Hydrotest Ansi b31.3 2017

Diunggah oleh

Bangkit SusiloDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hydrotest Ansi b31.3 2017

Diunggah oleh

Bangkit SusiloHak Cipta:

Format Tersedia

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 1 of 13

TABLE OF CONTENTS

Paragraph Description Page

1. Scope 2

2. Purpose 2

3. Reference Code 2

4. Responsibilities 2

5. General 2

6. Vacuum Test 2

7. Hydrostatic Test 3

8. Air Test 5

9. Safety Precautions 6

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 2 of 13

1. Scope: 4.3 Tank Technician

This Procedure specifies the requirements of a. Responsible to carryout pressure testing and

Hydrostatic Test, Vacuum Test and Air Test for other activities in support of pressure testing.

Aboveground Water Storage Tank. b. Ensure that all marking around the thank is done

as per the drawing

2. Purpose c. Ensures the pressure gauges used have current

This Procedure describes the equipment and calibrated stickers.

materials to be used and factors to be d. Complete pressure test record and submit copy

considered during the Pressure Test of Storage to program manager.

Tank, and ensure that this procedure shall be

5. General

done in accordance with the Project

5.1 After the completion of all welding works and non-

Specifications and related Standards and Codes.

destructive examinations of bottom plate welds,

shell plate welds, roof plate welds and reinforced

3. Reference Code:

plate welds of the tank

a. ASME Code Sec. I the applicable 2015 Edition

5.2 The tank shall be pressure tested for the

and Addenda,

identifications of leakage. This pressure shall be

b. ASME Code Sec VIII Div. 1, 2015 the carried out as per the approved drawing, approved

applicable Edition and Addenda, ITP and standard API 650.

c. API 650, 2015 Edition Applicable Code For 5.3 This test will divide into following mentioned

Storage Tank stages:

a. Test preliminaries such as Visual Inspection.

4. Responsibilities b. nspection of Tank Bottom Welds (Vacuum Box

4.1 QA/QC Engineer / Inspector Testing).

a. Shall be responsible to witness the test and c. Testing of the Shell Course and Tank Bottom

judge the suitability of work carried out. Settlement (Hydrostatic- Testing).

b. Responsible to make calculations, prepare d. Inspection of Roof-Plate and Reinforcing Plates

documents and layout systems of work. (Air Testing).

c. Assessing the suitability of the method, 5.4 Ensure that all of the mentioned test must perform

medium and test pressure requested given after controlling all of the N.D.T. test reports.

the design of the item submitted for testing. 5.5 Vacuum test is carried out to find any leakage in the

d. Produce written instructions for the bottom plate by the use the vacuum box testing

supervisor and technicians relating to the equipment.

procedures, equipment and personnel to be 5.6 Hydrostatic test is conducted to find any leakage in

employed in the test. the shell plate weld and to check the elevation of

4.2 Construction Supervisor the tank bottom settlement. Potable water shall be

a. Shall be responsible for organizing the test used to fill the tank.

as per this procedure and approved ITP and 5.7 Air test is conducted to check the gas tight of roof

shall also be responsible for maintaining the and reinforced plates of shell openings of the tank.

records duly signed by all concerns.

b. Responsible to ensure that the technicians 6. Vacuum Test

working under his supervision The Vacuum box test is conducted to check soundness of

c. Shall communicate with his management, annular welded joints and all lap joints of bottom plates

client and other contractors. (long seam and short seam).

d. Shall ensure method statements, risk 6.1 Equipment and Material

assessments and permit to work a. The vacuum box test is performed by using a box

requirements are communicated to the with visible window of fiber glass (i.e. 6’’ Wide by

technicians and other personnel. 30’’ long metallic box with a fiber glass). The

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 3 of 13

open bottom is sealed against the tank seconds examination time, stop watch to be

surface by a sponge rubber gasket. used after reaching the 21Kpa /designation

b. The test scheme shall have suitable vacuum.

connections, such as necessary valves and 6.4 Evaluation of Defects

calibrated vacuum gauge. a. Bubbles produced by air sucked through the

c. The gauge shall have a range of 21Kpa (6 in. welded seam can detect the presence of defect.

Hg) to 35Kpa (10 in. Hg) for normal leaks b. The tested areas are accepted only when no

and 56Kpa (16 in. Hg) to 70Kpa (20 in. Hg) continuous bubbles formation is observed.

shall be performed for the detection of very c. A minimum light intensity of 100Lux is required

small leaks. for conducting the examination.

d. The test scheme shall be demonstrated with d. Upon satisfactory inspection, a report shall be

sample test block by application bubble prepared for the further activities.

solution at site before conduction of the test 6.5 Repair and Retest

on the job. a. Defects in welds shall be repaired by chipping,

e. The bubble forming solution shall produce a grinding or melting out the defects from one side

film that does not break away from the area or both sides of the joints as required and re-

to be tested, and the bubbles formed shall welding are done.

not break rapidly due to air drying or low b. Only the cutting out of defective joints that is

surface tension. necessary to correct the defect is required.

f. A vacuum can be drawn on the box by any c. After repairing, retest of vacuum box test of

convenient method, such as connection to a welded joint shall be carried out.

diesel motor intake manifold or special 6.6 Cleaning

vacuum pump. After test the area shall be thoroughly cleaned for

6.2 Surface Preparation the further activities.

a. The surface to be examined and all adjacent

areas shall be cleaned thoroughly and free 7. Hydrostatic Test

from all dirt, grease, lint, scale, welding flux, Hydrostatic test is conducted to carry out the leakage in

weld spatters, paint, oil and other the shell plates and also to carry out elevation

extraneous matter that could obstruct measurement of the bottom foundation of tank by using

surface openings. tank foundation settlement method.

b. Prior to vacuum testing all joints shall be 7.1 General Consideration

checked visually. a. The water for hydro test will be provided by

6.3 Procedure of Vacuum Test SWCC, the initial filling of the first and second

a. The temperature of the surface of the part will come from this pipe system source.

to be examined shall not below 40C (400F) b. After the first tank is tested, the water will be

and nor above 520C (1250F). transferred to the second tank. After the second

b. The weld seam on the test shall be applied tank is tested, the water will be transferred to

with a bubble solution for detecting leaks the third and fourth tank for Testing.

prior to placing vacuum box. c. Contractor will furnish the pipe and pumps

c. The foaming shall be minimized by means of required to move the water from tank to tank.

uniform application of bubble solution. d. After the completion of the hydro testing

d. A vacuum can be drawn on the box by any operations for the first and fourth tank,

convenient method, such as connection to a contractor will dispose of the water on site at

gasoline- or diesel motor intake manifold. the designated point.

e. The gauge shall register a partial vacuum of 7.2 Preparation of Hydrostatic Test

at least 21Kpa for inspection of the joints. a. After the completion of all welding works and

f. The required partial vacuum shall be non-destructive examination of tank and all

maintained for greater or either at least 5 welded joints shall be signed off by QC welding

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 4 of 13

inspector prior to commencement of the f. Continue filling the tank until the water level

hydrostatic test. reaches the quarter point of the tank height. At

b. Temporary test gaskets shall be used for all this point discontinue filling while the level

fittings and manholes. readings are taken on the 16 points as described

c. The hydrostatic test of tank shall be in above (7.1- Item no.7) and readings are

conducted before permanent external recorded.

piping is connected to the tank. g. If the differential readings do not exceed 1½ mm

d. Cleaning inside the tank and removal of per meter of circumference, the filling of water

temporary jigs and tools shall be completed. shall continue.

e. All shell openings shall be closed by block h. As water is being pumped into the tank. Observe

valves or by appropriate cover plates. the circumference of the tank for any signs of

f. Roof manholes shall be opened while leak or distortion in each shell course. If any

introducing water into the tank or drawing signs appear immediately discontinue filling and

off water. determine the cause. Repair shall be made with

g. Initial tank level readings shall be taken the water level at least 300mm below the point

using 16 equally spaced points marked on being repaired.

the bottom plate projecting out from the i. Take additional readings when the tank is half

bottom shell around the tank at its base. full, three quarter full and full height. The same

h. The above points will be referenced back to criteria for differential settlement as stated in

a permanent benchmark. above (7.1- Item no.7) shall apply to each of the

i. Install temporary plastic tube to be used as a level readings.

water level indicator during hydrostatic test. j. Filling of water into the tank shall be continue

7.3 Procedure of Hydrostatic Test until the level reaches the maximum desired

a. Proper arrangement shall be carried out for height as shown on approved IFC drawing.

the water filling. Pipe connection from the k. The test water will remain in the tank at the

water resource point and providing valves maximum desired height for a period of 48

wherever required. hours. Final level readings shall be taken prior to

b. Potable water shall be used for hydrostatic removing any water from the tank.

testing. l. Water filling schedule and holding period shall

c. To protect urgent uneven settlement, water be in accordance with API 650 as given in below

filling rate shall be controlled. Therefore the table 2:

maximum filling and discharge rate shall be

as per standard API 650 as given in the

below table 1.

7.4 Tank Foundation Settlement

a. For the adequacy of tank foundation

performance, a staged hydrostatic procedure

and an extensive settlement monitoring

d. Filling shall be done in four stages 25%, 50%,

program is performed as per project

75% and 100%. After each stage a load

specification and API 650.

stabilization period shall be observed.

b. Therefore the following tolerable settlement

e. As water rises in the tank, observe the shell

criteria are adopted as a basis for evaluating

fittings for any signs of leakage around the

tank performance during hydrostatic testing

blind flanges.

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 5 of 13

Filling of water shall continue while 10m (32ft). A minimum of four diametrical lines

elevation measurements are being made shall be used.

as long as the change in water elevation for 7.5 Removal of Test Water

a set of reading does not exceed 300 mm. a. After the completion of Hydrostatic test, the

c. Shell elevation measurements shall be tank shall be emptied at a maximum water level

made at equally-spaced intervals around variation rate as per specification.

the tank circumference not exceeding 10 m b. Make sure that roof manholes and vents are

(32 ft). open during empty operation of conical roof

d. Install settlement monitoring markers at tank.

eight equally spaced locations along the c. When the first tank has been tested, make

perimeter of the tanks. connections to the second tank through a gate

e. Observed elevations shall be referred to a valve and extend the piping to the designated

permanent benchmark. The level point.

instrument shall be set up at least 1½ times d. When the second tank has been tested, connect

tank diameter away from the tank when the tested tank to the next tank and water to be

tank elevation readings are taken. filled through the system of temporary valves

f. There are six sets of settlement readings and piping.

are required as follows: e. Prior to starting the pumping operation between

- Before start of the hydrostatic test. two tanks, make sure that roof manholes and

- With tank filled to 1/4 test height (±600 vents are open on both tanks.

mm). f. Transfer to the next tank using gravity and a

- With tank filled to 1/2 test height (±600 temporary pump as required to empty the

mm). tested tank.

- With tank filled to 3/4 test height (±600 g. After all water has been removed from the

mm). tested tank, open all manholes and remove all

- At least 24 hours after the tank has temporary blinds and equipment.

been filled to the maximum test height. h. After final draining and drying, brushing, broom

This period may be increased in or vacuum cleaner shall clean surface of the

accordance to the requirement of the tanks bottoms.

project specification. i. QC Inspectors sign the test data sheet at the

- After tank has been emptied of test completion of hydro test.

water.

g. g. If settlement measurements are 8. Air Test

specified by the Purchaser, any differential Air test is carried out to check the gas tight of the

settlement greater than 13 mm per 10 m. roof plate and reinforced plate of shell openings of

of circumference or a uniform settlement the tank.

over 50 mm shall be reported to 8.1 Equipment and Material

contractor. a. Pressure Gauge or Manometer

h. Filling of the tank shall be stopped until b. Blank/Blind Flange with Safety Relief Valve.

cleared by the contractor. c. Soapsuds

i. Internal bottom elevation measurements d. Air Supply System

shall be made before and after hydrostatic

testing. Measurements shall be made at

maximum intervals of 3m (10ft) measured 8.2 Procedure of Air Test

on diametrical lines across the tank. After final welding and clearing the tank, an air test

j. The diametrical lines shall be spaced at shall be conducted to ensure water tightness and

equal angles, with a maximum separation the integrity of welding according to the procedure

measured at the tank circumference of as follows:

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 6 of 13

a. The tank workers shall prepare the test q. Release the air pressure once the test is

equipment and materials such as; pressure completed then put back all components/parts

gauge or manometer, testing piece, supply that have been removed.

air and soapsuds etc.,

b. Before starting the air pressure test, water 9. Safety Precautions

shall be filled to 50mm below the curb a. The safety measures shall be implemented during

angle. testing activities and the contractor shall provide

c. Cleaning and visual inspection of entire the necessary safety equipment, communication

welding of roof plates and all roof equipment, access barriers etc.

accessories shall be carried out prior to test. b. Contractor shall issue a statement to all persons

d. A manometer of suitable range shall be connected with testing, warning of the hazards of

connected to the roof nozzle with ¼’’ failure under pressure.

diameter PVC tube for measurement of c. There is a possibility that workers can take

pressure remedial action once minor leakages are noticed

e. Inlet connection shall be done with ½’’ hose

before total failure occurs.

from the compressor outlet to one of the

d. Hydrostatic tests are conducted under the

roof nozzle.

constraints of projects specifications.

f. To regulate the pressure, valves shall be

e. Air/gas used for Air test is compressible to large

provided on both ends.

extent and has very high potential energy stored

g. Once all nozzles and manhole are closed,

pressure shall be applied slowly inside the when compressed.

roof by controlling the isolation valves. f. Ensure that no any worker shall present inside the

h. Once the required tank prior to pressure test.

i. Set the testing piece to the desired filling g. Use and storage of any compressed gas under high

point of air either on manhole or air vents. pressure can be extremely dangerous if proper gas

j. Fill and press up the tank with compressed handling procedures are not observed.

air until it reaches 2.2 Psi on the pressure h. Where the test system is testing using

gauge or an equivalent water level in the pressurization above its normal working level, it

manometer and hold at this pressure for at follows that the tester should be prepared for the

least for 1 hour. consequences of failure.

k. Observe the pressure gauge or water level i. This means that there may need to be protective

in the manometer if it remains in the barriers or screens, but all such precautions will be

desired test pressure. specifically dedicated to the risk involved in the

l. If this pressure remains the same then apply test.

soapsuds to welding seams or joint and the j. The technician must be conscious at all times of the

areas to be check for leaks. potential for a rise in temperature to significantly

m. If the pressure decreases, re-check the increase pressure.

possible air passage and blank-off or k. Safety officer must be present at site during test.

retighten. l. Tested & certified Lifting equipment shall be used

n. If there are leaks then identify and mark the

for lifting and shifting purpose.

exact location of defects.

m. Safety Precautions shall be followed during

o. Release the air pressure, rectify the leak and

fabrication and erection as per project

retest again until successful passed the test

specification.

in the presence of Client QC Engineer.

n. Welding cables and power cables to be laid

p. The inspection and acceptance report shall

be fully accomplished and signed by the properly as per Instrumentation and Electrical rules

Clients representative, Tank Supervisor and and local state govt. rules and regulation.

QC Engineer. o. Proper housekeeping and clean condition shall be

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 7 of 13

maintained in the fabrication shop and site as

per requirement.

p. Wear proper PPE i.e. tall protection harness,

goggles etc.

q. Clean and clear the area and return the used

equipment and materials to the tool room or

shop.

r. Conduct hazard assessment and safety

meeting.

s. Barricading of Tank, First-Aid kit and

emergency phone number shall be available.

t. The contractor shall provide patrols to all

around the tank to watch any special points of

hazards during pressure test of tank.

u. Safety sign boards both in English and

Indonesia language shall be posted at

appropriate locations during tank testing the

display shall be "TANK UNDER PRESSURE TEST

KEEP AWAY".

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 8 of 13

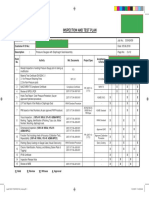

REPORT SAMPLE

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 9 of 13

0 % TANK SETTLEMENT REPORT

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 10 of 13

25 % TANK SETTLEMENT REPORT

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 11 of 13

50 % TANK SETTLEMENT REPORT

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 12 of 13

75 % TANK SETTLEMENT REPORT

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

INDEPENDENT SURVEYOR, NDT & TECHNICAL SERVICES

HYDROTEST PROCEDURE

DOC. NO : 007/HT/ISyP/API/IX/2017 REVISION:

PT. INDOTIMAS DATE : September, 2017

00

SYIFA PERKASA PAGE : Page 13 of 13

100% TANK SETTLEMENT REPORT

PT.INDOTIMAS SYIFA PERKASA

Hydrotest Test Procedure for Storage Tank

Anda mungkin juga menyukai

- Procedure For DYE PENETRANT TestingDokumen10 halamanProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- 16 - SGU - RT - ASME - 16 - Radiographic - REV - 00Dokumen53 halaman16 - SGU - RT - ASME - 16 - Radiographic - REV - 00pankrasius herbudiBelum ada peringkat

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDokumen13 halamanJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaBelum ada peringkat

- Hydrotest QI304-sampleDokumen3 halamanHydrotest QI304-sampleHanuman Rao100% (1)

- Reverse Engineering Pressure Vessel ChecklistDokumen5 halamanReverse Engineering Pressure Vessel ChecklistES RouzaBelum ada peringkat

- BES - IsO - UT - 12 - Ultrasonic Test - Rev 00Dokumen43 halamanBES - IsO - UT - 12 - Ultrasonic Test - Rev 00Ciety Ma100% (1)

- Client: Job No.: Job Title: Client's Job No.:: Company NameDokumen13 halamanClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprBelum ada peringkat

- Circularity Inspection Report: Shell Course (LW) CW CWDokumen14 halamanCircularity Inspection Report: Shell Course (LW) CW CWaszlizaBelum ada peringkat

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Dokumen9 halamanMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil OzanBelum ada peringkat

- Jacobs: Equipment Inspection Code: ADokumen2 halamanJacobs: Equipment Inspection Code: ASigit BintanBelum ada peringkat

- Std-Insp-0002 (Incoming Material Inspection Procedure)Dokumen3 halamanStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomBelum ada peringkat

- ITP For Piping SystemsDokumen6 halamanITP For Piping SystemsGia Minh Tieu TuBelum ada peringkat

- Procedure Fabrikasi TankiDokumen10 halamanProcedure Fabrikasi TankiMuhammad Yunus NurdinBelum ada peringkat

- How To Calculate Hydrostatic Test Height in TanksDokumen4 halamanHow To Calculate Hydrostatic Test Height in TanksEric MagnayeBelum ada peringkat

- Storage Tank Test & Inspection Report enDokumen10 halamanStorage Tank Test & Inspection Report enMarketing CTNBelum ada peringkat

- Hydrostatic Test of Pandi WaterDokumen7 halamanHydrostatic Test of Pandi WaterOscar C. GabinayBelum ada peringkat

- Chemical Resistance (LLDPE) PDFDokumen24 halamanChemical Resistance (LLDPE) PDFrubyshreeBelum ada peringkat

- IRN For QC 64210-1 Ansao Venturi Pin (1-800)Dokumen1 halamanIRN For QC 64210-1 Ansao Venturi Pin (1-800)Senthil KumarBelum ada peringkat

- Procedure For Ferrit TestingDokumen11 halamanProcedure For Ferrit TestingKarrar TalibBelum ada peringkat

- Pig Launcher Fabrication Activity PlanDokumen1 halamanPig Launcher Fabrication Activity PlanbeqsBelum ada peringkat

- Valve Service Report: Mbaraki Bulk Terminal LTDDokumen1 halamanValve Service Report: Mbaraki Bulk Terminal LTDALI KAHINDIBelum ada peringkat

- Peaking-Bend Tank 011Dokumen13 halamanPeaking-Bend Tank 011yuwantoniBelum ada peringkat

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDokumen1 halamanBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraBelum ada peringkat

- TDC 004 CS Fittings r0Dokumen1 halamanTDC 004 CS Fittings r0samkarthik47Belum ada peringkat

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDokumen5 halamanSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalBelum ada peringkat

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDokumen4 halamanProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarBelum ada peringkat

- 60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingDokumen109 halaman60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingTauqeer SalimBelum ada peringkat

- Hydrotest Procedure For Pressure VesselDokumen6 halamanHydrotest Procedure For Pressure VesselAbdul Kharis100% (1)

- Test Pack Clearance FormatDokumen2 halamanTest Pack Clearance FormatKarthikBelum ada peringkat

- Occpl: Hydro & Pneumatic Test ProcedureDokumen3 halamanOccpl: Hydro & Pneumatic Test ProcedureNupesh katreBelum ada peringkat

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDokumen15 halamanPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- ITP SampleDokumen6 halamanITP SampleMat RidhanBelum ada peringkat

- Pretest Piping Punch List (Empty)Dokumen1 halamanPretest Piping Punch List (Empty)Jorge GarciaBelum ada peringkat

- Roundness Before Weld TK012-strike 1Dokumen2 halamanRoundness Before Weld TK012-strike 1yuwantoniBelum ada peringkat

- Job Procedure For Puncture/Floatation/Rain Water Accumulation TestDokumen4 halamanJob Procedure For Puncture/Floatation/Rain Water Accumulation Testfaisal jasim100% (1)

- Check List-Heat ExchangerDokumen2 halamanCheck List-Heat Exchangersarmad009Belum ada peringkat

- Pmi Procedure: Superflow Pumps Pvt. LTDDokumen6 halamanPmi Procedure: Superflow Pumps Pvt. LTDashish tiwariBelum ada peringkat

- Sample Hydro Test ProcedureDokumen2 halamanSample Hydro Test ProcedureJose Luis GonzálezBelum ada peringkat

- QAP For Conical StrainerDokumen2 halamanQAP For Conical StrainersatishchidrewarBelum ada peringkat

- Qap 8000ce Reactor - Repat - 1Dokumen2 halamanQap 8000ce Reactor - Repat - 1AliasgarBelum ada peringkat

- GSB-Form-246 Dimension Inspection Report (Circum)Dokumen1 halamanGSB-Form-246 Dimension Inspection Report (Circum)Made GileeBelum ada peringkat

- Calculation Tank - 1500 KL SolarDokumen2 halamanCalculation Tank - 1500 KL SolarAnonymous 6S9tcbhBelum ada peringkat

- Sample WPS 1Dokumen13 halamanSample WPS 1waqas pirachaBelum ada peringkat

- To Commissioning Manual: Appendix No. 1Dokumen7 halamanTo Commissioning Manual: Appendix No. 1Bassem BalghouthiBelum ada peringkat

- Inspection and Repair of Storage Tanks 1710346228Dokumen113 halamanInspection and Repair of Storage Tanks 1710346228Jayapal BhukyaBelum ada peringkat

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Dokumen1 halamanSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganBelum ada peringkat

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDokumen6 halamanF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoBelum ada peringkat

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallDokumen1 halamanSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun AkkayaBelum ada peringkat

- ITPDokumen1 halamanITPVenkatesh PethurajBelum ada peringkat

- Itp - Tanks - 01Dokumen10 halamanItp - Tanks - 01ravigurajapuBelum ada peringkat

- Pipeline Inspection Method Metode Inspeksi Pipa PenyalurDokumen35 halamanPipeline Inspection Method Metode Inspeksi Pipa PenyaluradityaromasBelum ada peringkat

- 6 MM TCDokumen1 halaman6 MM TCpranesh kadamBelum ada peringkat

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDokumen1 halamanStorage Tank Hydrostatic Test Quality Control and Inspection Report FormMHT allamBelum ada peringkat

- Pms Eil BPCLDokumen79 halamanPms Eil BPCLManjunatha VBelum ada peringkat

- Api 1104-20.07Dokumen61 halamanApi 1104-20.07Andy Chong100% (1)

- Radiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0Dokumen13 halamanRadiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0BCE DeBelum ada peringkat

- 16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Dokumen28 halaman16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Fauzan Rusmayadi Reharder100% (1)

- TDC 003 - SS Pipes - r0Dokumen1 halamanTDC 003 - SS Pipes - r0samkarthik47Belum ada peringkat

- NDT Penetran ProcedureDokumen15 halamanNDT Penetran ProcedureBayu PutraBelum ada peringkat

- MS For Heat ExchangersDokumen6 halamanMS For Heat ExchangersravikumarBelum ada peringkat

- Carbosulfan Technical MTR AGHS enDokumen9 halamanCarbosulfan Technical MTR AGHS enBangkit Susilo100% (1)

- List Tank Infodood: No Material Description Q'tyDokumen1 halamanList Tank Infodood: No Material Description Q'tyBangkit SusiloBelum ada peringkat

- Komisi Jetis Juni 18Dokumen1 halamanKomisi Jetis Juni 18Bangkit SusiloBelum ada peringkat

- Ferrite Test Procedure: Doc No 009/Ft/Isyp/Ix/2017 Revision: 00 Date: September, 2017Dokumen1 halamanFerrite Test Procedure: Doc No 009/Ft/Isyp/Ix/2017 Revision: 00 Date: September, 2017Bangkit SusiloBelum ada peringkat

- AcknowledgmentDokumen12 halamanAcknowledgmentShaleen SoganiBelum ada peringkat

- OPRA Turbines Brochure (English)Dokumen8 halamanOPRA Turbines Brochure (English)HyungTae JangBelum ada peringkat

- Experiment No.8Dokumen5 halamanExperiment No.8Osama RashaydaBelum ada peringkat

- Pola Operasi PLTU MamujuDokumen20 halamanPola Operasi PLTU MamujuKunyuk KunyukBelum ada peringkat

- Pumps Catalog enDokumen36 halamanPumps Catalog enJoão Paulo FogarolliBelum ada peringkat

- ErythromycinDokumen2 halamanErythromycinAHMAD SYAUQI AIMAN BIN ABU BAKARBelum ada peringkat

- Mine GasesDokumen48 halamanMine GasesRavi Krishnan100% (1)

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionDokumen8 halamanVung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionHai NguyenBelum ada peringkat

- Fluid and Fluid PropertiesDokumen42 halamanFluid and Fluid PropertiesCIPETIPT Tool RoomBelum ada peringkat

- RP 41filter Manual AM ENESDE Low 6091100067Dokumen12 halamanRP 41filter Manual AM ENESDE Low 6091100067Joe BranamBelum ada peringkat

- Boyle's LawDokumen2 halamanBoyle's LawMixer 5000Belum ada peringkat

- Glycol Dehydration Instrumentation and ControlsDokumen3 halamanGlycol Dehydration Instrumentation and ControlsdndudcBelum ada peringkat

- LPG Bottling Know HowDokumen28 halamanLPG Bottling Know HowJosmar AnguloBelum ada peringkat

- Roto Inject Fluid NDURANCE: Atlas Copco LubricantsDokumen2 halamanRoto Inject Fluid NDURANCE: Atlas Copco LubricantsJoao BotasBelum ada peringkat

- Powerpoint For Chapter 11Dokumen36 halamanPowerpoint For Chapter 11Jomar CarabotBelum ada peringkat

- 2 - 254624-400-DS-INT-021 Plug Valve DSDokumen10 halaman2 - 254624-400-DS-INT-021 Plug Valve DSNerudaArarBelum ada peringkat

- Turbines PDFDokumen361 halamanTurbines PDFTamas SandulyBelum ada peringkat

- Southern Philippines Agribusiness and Marine and Aquatic School of TechnologyDokumen8 halamanSouthern Philippines Agribusiness and Marine and Aquatic School of TechnologyJoanne Louise Camonias BirondoBelum ada peringkat

- All DC Inverter VRFDokumen31 halamanAll DC Inverter VRFمحمد عليBelum ada peringkat

- Dimensionless Numbers in Fluid MechanicsDokumen7 halamanDimensionless Numbers in Fluid MechanicsghazalBelum ada peringkat

- Data Sheet: Scrd-Ut SeriesDokumen2 halamanData Sheet: Scrd-Ut SeriesMustafa PardawalaBelum ada peringkat

- The Anaesthesia Viva Vol 2, Physics, Clinical Measurement, Safety and Clinical Anaesthesia 2nd EdDokumen170 halamanThe Anaesthesia Viva Vol 2, Physics, Clinical Measurement, Safety and Clinical Anaesthesia 2nd EdAbdulRhman Ibnouf100% (2)

- 67D Series Pressure Reducing Regulators Instruction Manual en 125226 PDFDokumen12 halaman67D Series Pressure Reducing Regulators Instruction Manual en 125226 PDFravichandran0506Belum ada peringkat

- Valves Used in Fire Protection SystemDokumen20 halamanValves Used in Fire Protection SystemrashalBelum ada peringkat

- Reciprocating Pumps: Mid La Union CampusDokumen21 halamanReciprocating Pumps: Mid La Union CampusLorenz BanadaBelum ada peringkat

- Engineering Aspects of Cabin Air QualityDokumen8 halamanEngineering Aspects of Cabin Air QualityRaghuThimmegowdaBelum ada peringkat

- Liquid Liquid SeparatorsDokumen26 halamanLiquid Liquid SeparatorsAjay Pratap SinghBelum ada peringkat

- GATE Fluid Mechanics Paper 2018Dokumen5 halamanGATE Fluid Mechanics Paper 2018MOHANKUMAR.P.N MIT-AP/MECHBelum ada peringkat

- 1316323815-Fabius GS ManualDokumen312 halaman1316323815-Fabius GS ManualJose De Abreu100% (1)

- Valve Philosophy Valve Application GeneralDokumen3 halamanValve Philosophy Valve Application GeneralWade ColemanBelum ada peringkat