General Information: Current Transformers

Diunggah oleh

Pardeep KhosaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

General Information: Current Transformers

Diunggah oleh

Pardeep KhosaHak Cipta:

Format Tersedia

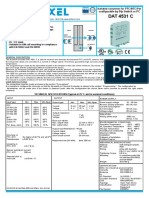

CURRENT TRANSFORMERS / DC SHUNTS

Current Transformers

General Information

Reference Standards BS7626 1993, BS3938, When using CT’s with an aperture, it is possible to reduce primary ratio

CENELEC HD 533 S2 1993, by passing multiple turns of the primary conductor cable through the

I EC185, VDE 0414, aperture. The resultant ratio will be CT primary divided by the number

CEI 38-1, UTE NF 42-502 of turns, e.g. a 200/5A CT with the primary conductor passed through

Housing Self extinguishing thermoplastic the aperture twice will produce a CT ratio of 100/5A.

classification VO to UL94

I nsulation Class E

Temperature Range Working –25 to +50°C, relative

humidity 85%

Max conductor temperature 70°C

When selecting a current transformer, it is important to consider the

Storage –40 to +80°C

power absorbed by the cables connected between the CT secondary

Frequency 50/60Hz

terminals and the measuring instrument. The resultant cable burden

(higher frequency on request)

should be added to the equipment burden, and the total should not

System Voltage 720V max.

exceed the available VA of the CT. Where the current transformer is to

Test Voltage 3KV for 1 minute

be mounted remotely, a -/1A secondary is recommended.

Thermal short circuit current (I th) Limited by conductor size, except

For every 10°C variation in temperature, the VA absorbed by the

wound primary models 60 In

cables will increase by 4% (Ambient Reference Temp °C)

Dynamic short

circuit current (I dyn) 2 5 I th

Saturation Co-efficient <5

Terminal Markings Primary P1 & P2 (K & L)

Secondary S1 & S2 (k & l)

Tropicalized execution Working temperature

–25 to +60°C,

relative humidity >95%

Max conductor temperature 90°C

Storage temperature –40 to +80°C

H2S execution Max. concentration 8ppm

System Voltage 1 2KV

Test Voltage 6KV for 1 minute

* Medium Voltage CT’s (system voltage up to 24KV) * Three Phase

CT’s * Ratio Calibration CT’s * Split Core CT’s (for temporary or

permanent installation) * Saturation CT’s * Heavy Starting CT’s

* Signal Generator CT’s * Overload CT’s

1. It is essential with certain instrumentation that the CT is physically

positioned correctly on the conductor. P1 (K) must face the supply

feeder, and P2 (L) must face the load. It is also important to ensure

that secondary connections are made in accordance with

i nstrument diagrams.

2. The secondary terminals of the CT must NOT be open-circuited on

load as dangerously high voltages may be present under these

conditions. It is recommended that one side of the secondary

windings is earthed.

Anda mungkin juga menyukai

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Electronic three-phase meter for commercial and industrial customersDokumen2 halamanElectronic three-phase meter for commercial and industrial customersrzgarBelum ada peringkat

- Technical Description Td-108aDokumen37 halamanTechnical Description Td-108abinodeBelum ada peringkat

- Specification and Selection of Instrument TransformerDokumen4 halamanSpecification and Selection of Instrument TransformerrodrigoBelum ada peringkat

- CXPS 24-2T 24Vdc Power SystemDokumen49 halamanCXPS 24-2T 24Vdc Power SystemroybutcherBelum ada peringkat

- DDZ1513 Single Phase: Modular Integrated Smart Prepayment Meter (Class 1)Dokumen2 halamanDDZ1513 Single Phase: Modular Integrated Smart Prepayment Meter (Class 1)anwarBelum ada peringkat

- ReleDokumen4 halamanReledavidBelum ada peringkat

- 001 004 Rev 00Dokumen11 halaman001 004 Rev 00Muhammad Asif IqbalBelum ada peringkat

- AirpaxDokumen46 halamanAirpaxbandaraBelum ada peringkat

- e560CVD03 InstructionManual v12Dokumen76 halamane560CVD03 InstructionManual v12gnyankovBelum ada peringkat

- Thermometer TR61Dokumen20 halamanThermometer TR61Migos MareBelum ada peringkat

- Fftmu 2ch@aDokumen3 halamanFftmu 2ch@asteam100deg8229Belum ada peringkat

- Finder-general-technical-information-enDokumen15 halamanFinder-general-technical-information-encuonglammanh98Belum ada peringkat

- Technical Specification of 11Kv & 33Kv Oil Immersed CT:PT (Metering Equipment) UnitsDokumen9 halamanTechnical Specification of 11Kv & 33Kv Oil Immersed CT:PT (Metering Equipment) Unitsrajeeb1985Belum ada peringkat

- TDX 120 TRAX Accessory Measures Capacitance & Tan DeltaDokumen4 halamanTDX 120 TRAX Accessory Measures Capacitance & Tan DeltaDimitar MarkovBelum ada peringkat

- NivoCAP Manual PDFDokumen6 halamanNivoCAP Manual PDFarfanBelum ada peringkat

- Type VHXM: Under / Over Voltage RelayDokumen6 halamanType VHXM: Under / Over Voltage RelayNikki AgarwalBelum ada peringkat

- 74 MP100 TD enDokumen5 halaman74 MP100 TD enBa DuyBelum ada peringkat

- MicroNet VAV Controllers MNL-V3RVx Datasheet F-26366-8Dokumen4 halamanMicroNet VAV Controllers MNL-V3RVx Datasheet F-26366-8Arthur BastosBelum ada peringkat

- 2S7B 3upDokumen5 halaman2S7B 3upJlavieraBelum ada peringkat

- A1350 Flyer Ea3Dokumen2 halamanA1350 Flyer Ea3Bojan IlievBelum ada peringkat

- Axiomatix TDAX184000 - J1939 RTD ScannerDokumen7 halamanAxiomatix TDAX184000 - J1939 RTD Scannerkman548Belum ada peringkat

- Merlin Gerin Medium VoltageDokumen10 halamanMerlin Gerin Medium VoltagekjfenBelum ada peringkat

- POLIM-D Datasheet 1HC0075853 AI enDokumen8 halamanPOLIM-D Datasheet 1HC0075853 AI enAlomaki KismaBelum ada peringkat

- Hgsemi LM331M TRDokumen16 halamanHgsemi LM331M TREDU GCBelum ada peringkat

- TI266ten 0409Dokumen12 halamanTI266ten 0409Keren ArteagaBelum ada peringkat

- Static Converter 18 KVDokumen26 halamanStatic Converter 18 KVVipin KumarBelum ada peringkat

- Epcos CapacitorDokumen8 halamanEpcos CapacitorcoronaqcBelum ada peringkat

- Technical Information Omnigrad S TR66, TC66Dokumen20 halamanTechnical Information Omnigrad S TR66, TC66oliBelum ada peringkat

- Endress Modular Thermometer TR66 TC66Dokumen24 halamanEndress Modular Thermometer TR66 TC66saeed_393512703Belum ada peringkat

- Schrack Power PCB Relay RTH 105°C 16ADokumen2 halamanSchrack Power PCB Relay RTH 105°C 16AjpbarrioBelum ada peringkat

- Capacitor Information (PT 2) PDFDokumen18 halamanCapacitor Information (PT 2) PDFwillchamBelum ada peringkat

- Siemens Drytransformer PDFDokumen30 halamanSiemens Drytransformer PDFOSCAR ARDILABelum ada peringkat

- TA-Smart EN LowDokumen8 halamanTA-Smart EN LowRendiBelum ada peringkat

- Stps 10120 CDokumen9 halamanStps 10120 CLEWIS RODRIGUEZBelum ada peringkat

- Technical Information Omnigrad S TR62, TC62: Modular Thermometer, Explosion-Protected, For Screwing Into A ThermowellDokumen20 halamanTechnical Information Omnigrad S TR62, TC62: Modular Thermometer, Explosion-Protected, For Screwing Into A ThermowellKarlBelum ada peringkat

- IPR-A Current Monitoring & Protection RelayDokumen4 halamanIPR-A Current Monitoring & Protection RelayVictor Hugo González BaezaBelum ada peringkat

- Temperature Converter Dat4531cDokumen4 halamanTemperature Converter Dat4531cDicky EkaBelum ada peringkat

- Acme PIUDokumen4 halamanAcme PIUJay TrivediBelum ada peringkat

- DTZ1513 CT/VT or CT Connection: High Accuracy Three Phase Smart Meter (Class 0.2S/C or 0.5S/C)Dokumen2 halamanDTZ1513 CT/VT or CT Connection: High Accuracy Three Phase Smart Meter (Class 0.2S/C or 0.5S/C)Boubacar Mamoudou IbrahimBelum ada peringkat

- sm2000 GBDokumen4 halamansm2000 GBRikky ChaniagoBelum ada peringkat

- Three-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmDokumen12 halamanThree-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmSalaar AnsarBelum ada peringkat

- A1500 Flyer e PDFDokumen2 halamanA1500 Flyer e PDFrazvansasuBelum ada peringkat

- Fluke Topas 10201040 - EnglDokumen4 halamanFluke Topas 10201040 - EnglDiego HDBelum ada peringkat

- A1350 Flyer eDokumen2 halamanA1350 Flyer eBojan IlievBelum ada peringkat

- Aceleoromometru330450 40Dokumen9 halamanAceleoromometru330450 40AlexandraAndreeaBelum ada peringkat

- Catalogue tr-7543Dokumen2 halamanCatalogue tr-7543arupamguria05Belum ada peringkat

- 09 FCS084 A09 1 PDFDokumen2 halaman09 FCS084 A09 1 PDFsaurabh kumarBelum ada peringkat

- GTP of 400kv CVT Rev 01 - D 98Dokumen3 halamanGTP of 400kv CVT Rev 01 - D 98annuvyasBelum ada peringkat

- Absopulse PWI 150-P59Dokumen1 halamanAbsopulse PWI 150-P59Mt. SasongkoBelum ada peringkat

- Ctcore PDFDokumen1 halamanCtcore PDFALOK BEHERABelum ada peringkat

- DTZ1513 Three Phase: Modular Integrated Smart Prepayment Meter (Class 1)Dokumen2 halamanDTZ1513 Three Phase: Modular Integrated Smart Prepayment Meter (Class 1)GNBelum ada peringkat

- TDX120 DS enDokumen3 halamanTDX120 DS enMarc Paul EumagueBelum ada peringkat

- BPMSX60 64Dokumen4 halamanBPMSX60 64Bel BarretoBelum ada peringkat

- Data SheetDokumen4 halamanData Sheetoyelowo nurudeenBelum ada peringkat

- Chapter 3Dokumen2 halamanChapter 3JohnBelum ada peringkat

- Temperature Monitoring of The Motor Winding: G2TFKN02Dokumen2 halamanTemperature Monitoring of The Motor Winding: G2TFKN02Malek KamelBelum ada peringkat

- Current Limitation in High Temperature Superconducting Transformers and Impact On The GridDokumen6 halamanCurrent Limitation in High Temperature Superconducting Transformers and Impact On The GridV S B Chaitanya DuvvuryBelum ada peringkat

- TEC046-2920FTT-20210527 VarecDokumen2 halamanTEC046-2920FTT-20210527 VarecteresaBelum ada peringkat

- Switching Power Supply CalculationsDokumen4 halamanSwitching Power Supply CalculationsEdilson TavaresBelum ada peringkat

- Is 8130 1984 PDFDokumen21 halamanIs 8130 1984 PDFisaacwabbi100% (1)

- Not For SaleDokumen2 halamanNot For SalePardeep KhosaBelum ada peringkat

- Suggested Specification For Automatic Transfer Switches: 10-2006 1 Publication 3163Dokumen12 halamanSuggested Specification For Automatic Transfer Switches: 10-2006 1 Publication 3163Pardeep KhosaBelum ada peringkat

- 2.1, 2.2, 2.3, 2.4, 2.5, 2.6 PDFDokumen21 halaman2.1, 2.2, 2.3, 2.4, 2.5, 2.6 PDFPardeep KhosaBelum ada peringkat

- 7098 2Dokumen28 halaman7098 2atl1234Belum ada peringkat

- Conductorsandearthwire Accessoriesforoverheadlines: IS 2121 (Part 4) 1991Dokumen8 halamanConductorsandearthwire Accessoriesforoverheadlines: IS 2121 (Part 4) 1991Pardeep KhosaBelum ada peringkat

- IS 14665 Part-4 - 2001Dokumen40 halamanIS 14665 Part-4 - 2001Vikas Krishnavihar Kalissery100% (1)

- 694Dokumen13 halaman694farhanBelum ada peringkat

- Is 1554Dokumen14 halamanIs 1554Pardeep KhosaBelum ada peringkat

- Is 4722-2001Dokumen23 halamanIs 4722-2001Saranya Sumi100% (3)

- Microsoft PowerPoint - 9 - Final Power LayoutDokumen42 halamanMicrosoft PowerPoint - 9 - Final Power LayoutPardeep KhosaBelum ada peringkat

- Microsoft PowerPoint - 2 - Basic Design Calculation 31.08.2007 PDFDokumen27 halamanMicrosoft PowerPoint - 2 - Basic Design Calculation 31.08.2007 PDFPardeep KhosaBelum ada peringkat

- 3842 - 12 Application Guide For Electrical Relay Ac Systems PDFDokumen23 halaman3842 - 12 Application Guide For Electrical Relay Ac Systems PDFPardeep KhosaBelum ada peringkat

- 2121 - 3 Spcs For Conductor & Earth Wire Assoc. of O.H. PowerDokumen8 halaman2121 - 3 Spcs For Conductor & Earth Wire Assoc. of O.H. PowerPardeep KhosaBelum ada peringkat

- Indian Standard: Application Guide For Electrical Relays For Ac SystemsDokumen61 halamanIndian Standard: Application Guide For Electrical Relays For Ac SystemsMayank VyasBelum ada peringkat

- Motor StandardsDokumen17 halamanMotor Standardskodandaram100% (4)

- Is 4722-2001Dokumen23 halamanIs 4722-2001Saranya Sumi100% (3)

- Indian Standard: Specification For Hard-Drawn Copper Conductors For Overhead Power TransmissionDokumen19 halamanIndian Standard: Specification For Hard-Drawn Copper Conductors For Overhead Power TransmissionPardeep KhosaBelum ada peringkat

- 4146 Application Guide For Voltage Transformer PDFDokumen16 halaman4146 Application Guide For Voltage Transformer PDFPardeep KhosaBelum ada peringkat

- Indian Standard: Application Guide For Voltage Transformers (Dokumen16 halamanIndian Standard: Application Guide For Voltage Transformers (Pardeep KhosaBelum ada peringkat

- IS 14665 Part-4 - 2001Dokumen40 halamanIS 14665 Part-4 - 2001Vikas Krishnavihar Kalissery100% (1)

- 613 Copper Rods & Bars PDFDokumen12 halaman613 Copper Rods & Bars PDFPardeep KhosaBelum ada peringkat

- Ansi CodesDokumen51 halamanAnsi CodesPardeep KhosaBelum ada peringkat

- Motor StandardsDokumen17 halamanMotor Standardskodandaram100% (4)

- 7098 1 PDFDokumen18 halaman7098 1 PDFprasoon_bhardwaj_1Belum ada peringkat

- Catalogue Motor Protection Relay MPR200nXDokumen1 halamanCatalogue Motor Protection Relay MPR200nXPardeep KhosaBelum ada peringkat

- Indian Standard: Guide For Testing Synchronous Machines (Dokumen56 halamanIndian Standard: Guide For Testing Synchronous Machines (Pardeep KhosaBelum ada peringkat

- Is 1554Dokumen14 halamanIs 1554Pardeep KhosaBelum ada peringkat

- Lessons in Electric Circuits, Volume I - DCDokumen560 halamanLessons in Electric Circuits, Volume I - DCyoonghmBelum ada peringkat

- Technical Data Sheet: LPI Stormaster EseDokumen29 halamanTechnical Data Sheet: LPI Stormaster EsePardeep KhosaBelum ada peringkat

- Arandelas Hill Side A325Dokumen1 halamanArandelas Hill Side A325Oscar SanabriaBelum ada peringkat

- Network Rail Asset Protection Handbook High Speed Rail PDFDokumen58 halamanNetwork Rail Asset Protection Handbook High Speed Rail PDFhugojameswoodBelum ada peringkat

- Diagrama de MuflaDokumen56 halamanDiagrama de MuflaitzelBelum ada peringkat

- D427Dokumen4 halamanD427Nouman KhalidBelum ada peringkat

- Aircraft Performance I PDFDokumen18 halamanAircraft Performance I PDFJJBelum ada peringkat

- Rt37m5538s8hl User Manual HLDokumen92 halamanRt37m5538s8hl User Manual HLpandian002Belum ada peringkat

- Alcance Proyecto CartagenaDokumen3 halamanAlcance Proyecto CartagenamarraezBelum ada peringkat

- Manual On TransformersDokumen595 halamanManual On TransformersRK K100% (3)

- Hydropower Engineering IIDokumen141 halamanHydropower Engineering IIashe zinab100% (7)

- Separations and Reaction Engineering Design Project Production of AmmoniaDokumen10 halamanSeparations and Reaction Engineering Design Project Production of AmmoniaRyan WahyudiBelum ada peringkat

- Manual de Desarme PDFDokumen118 halamanManual de Desarme PDFSantiagoBelum ada peringkat

- Job Safety Analysis Sheet: FacilityDokumen1 halamanJob Safety Analysis Sheet: Facilitysanjeev kumar100% (1)

- John Ngaya Mukabi, PHD Full CV 23NOV09Dokumen104 halamanJohn Ngaya Mukabi, PHD Full CV 23NOV09John Ngaya MukabiBelum ada peringkat

- Bomba de Cebado DespieceDokumen2 halamanBomba de Cebado DespiecehenotharenasBelum ada peringkat

- BirthtubcleaningDokumen1 halamanBirthtubcleaningapi-419200857Belum ada peringkat

- Alpha Eritrean Engineers Magazine 2018 February IssueDokumen20 halamanAlpha Eritrean Engineers Magazine 2018 February Issuemeharigrw100% (3)

- Salary Guide for Creative, Architecture & Design ProfessionsDokumen1 halamanSalary Guide for Creative, Architecture & Design ProfessionssaaBelum ada peringkat

- Steps in production of titanium from ore to ingotsDokumen4 halamanSteps in production of titanium from ore to ingotsUyGrEdSQBelum ada peringkat

- Chilled Beams in Heating: Design Criteria and Case StudyDokumen8 halamanChilled Beams in Heating: Design Criteria and Case StudyarjantinBelum ada peringkat

- Or71 26Dokumen137 halamanOr71 26Piotr JwrskBelum ada peringkat

- T PAUL Uni DuE 2014-10-07Dokumen118 halamanT PAUL Uni DuE 2014-10-07Le LuuBelum ada peringkat

- Terrazo Concrete: Characteristics of TerrazzoDokumen8 halamanTerrazo Concrete: Characteristics of Terrazzodanishali1090Belum ada peringkat

- 50cc Engine Parts List PDFDokumen23 halaman50cc Engine Parts List PDFFebri MaulanaBelum ada peringkat

- The Bottom Up Refining Revolution Part4 PDFDokumen1 halamanThe Bottom Up Refining Revolution Part4 PDFOscar ViverosBelum ada peringkat

- Industry Alloted Property 111Dokumen46 halamanIndustry Alloted Property 111JeffBelum ada peringkat

- Compressor Data Sheet SummaryDokumen2 halamanCompressor Data Sheet SummarygoharmahmoodkhokharBelum ada peringkat

- Minimum Heights and Size Standards For Rooms Ensures That There Is Good VentilationDokumen4 halamanMinimum Heights and Size Standards For Rooms Ensures That There Is Good VentilationJaved ZakhilBelum ada peringkat

- Compact and versatile low profile cylinders for confined spacesDokumen1 halamanCompact and versatile low profile cylinders for confined spaceslaluBelum ada peringkat

- 15 Design For Safety HazanDokumen12 halaman15 Design For Safety Hazansauravsagar14Belum ada peringkat