Technical Information Sheet: Harris O Brazing Filler Metal

Diunggah oleh

Khyle Laurenz DuroJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Technical Information Sheet: Harris O Brazing Filler Metal

Diunggah oleh

Khyle Laurenz DuroHak Cipta:

Format Tersedia

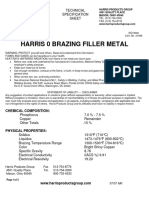

TECHNICAL INFORMATION SHEET

HARRIS® O BRAZING FILLER METAL

NOMINAL CHEMICAL COMPOSITION%: RECOMMENDED FLUX:

No flux is required for copper brazing. For brazing brass or

Copper Remainder copper to brass, use Stay-Silv® white flux. Harris ECO SMART®

Phosphorus 7.1 boric acid free flux, (powder or paste), is an excellent choice to

Other (Total) 0.15 promote sound brazed assemblies and comply with European

REACH requirements.

SPECIFICATION COMPLIANCE:

TYPICAL PHYSICAL PROPERTIES:

AWS A5.8 BCuP-2, ASME Section IIC SFA 5.8 BCuP-2, ISO

Solidus 1310ºF (710°C) 17672 CuP 181

Liquidus 1460°F (793°C)

Brazing Range 1345°F- 1500°F (730°C -816°C) SAFETY INFORMATION:

Electrical Conductivity 9.9 (%IACS)

Electrical Resistivity 19.2 WARNING: PROTECT yourself and others. Read and understand this

information.

FUMES AND GASES can be hazardous to your health.

BRAZING PROPERTIES: HEAT RAYS, (infrared radiation) from flame or hot metal can injure eyes.

Before use, read and understand the manufacturer’s instructions,

Material Safety Data Sheets (MSDS), and your employer's safety

Harris 0 is an economical alloy designed for brazing copper to practices.

copper connections. This alloy flows quickly at brazing Keep your head out of fumes.

Use enough ventilation, exhaust at the flame, or heat source, to

temperature so requires close joint tolerance, less than 0.005”. keep fumes and gases from your breathing zone and the general

is a frequent choice for copper brazing. area.

Wear correct eye, ear, and body protection.

Harris 0 is also a suitable choice for brazing brass. In this See American National Standard Z49.1, Safety in Welding, Cutting,

application operators should take care to avoid over heating the and Allied Processes, published by the American Welding Society,

8669 Doral Blvd., Doral, Florida 33166; OSHA Safety and Health

brass and use Harris Stay Silv® white brazing flux. Standards, available from the U.S. Government Office, Washington,

DC 20402.

Harris 0 is not recommended for brazing steel or other ferrous

base metals. The phosphorus content will form a low ductility STATEMENT OF LIABILITY- DISCLAIMER

intermetallic with the base metal

Any suggestion of product applications or results is given without representation

CORROSION RESISTANCE or warranty, either expressed or implied. Without exception or limitation, there

are no warranties of merchantability or of fitness for particular purpose or

application. The user must fully evaluate every process and application in all

Generally similar to the copper base metal, but phosphorus aspects, including suitability, compliance with applicable law and non-

containing alloys, including Harris 0, should not be used if the infringement of the rights of others. The Harris Products Group and its affiliates

braze is exposed to sulfur or sulfur compounds in service. shall have no liability in respect thereof.

AVAILABLE FORMS

Standard wire diameters rods, spools, and preform rings,

THE HARRIS PRODUCTS GROUP

A LINCOLN ELECTRIC COMPANY

4501 Quality Place • Mason, OH 45040 U.S.A Tel: 513-754-2000 Fax: 513-754-6015

Additional information available at our web site: www.harrisproductsgroup.com

6.16.

Anda mungkin juga menyukai

- Mig Wire ER 70S-6 SpecificationsDokumen2 halamanMig Wire ER 70S-6 Specificationsabhics67Belum ada peringkat

- F1545 15a PDFDokumen8 halamanF1545 15a PDFMarius Onofrei100% (2)

- Anodic Oxidation of Aluminium and Its Alloys: The Pergamon Materials Engineering Practice SeriesDari EverandAnodic Oxidation of Aluminium and Its Alloys: The Pergamon Materials Engineering Practice SeriesPenilaian: 5 dari 5 bintang5/5 (1)

- Jack Bolt CalculationDokumen4 halamanJack Bolt CalculationKhyle Laurenz DuroBelum ada peringkat

- Saso PDFDokumen1 halamanSaso PDFKhyle Laurenz DuroBelum ada peringkat

- Accident and Incident Reporting Flow ChartDokumen1 halamanAccident and Incident Reporting Flow ChartKhyle Laurenz Duro100% (1)

- Construction Safety Checklist: Find and Record Common Construction HazardsDokumen3 halamanConstruction Safety Checklist: Find and Record Common Construction HazardsKhyle Laurenz Duro100% (1)

- Method Statement of Steel FabricationDokumen14 halamanMethod Statement of Steel FabricationKhyle Laurenz Duro100% (4)

- Time Frame For 6s ImplementationDokumen10 halamanTime Frame For 6s ImplementationKhyle Laurenz DuroBelum ada peringkat

- Technical Information Sheet: Harris 15 Low Fuming BronzeDokumen1 halamanTechnical Information Sheet: Harris 15 Low Fuming BronzeMarcelino Navarrete EvaristoBelum ada peringkat

- Stay Silv2SpecDokumen1 halamanStay Silv2SpecEfraim AndersonBelum ada peringkat

- Technical Information Sheet: Stay-Silv 15 Brazing Filler MetalDokumen1 halamanTechnical Information Sheet: Stay-Silv 15 Brazing Filler MetalRussell ShacklefordBelum ada peringkat

- Technical Information Sheet: Stay Silv 5 Brazing Filler MetalDokumen1 halamanTechnical Information Sheet: Stay Silv 5 Brazing Filler MetalMind´s EyesBelum ada peringkat

- 95 5specDokumen1 halaman95 5specYesuaBelum ada peringkat

- Stay Silv White Flux SpecDokumen1 halamanStay Silv White Flux SpecJOHN NESTOR RAMIREZ CALDERÓNBelum ada peringkat

- Al Braze 1070 SpecDokumen1 halamanAl Braze 1070 SpecDíazGozueBelum ada peringkat

- Harris 5Dokumen13 halamanHarris 5frio industrialBelum ada peringkat

- 50 50specDokumen1 halaman50 50specYesuaBelum ada peringkat

- Stay Silv White Flux SpecDokumen1 halamanStay Silv White Flux SpecAnte NinićBelum ada peringkat

- Technical Information Sheet: Harris Speedy Lead Free SolderDokumen1 halamanTechnical Information Sheet: Harris Speedy Lead Free SolderjohnsgdBelum ada peringkat

- Silverphos 6HP BCuP-4 TDSDokumen2 halamanSilverphos 6HP BCuP-4 TDS顏煥杰Belum ada peringkat

- Stay Clean Aluminum Soldering FluxDokumen1 halamanStay Clean Aluminum Soldering FluxaximitedzBelum ada peringkat

- Phoscopper 0 (BCuP-2) TDSDokumen2 halamanPhoscopper 0 (BCuP-2) TDS顏煥杰Belum ada peringkat

- Cherry RedDokumen1 halamanCherry Redjcordon-2Belum ada peringkat

- Dynaflow Vs Stay Silv 15Dokumen2 halamanDynaflow Vs Stay Silv 15Zeljko RisticBelum ada peringkat

- Handy Flo 6Dokumen2 halamanHandy Flo 6Tecnoserv Ingenieros S.A:Belum ada peringkat

- Hastelloy G-30 Alloy: Corrosion-Resistant AlloysDokumen16 halamanHastelloy G-30 Alloy: Corrosion-Resistant AlloysLizbeth CamachoBelum ada peringkat

- Phosphorus/Copper Brazing Alloys: Harris O Stay-Silv 5 and Stay-Silv 6 Dynaflow Stay-Silv 15Dokumen6 halamanPhosphorus/Copper Brazing Alloys: Harris O Stay-Silv 5 and Stay-Silv 6 Dynaflow Stay-Silv 15HassanSobohBelum ada peringkat

- Fabrication of Hastelloy Corrosion-Resistant AlloysDokumen40 halamanFabrication of Hastelloy Corrosion-Resistant AlloysAli VarmazyarBelum ada peringkat

- Corrosion Resistant AlloysDokumen40 halamanCorrosion Resistant Alloysmiker100Belum ada peringkat

- BestolifeDokumen1 halamanBestolifecitra mandiri sejatiBelum ada peringkat

- Er70s 2Dokumen1 halamanEr70s 2t.mohammedBelum ada peringkat

- Avesta Ernicrmo-3: Material Safety Data Sheet Nickel Base Welding WireDokumen7 halamanAvesta Ernicrmo-3: Material Safety Data Sheet Nickel Base Welding WireLawrence Lancy LoboBelum ada peringkat

- High Performance: Properties & General DataDokumen4 halamanHigh Performance: Properties & General DataRaghBelum ada peringkat

- Silverbraze 45T BAg-36 TDSDokumen2 halamanSilverbraze 45T BAg-36 TDSMAURO MORESCOBelum ada peringkat

- StaySilv15 Brazing Filler MetalDokumen1 halamanStaySilv15 Brazing Filler Metalremwel_Belum ada peringkat

- Copper Guard 4: Subtitle SubtitleDokumen1 halamanCopper Guard 4: Subtitle Subtitleharvinder singhBelum ada peringkat

- Material Safety Data Sheet (MSDS) : Section I - IdentificationDokumen2 halamanMaterial Safety Data Sheet (MSDS) : Section I - IdentificationSalem GarrabBelum ada peringkat

- Stainless Steel AL 17-4 Precipitation Hardening Alloy: General PropertiesDokumen5 halamanStainless Steel AL 17-4 Precipitation Hardening Alloy: General PropertiesforuzzBelum ada peringkat

- Harris Brazing MaterialsDokumen3 halamanHarris Brazing MaterialsfontyflockBelum ada peringkat

- Harris 0Dokumen2 halamanHarris 0selauBelum ada peringkat

- Material Specifications For Cartridge Valves and Manifolds: Better Performance Comes From Working TogetherDokumen2 halamanMaterial Specifications For Cartridge Valves and Manifolds: Better Performance Comes From Working TogetherMiguel VlntìnBelum ada peringkat

- GMORS Rubber Especification O Rings Guidebook AS568ADokumen90 halamanGMORS Rubber Especification O Rings Guidebook AS568AfeltofsnakeBelum ada peringkat

- Heat and Corrosion Resistant Alloys (Alloy Performance Guide)Dokumen20 halamanHeat and Corrosion Resistant Alloys (Alloy Performance Guide)jason_1574Belum ada peringkat

- Material Safety Data Sheet: I. Product IdentificationDokumen2 halamanMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoBelum ada peringkat

- Pig Iron SDS PrimetradeDokumen4 halamanPig Iron SDS PrimetradePravin PatilBelum ada peringkat

- Stainless Steel Bolts, Hex Cap Screws, and Studs: Standard Specification ForDokumen8 halamanStainless Steel Bolts, Hex Cap Screws, and Studs: Standard Specification ForAlejandro ValdesBelum ada peringkat

- Oxford Alloy 420 (ER420)Dokumen1 halamanOxford Alloy 420 (ER420)brunizzaBelum ada peringkat

- Dr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of JakartaDokumen31 halamanDr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of JakartaCANDRA ANDREAN Mahasiswa PNJBelum ada peringkat

- 8620 Alloy Steels Material Property Data Sheet - Product Availability and Request A QuoteDokumen4 halaman8620 Alloy Steels Material Property Data Sheet - Product Availability and Request A QuoteManuel NavarroBelum ada peringkat

- B907 162021 2 04 Standard Specification For Zinc, Tin and CadmiumDokumen6 halamanB907 162021 2 04 Standard Specification For Zinc, Tin and CadmiumShodji MabungaBelum ada peringkat

- 17 4 Technical DataDokumen4 halaman17 4 Technical DataBalakrishnan MeikandasivamBelum ada peringkat

- Harris ER90S B3Dokumen2 halamanHarris ER90S B3Mingo EvaBelum ada peringkat

- Blockade SpecsDokumen2 halamanBlockade SpecssafeantBelum ada peringkat

- Metal Finishing Products: Phosbrite 174LC Aluminum Brightening PB174LC 222Dokumen2 halamanMetal Finishing Products: Phosbrite 174LC Aluminum Brightening PB174LC 222Đức Tùng NgôBelum ada peringkat

- Fabricating of Hastelloy Corrosion Resistant Alloys of HaynesDokumen40 halamanFabricating of Hastelloy Corrosion Resistant Alloys of HayneszuudeeBelum ada peringkat

- Stainless Steel Nuts: Standard Specification ForDokumen8 halamanStainless Steel Nuts: Standard Specification ForChris MedeirosBelum ada peringkat

- Honilo OilDokumen2 halamanHonilo Oilpiston brokeBelum ada peringkat

- Safety Data Sheet: 1. Product and Company IdentificationDokumen4 halamanSafety Data Sheet: 1. Product and Company IdentificationMohamed AdelBelum ada peringkat

- Aerospace Material SpecificationDokumen8 halamanAerospace Material SpecificationDUBelum ada peringkat

- F 3215 - 16Dokumen4 halamanF 3215 - 16jose floresBelum ada peringkat

- ASTM A563 - 07 Standard Specification For Carbon and Alloy Steel NutsDokumen8 halamanASTM A563 - 07 Standard Specification For Carbon and Alloy Steel NutsDagoberto AguilarBelum ada peringkat

- TD KC2Dokumen1 halamanTD KC2David PomaBelum ada peringkat

- Astm F593 - 17Dokumen9 halamanAstm F593 - 17Jon DownBelum ada peringkat

- Safety Data Sheet: 1. Product and Company IdentificationDokumen4 halamanSafety Data Sheet: 1. Product and Company Identificationmohamed AdelBelum ada peringkat

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalDari EverandFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Makana Wps /PQR Summary Log: Exhibit No.: 39 Edition No.: 1 Revision: 0Dokumen1 halamanMakana Wps /PQR Summary Log: Exhibit No.: 39 Edition No.: 1 Revision: 0Khyle Laurenz DuroBelum ada peringkat

- Sludge CalculationDokumen1 halamanSludge CalculationKhyle Laurenz DuroBelum ada peringkat

- Tank Painting SpecificationsDokumen1 halamanTank Painting Specificationsjohn gonzalezBelum ada peringkat

- 42.exhibit-42. CONSUMABLE HOLDING LOGDokumen1 halaman42.exhibit-42. CONSUMABLE HOLDING LOGKhyle Laurenz DuroBelum ada peringkat

- Weld Plan: Client: Mfr's SL - No.: Project: DWG. No.: Description: WO. No.Dokumen1 halamanWeld Plan: Client: Mfr's SL - No.: Project: DWG. No.: Description: WO. No.Khyle Laurenz DuroBelum ada peringkat

- 41.exhibit-41. CONSUMABLE BAKING LOGDokumen1 halaman41.exhibit-41. CONSUMABLE BAKING LOGKhyle Laurenz DuroBelum ada peringkat

- Civil WorksDokumen3 halamanCivil WorksKhyle Laurenz DuroBelum ada peringkat

- CrayolaDokumen1 halamanCrayolaaronschneersonBelum ada peringkat

- 021 Itp For Site Preparation and Earth Works PDFDokumen2 halaman021 Itp For Site Preparation and Earth Works PDFKhyle Laurenz DuroBelum ada peringkat

- Mobile Equipment - 14 March 2018Dokumen10 halamanMobile Equipment - 14 March 2018Khyle Laurenz DuroBelum ada peringkat

- Pds Maestro Alkyd Primer 12070 En-GbDokumen2 halamanPds Maestro Alkyd Primer 12070 En-GbKhyle Laurenz DuroBelum ada peringkat

- App S.2-Award Criteria & Nomination ProcessDokumen12 halamanApp S.2-Award Criteria & Nomination ProcessKhyle Laurenz DuroBelum ada peringkat

- App S.2-Award Criteria & Nomination ProcessDokumen6 halamanApp S.2-Award Criteria & Nomination ProcessKhyle Laurenz DuroBelum ada peringkat

- Safety Manual: Revision / Establishment Approved Checked OriginatorDokumen1 halamanSafety Manual: Revision / Establishment Approved Checked OriginatorKhyle Laurenz DuroBelum ada peringkat

- Uniform & Equipment Issuance Agreement: Cal Poly Pomona Foundation, IncDokumen1 halamanUniform & Equipment Issuance Agreement: Cal Poly Pomona Foundation, IncKhyle Laurenz DuroBelum ada peringkat

- Safety Slogan EnglishDokumen8 halamanSafety Slogan EnglishKhyle Laurenz DuroBelum ada peringkat

- PMI ReportsDokumen3 halamanPMI ReportsKhyle Laurenz DuroBelum ada peringkat

- Nominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe ChartDokumen5 halamanNominal Pipe Sizes: Pipe Dimensions, Imperial / Metric Pipe CharthappywhewmiBelum ada peringkat

- 15004719Dokumen21 halaman15004719Ryka AguinaldoBelum ada peringkat

- Saes A114 Excavation and BackfillDokumen19 halamanSaes A114 Excavation and BackfillKhyle Laurenz Duro100% (1)

- Gratings Required SpecsDokumen1 halamanGratings Required SpecsKhyle Laurenz DuroBelum ada peringkat

- Pouring Concrete Slab in GradeDokumen4 halamanPouring Concrete Slab in GradeKhyle Laurenz DuroBelum ada peringkat

- Blinding WorksDokumen3 halamanBlinding WorksKhyle Laurenz DuroBelum ada peringkat

- Column Side w610 X 155Dokumen73 halamanColumn Side w610 X 155Khyle Laurenz DuroBelum ada peringkat

- NBRDokumen4 halamanNBRSid ShahBelum ada peringkat

- KICE Profile 2020Dokumen21 halamanKICE Profile 2020pioneersmepBelum ada peringkat

- Advantages of Steel As A Structural MaterialDokumen3 halamanAdvantages of Steel As A Structural MaterialIrfan MunirBelum ada peringkat

- Maraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownDokumen5 halamanMaraging Steel: Maraging Steels (A Portmanteau of "Martensitic" and "Aging") Are Steels (Iron Alloys) That Are KnownVysakh VasudevanBelum ada peringkat

- Handbook of Plastic Films EditorDokumen422 halamanHandbook of Plastic Films EditorKatherineCastro100% (1)

- EMT Conduit PDFDokumen2 halamanEMT Conduit PDFbluesierBelum ada peringkat

- Din 8140 AmecoilDokumen1 halamanDin 8140 Amecoiljuanpalomo74Belum ada peringkat

- Powerfix Set15Dokumen2 halamanPowerfix Set15Darwin AlejandroBelum ada peringkat

- Pulley Lagging PDFDokumen2 halamanPulley Lagging PDFSanatha AgungBelum ada peringkat

- ACI318-08 RC Beam - XLS: Material PropertiesDokumen3 halamanACI318-08 RC Beam - XLS: Material PropertiesEdgardo ArriesgadoBelum ada peringkat

- Katalog Vers 2 ReprintDokumen52 halamanKatalog Vers 2 ReprintfernandoBelum ada peringkat

- SCI Merchant Steel Fittings PDFDokumen6 halamanSCI Merchant Steel Fittings PDFMohammed ZabiBelum ada peringkat

- W Stacbond Metallic Colors STB TMC 102Dokumen2 halamanW Stacbond Metallic Colors STB TMC 102Reona VulpeBelum ada peringkat

- Technical Data Sheet For HIT RE 500 V3 Injectable Mortar in Concrete Technical Information ASSET DOC 8257123Dokumen41 halamanTechnical Data Sheet For HIT RE 500 V3 Injectable Mortar in Concrete Technical Information ASSET DOC 8257123Lawrence Miguel FerrerBelum ada peringkat

- Boq Standard SST 50m XL Outdoor Protelindo JabarDokumen50 halamanBoq Standard SST 50m XL Outdoor Protelindo JabarHeri SetiawanBelum ada peringkat

- ISO 4020 ExtractDokumen2 halamanISO 4020 ExtractBartek HajaBelum ada peringkat

- Chapter 9 COMPOSITE MATERIALSDokumen2 halamanChapter 9 COMPOSITE MATERIALSLinwoodBelum ada peringkat

- V-1 2Dokumen44 halamanV-1 2tarunmisra85Belum ada peringkat

- William Valve Catalogue Ball ValveDokumen24 halamanWilliam Valve Catalogue Ball ValveVinayBelum ada peringkat

- Pipe Inspection, Testing & MarkingDokumen12 halamanPipe Inspection, Testing & MarkingRamalingam PrabhakaranBelum ada peringkat

- Piping Material - GuidanceDokumen17 halamanPiping Material - GuidanceAlfon50% (2)

- Astm D-3840 - 01Dokumen9 halamanAstm D-3840 - 01Bipin SasikumarBelum ada peringkat

- GF-304CR Dossier.Dokumen35 halamanGF-304CR Dossier.suria qaqcBelum ada peringkat

- TC 302010-3 602 BW SCH 80-11121B1,10440B1,19M3792B2 (440 To 476) (JC 6303)Dokumen2 halamanTC 302010-3 602 BW SCH 80-11121B1,10440B1,19M3792B2 (440 To 476) (JC 6303)SAMANOBelum ada peringkat

- Design Basis Report (DBR) : Proposed Steel Truss With Crane Essembly"Dokumen18 halamanDesign Basis Report (DBR) : Proposed Steel Truss With Crane Essembly"Architects AsiaBelum ada peringkat

- Technical SpecificationDokumen211 halamanTechnical SpecificationVitali MihalachiBelum ada peringkat

- Table 1A (Cont'd) Section I Section III, Classes 2 and 3 Section VIII, Division 1 and Section XII Maximum Allowable Stress Values ( See Maximum Temperature Limits For Restrictions On Class)Dokumen3 halamanTable 1A (Cont'd) Section I Section III, Classes 2 and 3 Section VIII, Division 1 and Section XII Maximum Allowable Stress Values ( See Maximum Temperature Limits For Restrictions On Class)Latif RadwanBelum ada peringkat

- Masterseal 595: Technical Data GuideDokumen4 halamanMasterseal 595: Technical Data GuideKannan MurugesanBelum ada peringkat

- Neo Shower Enclosure Installation Instructions: ImportantDokumen8 halamanNeo Shower Enclosure Installation Instructions: Importantwww.everything4less.comBelum ada peringkat

- Masterflow 150 v1Dokumen2 halamanMasterflow 150 v1vinayBelum ada peringkat