Extraction of Precious Metals From E-Waste

Diunggah oleh

Razvan MicanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Extraction of Precious Metals From E-Waste

Diunggah oleh

Razvan MicanHak Cipta:

Format Tersedia

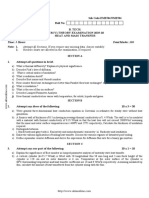

National Seminar on Impact of Toxic Metals, Minerals and Solvents leading to Environmental Pollution-2014

Journal of Chemical and Pharmaceutical Sciences ISSN: 0974-2115

EXTRACTION OF PRECIOUS METALS FROM E-WASTE

A. V. Kavitha*

Lecturer in Computer Science, Govt. College for Women, Guntur.

*Corresponding author: Email: drmuttareddys@gmail.com

ABSTRACT

E-waste is a popular, informal name for electronic products nearing the end of their “useful life. “E-wastes are

considered dangerous, as certain components of some electronic products contain materials that are hazardous, depending on

their condition and density. The hazardous content of these materials pose a threat to human health and environment.

Discarded computers, televisions, VCRs, stereos, copiers, fax machines, electric lamps, cell phones, audio equipment and

batteries if improperly disposed can leach lead and other substances into soil and groundwater. Also e-waste contains precious

metals like Gold, Silver, Copper, Selenium, mercury etc. Many of these products can be reused, refurbished, or recycled.

Recovering precious metals from e-waste can also provide additional income with in the disposal process of end “of life

electronics”. In this paper few methods of extracting precious metals have been studied.

Key words: stereos, e-waste, mercury

INTRODUCTION

In this era of technology, usage of electronic gadgets has been tremendously increased. Alost every one of us are

having cell phones and half of the population have television sets and computers. Many of us are looking for a better cell

phone, latest laptop, a new iPad or an iPod. This demand for new technology gadgets is increasing day by day may be because

of the shorter span of life of the gadgets. This has resulted in the generation of large quantities of e-waste.

E-waste, which is growing on par with municipal waste is throwing a great challenge for environment and human

health. End of use electronic products like Computers, televisions, cell phones, refrigerators, batteries, comes under e-waste.

Any electronic product when intact and in use do not create a problem. But, if e-waste is disposed along with other house hold

waste, becomes a threat to the environment. E-waste contains many toxic elements like lead, mercury, cadmium, tin, bromide

dioxins that leach into the leach into the earth. When dumped in a land fill or thrown into water body, they can cause

unimaginable harm to the soil and water resources, thus causing severe ailments like Cancer, Kidney problems, Liver Damage

etc., for the mankind.

However along with these hazardous materials e-waste also contains precious metals like Gold (Ace), Silver(Ag),

Platinum (Pt), Palladium(pd), Selenium (Se)etc. In this paper, few methods for extraction of precious metals have been

studied.

Facts and Figures:

Generation of e-waste:

According to EPA tons and tons of e-waste is being generated every year.

Hazardous Components in e-waste:

Major Hazardous components and materials present in e-waste are shown in the following table.

S.No Materials and Components Description

1 Batteries Heavy metals such as lead, mercury and cadmium are present in batteries

2 Cathode ray tubes (CTRs) Lead in the cone glass and fluorescent coating cover the inside of panel glass

3 Mercury containing components such Mercury is used in thermostats, sensors, relays and switches (e.g., on PCBs and

as switches in measuring equipment and discharge lamps). It is also used in medical

equipment, data transmission, telecommunication, and mobile phones

4 Asbestos waste Asbestos waste has to be treated selectively

5 Toner cartridges, liquid and pasty, as Toner and toner cartridges have to be removed from any separately collected

well as color toner WEEE

6 PCBs In PCBs, cadmium occurs in certain components, such as SMD chip resistors,

infrared detectors and semiconductors

7 Polychlorinated biphenyl (PCB) PCB-containing capacitors have to be removed for safe destruction

containing capacitors

8 Liquid crystal displays (LCDs) LCDs of a surface greater than 100 cm2 have to be removed from WEEE

9 Plastics containing halogenated During incineration/combustion of the plastics, halogenated flame retardants

flame retardants can produce toxic components

10 Equipment containing CFCs present in foam and refrigerating circuit must be properly extracted and

chlorofluorocarbons (CFCs), destroyed. HCFCs or CFCs present in foam and refrigerating circuit must be

hydrochlorofluorocarbons (HCFCs) properly extracted and destroyed or recycled

or hydrofluorocarbons (HFCs)

11 Gas discharge lamps Mercury has to be removed

Precious Metals in e-waste:

According to the EPA, “Experts estimate that recycling 1 million cell phones can recover about 24 kg (50 lb) of gold,

250 kg (550 lb) of silver, 9 kg (20 lb) of palladium, and more than 9,000 kg (20,000 lb) of copper.”

JCHPS Special Issue 3: October 2014 www.jchps.com Page 147

National Seminar on Impact of Toxic Metals, Minerals and Solvents leading to Environmental Pollution-2014

Journal of Chemical and Pharmaceutical Sciences ISSN: 0974-2115

Weight vs. value distribution precious metals,[ 2 ] 2006.

Weights% Fe (wt %) Al (wt %) Cu (wt. %) Plastics (wt %) Ag (ppm) Au (ppm) Pd (ppm)

TV-board 28% 10% 10% 28% 280 20 10

PCBs 7% 5% 20% 23% 1000 250 110

Mobile phone 5% 1% 13% 56% 1380 350 210

Portable audio 23% 1% 21% 47% 150 10 4

DVD-player 62% 2% 5% 24% 115 15 4

Calculator 4% 5% 3% 61% 260 50 5

Value-share Fe Al Cu Sum PMs Ag Au Pd

TV-board 4% 11% 42% 43% 8% 27% 8%

PCBs 0% 1% 14% 85% 5% 65% 15%

Mobile phone 0% 0% 7% 93% 5% 67% 21%

Portable audio 3% 1% 77% 19% 4% 13% 2%

DVD-player 13% 4% 36% 47% 5% 37% 5%

Calculator 0% 5% 11% 84% 7% 73% 4%

The following Chart shows that growth of e-waste is alarming.

Processes and procedures

E-waste processing:

e-waste after collection, is dismantled and individual components are teasted and isolated. Here, hazardous materials

are separated and are disposed safely without creating any harm to environment. Then precious metals like gold, copper,

silver, palladium etc., are extracted from e-waste and can be reused. Some materials like plastic could be recycled.

Procedures for extracting precious metals:

Hydrometallurgical process:

In hydrometallurgical processes, valuable metals contained in e-waste are first leached into acid or alkali solutions,

and then concentrated by using various methods like precipitation, cementation and solvent extraction. The methods which

could be used for extracting precious metals from e-waste are similar to traditional hydrometallurgical technology used for

metals extraction from their primary ores. However, the complex nature of e-waste makes the process complicated compared

to natural ores.

The following table shows recovery of precious metals from ewaste as done by few investigators.

Investigators Leaching agent Process conditions Recovered metals

Quinet et al H2SO4, chloride, thiourea Leaching & metals recovery by cementation, Au, Ag, Pd and Cu

and cyanide leaching precipitation, ion exchange and carbon

adsorption

Park and Fray Aqua regia Ratio of metals to leachant = 1:20 g/mL Au, Ag and Pd

Sheng and Estell HNO3 (1st stage), epoxy Extraction was carried out in the three stages Au

resin (2nd stage), and aqua (self-agitation)

regia (3rd stage)

Chielewski et al HNO3 and aqua regia Roasting of e-waste in the presence of carbon; Au

leaching with HNO3 and aqua regia; and solvent

extraction with diethyle malonate

Pyro metallurgical process:

In the pyro metallurgical process, e-waste is melted with several flux components as slag formatives. The molten

material containing valuable metals contacts with a molten metal pool into which the valuable metals dissolve and accumulate.

The molten metal is called as collector metal. Commonly used collector metals include iron, copper, nickel, lead-copper and

nickel matte. And then, the extracted valuable metals must be further treated in order to separate and purity them. Many

metals like lead, copper etc., can be extracted through pyro metallurgical process.

JCHPS Special Issue 3: October 2014 www.jchps.com Page 148

National Seminar on Impact of Toxic Metals, Minerals and Solvents leading to Environmental Pollution-2014

Journal of Chemical and Pharmaceutical Sciences ISSN: 0974-2115

Bio Leaching:- This method employs bacterial leaching of metals from e-waste. Microbiological leaching uses a natural

ability of microorganisms to transform metals present in the waste in a solid form to a dissolved from Apart from the

possibility of bioleaching of metals in alkaline environment (involving cyanegenic bacteria), acidophilus microorganisms and

conducting biological process of leaching in an acidic environment play a crucial role in the biohydrometallurgical techniques.

Among major groups of bacteria, the most commonly used are: acidophi- lus and chemolithotrophic microbial consortia of:

Acidithiobacillus ferrooxidans, Acidithiobacillus thiooxidans, Leptospirillum ferrooxidans and heterotrophs, for example

Sulfolobus sp. In addition, fungi such as Penicillium sp. and Aspergillus niger are examples of some eucaryotic

microorganisms used in bioleaching during metal recovery from industrial wastes.

Examples of industrial waste treated with bacterial leaching [3].

Waste Leached metal Used microorganisms

Electronic scrap Cu, Ni, Al, Zn Acidithiobacillus ferrooxidans +

Acidithiobacillus thiooxidans

Lithium batteries Li, Co Acidithiobacillus ferrooxidans

Discussion: All the methods hydro metallurgical process, pyro metallurgical process and bioleaching have been successfully

used to recover precious metals from e-waste. However, recovery of plastics etc. is not possible with pyro metallurgical

process. Also, hazardous emissions such as dioxins may be generated during smelling of materials containing halogenated

flame retardants. Some elements like cyanide are dangerous lechants and therefore should be used with very high safely

standards. When compared with chemical procsses, bioleaching is more eco-friendly as it will not release any dangerous gases

or hazardous substances into the environment. But, bioleaching methods at present are not as effective as chemical methods.

Conclusion: As end-of-life electronic products are not only hazardous to health, but also can generate income. This could be

a motivated factor for not disposing e-waste along with other house hold waste. Awareness should be created among general

public not to throw away e-waste. Also, collection points of e-waste are to be established in every city, town or village.

Though recycling units of e-waste are there in India, procedures of collecting and transport are to be improved. e-waste

management and handling rules came into existence from 2012, and according to them every manufacturer is responsible for

safer disposal and this should be implemented effectively.

References:

1. Department of Information technology Electronic waste management in India.

2. Abdul Khaliq, Metal Extraction process for electronic waste and existing industrial routes: A review and Australian

Perspective, Resources 2014,3, 152-179.

3. Joanna Willner, Extraction of metals from electric waste by bacterial leaching., Environment Protection Engineering

.J. 2013,39.

4. www.electronicstakeback.com – Facts and figures on e-waste and recycling.

JCHPS Special Issue 3: October 2014 www.jchps.com Page 149

Anda mungkin juga menyukai

- AnexeDokumen1 halamanAnexeRazvan MicanBelum ada peringkat

- Weee Electrical and Electronic Equipment Wastes in Nigeria Adoption of Environmental Sound Recycling SystemDokumen38 halamanWeee Electrical and Electronic Equipment Wastes in Nigeria Adoption of Environmental Sound Recycling SystemRazvan MicanBelum ada peringkat

- E-Waste Treatment Facility in Uganda Business PlanDokumen71 halamanE-Waste Treatment Facility in Uganda Business PlanRazvan MicanBelum ada peringkat

- Disposal Methods and Heavy Metals Released From Certain Electrical and Electronic Equipment Wastes in Nigeria Adoption of Environmental Sound Recycling SystemDokumen8 halamanDisposal Methods and Heavy Metals Released From Certain Electrical and Electronic Equipment Wastes in Nigeria Adoption of Environmental Sound Recycling SystemRazvan MicanBelum ada peringkat

- Chi 2011 WasteMgmt PDFDokumen12 halamanChi 2011 WasteMgmt PDFRazvan MicanBelum ada peringkat

- Dissertation Irina OswaldDokumen154 halamanDissertation Irina OswaldRazvan MicanBelum ada peringkat

- Feasibility of E-Waste Recycling in Morocco PDFDokumen86 halamanFeasibility of E-Waste Recycling in Morocco PDFRazvan MicanBelum ada peringkat

- Bioleaching of Gold, Copper and Nickel From Waste Cellular Phone PCBsDokumen7 halamanBioleaching of Gold, Copper and Nickel From Waste Cellular Phone PCBsRazvan MicanBelum ada peringkat

- Recovery of Precious Metals From E-WasteDokumen74 halamanRecovery of Precious Metals From E-WasteRazvan Mican100% (2)

- Eco-Recycling of Precious Metal FromDokumen33 halamanEco-Recycling of Precious Metal FromRazvan Mican50% (2)

- E Waste Guidelines Partnership 2015Dokumen52 halamanE Waste Guidelines Partnership 2015Razvan MicanBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Colombo Port City Causing Unimaginable Environmental HarmDokumen6 halamanColombo Port City Causing Unimaginable Environmental HarmThavam RatnaBelum ada peringkat

- RegistryDokumen4 halamanRegistryRajan KhandelwalBelum ada peringkat

- Development and Application of "Green," Environmentally Friendly Refractory Materials For The High-Temperature Technologies in Iron and Steel ProductionDokumen6 halamanDevelopment and Application of "Green," Environmentally Friendly Refractory Materials For The High-Temperature Technologies in Iron and Steel ProductionJJBelum ada peringkat

- Unit 1 My Hobbies Lesson 1 Getting StartedDokumen14 halamanUnit 1 My Hobbies Lesson 1 Getting StartedhienBelum ada peringkat

- 5G, 4G, Vonr Crash Course Complete Log AnaylsisDokumen11 halaman5G, 4G, Vonr Crash Course Complete Log AnaylsisJavier GonzalesBelum ada peringkat

- NM Integrative Wellness MRC Public Health Acupuncture JITTDokumen40 halamanNM Integrative Wellness MRC Public Health Acupuncture JITTPrince DhillonBelum ada peringkat

- Sagan WaltzDokumen14 halamanSagan WaltzKathleen RoseBelum ada peringkat

- Acute Conditions of The NewbornDokumen46 halamanAcute Conditions of The NewbornCamille Joy BaliliBelum ada peringkat

- 61-Article Text-180-1-10-20170303 PDFDokumen25 halaman61-Article Text-180-1-10-20170303 PDFSOUMYA GOPAVARAPUBelum ada peringkat

- Pro Con ChartDokumen3 halamanPro Con Chartapi-461614875Belum ada peringkat

- Support of Roof and Side in Belowground Coal MinesDokumen5 halamanSupport of Roof and Side in Belowground Coal MinesNavdeep MandalBelum ada peringkat

- Soal Try Out Ujian NasionalDokumen9 halamanSoal Try Out Ujian NasionalAgung MartaBelum ada peringkat

- Transformational and Charismatic Leadership: The Road Ahead 10th Anniversary EditionDokumen32 halamanTransformational and Charismatic Leadership: The Road Ahead 10th Anniversary Editionfisaac333085Belum ada peringkat

- Syllabus EM1Dokumen2 halamanSyllabus EM1Tyler AnthonyBelum ada peringkat

- Centiloquium of PtolemyDokumen37 halamanCentiloquium of PtolemyNatasa Karalic Koprivica100% (9)

- PWC - Digital Pocket Tax Book 2023 - SlovakiaDokumen52 halamanPWC - Digital Pocket Tax Book 2023 - SlovakiaRoman SlovinecBelum ada peringkat

- Week 5 Teradata Practice ExerciseDokumen14 halamanWeek 5 Teradata Practice ExerciseWooyeon ChoBelum ada peringkat

- ENG11H Realism 6-Outcasts of Poker FlatDokumen3 halamanENG11H Realism 6-Outcasts of Poker FlatJosh Cauhorn100% (1)

- 311762en WDokumen36 halaman311762en WOprisor CostinBelum ada peringkat

- Science9 Q3 SLM1Dokumen15 halamanScience9 Q3 SLM1Zandra Musni Delos ReyesBelum ada peringkat

- Note 15-Feb-2023Dokumen4 halamanNote 15-Feb-2023Oliver ScissorsBelum ada peringkat

- Steve Talbott Getting Over The Code DelusionDokumen57 halamanSteve Talbott Getting Over The Code DelusionAlexandra DaleBelum ada peringkat

- DRUG STUDY (Erythromycin)Dokumen3 halamanDRUG STUDY (Erythromycin)Avianna CalliopeBelum ada peringkat

- Philippines and Singapore Trade Relations and Agreements: 1. What Leads To Said Agreement?Dokumen11 halamanPhilippines and Singapore Trade Relations and Agreements: 1. What Leads To Said Agreement?Ayrah Erica JaimeBelum ada peringkat

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Dokumen2 halamanBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaBelum ada peringkat

- Shaheed Suhrawardy Medical College HospitalDokumen3 halamanShaheed Suhrawardy Medical College HospitalDr. Mohammad Nazrul IslamBelum ada peringkat

- UBO - Lecture 07 - Implementing and Managing Organisational ChangeDokumen0 halamanUBO - Lecture 07 - Implementing and Managing Organisational ChangeShahNooraniITBelum ada peringkat

- Apc 10kva Ups ManualDokumen36 halamanApc 10kva Ups Manualraj rajBelum ada peringkat

- Bruner, Jerome - The Growth of MindDokumen11 halamanBruner, Jerome - The Growth of MindTalia Tijero100% (1)

- C779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesDokumen7 halamanC779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesFahad RedaBelum ada peringkat