Dry Grinding

Solids Size Rittinger’s, Breakage

bed 21-26, Relation 21- Solids Mixing Work Index (Impact and

Handling Kozeny-Carman Reduction Bond’s Laws mode

relation, 21-27

28 21-73 – 21-75 Roller Mills)

Critical Speed Size

Capacity Roll Net Power of Crushing and Principles of Objectives of

Fluid Energy Wet/Dry of Mill 21-92, Enlargement

Crushers 21- driving a ball Grinding Size Size

or Jet Mills Grinding Ball Diameter Methods and

91 21-93 mill 21-94 Practice Enlargement Enlargement Enlargement

Agglomeration Air Pollution

CHAPTER 22 Ambient Air Capital

Rate Net Emission Hazardous Pollution Management

Waste Introduction Quality Recovery

Processes and Increase Air Pollutants Prevention of Stationary

Mechanics Management Standards Factor Sources

Biofilm interface Estimation of

Different pollutant Industrial BOD, COD,

Gaseous Effects of Air Henry’s Wastewater Priority

Types of concentration 22- Wastewater and TOC

Pollutants Pollutants 12, Pollutant Constant 22- characteristics chemicals

Plume stability 22-13 14 Management Relationships

Sources and Density and

Wastewater Management Moisture

Primary Secondary Ion Exchange Sludge Types of Moisture

Treatment of Solid content 22-

Treatment Treatment Resins Processing Industrial Content of

Pretreatment Wastes 26

Wastes some waste

Ultimate Factors in CHAPTER 25 Thermal Melting

Dulong Analysis of Fluid Galvanic Properties of Temperatures

some Industrial

Selecting a Materials of Expansion of some

Formula Corrosion Series Materials

Waste Landfill Site Construction Coefficients common Alloys

Physical and High and Low Chemical Graphite and

Mechanical Thermoplastic

Properties of

Temperature Resistance of Silicon Carbide

Properties

Low Alloy Steels Materials Elastomers Properties

Monod Equations

Volumetric Monod Substrate

Laplace Tyler Mesh Process

Math Fluid Flow Flow Rate 6- Kinetics Equation 7- Inhibition,

Transforms Number Product Inhibition Control

36 92 7-151, 7-152

Feedback loop Clapeyron

Henry’s Heat of

Transfer Chapter 2 Thermo Equation 4- Chapter 2 math Areas

Function 8-48

Constants Solution

140

Minimum Equivalent ht = HOGNOG 14-15,

Reynold’s Diameter HOG Equation,

Chapter12 Chapter 17 Number for

Chapter 6 Equations 6-50

Chapter 14 Colburn Equation

Fluidized Bed – 6-52 14-23

Turbine Transition state,

Conversion

thermo efficiency Kinetics Collision 1, 0.5

7-9 7-20

Wactual/Wtheo

Anda mungkin juga menyukai

- Perry Tabs FinalDokumen5 halamanPerry Tabs FinalCeazar Justine FuluganBelum ada peringkat

- Topics: Psychro. Evaporative, Cooling & Solids Drying Energy Resources Conversion & UtilizationDokumen3 halamanTopics: Psychro. Evaporative, Cooling & Solids Drying Energy Resources Conversion & UtilizationErwin DoloresBelum ada peringkat

- Final Exam Drill 1 Set ADokumen41 halamanFinal Exam Drill 1 Set APrincess Dianne Dug-aBelum ada peringkat

- Module 2. Solutions Thermodynamics - Part 3Dokumen46 halamanModule 2. Solutions Thermodynamics - Part 3VanBelum ada peringkat

- Blank Sticker Tabs TemplateDokumen3 halamanBlank Sticker Tabs TemplateHina OdaBelum ada peringkat

- Tabs (From Zee)Dokumen4 halamanTabs (From Zee)Stefani Ann CabalzaBelum ada peringkat

- Colligative Properties Full ReportDokumen8 halamanColligative Properties Full ReportArnoldus Marzonia MangaoBelum ada peringkat

- (Differential Calculus, Integral Calculus, Differential Equations, Probability and StatisticsDokumen7 halaman(Differential Calculus, Integral Calculus, Differential Equations, Probability and Statisticskimuel demesaBelum ada peringkat

- Chap 1 Workshop HandoutDokumen2 halamanChap 1 Workshop HandoutHenry RodriguezBelum ada peringkat

- Adsorption Review Questions and ProblemsDokumen4 halamanAdsorption Review Questions and ProblemsJohn Bryan Aldovino0% (2)

- Laboratory Exercise #8Dokumen26 halamanLaboratory Exercise #8Yasmin KayeBelum ada peringkat

- Phychem Jul 6,2018Dokumen25 halamanPhychem Jul 6,2018jantskieBelum ada peringkat

- Physical Chemistry Competency ExamDokumen2 halamanPhysical Chemistry Competency ExamRaymond YabutBelum ada peringkat

- Module 2. Solutions Thermodynamics - Part 1Dokumen18 halamanModule 2. Solutions Thermodynamics - Part 1VanBelum ada peringkat

- Aquino Lab04Dokumen18 halamanAquino Lab04Ai RahBelum ada peringkat

- Perrys TabssszDokumen5 halamanPerrys Tabssszeugenio jackz100% (1)

- 05 ChE421 - Multistage OperationsDokumen15 halaman05 ChE421 - Multistage OperationsAllan PaoloBelum ada peringkat

- 96719302871Dokumen41 halaman96719302871yourmomstitsBelum ada peringkat

- Name of Students: Rucha Lokhande, Rucha Dhavale, Prajakta Kulal, Isha Meshram Under Guidance of DR - Tanushree BhattacharjeeDokumen41 halamanName of Students: Rucha Lokhande, Rucha Dhavale, Prajakta Kulal, Isha Meshram Under Guidance of DR - Tanushree BhattacharjeeIsha MeshramBelum ada peringkat

- FLR8 - Unsteady Flow HeadDokumen9 halamanFLR8 - Unsteady Flow HeadElijah SorianoBelum ada peringkat

- University: EBU Nstitute of EchnologyDokumen11 halamanUniversity: EBU Nstitute of EchnologyEllena SitonBelum ada peringkat

- Corr 2018 SRC Analytical Chemistry Module 5 JGDokumen5 halamanCorr 2018 SRC Analytical Chemistry Module 5 JGpaula lunaBelum ada peringkat

- ElectrophoresisDokumen10 halamanElectrophoresisabcdef12333Belum ada peringkat

- Experiment 3 Transference NumberDokumen3 halamanExperiment 3 Transference NumberRicky JayBelum ada peringkat

- Chapter 8Dokumen84 halamanChapter 8Hafizszul FeyzulBelum ada peringkat

- CHEE 321: Chemical Reaction Engineering: Module 3: Isothermal Reactor DesignDokumen16 halamanCHEE 321: Chemical Reaction Engineering: Module 3: Isothermal Reactor DesignPranav NakhateBelum ada peringkat

- Polygon Names and Miscellaneous PropertiesDokumen2 halamanPolygon Names and Miscellaneous PropertieskhumisoBelum ada peringkat

- Chemical Engineering Board Exam PDFDokumen3 halamanChemical Engineering Board Exam PDFJohn Leonard FazBelum ada peringkat

- FR Experiment 3Dokumen7 halamanFR Experiment 3m kimBelum ada peringkat

- 2015 NovemberDokumen13 halaman2015 NovemberAkiBelum ada peringkat

- ChE - Project Design RubricDokumen5 halamanChE - Project Design RubricMadel IsidroBelum ada peringkat

- GX Operating Manual v0.4 EDokumen38 halamanGX Operating Manual v0.4 EBadmaarag JlssBelum ada peringkat

- Exercises For Lecture x2Dokumen8 halamanExercises For Lecture x2Tara EdwardsBelum ada peringkat

- cHEM 26 LE 1 NOTESDokumen3 halamancHEM 26 LE 1 NOTESChrissa GuicoBelum ada peringkat

- orgINORG BIOCHEM RANDOMnotesDokumen21 halamanorgINORG BIOCHEM RANDOMnotesDianne VillanuevaBelum ada peringkat

- PhychmDokumen10 halamanPhychmInie DimaanoBelum ada peringkat

- ChE Calc Recyle Bypass and Purge - 003Dokumen32 halamanChE Calc Recyle Bypass and Purge - 003Julaiza SalazarBelum ada peringkat

- Lecture 4 - Rate Law and StoichiometryDokumen32 halamanLecture 4 - Rate Law and StoichiometryNizam JumadiBelum ada peringkat

- Solution Thermodynamics: Theory: Fundamental Property RelationDokumen6 halamanSolution Thermodynamics: Theory: Fundamental Property RelationLim Ying PeiBelum ada peringkat

- Ch116L: Physical Chemistry (Laboratory) 1 Quarter SY 2019-2020Dokumen8 halamanCh116L: Physical Chemistry (Laboratory) 1 Quarter SY 2019-2020John Andrae MangloBelum ada peringkat

- Chapter 21 Questions 8th Ed.Dokumen5 halamanChapter 21 Questions 8th Ed.Danika PutriBelum ada peringkat

- Particle Technology ProblemsDokumen1 halamanParticle Technology ProblemsGerry Lou QuilesBelum ada peringkat

- Branching Applications: Ch.E. 412: Topic 2dDokumen25 halamanBranching Applications: Ch.E. 412: Topic 2dAriana ReligiosoBelum ada peringkat

- CHEE 321 - Chemical Reaction Engineering - BonneDokumen46 halamanCHEE 321 - Chemical Reaction Engineering - BonneDha OstrIxBelum ada peringkat

- Oxidation of Sulfur and Its CompoundsDokumen6 halamanOxidation of Sulfur and Its CompoundsKeishaBelum ada peringkat

- Organic Chemistry With AnswersDokumen3 halamanOrganic Chemistry With AnswersAhmed HashkarBelum ada peringkat

- Reading Phase Diagrams and ILAR University of The Philippines DilimanDokumen5 halamanReading Phase Diagrams and ILAR University of The Philippines DilimanAcademicBMBelum ada peringkat

- Final Laboratory Report: de La Salle UniversityDokumen15 halamanFinal Laboratory Report: de La Salle UniversityGela EcalBelum ada peringkat

- Chapter 8 - AtkinsDokumen14 halamanChapter 8 - AtkinsLarasati DenaputriBelum ada peringkat

- Reactions of Acid DerivativesDokumen19 halamanReactions of Acid DerivativesnicoBelum ada peringkat

- 9RDRchem26 1Dokumen2 halaman9RDRchem26 1James ChuaBelum ada peringkat

- 03 Equilibria (I)Dokumen11 halaman03 Equilibria (I)David LevisteBelum ada peringkat

- Lecture 1 - Intro of Anal Chem (Compatibility Mode)Dokumen26 halamanLecture 1 - Intro of Anal Chem (Compatibility Mode)Nam NguyenBelum ada peringkat

- Indiabix SummaryDokumen6 halamanIndiabix SummaryMayBelum ada peringkat

- Transference NumberDokumen4 halamanTransference NumberLin Xian Xing50% (2)

- Chem 112.1 - Exer 2 PostlabDokumen7 halamanChem 112.1 - Exer 2 PostlabGerry Mark GubantesBelum ada peringkat

- 05Dokumen18 halaman05gatototBelum ada peringkat

- Physical AND Chemical: Mathema TicsDokumen1 halamanPhysical AND Chemical: Mathema TicsJenny LlanesBelum ada peringkat

- This Study Resource WasDokumen2 halamanThis Study Resource WasAdelaida CruzBelum ada peringkat

- This Study Resource Was: CombustionDokumen3 halamanThis Study Resource Was: CombustionAdelaida CruzBelum ada peringkat

- Srs HP Aug2017Dokumen1 halamanSrs HP Aug2017Marife dela CruzBelum ada peringkat

- Affidavit of LossDokumen1 halamanAffidavit of LossMarife dela CruzBelum ada peringkat

- Philhealth Requirements For Unemployed MembersDokumen1 halamanPhilhealth Requirements For Unemployed MembersAlyssa Clarizze Malaluan75% (12)

- Abstract CpixdhdbdhdudhduDokumen1 halamanAbstract CpixdhdbdhdudhduMarife dela CruzBelum ada peringkat

- UV EXPRESS ROUTE (National Capital Region)Dokumen3 halamanUV EXPRESS ROUTE (National Capital Region)Eric CorbezaBelum ada peringkat

- 2 Term AY 2015-2016: University of Santo TomasDokumen4 halaman2 Term AY 2015-2016: University of Santo TomasMarife dela CruzBelum ada peringkat

- QwertyDokumen1 halamanQwertyMarife dela CruzBelum ada peringkat

- SW-Project-Proposal-Template-2016-rationale MarifeDokumen2 halamanSW-Project-Proposal-Template-2016-rationale MarifeMarife dela CruzBelum ada peringkat

- A A Aaaaaaaaaaaaaaaaaaaaaaaaaa AaaaaaaaaaaaaaaaaaaaaaaaaaDokumen1 halamanA A Aaaaaaaaaaaaaaaaaaaaaaaaaa AaaaaaaaaaaaaaaaaaaaaaaaaaMarife dela CruzBelum ada peringkat

- Inorganic Chem QuestionsDokumen2 halamanInorganic Chem QuestionsMarife dela CruzBelum ada peringkat

- Computation of The Average Density For The Computation of The Mixing TankDokumen6 halamanComputation of The Average Density For The Computation of The Mixing TankMarife dela CruzBelum ada peringkat

- Phychem QuestionsDokumen2 halamanPhychem QuestionsMarife dela CruzBelum ada peringkat

- My Class Schedule - Fall Semester: Time Mon Tue Wed Thu Fri SatDokumen1 halamanMy Class Schedule - Fall Semester: Time Mon Tue Wed Thu Fri SatMarife dela CruzBelum ada peringkat

- Dynamics Assignment 3Dokumen2 halamanDynamics Assignment 3Marife dela CruzBelum ada peringkat

- Dynamics Assignment 3Dokumen2 halamanDynamics Assignment 3Marife dela CruzBelum ada peringkat

- Integ Explanation 16Dokumen1 halamanInteg Explanation 16Marife dela CruzBelum ada peringkat

- 4M03 2012 Day1 Slides PDFDokumen32 halaman4M03 2012 Day1 Slides PDFMarife dela CruzBelum ada peringkat

- Title: HeadingDokumen1 halamanTitle: HeadingMarife dela CruzBelum ada peringkat

- CDFD NewDokumen4 halamanCDFD NewMarife dela CruzBelum ada peringkat

- Lores CoDokumen2 halamanLores CoMarife dela CruzBelum ada peringkat

- Affidavit of LossDokumen1 halamanAffidavit of LossMarife dela CruzBelum ada peringkat

- SW-Project-Proposal-Template-2016-rationale MarifeDokumen2 halamanSW-Project-Proposal-Template-2016-rationale MarifeMarife dela Cruz100% (1)

- CDFDDokumen4 halamanCDFDMarife dela CruzBelum ada peringkat

- DiagramDokumen4 halamanDiagramMarife dela CruzBelum ada peringkat

- DiagramDokumen4 halamanDiagramMarife dela CruzBelum ada peringkat

- Integ Explanation 16Dokumen1 halamanInteg Explanation 16Marife dela CruzBelum ada peringkat

- Name: Section: Answer The Following Questions Truthfully. Use Complete Sentences. Questions Before AfterDokumen2 halamanName: Section: Answer The Following Questions Truthfully. Use Complete Sentences. Questions Before AfterMarife dela CruzBelum ada peringkat

- CMDCFG 3dpaintDokumen1 halamanCMDCFG 3dpaintMarife dela CruzBelum ada peringkat

- App MGR CommandDokumen1 halamanApp MGR CommandMarife dela CruzBelum ada peringkat

- Mineral and Power Resources of Chhota Nagpur RegionDokumen10 halamanMineral and Power Resources of Chhota Nagpur RegionJasvinder Singh0% (1)

- Case Study: Materials For Blood Bags: WWW - Blood.co - UkDokumen6 halamanCase Study: Materials For Blood Bags: WWW - Blood.co - UkBijuChudraponvelilThomasBelum ada peringkat

- ENG MasterGlenium ACE 30 TdsDokumen4 halamanENG MasterGlenium ACE 30 TdsPrateek ModyBelum ada peringkat

- FT-NIR For PIRDokumen13 halamanFT-NIR For PIRDovganBelum ada peringkat

- 66spontaneous BreakagesDokumen4 halaman66spontaneous Breakageschuanhan_tanBelum ada peringkat

- Product Dissection Project BicycleDokumen18 halamanProduct Dissection Project BicycleSaroya ਮੀਤBelum ada peringkat

- Nano SensorsDokumen16 halamanNano SensorsAnkusjBelum ada peringkat

- Acid Rain Explanation TextDokumen2 halamanAcid Rain Explanation TextIndah Dwi Cahayany100% (2)

- HILTI Anchor FasteningDokumen91 halamanHILTI Anchor FasteningkstayroskBelum ada peringkat

- Is 5082 1998 PDFDokumen11 halamanIs 5082 1998 PDFRa Hul0% (1)

- PhysicsDokumen10 halamanPhysicsHuidrom SharatBelum ada peringkat

- Effective Stiffness of Reinforced Concrete ColumnsDokumen9 halamanEffective Stiffness of Reinforced Concrete ColumnsAlberto Ezequiel León TamayoBelum ada peringkat

- Compression Deflection Hardness Chart: Shore OODokumen1 halamanCompression Deflection Hardness Chart: Shore OOAisya IbrahimBelum ada peringkat

- Nano DeBeeDokumen2 halamanNano DeBeeCarmen RaveBelum ada peringkat

- Plastic Raw Material MIS: Date 18-Apr-2022Dokumen3 halamanPlastic Raw Material MIS: Date 18-Apr-2022Office atozBelum ada peringkat

- Experiment 8: Properties of Organic Compounds With Carbonyl GroupDokumen7 halamanExperiment 8: Properties of Organic Compounds With Carbonyl GroupMarita AlcansadoBelum ada peringkat

- GE Engineering Thermoplastics Design GuideDokumen292 halamanGE Engineering Thermoplastics Design GuideLoke Fong67% (3)

- STP 538-1973Dokumen239 halamanSTP 538-1973Tim SchouwBelum ada peringkat

- E Waste Management in INDIADokumen8 halamanE Waste Management in INDIAmachiwalBelum ada peringkat

- Nas 1714Dokumen2 halamanNas 1714YossiBelum ada peringkat

- Safety Data Sheet: 1. IdentificationDokumen6 halamanSafety Data Sheet: 1. IdentificationJessie O.BechaydaBelum ada peringkat

- Guidelines For Sediment Management in Hydropower Projects CWC 2018Dokumen16 halamanGuidelines For Sediment Management in Hydropower Projects CWC 2018ManojBelum ada peringkat

- 04262-En-30 DRBFM Worksheet ExampleDokumen2 halaman04262-En-30 DRBFM Worksheet Examplejefry sitorusBelum ada peringkat

- 2012 Chem E Car Job Safety Form For IHLDokumen13 halaman2012 Chem E Car Job Safety Form For IHLrofiqq4Belum ada peringkat

- BEC008 - MemsnemsDokumen39 halamanBEC008 - MemsnemsACHIEVER MBelum ada peringkat

- Chem Unit 5 Quantitative QuestionsDokumen27 halamanChem Unit 5 Quantitative QuestionsRizam UmerBelum ada peringkat

- Chapter 8Dokumen31 halamanChapter 8helloblarg100% (4)

- Pub 83 Al Bronze Alloys For Industry PDFDokumen24 halamanPub 83 Al Bronze Alloys For Industry PDFpbanerjeeBelum ada peringkat

- Chemlube 215 229 230 501 751 822Dokumen2 halamanChemlube 215 229 230 501 751 822Suprastowo Bin SarinoBelum ada peringkat

- Resins For: Vehicle Refinish & Commercial Transportation CoatingsDokumen6 halamanResins For: Vehicle Refinish & Commercial Transportation CoatingsEmilio HipolaBelum ada peringkat