Iom-1 2 21

Diunggah oleh

chris110Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Iom-1 2 21

Diunggah oleh

chris110Hak Cipta:

Format Tersedia

I-1-A

John Crane

Simple Shaft Seal

Installation and

Troubleshooting for

Types 1, 2 and 21

INSTALLATION

Step 1: Mark the face of the stuffing box

on the shaft.

1

4 Square Tool Stock

45˚

Suggested Marking Tool

Step 2:

Polish shaft about the same

as a ground surface.

Check for proper radius or

chamfer. Remove burrs.

INSTALLATION (continued)

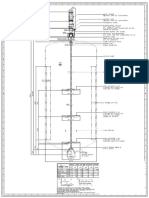

Step 3: Look at pump installation

drawing. Locate installation

Inst. Ref.

reference dimension (the

1 3/32

dimension from the face of

the stuffing box to the rear

of the seal).

John Crane Inc.

Step 4:

Measure the installation reference

dimension and mark the shaft

with a felt tip pen, layout dye

or marking tool.

Installation

Reference

An alternate method is to measure from the face to the

stuffing box to the end of the shaft. Then, subtract the

installation dimension. This gives you the dimension

from the end of the shaft to the rear of the seal.

Step 5:

Lubricate seal I.D. with

light oil, “STP,” ethylene

glycol (anti-freeze) or

soapy water. Slide seal

over shaft. Lock set

screw collar in place.

Put the seat and gland

together and slide over shaft. IMPORTANT: Oil is injurious to some rubbers such as ethylene propylene.

Use only anti-freeze or soapy water to lubricate.

Step 6: Reassemble pump.

TROUBLESHOOTING

Step 1: Seal Wears Out Shaft

Reason: Pump is in poor mechanical Check bearings for shaft end play.

condition. Check squareness Check bearings

of stuffing box face to shaft for radial shaft

centerline (.002” max. ). .002” movement.

max.

.002”

max.

Check shaft straightness.

.002”

max.

.002”

max.

Step 2: Seal is Burned Up

Reason: Not enough liquid flow to seal.

Check flush line to

be sure it is clear.

Check location or flush port.

It should be as close to seal

face as possible.

Did the pump

cavitate or run dry?

TROUBLESHOOTING (continued)

To seal

STEP 3: Seal is Worn Out

Reason: Abrasives are in the seal cavity.

The pumped liquid may be

carrying dirt, rust or suspended

abrasive particles.

If so, install an abrasives separator in the In

flush line.

A filter will also work.

If the liquid carries dissolved solids, contact

your local John Crane Representative.

To low pressure

John Crane Mechanical Seals

Engineered Sealing Systems

North America Latin America Europe, Middle East, Africa Asia Pacific

Morton Grove, Illinois USA Mexico City, Mexico Slough, UK Singapore

Tel: 1-847-967-2400 Tel: 52-5-567-4511 Tel: 44-1753-224000 Tel: 65-222-9161

Fax: 1-847-967-3915 Fax: 52-5-587-2342 Fax: 44-1753-224224 Fax: 65-223-5035

1-800-SEALING

If the products featured will be used in a potentially dangerous and/or hazardous process, your John Crane representative should be consulted prior to their selection and use.

In the interest of continuous development, John Crane Companies reserve the right to alter designs and specifications without prior notice.

©1998 John Crane Mechanical Seals Print 4/98 Web Site: http://www.johncrane.com ISO 9001 Certified

Anda mungkin juga menyukai

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementDari EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Dari EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Penilaian: 5 dari 5 bintang5/5 (2)

- Mechanical Seal Presentation (2009)Dokumen28 halamanMechanical Seal Presentation (2009)LelosPinelos123100% (5)

- Anchor Bolt Grouting GuideDokumen2 halamanAnchor Bolt Grouting Guidetotoy1234Belum ada peringkat

- Troubleshooting of Mechanical Seals PDFDokumen5 halamanTroubleshooting of Mechanical Seals PDFNasser KhattabBelum ada peringkat

- Fis122 Cartridge InstallDokumen4 halamanFis122 Cartridge InstalllubangjarumBelum ada peringkat

- Fis122 Cartridge Install PDFDokumen4 halamanFis122 Cartridge Install PDFPdm BadakBelum ada peringkat

- CFA Sample Method Statement:: Resin Injection Anchors - in ConcreteDokumen2 halamanCFA Sample Method Statement:: Resin Injection Anchors - in ConcreteansarisaeedBelum ada peringkat

- Radial Shaft Seals - Troubleshooting 2016Dokumen46 halamanRadial Shaft Seals - Troubleshooting 2016Chia PeterBelum ada peringkat

- A Guide To Shaft SealsDokumen5 halamanA Guide To Shaft SealsSrinivasan RaviBelum ada peringkat

- Positest: Pull-Off Adhesion TesterDokumen12 halamanPositest: Pull-Off Adhesion TesterASESORIAS SOLDADURASBelum ada peringkat

- LT36720 Drain Valve Service InstructionsDokumen3 halamanLT36720 Drain Valve Service InstructionsKe HalimunBelum ada peringkat

- Valve Lapping PDFDokumen3 halamanValve Lapping PDFAmy Hull100% (1)

- (001-026) Cylinder BlockDokumen30 halaman(001-026) Cylinder Blockteknisi ABBelum ada peringkat

- CB Series Installation ManualDokumen8 halamanCB Series Installation ManualJuan Jose Ramirez CorralesBelum ada peringkat

- V PAT TechniqueDokumen8 halamanV PAT TechniqueCls RicardoBelum ada peringkat

- Mech Seal FundamentalsDokumen117 halamanMech Seal FundamentalsSri Sri100% (1)

- VW CrackmeterDokumen9 halamanVW CrackmeterGema MarisolBelum ada peringkat

- JC Seal Leakage CausesDokumen1 halamanJC Seal Leakage CausesasrikalyanBelum ada peringkat

- Manual de Reparacion Motor Jac 4da1 Parte 4Dokumen100 halamanManual de Reparacion Motor Jac 4da1 Parte 4Anonymous iBenl3mNBelum ada peringkat

- What Is Tappet Clearance - How To Check and Adjust Tapper Clearance - MarinesiteDokumen6 halamanWhat Is Tappet Clearance - How To Check and Adjust Tapper Clearance - MarinesiteIslam SahafayatBelum ada peringkat

- OsmaDrain Jointing Quick GuideDokumen2 halamanOsmaDrain Jointing Quick GuideHatem AbdelnabiBelum ada peringkat

- Nstructions OR Amshaft Earing OOL: I F C B TDokumen2 halamanNstructions OR Amshaft Earing OOL: I F C B TcunBelum ada peringkat

- PD Trainee-Mechanical Seal#1Dokumen39 halamanPD Trainee-Mechanical Seal#1Oktobena F.TariganBelum ada peringkat

- 14.0 Casing RepairDokumen19 halaman14.0 Casing RepairSaritaBelum ada peringkat

- Reduce Clamping Issues in Gleason 20088/20089Dokumen18 halamanReduce Clamping Issues in Gleason 20088/20089nestorBelum ada peringkat

- Chrysler AS Town Country Caravan Voyager 1994 Service Manual Body ComponentsDokumen46 halamanChrysler AS Town Country Caravan Voyager 1994 Service Manual Body Componentssimple383Belum ada peringkat

- Mz562863ex Lancer PG1Dokumen7 halamanMz562863ex Lancer PG1fonid53894Belum ada peringkat

- Installation Guide: LS2 Dry Sleeve KitDokumen18 halamanInstallation Guide: LS2 Dry Sleeve KitManabu WakisakaBelum ada peringkat

- WWW - Zerelli.com Form Leakageguide - PHPDokumen4 halamanWWW - Zerelli.com Form Leakageguide - PHPBolso InteligenteBelum ada peringkat

- NorrisDokumen2 halamanNorrisGhodbunderBelum ada peringkat

- Cased Hole Logging Procedures: Special ConsultationsDokumen32 halamanCased Hole Logging Procedures: Special ConsultationsAhmed GharbiBelum ada peringkat

- 3DD029-A06-IOM-Gate Globe and Check ValvesDokumen6 halaman3DD029-A06-IOM-Gate Globe and Check ValvesgabrielBelum ada peringkat

- Ficha Tecnica Positestat-mautomaticdefelsko Es133Dokumen43 halamanFicha Tecnica Positestat-mautomaticdefelsko Es133José Lébolo OrtizBelum ada peringkat

- JSA-Dewatering Activities 2Dokumen1 halamanJSA-Dewatering Activities 2halfy safitri100% (4)

- Manual de Instalação 442 LargeDokumen12 halamanManual de Instalação 442 LargeDanilo D'AmatoBelum ada peringkat

- Instruction Manual 6460: Lead Seal Cementing Type Casing PatchDokumen10 halamanInstruction Manual 6460: Lead Seal Cementing Type Casing PatchRagui StephanosBelum ada peringkat

- Conax MHM Series Assembly InstructionsDokumen4 halamanConax MHM Series Assembly InstructionsColin ZhangBelum ada peringkat

- Tas 85 Manual 1Dokumen4 halamanTas 85 Manual 1Mauricio Ariel H. OrellanaBelum ada peringkat

- Norris Recommended Makeup Procedures T003 V02 081908Dokumen2 halamanNorris Recommended Makeup Procedures T003 V02 081908Hamed Gerami100% (1)

- Norris Recommended Makeup Procedures T003 V02 081908 PDFDokumen2 halamanNorris Recommended Makeup Procedures T003 V02 081908 PDFHamed GeramiBelum ada peringkat

- Clipper Duet Manual 19 PDFDokumen16 halamanClipper Duet Manual 19 PDFcarylangleyBelum ada peringkat

- KYB and Showa Shock ServiceDokumen4 halamanKYB and Showa Shock ServiceJose Luis SabinoBelum ada peringkat

- PDF139Dokumen2 halamanPDF139Rodolfo AlbaBelum ada peringkat

- Basics Sealing Fundamental (BPS-Pertamina) 2Dokumen91 halamanBasics Sealing Fundamental (BPS-Pertamina) 2Yahya AyasBelum ada peringkat

- Installation Instructions: Durametallic MW-200 SeriesDokumen8 halamanInstallation Instructions: Durametallic MW-200 SeriesEli Emmanuel Cárcamo Rodríguez100% (1)

- Stromberg NeedleDokumen2 halamanStromberg Needlevanapeer100% (2)

- EN75558 FP TroubleshootingGuideDokumen8 halamanEN75558 FP TroubleshootingGuideALEXSANDROBelum ada peringkat

- 320D2 Troubleshooting9Dokumen124 halaman320D2 Troubleshooting9evan100% (6)

- 320D2 Troubleshooting2Dokumen5 halaman320D2 Troubleshooting2evan100% (1)

- Jar Intensifiers: Instruction Manual 4019Dokumen20 halamanJar Intensifiers: Instruction Manual 4019bilalpearltecBelum ada peringkat

- Front Brakes 1-10Dokumen10 halamanFront Brakes 1-10api-327987286Belum ada peringkat

- 40 90 Mechanical Seal Kits SWIDokumen2 halaman40 90 Mechanical Seal Kits SWIWong DaBelum ada peringkat

- TRW Input Shaft Seal RemovalDokumen6 halamanTRW Input Shaft Seal RemovalMichael ForrestBelum ada peringkat

- Installation, Operation & Maintenance Manual: Model 72 Simplex Basket Strainer, Sizes 3/8" - 8"Dokumen5 halamanInstallation, Operation & Maintenance Manual: Model 72 Simplex Basket Strainer, Sizes 3/8" - 8"Arvnd VckyBelum ada peringkat

- 3-Well Complation PDFDokumen4 halaman3-Well Complation PDFDodi DodoBelum ada peringkat

- Oil and Gas Well Completion TaskDokumen4 halamanOil and Gas Well Completion Taskapi-370721250% (2)

- Service Manual Rgd/Rgs Series Index Drives Models 350RGD/RGS, 500RGD/RGS & 600RGD/RGSDokumen16 halamanService Manual Rgd/Rgs Series Index Drives Models 350RGD/RGS, 500RGD/RGS & 600RGD/RGSSuhas KODREBelum ada peringkat

- Service Procedures Safety Precautions and WarningsDokumen122 halamanService Procedures Safety Precautions and WarningsRob GustBelum ada peringkat

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Dari EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Belum ada peringkat

- Oil TypeDokumen2 halamanOil Typechris110Belum ada peringkat

- Future DevelopmentDokumen1 halamanFuture Developmentchris110Belum ada peringkat

- PIP PIC Part3Dokumen10 halamanPIP PIC Part3chris110Belum ada peringkat

- P&ID Symbol Diagram Basics - Part 2: International StandardsDokumen14 halamanP&ID Symbol Diagram Basics - Part 2: International Standardschris110100% (1)

- Be 3Dokumen2 halamanBe 3chris110Belum ada peringkat

- Packing and Distributor Technology: Dan Summers - March 8, 2011Dokumen51 halamanPacking and Distributor Technology: Dan Summers - March 8, 2011chris110Belum ada peringkat

- Be 2Dokumen2 halamanBe 2chris110Belum ada peringkat

- Bio EthanolDokumen2 halamanBio Ethanolchris110Belum ada peringkat

- Be 4Dokumen2 halamanBe 4chris110Belum ada peringkat

- Be 1Dokumen2 halamanBe 1chris110Belum ada peringkat

- PIP PIC Part1Dokumen9 halamanPIP PIC Part1chris110Belum ada peringkat

- PIP PIC001 Documentation CriteriaDokumen10 halamanPIP PIC001 Documentation Criteriachris110Belum ada peringkat

- GA Drawing - MixerDokumen1 halamanGA Drawing - Mixerchris110Belum ada peringkat

- P&ID Diagram Basics - Part 1 Purpose, Owner & ContentsDokumen15 halamanP&ID Diagram Basics - Part 1 Purpose, Owner & Contentschris110100% (1)

- Essential Water Chiller ManualDokumen2 halamanEssential Water Chiller Manualchris110Belum ada peringkat

- Dunham Bush - IntroductionDokumen3 halamanDunham Bush - Introductionchris110Belum ada peringkat

- Chiller - Touch Screen - Status ReadingDokumen2 halamanChiller - Touch Screen - Status Readingchris110Belum ada peringkat

- Dunham Bush - General InfoDokumen3 halamanDunham Bush - General Infochris110Belum ada peringkat

- Chiller - Schematic Piping DiagramDokumen1 halamanChiller - Schematic Piping Diagramchris110Belum ada peringkat

- Chiller - Dimensional DataDokumen1 halamanChiller - Dimensional Datachris110Belum ada peringkat

- Force and Moment LimitDokumen1 halamanForce and Moment Limitchris110Belum ada peringkat

- Addendum To Chiller Design - Floor Flooding DiagramDokumen1 halamanAddendum To Chiller Design - Floor Flooding Diagramchris110Belum ada peringkat

- Eco 207e51Dokumen1 halamanEco 207e51chris110Belum ada peringkat

- E6855 - Add Rev01Dokumen8 halamanE6855 - Add Rev01chris110Belum ada peringkat

- Force and Moment LimitDokumen1 halamanForce and Moment Limitchris110Belum ada peringkat

- 380VY 50Hz 1.1kW 4P M3GP Motor Data Sheet (IE3 & IP56)Dokumen3 halaman380VY 50Hz 1.1kW 4P M3GP Motor Data Sheet (IE3 & IP56)chris110Belum ada peringkat

- DBG5 Touch Screen Display Write UpDokumen9 halamanDBG5 Touch Screen Display Write Upchris110Belum ada peringkat

- Section A-A: Grounding Lug DetailDokumen1 halamanSection A-A: Grounding Lug Detailchris110Belum ada peringkat

- KRN - Vortex Flow MeterDokumen4 halamanKRN - Vortex Flow Meterchris110Belum ada peringkat

- KRN - Vortex Flow Meter FT4301Dokumen4 halamanKRN - Vortex Flow Meter FT4301chris110Belum ada peringkat

- Lighting System: SectionDokumen280 halamanLighting System: SectionChristopher DuffinBelum ada peringkat

- Modeling of Spindle-Bearing and Machine Tool Systems For Virtual Simulation of Milling OperationsDokumen9 halamanModeling of Spindle-Bearing and Machine Tool Systems For Virtual Simulation of Milling OperationsYak OubBelum ada peringkat

- Putzmeister M36 DataDokumen2 halamanPutzmeister M36 DataJayath Bogahawatte67% (3)

- Fixture Mount Integral Luminaire Occupancy Sensors (OSF10) Data Sheet PDFDokumen2 halamanFixture Mount Integral Luminaire Occupancy Sensors (OSF10) Data Sheet PDFRobertoHerediaJacoboBelum ada peringkat

- A320 Fuel System SchematicDokumen1 halamanA320 Fuel System SchematicAmir BoulkoutBelum ada peringkat

- SEBoK v. 1.9.1 PDFDokumen1.035 halamanSEBoK v. 1.9.1 PDFprasoft100% (1)

- UK DynaSand C0209Dokumen2 halamanUK DynaSand C0209Mee DepoBelum ada peringkat

- Em Band ElectDokumen11 halamanEm Band ElectMayank Kumar VermaBelum ada peringkat

- The Drawing Club - Master The Art of Drawing Characters From Life (2014)Dokumen147 halamanThe Drawing Club - Master The Art of Drawing Characters From Life (2014)Ronald Meza Puentes100% (5)

- c172 Exam Edited1Dokumen5 halamanc172 Exam Edited1rayaduqsBelum ada peringkat

- Vehicle MainDokumen89 halamanVehicle MainmgitecetechBelum ada peringkat

- Jindal SteelDokumen8 halamanJindal SteelVishal HBelum ada peringkat

- 5182 Aluminium: Take-Away FactsDokumen5 halaman5182 Aluminium: Take-Away FactsshakeerBelum ada peringkat

- Water: City of RichardsonDokumen15 halamanWater: City of RichardsonSnezana RaicevicBelum ada peringkat

- Brosur NKDokumen8 halamanBrosur NKHeroe PoernomoBelum ada peringkat

- The Role of Modularity in Sustainable Design - A Systematic ReviewDokumen14 halamanThe Role of Modularity in Sustainable Design - A Systematic ReviewAlejandra QuintinBelum ada peringkat

- Hotel Cortez - Autocad VersionDokumen32 halamanHotel Cortez - Autocad Versionapi-624704399Belum ada peringkat

- Foundation Plan - Level 1: 2'-0" SLAB TOS - 5'-4" BOS - 7'-6"Dokumen1 halamanFoundation Plan - Level 1: 2'-0" SLAB TOS - 5'-4" BOS - 7'-6"Godino ChristianBelum ada peringkat

- Plan - Soldier Pile Wall Without P. G. A.: Timber Lagging SizesDokumen1 halamanPlan - Soldier Pile Wall Without P. G. A.: Timber Lagging SizesgmkmalBelum ada peringkat

- Service Manual: Color Television Chassis No. SN-81Dokumen2 halamanService Manual: Color Television Chassis No. SN-81Manuel SierraBelum ada peringkat

- Comparison of Product Carbon Footprint Standards With A Case Study On Poinsettia (Euphorbia Pulcherrima)Dokumen12 halamanComparison of Product Carbon Footprint Standards With A Case Study On Poinsettia (Euphorbia Pulcherrima)Liah Piano-Beast UchihaBelum ada peringkat

- Shallow PileDokumen32 halamanShallow PileBao Gia LuongBelum ada peringkat

- Automatic Scorer CatalogDokumen222 halamanAutomatic Scorer CatalogNathan Bukoski100% (1)

- Lapp - Pro217en - PT FSL 5x075 - Db0034302en - DatasheetDokumen1 halamanLapp - Pro217en - PT FSL 5x075 - Db0034302en - DatasheetMihai BancuBelum ada peringkat

- Thesis ReportDokumen35 halamanThesis ReportKashif MuhammadBelum ada peringkat

- (Rock Crusher) : Machine Design 2Dokumen64 halaman(Rock Crusher) : Machine Design 2almira genabeBelum ada peringkat

- Trump BakerDokumen3 halamanTrump BakerNadya PriciliaBelum ada peringkat

- Chilled Beams in Heating: Design Criteria and Case StudyDokumen8 halamanChilled Beams in Heating: Design Criteria and Case StudyarjantinBelum ada peringkat

- Getting Started With Indexed 4TH Axis MillingDokumen17 halamanGetting Started With Indexed 4TH Axis MillingMohamed IbrahimBelum ada peringkat

- PERKINS 1506 SERIES 1506A-E88TA, 1506-E88TA AND 1506D-E88TA INDUSTRIAL ENGINES Model PK9 Service Repair Manual PDFDokumen23 halamanPERKINS 1506 SERIES 1506A-E88TA, 1506-E88TA AND 1506D-E88TA INDUSTRIAL ENGINES Model PK9 Service Repair Manual PDFfjjskeksemmde100% (12)