Manual JPT Interface en v1.0.0

Diunggah oleh

tokerodevHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Manual JPT Interface en v1.0.0

Diunggah oleh

tokerodevHak Cipta:

Format Tersedia

Hardware Manual

JPT Interface Board

This manual has been compiled by RAYLASE for its customers and employees.

RAYLASE reserves the right to change the product described in this manual and the infor-

mation contained therein without prior notice.

The software included in the product and this manual itself are protected by copyright. All

rights are reserved. Duplication of this manual in whole or in part, particularly by photocopy-

ing, scanning or imaging, and reproduction by any means are forbidden without the prior, writ-

ten consent of RAYLASE.

Contents

TABLE OF CONTENTS

1 BASIC INFORMATION ................................................................................................... 4

1.1 Delivery Scope ................................................................................................................ 4

1.2 Warranty .......................................................................................................................... 4

1.3 Signs................................................................................................................................ 5

1.4 Conformity with directives ............................................................................................... 5

1.5 Laser Safety .................................................................................................................... 6

1.6 Manufacturer ................................................................................................................... 6

1.7 Customer Support ........................................................................................................... 6

1.8 Disposal ........................................................................................................................... 6

2 TECHNICAL DATA......................................................................................................... 7

2.1 Dimension and Weight .................................................................................................... 7

2.2 Environmental Conditions ............................................................................................... 7

2.3 SET-UP Procedure .......................................................................................................... 7

2.4 Connections..................................................................................................................... 8

2.4.1 JPT Laser Interface ......................................................................................................... 9

2.4.2 Laser Power Input and Laser Power Output ................................................................. 10

2.4.3 Cable Specifications ...................................................................................................... 10

2.4.4 Status LEDs................................................................................................................... 10

3 PROGRAMMING .......................................................................................................... 11

3.1 Signals ........................................................................................................................... 11

3.2 Commands .................................................................................................................... 11

3.3 Programming sequence ................................................................................................ 12

MN077 / v1.0.0 RAYLASE JPT Interface Board 3

Chapter 1 Basic Information

1 BASIC INFORMATION

The RAYLASE JPT interface board is used to control a pulsed JPT laser in combination with

RAYLASE control cards SP-ICE.

Compared to IPG interface modulation frequency is limited to 250 kHz, in order to operate the

laser JPT stable. A pulse width of 1µs is recommended. The modulation frequency limit for

JPT laser is 250 kHz.

Features

Interface to Ytterbium pulsed JPT Fiber Laser

D-SUB 25 connector for 1:1 connection to pulsed JPT laser

Detection, if 24V power is attached. Soft start to switch on the laser.

Optically isolated control signals

Detection of laser error conditions

Reset of laser after detection of laser error either by push-button or software

Support of integrated visible pointer

Quick Stop input for immediate shut off of laser output

1.1 Delivery Scope

JPT interface board

Connecting cable between JPT interface board and control card

Laser adaptor

Hardware manual

1.2 Warranty

The rights of the customer in respect of any defects in quality or deficiencies in title are gov-

erned by the general conditions of business of RAYLASE AG. These conditions are available

for review on our website.

Before returning the product, please request an authorization number from RAYLASE. Pack

the product in the original packaging or in packaging that provides equivalent protection for

shipping.

RAYLASE shall not be obliged to repair defects under the following circumstances:

If persons not authorized by RAYLASE have attempted to repair the product.

If persons not authorized by RAYLASE have modified the product.

If the product has been used improperly.

If the product has been connected to incompatible devices.

If the product has been damaged because of inadmissible high laser power or focusing the

laser on optical areas.

If the product has been damaged because of unqualified cleaning of the optical areas.

Note: No implicit guarantee or warranty of suitability for specific purposes has been made.

RAYLASE is not responsible for damages arising from use of the product. Individual assem-

blies or other assemblies manufactured by RAYLASE may be subject to separate warranty

conditions. Refer to the corresponding manuals for further information.

4 RAYLASE JPT Interface Board MN077 / v1.0.0

Basic Information Chapter 1

1.3 Signs

The following signs must be attached to the Interface Board. These signs may not be re-

moved. Signs that have become illegible must be replaced.

Rating plate

The rating plate and the identification code printed on it allow

the determination of the Interface Board type.

The CE symbol confirms the compliance of the Interface

Board with European directives. It indicates that the Interface

Board is approved for free trade within the EU.

The seal label warns against unauthorized opening of the In-

terface Board. If the seal is broken, all warranty claims against

RAYLASE are void.

1.4 Conformity with directives

The Interface Board conforms to the requirements of the following directives:

EU Directive 2004/108/EC (EMC)

WEEE Directive 2012/19/EC

RoHS II 2011/65/EU

For details of conformity with other directives, contact RAYLASE.

MN077 / v1.0.0 RAYLASE JPT Interface Board 5

Chapter 1 Basic Information

1.5 Laser Safety

Customers assume all responsibility for maintaining a laser-safe working environment. OEM

customers must assume all responsibility for CDRH (Center for Devices and Radiological

Health) certification.

WARNING:

Switch on the PC first, before switching on the laser system. In this way you can avoid an

uncontrolled action of the laser when starting the control card.

1.6 Manufacturer

RAYLASE AG

Argelsrieder Feld 2+4

82234 Wessling

Germany

Tel.: +49 (0) 81 53 - 88 98 - 0

Fax: +49 (0) 81 53 - 88 98 - 10

http://www.raylase.de

E-mail: info@raylase.de

1.7 Customer Support

The RAYLASE support services are available for your problems either in respect to the prod-

uct or the accompanying manual. Before calling for support, please make sure you refer to

any appropriate sections in this manual that may answer your questions.

If you need further assistance call RAYLASE customer service department, Monday through

Friday between 8 A.M. and 4 P.M. (Middle European Time).

The customer service personnel will be able to give you direct assistance and answers to your

questions.

Germany (Wessling)

+49 (0) 81 53 - 88 98 - 0

... ask for the customer service department

1.8 Disposal

For the disposal of the Interface Board, note local policies, regulations and laws.

6 RAYLASE JPT Interface Board MN077 / v1.0.0

Technical Data Chapter 2

2 TECHNICAL DATA

2.1 Dimension and Weight

Dimensions: W 85mm, L 103mm, H 30mm

Weight: 400g

2.2 Environmental Conditions

Ambient temperature: +15°C to +35°C

Storage temperature: 0°C to +80°C

Humidity rel.: 80% non-condensing

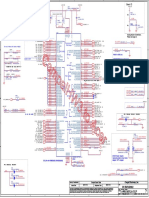

2.3 SET-UP Procedure

Make sure that all requirements for laser safety, as described in the scan head manuals, are

fulfilled. It is the user’s responsibility to follow the regulations on laser safety.

Fig. 1

Block diagram

Installation

Connect power supply for laser to J1.

Connect laser power supply output J2 to JPT laser.

Connect JPT interface board output J4 to laser interface.

Connect RAYLASE control card via adapter to JPT interface board input J3.

Switch on laser power supply. After a short delay, the laser will be switched on.

Please note: J5 must be connected to switch on the laser.

MN077 / v1.0.0 RAYLASE JPT Interface Board 7

Chapter 2 Technical Data

2.4 Connections

Fig. 2

JPT interface

board, overview

ID Assignment Details

J1 Laser Power Input (24V) ---

J2 Laser Power Output ---

J3 JPT Interface Input ---

J4 JPT Interface Output page 9

J5 Shutter / Quick Stop must be connected to switch-on the laser

T1 Laser Reset resets the laser or the JPT interface in case of a fault

8 RAYLASE JPT Interface Board MN077 / v1.0.0

Technical Data Chapter 2

2.4.1 JPT Laser Interface

J4 PIN Signal PIN Signal

1 IP0 14 GND

1 2 IP1 15 GND

3 IP2 16 Warning/Temp

14

4 IP3 17 nc

5 IP4 18 MO

13

6 IP5 19 PA

25

7 IP6 20 Frequ. Modulation (TTL)

25 PIN D-SUB 8 IP7 21 Warning/Temp

9 nc 22 Enable

10 GND 23 Quick Stop

11 GND 24 nc

12 GND 25 nc

13 GND ---

MO = Master oscillator [interface type B]

nc = Not connected

Specifications

Output

Output low max. 0.55V 64mA

Output high 2.0 – 5.0V 32mA

MN077 / v1.0.0 RAYLASE JPT Interface Board 9

Chapter 2 Technical Data

2.4.2 Laser Power Input and Laser Power Output

J1, J2 PIN Signal

1 24V

1 2 3

2 Return

Laser power

interconnection 3 Safety Ground

2.4.3 Cable Specifications

Connection Cross-section Length Signals

24V power supply − J1 min. 3x2,5mm² --- ---

J2 − JPT laser min. 3x2,5mm² max. 2m ---

J4 − JPT laser --- max. 2m 1:1

2.4.4 Status LEDs

LED Meaning

1 2 3 4

green - - - 5V Input Voltage from control card is ready

- green - - 24V Input Voltage for laser is ready

- - red - Soft start process of JPT laser is active.

24V Output

- - green - JPT laser is powered up

- - - red Laser emission ON Laser is active

LED Meaning

5 6 7

green green green Normal state

yellow - - Shutter open (combinations with other fault possible)

- - red Laser temperature out of range

red* red* red* Internal system error

* flashing

10 RAYLASE JPT Interface Board MN077 / v1.0.0

Programming Chapter 3

3 PROGRAMMING

The following sections describe how to program an JPT laser for use with RAYLASE control

card and RAYLASE JPT interface board.

3.1 Signals

Use the following signals to program the JPT interface board:

Signals of control card Description

/LM Setting Input Pulse Repetition Rate of JPT Laser

/MIP Switching On/Off the Master Oscillator Input of JPT Laser

/FPS Setting Power Setting Latch Input of JPT Laser

/PB 0-7 Setting 8 Bit Power Inputs of JPT Laser

/LM_Gate Switching On/Off the Laser Modulation Input of JPT Laser

/Remote_Execute 1 Reset JPT Laser after Detection of Alarm Condition

/PA 6 Monitors the error status of the laser

3.2 Commands

To program the JPT interface board use the following commands:

Set_Delays_7_8, Set_Delays_9_10

Write_Port_List

Long_Delay

Read_Port

Write_Port

YAG1-Mode is required, Bit 4 = 0, Bit 5 = 1

See also the manual „Commands and Functions“ for details.

MN077 / v1.0.0 RAYLASE JPT Interface Board 11

Chapter 3 Programming

3.3 Programming sequence

Initialisation:

Init_Scan_Card (); // Initialise Scan Card

Load_Cor (lpstrFileName); // Load Correction File

Set_Mode (0x0420); // Set YAG1-mode (Bit 5 = 1, Bit

4 = 0)

Setting Master Oscillator input of JPT Laser with Control Commands:

Set_Start_List_1(); // Filling Job Data into List 1

Set_Delays_7_8 (t1, t2); // Set Laser Modulation Signal

Set_Delays_9_10 (t3, t4); // t4 = 0

Write_Port_List (0x0A, value); // Set Laser Power

... // List Commands for Marking

Set_End_Of_List();

... // Start Marking

Write_Port (0x0C, 0x0010); // Switch-On Master Oscillator of

JPT Laser

... // Wait 10msec

Execute_List_1(); // Execute Job

...

Write_Port (0x0C, 0x0000); // Switch-Off Master Oscillator

of JPT Laser

Setting Master Oscillator input of JPT Laser with List Commands:

Set_Start_List_1(); // Filling Job Data into List 1

Write_Port_List (0x0C, 0x0010); // Switch-On Master Oscillator of

JPT Laser

Long_Delay 1000(); // Wait 10msec

Set_Delays_7_8 (t1, t2); // Set Laser Modulation Signal

Set_Delays_9_10 (t3, t4); // t4 = 0

Write_Port_List (0x0A, value); // Set Laser Power

... // List Commands for Marking

Write_Port_List (0x0C, 0x0); // Switch-Off Master Oscillator

of JPT Laser

Set_End_Of_List();

...

Execute_List_1(); // Execute Job

Checking Laser Alarms and Resetting of JPT Laser:

Read_Port (0x08); // Read Bit 6 of Port A for

checking of Laser Alarm

// If Bit 6 set to FALSE then an

error occured

...

Write_Port (0x0C, 0x0020); // Set Signal Remote_Execute_1 to

TRUE

... // Wait 1ms

Write_Port (0x0C, 0x0); // Set Signal Remote_Execute_1 to

FALSE

12 RAYLASE JPT Interface Board MN077 / v1.0.0

Index

INDEX

C L

CE symbol....................................................... 5

Laser Safety ................................................ 6, 7

Conformity with directives ............................... 5

Connections .................................................... 8

Customer Support ........................................... 6 M

Manufacturer ................................................... 6

D

Delivery Scope ................................................ 4 R

Dimension ....................................................... 7

Disposal .......................................................... 6 Rating plate ..................................................... 5

E S

Environmental Conditions ............................... 7 Seal label ........................................................ 5

SET-UP Procedure ......................................... 7

Signs ............................................................... 5

F

Features .......................................................... 4 T

Technical Data ................................................ 7

I

Installation ....................................................... 7 W

Warranty.......................................................... 4

J Weight ............................................................. 7

JPT-Laser Interface......................................... 9

MN077 / v1.0.0 RAYLASE JPT Interface Board 13

Anda mungkin juga menyukai

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDari EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusBelum ada peringkat

- Docsity Uzam PLC Ew 22 ArticlesDokumen94 halamanDocsity Uzam PLC Ew 22 ArticlesRecep Ivedik100% (1)

- Caddy LHN 130, 140, 200, (Caddy) PDFDokumen36 halamanCaddy LHN 130, 140, 200, (Caddy) PDFPE TruBelum ada peringkat

- Hitaci B PDFDokumen461 halamanHitaci B PDFakilBelum ada peringkat

- Tolerance Data 2009.1 Tools 1. "999-5452"Dokumen8 halamanTolerance Data 2009.1 Tools 1. "999-5452"volvoosad100% (1)

- Kirisun PT260-Service-ManualDokumen29 halamanKirisun PT260-Service-ManualRobertinoBelum ada peringkat

- A.C Components PDFDokumen368 halamanA.C Components PDFTERO100% (1)

- A5 Octavia Audience CarRadioDokumen17 halamanA5 Octavia Audience CarRadioJesús NuñoBelum ada peringkat

- VW SSP PDFDokumen78 halamanVW SSP PDFAndres GuamanBelum ada peringkat

- Vanagon 1 9 WBX Manual 1983 (1) CompressedDokumen52 halamanVanagon 1 9 WBX Manual 1983 (1) CompressedJonathan RamosBelum ada peringkat

- 05-1-26am5 1995 MYRecall R493 PDFDokumen18 halaman05-1-26am5 1995 MYRecall R493 PDFbibibibibiib123123Belum ada peringkat

- 1996 850 Wiring DiagramDokumen238 halaman1996 850 Wiring DiagramwilderBelum ada peringkat

- Glow Plug DriverDokumen2 halamanGlow Plug DrivercooldamageBelum ada peringkat

- Owners Manual - 5NA012720ADDokumen341 halamanOwners Manual - 5NA012720ADPauloBelum ada peringkat

- Ati 1165615269Dokumen15 halamanAti 1165615269Bob Runman100% (1)

- 1991 VW LT Owners ManualWMDokumen141 halaman1991 VW LT Owners ManualWMTom capitao. skipperBelum ada peringkat

- Restraints: Air Bag ModuleDokumen135 halamanRestraints: Air Bag ModuleFabianBelum ada peringkat

- CURTIS 50152 - 1298 - RevG3Dokumen6 halamanCURTIS 50152 - 1298 - RevG3Iker BasqueAdventureBelum ada peringkat

- Transtig 1600 Transtig 1700: Operating Instructions Spare Parts List GBDokumen58 halamanTranstig 1600 Transtig 1700: Operating Instructions Spare Parts List GBSaulius KuzmaBelum ada peringkat

- Control UnitDokumen13 halamanControl Unitgourav chauhanBelum ada peringkat

- Pioneer Gm-A6604 Crt5455Dokumen31 halamanPioneer Gm-A6604 Crt5455boroda2410Belum ada peringkat

- Carrier DC Inverter Xpower DiamondDokumen16 halamanCarrier DC Inverter Xpower Diamondesteban0% (1)

- Safety Recall H03 Front Control Module: Dealer Service Instructions ForDokumen9 halamanSafety Recall H03 Front Control Module: Dealer Service Instructions ForobazmssamiBelum ada peringkat

- Range Rover - 1995 - 4th EditionDokumen569 halamanRange Rover - 1995 - 4th EditionJorge TeixeiraBelum ada peringkat

- MMI A4 - A5 - Q5 - Q3 - A6 Manual - AC Canbus PDFDokumen5 halamanMMI A4 - A5 - Q5 - Q3 - A6 Manual - AC Canbus PDFLucas Ferero CasadBelum ada peringkat

- Aeon NEW SPORTY 125-180 Repair ManualDokumen93 halamanAeon NEW SPORTY 125-180 Repair ManualGassmeBelum ada peringkat

- 5MT Manual Trans & DiffDokumen82 halaman5MT Manual Trans & DiffghotimeBelum ada peringkat

- 0349 300 543 Spare PartsDokumen14 halaman0349 300 543 Spare PartsJaime ArreolaBelum ada peringkat

- SprinterDokumen292 halamanSprinterHector HectorBelum ada peringkat

- 1.577 81 1.655 66 77 KW TDI CR Engine (CAYA CAYB CAYC CLNA CWXB CWXC)Dokumen577 halaman1.577 81 1.655 66 77 KW TDI CR Engine (CAYA CAYB CAYC CLNA CWXB CWXC)Kunji ManiBelum ada peringkat

- M35160 Ug Rev 3Dokumen19 halamanM35160 Ug Rev 3FreezzbyBelum ada peringkat

- .Toshiba Satelilite L675 - LA-6042PDokumen58 halaman.Toshiba Satelilite L675 - LA-6042PАлександр Ткачук100% (2)

- High Beam Assist (FLA) Retrofit Kit - Mirror With FLA Camera, Steering Wheel Column..Dokumen10 halamanHigh Beam Assist (FLA) Retrofit Kit - Mirror With FLA Camera, Steering Wheel Column..Zakaria ElBelum ada peringkat

- 960 - 1996 Owner's ManualDokumen254 halaman960 - 1996 Owner's ManualhucnBelum ada peringkat

- Front SuspensionDokumen3 halamanFront Suspensionjacob.313Belum ada peringkat

- Formula R1 Racing - Explosionszeichnungen Und Adapter PDFDokumen9 halamanFormula R1 Racing - Explosionszeichnungen Und Adapter PDFIBC_TobiBelum ada peringkat

- Ae-Hev Hyundai IoniqDokumen107 halamanAe-Hev Hyundai IoniqafboullosaBelum ada peringkat

- Kawasaki Z1000 - 2009 - Manual de Usuario ENGDokumen165 halamanKawasaki Z1000 - 2009 - Manual de Usuario ENGParts JkawaBelum ada peringkat

- 2010 Mclass PDFDokumen368 halaman2010 Mclass PDFSomadbsiBelum ada peringkat

- Wiper Linkage 2023 CatalogDokumen35 halamanWiper Linkage 2023 CatalogAlice DaiBelum ada peringkat

- Mercedes 7g-Tronic PlusDokumen6 halamanMercedes 7g-Tronic PlusЕвгений ДударевBelum ada peringkat

- EV6000 Series Inverter Controller Inside User ManualDokumen96 halamanEV6000 Series Inverter Controller Inside User ManualCarlito MoralesBelum ada peringkat

- Instrument Panel Yaris 2008Dokumen89 halamanInstrument Panel Yaris 2008Pat NeenanBelum ada peringkat

- Inverter - English 2022Dokumen17 halamanInverter - English 2022Dudes and ToolsBelum ada peringkat

- Special Features of The MEGANE Sports TourerDokumen102 halamanSpecial Features of The MEGANE Sports Tourerhrc555Belum ada peringkat

- Frame Contained PDF File, Click To ViewDokumen263 halamanFrame Contained PDF File, Click To ViewArtur ArturowskiBelum ada peringkat

- Harrop Lc200-1ur InstallDokumen22 halamanHarrop Lc200-1ur InstallArtur ElectroMecânicoBelum ada peringkat

- Dayco Serpentine Belt GuideDokumen89 halamanDayco Serpentine Belt GuidemastervikingBelum ada peringkat

- 2007 250SXFDokumen43 halaman2007 250SXFMartin ValderramaBelum ada peringkat

- VW Passat B7 LightsDokumen8 halamanVW Passat B7 LightsasouliotBelum ada peringkat

- 1.4 Golf Fluctuating Idle and Poor StartingDokumen23 halaman1.4 Golf Fluctuating Idle and Poor StartingEngine Tuning UPBelum ada peringkat

- X250 Handbrake AdjustmentDokumen3 halamanX250 Handbrake AdjustmentJohn Greenslade100% (1)

- 2007 Saab 9-5 Owners PDFDokumen288 halaman2007 Saab 9-5 Owners PDFRicky-LeeBelum ada peringkat

- Panasonic Lumix DMC-FZ50 Service ManualDokumen69 halamanPanasonic Lumix DMC-FZ50 Service Manualdasxax100% (1)

- Ks Si 0014 en WebDokumen0 halamanKs Si 0014 en WebMoaed KanbarBelum ada peringkat

- Rear - Camera MINI OEMDokumen18 halamanRear - Camera MINI OEMEdiJonBelum ada peringkat

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDari EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualBelum ada peringkat

- Quotation and Service ManagementDokumen74 halamanQuotation and Service ManagementRohan Badri100% (1)

- VTC - Advanced Ethical HackingDokumen4 halamanVTC - Advanced Ethical Hackingapi-302336343Belum ada peringkat

- Grading Summary For ECE 2031 Lab ReportsDokumen13 halamanGrading Summary For ECE 2031 Lab ReportsChaewon MinBelum ada peringkat

- Events in Classical Reports of Sap AbapDokumen2 halamanEvents in Classical Reports of Sap AbapNagesh reddyBelum ada peringkat

- Processing AGILE Files Using XIDokumen15 halamanProcessing AGILE Files Using XIUma SaranBelum ada peringkat

- Ura PCHDokumen27 halamanUra PCHRajneesh Mohan100% (1)

- Passive Optical NetworkDokumen12 halamanPassive Optical NetworkRadh KamalBelum ada peringkat

- Print FinalDokumen78 halamanPrint FinalSATHISH MOTHEBelum ada peringkat

- Alcatel-Lucent KPI Optimization Test Plan For LTE April 22, 2010Dokumen41 halamanAlcatel-Lucent KPI Optimization Test Plan For LTE April 22, 2010dutta.somnathBelum ada peringkat

- For Power Consumption Measurement: PWM OutputDokumen1 halamanFor Power Consumption Measurement: PWM OutputyencoBelum ada peringkat

- OSPFDokumen3 halamanOSPFjamalnizamBelum ada peringkat

- Cpco - B - Cisco Prime Collaboration Provisioning Guide 11 6 PDFDokumen500 halamanCpco - B - Cisco Prime Collaboration Provisioning Guide 11 6 PDFMahmoud RamadanBelum ada peringkat

- Commandes Ms Dos en PDFDokumen2 halamanCommandes Ms Dos en PDFTimBelum ada peringkat

- Integra SPPT Elastix Asterisk ConfigurationDokumen24 halamanIntegra SPPT Elastix Asterisk ConfigurationBruno AurélioBelum ada peringkat

- Format Question Bank RevisedDokumen21 halamanFormat Question Bank RevisedkhananuBelum ada peringkat

- BCS-011 Computer Basics and PC Software Solved Assignment 2017Dokumen17 halamanBCS-011 Computer Basics and PC Software Solved Assignment 2017Sumit RanjanBelum ada peringkat

- Itu-T Q.1912.5 P020100707552040138128Dokumen114 halamanItu-T Q.1912.5 P020100707552040138128oneronerdBelum ada peringkat

- Sop For Image ProcessingDokumen5 halamanSop For Image ProcessingLOKESHWARA REDDYBelum ada peringkat

- CLDokumen252 halamanCLHenry1584Belum ada peringkat

- Active Directory Domain Services in The Perimeter Network (Windows Server 2008)Dokumen51 halamanActive Directory Domain Services in The Perimeter Network (Windows Server 2008)Ivan Brčić100% (1)

- Claxseries300E HAWK 300E: Product DataDokumen2 halamanClaxseries300E HAWK 300E: Product DataErmiasBelum ada peringkat

- EAS 520 UmassD Syllabus SheerDokumen2 halamanEAS 520 UmassD Syllabus SheerGurugubelli Venkata SukumarBelum ada peringkat

- IPNMS Technical Proposal - FinalDokumen50 halamanIPNMS Technical Proposal - FinalshareyhouBelum ada peringkat

- Coding With Minecraft 1 Introduction Student Workbook 1Dokumen13 halamanCoding With Minecraft 1 Introduction Student Workbook 1THONG JIAN YANG Moe0% (4)

- CI2001AS, BS - Owner's Manual PDFDokumen30 halamanCI2001AS, BS - Owner's Manual PDFErnesto TorresBelum ada peringkat

- Unxadm 3 ADokumen12 halamanUnxadm 3 AasaadsaadBelum ada peringkat

- Company ProfileDokumen5 halamanCompany ProfilePlaban Pratim BhuyanBelum ada peringkat

- MPLS - Troubleshooting GuideDokumen176 halamanMPLS - Troubleshooting GuideMai Saleh75% (4)

- Neo4j in Depth by Max de MarziDokumen88 halamanNeo4j in Depth by Max de MarziRyan DuttBelum ada peringkat

- Ac701 Bist PDF xtp194 2012.4 CDokumen32 halamanAc701 Bist PDF xtp194 2012.4 Cululuk21Belum ada peringkat