Aluminum Manual 44

Diunggah oleh

LUIS4563Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aluminum Manual 44

Diunggah oleh

LUIS4563Hak Cipta:

Format Tersedia

aerospace structural applications. The cost premium for A356.

0 is usually

justifiable in light of its better properties (strength, ductility, and fluidity)

compared to 356.0.

There are a number of other types of castings. Die castings (ASTM B85)

are produced by the introduction of molten metal under substantial pressure

into a metal die, producing castings with a high degree of fidelity to the die.

Die castings are used for castings produced in large volumes because they

can be produced rapidly within relatively tight dimensional tolerances. Investment

castings (ASTM B618) are produced by surrounding, or investing,

an expendable pattern (usually wax or plastic) with a refractory slurry that

sets at room temperature, after which the pattern is removed by heating and

the resulting cavity is filled with molten metal. ASTM also provides a

specification

for high-strength aluminum alloy castings (ASTM B686) used in

airframe, missile, or other critical applications requiring high strength,

ductility,

and quality.

Dimensional Tolerances Suggested standards for dimensional tolerances

for castings are given in the Aluminum Association�s publication Standards

for Aluminum Sand and Permanent Mold Castings. Tolerances are held on

castings only when purchasers specify them with orders. This is unlike the

case for rolled and extruded products, for which standard dimensional tolerances

are held by the mill even when purchasers do not specify them. The

dimensions of castings can be hard to control because of difficulty in predicting

shrinkage during solidification and warping due to uneven cooling of

thick and thin regions. Without requirements, castings may be produced with

dimensions that deviate more widely than you anticipated.

Minimum Mechanical Properties Minimum mechanical properties for some

cast alloys taken from ASTM B26 and B108 are shown in Table 3.9. Unless

shown otherwise in the ASTM specifications and Table 3.9, the values given

are the minimum values for separately cast test bars, not for production castings.

Minimum strengths for coupons cut from actual production castings

must be no less than 75% of the values given in Table 3.9. Elongation values

of coupons from castings must be no less than 25% of the values in Table

3.9; in other words, they may be considerably less than the values in the table.

Minimum mechanical properties (tensile ultimate and yield strengths and percent

elongation in 2 in. [50 mm]) for separately cast test bars of cast aluminum

alloys are also given in Standards for Aluminum Sand and Permanent

Mold Castings and the Aluminum Design Manual, Part V, Material Properties.

All strengths in these tables must be multiplied by 0.75 and all elongations

by 0.25 to obtain values for specimens cut from castings. The ASTM B26

and B108 specifications are updated more frequently than the Aluminum Association

publications and so may better reflect current industry standards.

pag 72

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- BC C Punmia BeamDokumen12 halamanBC C Punmia BeamSureshKumarBelum ada peringkat

- Aluminum Manual 80Dokumen2 halamanAluminum Manual 80LUIS4563Belum ada peringkat

- Aluminum Manual 79Dokumen1 halamanAluminum Manual 79LUIS4563Belum ada peringkat

- Aluminum Manual 75Dokumen1 halamanAluminum Manual 75LUIS4563Belum ada peringkat

- Aluminum Manual 72Dokumen1 halamanAluminum Manual 72LUIS4563Belum ada peringkat

- Aluminum Manual 78Dokumen1 halamanAluminum Manual 78LUIS4563Belum ada peringkat

- Aluminum Manual 70Dokumen2 halamanAluminum Manual 70LUIS4563Belum ada peringkat

- Aluminum Manual 77Dokumen1 halamanAluminum Manual 77LUIS4563Belum ada peringkat

- Aluminum Manual 79Dokumen1 halamanAluminum Manual 79LUIS4563Belum ada peringkat

- Aluminum Manual 78Dokumen1 halamanAluminum Manual 78LUIS4563Belum ada peringkat

- Aluminum Manual 76Dokumen1 halamanAluminum Manual 76LUIS4563Belum ada peringkat

- Aluminum Manual 73Dokumen1 halamanAluminum Manual 73LUIS4563Belum ada peringkat

- Aluminum Manual 74Dokumen1 halamanAluminum Manual 74LUIS4563Belum ada peringkat

- Aluminum Manual 71Dokumen1 halamanAluminum Manual 71LUIS4563Belum ada peringkat

- Aluminum Manual 72Dokumen1 halamanAluminum Manual 72LUIS4563Belum ada peringkat

- Aluminum Manual 68Dokumen2 halamanAluminum Manual 68LUIS4563Belum ada peringkat

- Aluminum Manual 69Dokumen1 halamanAluminum Manual 69LUIS4563Belum ada peringkat

- Aluminum Manual 67Dokumen2 halamanAluminum Manual 67LUIS4563Belum ada peringkat

- Aluminum Manual 70Dokumen2 halamanAluminum Manual 70LUIS4563Belum ada peringkat

- Aluminum Manual 66Dokumen1 halamanAluminum Manual 66LUIS4563Belum ada peringkat

- Aluminum Manual 65Dokumen1 halamanAluminum Manual 65LUIS4563Belum ada peringkat

- Aluminum Manual 62Dokumen1 halamanAluminum Manual 62LUIS4563Belum ada peringkat

- Aluminum Manual 65Dokumen1 halamanAluminum Manual 65LUIS4563Belum ada peringkat

- Aluminum Manual 59Dokumen1 halamanAluminum Manual 59LUIS4563Belum ada peringkat

- Aluminum Manual 64Dokumen1 halamanAluminum Manual 64LUIS4563Belum ada peringkat

- Aluminum Manual 61Dokumen1 halamanAluminum Manual 61LUIS4563Belum ada peringkat

- Aluminum Manual 57Dokumen1 halamanAluminum Manual 57LUIS4563Belum ada peringkat

- Aluminum Manual 63Dokumen1 halamanAluminum Manual 63LUIS4563Belum ada peringkat

- Aluminum Manual 60Dokumen2 halamanAluminum Manual 60LUIS4563Belum ada peringkat

- Aluminum Manual 58Dokumen1 halamanAluminum Manual 58LUIS4563Belum ada peringkat

- Aluminum Manual 58Dokumen1 halamanAluminum Manual 58LUIS4563Belum ada peringkat

- Introduction To Wastewater ManagementDokumen18 halamanIntroduction To Wastewater ManagementMuhammad IqmalBelum ada peringkat

- SUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSDokumen2 halamanSUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSWilliam LimBelum ada peringkat

- Experimental Investigation of Resistance Spot Welding of Duplex Stainless SteelDokumen5 halamanExperimental Investigation of Resistance Spot Welding of Duplex Stainless SteelM.SoundarrajanBelum ada peringkat

- Water Cooled Cable For Electric FurnaceDokumen4 halamanWater Cooled Cable For Electric FurnaceWAWANBelum ada peringkat

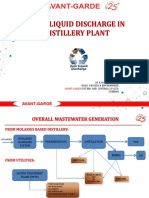

- Avant-Garde Mr. K Mohan KumarDokumen46 halamanAvant-Garde Mr. K Mohan KumarSivakumar SelvarajBelum ada peringkat

- YK60A Digital Inverter Battery Charger ManualDokumen35 halamanYK60A Digital Inverter Battery Charger ManualS M NaveedBelum ada peringkat

- Corrosion Assessment in Reinforced Concrete StructuresDokumen32 halamanCorrosion Assessment in Reinforced Concrete Structuresdineshkumar rBelum ada peringkat

- Civil Engineering Materials UOL Lahore: ConcreteDokumen119 halamanCivil Engineering Materials UOL Lahore: ConcreteNawab Zada ManekaBelum ada peringkat

- Dickella Premakumara Final Best Practices PDFDokumen36 halamanDickella Premakumara Final Best Practices PDFjune dela cernaBelum ada peringkat

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesDokumen40 halamanJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemBelum ada peringkat

- Plastic ShredderDokumen23 halamanPlastic ShredderJojimar JulianBelum ada peringkat

- Cane Ite PDFDokumen4 halamanCane Ite PDFJim HaigBelum ada peringkat

- METAL ORGANIC FRAMEWORKS (MOFs)Dokumen8 halamanMETAL ORGANIC FRAMEWORKS (MOFs)FabianCcahuanaAymaBelum ada peringkat

- Test Report: H.D.G. Bolts, Nuts & Plain WasherDokumen1 halamanTest Report: H.D.G. Bolts, Nuts & Plain WasherSumanta AdhikariBelum ada peringkat

- MEC E 563 Assignment 4Dokumen8 halamanMEC E 563 Assignment 4JasonBelum ada peringkat

- Blown Film CatalogueDokumen12 halamanBlown Film CatalogueMohammad-reza NabavinezhadBelum ada peringkat

- Cr-Mo Steel Vessel Repair ConsiderationsDokumen7 halamanCr-Mo Steel Vessel Repair Considerationsromanosky11Belum ada peringkat

- Corporate Image enDokumen8 halamanCorporate Image enDanfert PinedoBelum ada peringkat

- Week 2 Module - CHEMDokumen13 halamanWeek 2 Module - CHEMMichael AustriaBelum ada peringkat

- Manuf Pacop Pink Green Blue RedDokumen46 halamanManuf Pacop Pink Green Blue RedShane KimBelum ada peringkat

- LNG Ships: by F. R. ChowdhuryDokumen6 halamanLNG Ships: by F. R. ChowdhuryThusitha DalpathaduBelum ada peringkat

- Definition of Tunnel BoringDokumen13 halamanDefinition of Tunnel BoringUji FauziahBelum ada peringkat

- INKALUMDokumen110 halamanINKALUMjasasegaladesainBelum ada peringkat

- VIBRATION PROBLEM IN A HYDRO-TURBINE GENERATOR SETDokumen7 halamanVIBRATION PROBLEM IN A HYDRO-TURBINE GENERATOR SETAnonymous NUn6MESxBelum ada peringkat

- Glo Brochure Sikagard 555 W ElasticDokumen4 halamanGlo Brochure Sikagard 555 W ElasticYasndra AbeygunewardhaneBelum ada peringkat

- (Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodDokumen33 halaman(Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodAna Quintana100% (1)

- Articulado PDFDokumen90 halamanArticulado PDFMiguel Fuentes100% (1)

- TM 5-811-6 Generator and Electrical Facilities DesignDokumen26 halamanTM 5-811-6 Generator and Electrical Facilities DesignrockclaudiuBelum ada peringkat

- Sap kr97Dokumen79 halamanSap kr97tva400% (1)