Department Quality Assurance & Systems Responsibility: Key Performance Indicators Monitoring Sheet

Diunggah oleh

Anilkumar GJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Department Quality Assurance & Systems Responsibility: Key Performance Indicators Monitoring Sheet

Diunggah oleh

Anilkumar GHak Cipta:

Format Tersedia

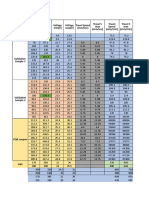

QA & S

KEY PERFORMANCE INDICATORS MONITORING SHEET

Department QUALITY ASSURANCE & SYSTEMS

Responsibility To Ensure organization system, Process qualification & validation.

Identification

Supporting documents

Frequency

WK-24

WK-25

WK-26

WK-27

WK-28

WK-29

MACRO Targe

WTG

APS FUNCTIONS MICRO FUNCTIONS Deliverables t

Source Evidence required

Man hour loss due to safety - Organizational

Safety D1 performance Zero incident 0 Security Security report W 15

QUALITY ASSURANCE & SYSTEMS - ONE TARGET AT A TIME & ALIGN THE TARGETS

EHS D2 Zone EHS performance (Legal compliance Zero incident 0 TQM Mail W 15

adherence – EHS,OSHAS) champion

5'S' D3 5'S' work place culture improvement Achieve score >4 Zone leaders Cross zone audit report W 4

D4 Qualified Process Availability SOP & PPAP / Homalogation 100% VS SOP & PPAP / Homalogation/ W 3

Drawings

Availability D5 Measuring Instrument Availability Availability 100% VS List of Equipments/OEE W 3

D6 Process Qualification for MEN Validation 100% HR Vaidation report & Updated list W 3

System System : ISO,OHSAS & EHS,IS-3834 On time completion & Certificate/Re-certification /

D7 100% QA Internal Audit report Plan Vs M 5

Certification implementation Adearence Actual,MRM

Routine Internal Audit 1 per qualrter and MRM

D8 monthly and on time completion 100% QA Internal Audit report / NC W 4

Work Centre Based Process Audit 3 cycle in a Control Chart / NC,Product Audit

Audit D9 week on time completion 100% QA Report W 5

D10 Product Audit - Shell- 1sec/wk, Black Section3 Inprocess Rejection 100% QA Product Audit report/NC W 5

sec/wk, FCL 3sec/wk section

D11 -Special

Welding

processes certification & Qualification On time completion 100% QA Qualification, re-qualification &

certification report W 5

D12 Validation of Jig & Fixtures Ontime completion 100% QA Vaidation report & Updated list M 2

Process

Certification, D13 Special Process Defect Control - Welding Maintain Weld defect within < VS UT,VT Repair trend W 5

Qualification 0.5%

D14 FARN Ontime completion 100% FIN Invoice/ FARN/ Customer Portal W 3

Customer Complaints,ECN Implementation &

D15 Management of changes Ontime completion 100% QA Management of Change Report W 3

Go See Act ECRS

Improveme Suggestions / Work station / 100%

& Stop To APS D16 APS Implementation ( QCC/QIT) RIW MR Report M 20

nts under Shift / Staff

Fix

PQCDSME

APS Align Targets Total 100 0 0 0 0 0 0

QA & S

D7

D

D9

D9

Anda mungkin juga menyukai

- AFAR Problems PrelimDokumen11 halamanAFAR Problems PrelimLian Garl100% (8)

- 01 Master List of DocumentsDokumen1 halaman01 Master List of DocumentsMuhammad ImranBelum ada peringkat

- PH Calibration LogDokumen1 halamanPH Calibration LogAlfred RangelBelum ada peringkat

- Trend Analysis Sheet OOSDokumen11 halamanTrend Analysis Sheet OOSHaroon RasheedBelum ada peringkat

- Analysis Request Form 2014Dokumen52 halamanAnalysis Request Form 2014Mohamad ArtaBelum ada peringkat

- S. No. Tests Specification STP / GTP No.: Current and Effective Versions of STP / GTP Shall Be FollowedDokumen1 halamanS. No. Tests Specification STP / GTP No.: Current and Effective Versions of STP / GTP Shall Be Followeddepardieu1973Belum ada peringkat

- Calibration FormatDokumen84 halamanCalibration FormatJagjeet SinghBelum ada peringkat

- No. of SOP Pending in All Cross Functional DepartmentDokumen64 halamanNo. of SOP Pending in All Cross Functional DepartmentNishit SuvaBelum ada peringkat

- Ag009 05 01Dokumen1 halamanAg009 05 01Nishit SuvaBelum ada peringkat

- QMS Trackerv1Dokumen2 halamanQMS Trackerv1ukhlaqBelum ada peringkat

- Alusim SuspensionDokumen5 halamanAlusim SuspensionAhmad HussainBelum ada peringkat

- Qualification RangeDokumen1 halamanQualification RangeSARSAN NDTBelum ada peringkat

- Revised SOP Index For Change ControlDokumen6 halamanRevised SOP Index For Change ControlswanandkulBelum ada peringkat

- WI No. QC 003Dokumen2 halamanWI No. QC 003Khrystin BerdosBelum ada peringkat

- Master Soppd101 02Dokumen23 halamanMaster Soppd101 02boimziiBelum ada peringkat

- IQ Risk AnalysisDokumen1 halamanIQ Risk AnalysisNadine LilleBelum ada peringkat

- In-Process Testing of Infusions: Novamed Pharmaceutical Quality Control Department Standard Operating ProcedureDokumen5 halamanIn-Process Testing of Infusions: Novamed Pharmaceutical Quality Control Department Standard Operating Procedurenaeem186Belum ada peringkat

- F-05 Corrective Action FormDokumen1 halamanF-05 Corrective Action Formsuhara hussainBelum ada peringkat

- Validation of Mixer Double Cone BlenderDokumen6 halamanValidation of Mixer Double Cone BlenderSyed RizviBelum ada peringkat

- Daily Calibration RecordDokumen5 halamanDaily Calibration Recordopd pharmacyBelum ada peringkat

- In Process QC FormatDokumen9 halamanIn Process QC FormatSunil ChaubeyBelum ada peringkat

- Weather Folds Pharmaceutical Standard Operating Procedures Good Laboratory PracticesDokumen5 halamanWeather Folds Pharmaceutical Standard Operating Procedures Good Laboratory PracticesWeatherfolds PharmaBelum ada peringkat

- Standard Operating Procedure: Darsh Pharmachem Pvt. LTDDokumen4 halamanStandard Operating Procedure: Darsh Pharmachem Pvt. LTDNishit SuvaBelum ada peringkat

- 01 Disintegration Test For Tablets and CapsulesDokumen30 halaman01 Disintegration Test For Tablets and CapsulesmefroBelum ada peringkat

- Chemical Analysis of Soft WaterDokumen4 halamanChemical Analysis of Soft WaterBhawani singhBelum ada peringkat

- Change Control Form: Giva Olviana YudhistaDokumen4 halamanChange Control Form: Giva Olviana YudhistaFajarRachmadiBelum ada peringkat

- Raw Data Report of TabletDokumen11 halamanRaw Data Report of TabletShubam SharmaBelum ada peringkat

- Quality Plan: X-47 (J-Ucas) 1 JULY 2005: Signature On FileDokumen9 halamanQuality Plan: X-47 (J-Ucas) 1 JULY 2005: Signature On FileஜெயசிவாBelum ada peringkat

- Arogyavardhini Flow Sheet - 25.08.07Dokumen2 halamanArogyavardhini Flow Sheet - 25.08.07Vaishali SalunkeBelum ada peringkat

- Format Ahu ValDokumen3 halamanFormat Ahu ValKrishna RajBelum ada peringkat

- Internal Calibration Check HPLC System (Agilent Prime LC 1260 Infinity II)Dokumen6 halamanInternal Calibration Check HPLC System (Agilent Prime LC 1260 Infinity II)Aayushi SanghalBelum ada peringkat

- Purpose: Top ManagementDokumen4 halamanPurpose: Top Managementdaizhussain004Belum ada peringkat

- Air Changes FormatDokumen1 halamanAir Changes Formatnaeem186Belum ada peringkat

- APPENDIX-I (Request Sheet)Dokumen2 halamanAPPENDIX-I (Request Sheet)iloveit52252Belum ada peringkat

- XYZ Tablet 20mg FCTDokumen123 halamanXYZ Tablet 20mg FCTAnonymous jzlKNORBelum ada peringkat

- 001 AbbrevationsDokumen86 halaman001 AbbrevationssreeniBelum ada peringkat

- Purified Water User PointDokumen1 halamanPurified Water User PointMuhammadAmdadulHoqueBelum ada peringkat

- AnnuallyDokumen70 halamanAnnuallyFloreidBelum ada peringkat

- Index of QA WorkingDokumen2 halamanIndex of QA WorkingsajidBelum ada peringkat

- Documents File IndexDokumen1 halamanDocuments File IndexMeet VermaaBelum ada peringkat

- Annexure - VIDokumen19 halamanAnnexure - VIKiran KumarBelum ada peringkat

- QSP-01 FR-01 Masterlist of QMSDokumen5 halamanQSP-01 FR-01 Masterlist of QMSWan Mohd FarzrinBelum ada peringkat

- UncontrolledDokumen31 halamanUncontrolledSerajahmad560% (1)

- DOEH Pesticide FilesDokumen20 halamanDOEH Pesticide FilesMichael_Lee_RobertsBelum ada peringkat

- Benzochem PDFDokumen359 halamanBenzochem PDFप्रियदर्शन गोंधळेकरBelum ada peringkat

- Quality Manual SampleDokumen51 halamanQuality Manual SampleFaizy NohBelum ada peringkat

- CRSE-SA-T-718 3rd Quality Management Review Meeting MOMDokumen60 halamanCRSE-SA-T-718 3rd Quality Management Review Meeting MOMAhmad Assad mrednBelum ada peringkat

- Qualification Rest Risk Based Approach EvaluationDokumen4 halamanQualification Rest Risk Based Approach EvaluationApoloTrevino100% (1)

- OQ Raw Materials Sample TentDokumen18 halamanOQ Raw Materials Sample TentAnup BajracharyaBelum ada peringkat

- SR. NO. Sop Name SOP NO. Format NO. Format Name Revision NO. Effective Date Next Review DateDokumen2 halamanSR. NO. Sop Name SOP NO. Format NO. Format Name Revision NO. Effective Date Next Review DateDRx Pradeep KumarBelum ada peringkat

- VR Aslow 81tab Validation ReportDokumen31 halamanVR Aslow 81tab Validation Reportziauddin bukhariBelum ada peringkat

- QC TestsDokumen12 halamanQC Testsembermich100% (1)

- Form 18 NABL 163Dokumen2 halamanForm 18 NABL 163asr labBelum ada peringkat

- Icr-Pr-18 NDT ProcedureDokumen4 halamanIcr-Pr-18 NDT ProcedureBauyrzhanBelum ada peringkat

- QA-R-12 Calibration History CardDokumen1 halamanQA-R-12 Calibration History CardRaja DuraiBelum ada peringkat

- Afcons - WPS LIST For E410C Updated (31.08.2019)Dokumen1 halamanAfcons - WPS LIST For E410C Updated (31.08.2019)Neem LalBelum ada peringkat

- Setco PDFDokumen3 halamanSetco PDFPrafullachandra ParikhBelum ada peringkat

- Pending Points of EngDokumen7 halamanPending Points of EngAbduljabbar SayedBelum ada peringkat

- Welders ManagementDokumen11 halamanWelders ManagementStanley AlexBelum ada peringkat

- LINE-5: Mx8 CakeDokumen1 halamanLINE-5: Mx8 CakeProchem ECBelum ada peringkat

- Tma RecifeDokumen1 halamanTma RecifeVinicius LinsBelum ada peringkat

- Final Unit IX NotesDokumen34 halamanFinal Unit IX NotesAnilkumar GBelum ada peringkat

- HSE Hindi ImprovementDokumen1 halamanHSE Hindi ImprovementAnilkumar GBelum ada peringkat

- CV-Jose George Alex-EngineeringDokumen2 halamanCV-Jose George Alex-EngineeringAnilkumar GBelum ada peringkat

- BW Selection+Guide+Stick+Electrodes EN 2018 046 Preview PDFDokumen30 halamanBW Selection+Guide+Stick+Electrodes EN 2018 046 Preview PDFmBelum ada peringkat

- 2018 - 20 School List With AddressDokumen2 halaman2018 - 20 School List With AddressAnilkumar GBelum ada peringkat

- Final Unit IX NotesDokumen34 halamanFinal Unit IX NotesAnilkumar GBelum ada peringkat

- Heat Input CalculationDokumen3 halamanHeat Input CalculationAnilkumar GBelum ada peringkat

- India Tamilnadu Kerala Total Daily Growth %ge Total Daily Growth %ge TotalDokumen15 halamanIndia Tamilnadu Kerala Total Daily Growth %ge Total Daily Growth %ge TotalAnilkumar GBelum ada peringkat

- 11-Childhood and Growing Up VI To X - 1Dokumen81 halaman11-Childhood and Growing Up VI To X - 1joshika sumiBelum ada peringkat

- SchoolsDokumen6 halamanSchoolsAnilkumar GBelum ada peringkat

- CBSE Chennai SchoolsDokumen5 halamanCBSE Chennai SchoolsAnilkumar GBelum ada peringkat

- Overall PerformanceDokumen5 halamanOverall PerformanceAnilkumar GBelum ada peringkat

- Section 80C PremiumDokumen3 halamanSection 80C PremiumAnilkumar GBelum ada peringkat

- SchoolsDokumen6 halamanSchoolsAnilkumar GBelum ada peringkat

- 5S Cross ZoneDokumen5 halaman5S Cross ZoneAnilkumar GBelum ada peringkat

- New India Claim FormDokumen2 halamanNew India Claim FormAnilkumar G50% (2)

- STBW Status MayDokumen3 halamanSTBW Status MayAnilkumar GBelum ada peringkat

- MathematicalDokumen2 halamanMathematicalAnilkumar GBelum ada peringkat

- Door Frame To Shell Welding UsingDokumen35 halamanDoor Frame To Shell Welding UsingAnilkumar GBelum ada peringkat

- EPC Middle East ContactsDokumen1 halamanEPC Middle East ContactsAnilkumar GBelum ada peringkat

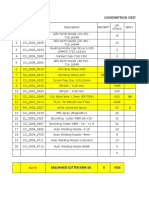

- Consumables Consumption Daily Update SheetDokumen2 halamanConsumables Consumption Daily Update SheetAnilkumar G NairBelum ada peringkat

- Unit - 2 5S & EHS ScoreDokumen2 halamanUnit - 2 5S & EHS ScoreAnilkumar GBelum ada peringkat

- Anilkumar Gopinathan Nair: Phone: +91-6380325363Dokumen2 halamanAnilkumar Gopinathan Nair: Phone: +91-6380325363Anilkumar GBelum ada peringkat

- NEW INDIA-discharge VoucherDokumen1 halamanNEW INDIA-discharge VoucherAnilkumar G56% (9)

- Consumables Consumption Daily Update Sheet As On Aug 17Dokumen530 halamanConsumables Consumption Daily Update Sheet As On Aug 17Anilkumar G NairBelum ada peringkat

- Supplier KpiDokumen18 halamanSupplier KpiAnilkumar GBelum ada peringkat

- Welding Monitors KPI MethodologyDokumen5 halamanWelding Monitors KPI MethodologyAnilkumar GBelum ada peringkat

- On Job TraineesDokumen11 halamanOn Job TraineesAnilkumar GBelum ada peringkat

- OctoberDokumen3 halamanOctoberAnilkumar GBelum ada peringkat

- Ibt - Module 2 International Trade - Theories Are: Classical and Are From The PerspectiveDokumen9 halamanIbt - Module 2 International Trade - Theories Are: Classical and Are From The PerspectiveLyca NegrosBelum ada peringkat

- 201183-B-00-20 Part ListDokumen19 halaman201183-B-00-20 Part ListMohamed IsmailBelum ada peringkat

- Sage 200 Evolution Training JourneyDokumen5 halamanSage 200 Evolution Training JourneysibaBelum ada peringkat

- Radix Sort - Wikipedia, The Free EncyclopediaDokumen13 halamanRadix Sort - Wikipedia, The Free EncyclopediasbaikunjeBelum ada peringkat

- TC 9-237 Welding 1993Dokumen680 halamanTC 9-237 Welding 1993enricoBelum ada peringkat

- 1610-2311-Executive Summary-EnDokumen15 halaman1610-2311-Executive Summary-EnKayzha Shafira Ramadhani460 105Belum ada peringkat

- LG+32LX330C Ga LG5CBDokumen55 halamanLG+32LX330C Ga LG5CBjampcarlosBelum ada peringkat

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateDokumen6 halamanEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubBelum ada peringkat

- CERES News Digest - Week 11, Vol.4, March 31-April 4Dokumen6 halamanCERES News Digest - Week 11, Vol.4, March 31-April 4Center for Eurasian, Russian and East European StudiesBelum ada peringkat

- (Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFDokumen317 halaman(Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFSneha SinghBelum ada peringkat

- Scout Activities On The Indian Railways - Original Order: MC No. SubjectDokumen4 halamanScout Activities On The Indian Railways - Original Order: MC No. SubjectVikasvijay SinghBelum ada peringkat

- Basics Stats Ti NspireDokumen7 halamanBasics Stats Ti NspirePanagiotis SotiropoulosBelum ada peringkat

- Assignment 03 Investments in Debt SecuritiesDokumen4 halamanAssignment 03 Investments in Debt SecuritiesJella Mae YcalinaBelum ada peringkat

- Imp121 1isDokumen6 halamanImp121 1isErnesto AyzenbergBelum ada peringkat

- Course Syllabus: Ecommerce & Internet MarketingDokumen23 halamanCourse Syllabus: Ecommerce & Internet MarketingMady RamosBelum ada peringkat

- Top Ten Helicopter Checkride TipsDokumen35 halamanTop Ten Helicopter Checkride TipsAbhiraj Singh SandhuBelum ada peringkat

- Aug 2020 Builders Line Tamil MonthlyDokumen48 halamanAug 2020 Builders Line Tamil MonthlyBuildersLineMonthlyBelum ada peringkat

- Steris Amsco Century v120Dokumen2 halamanSteris Amsco Century v120Juan OrtizBelum ada peringkat

- 2 1 PDFDokumen18 halaman2 1 PDFالمهندسوليدالطويلBelum ada peringkat

- Group Tour Operators in Pune - Best Tours and Travels in PuneDokumen10 halamanGroup Tour Operators in Pune - Best Tours and Travels in PuneGargi ToursBelum ada peringkat

- QT1-EVNPMB2-0-NCR-Z-013 Water Treament System of AccommondationDokumen3 halamanQT1-EVNPMB2-0-NCR-Z-013 Water Treament System of AccommondationDoan Ngoc DucBelum ada peringkat

- Business Mathematics and Statistics: Fundamentals ofDokumen468 halamanBusiness Mathematics and Statistics: Fundamentals ofSamirBelum ada peringkat

- Dorks List For Sql2019 PDFDokumen50 halamanDorks List For Sql2019 PDFVittorio De RosaBelum ada peringkat

- Uporedna Tabela Addinol-Ovih UljaDokumen4 halamanUporedna Tabela Addinol-Ovih UljaasimpeksBelum ada peringkat

- Item No. 6 Diary No 6856 2024 ConsolidatedDokumen223 halamanItem No. 6 Diary No 6856 2024 Consolidatedisha NagpalBelum ada peringkat

- Enabling Trade Report 2013, World Trade ForumDokumen52 halamanEnabling Trade Report 2013, World Trade ForumNancy Islam100% (1)

- Organization of Brigada Eskwela Steering and Working CommitteesDokumen2 halamanOrganization of Brigada Eskwela Steering and Working CommitteesCherry Lou RiofrirBelum ada peringkat

- Meco ReviewerDokumen9 halamanMeco ReviewerKang ChulBelum ada peringkat

- Millets: Future of Food & FarmingDokumen16 halamanMillets: Future of Food & FarmingKIRAN100% (2)