BMP 4th - Q

Diunggah oleh

smrutirekhaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

BMP 4th - Q

Diunggah oleh

smrutirekhaHak Cipta:

Format Tersedia

Registration no:

BASIC MANUFACTURING PROCESSES

BRANCH : MECHANICAL(I and II)

1

Time: 1 2 Hours Max Marks: 30

Answer Question No.1 and 2 which are compulsory and any THREE from the rest.

The figures in the right hand margin indicate marks

Q.1 Answer any three (5x1)

a. Which characteristic of material is used in forging process?

i. characteristics of elasticity of material ii. characteristics of ductility of material

iii. characteristics of plasticity of material iv. none of the above

b. In backward or indirect extrusion, _____ plunger is used

i. Solid ii. Hollow iii. No iv. both solid and hollow

c. Good surface finish and better dimensional accuracy can be achieved in

i. cold working process ii. hot working process

iii. both a. and b. iv . none of the above

d. Thermit welding.......

i.A process which uses a mixture of iron oxide and granular aluminum

ii.Accomplished by maintaining a hot molten metal pool between plates

iii.A process in which arc is maintained under blanket of flux

iv.In no welding process

e. Distortion in welding occures due to......

i. Use of excessive current ii. Improper clamping methods

iii. Use of wrong electrodes iv. Oxidation of weld pool

f. The parts produced by Powder metallurgy

i. always require machining ii. are of higher dimensional accuracy

iii. can not be heat treated iv. none of the above

g. Sintering increases

i. electrical conductivity, density and ductility ii. electrical conductivity, density and brittleness

iii. porosity, electrical conductivity and brittleness iv. porosity, density and ductility

h. In which of the following process the ductility of material decreases?

i. Hot working ii. Cold working

iii. Warm working iv. None of the mentioned

i. In which of the following forging metal is kept in the lower die?

i. Open die ii. Closed die

iii. Impression dies iv. None of the Mentioned

Q2. Answer any two (4x1)

a) Explain the sintering process used in powder metallurgy.

b) Name an extrusion process by which a tooth paste tube can be produced

c) What is the function of flux in welding?

d) Name the arc welding method in which the arc is not visible from outside.

e) Write short note on laser beam welding

f) Define arc blow . what are its effects?

g) What is ironing in deep drawing operation for sheet metal?

h) Write the various types of forging defects.

i) Name bonding agent s for core sands.

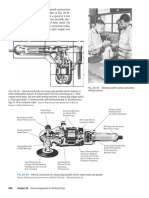

Q3. (a) With neat sketch explain the working of GTAW process and write its applications. (3)

(b) Explain working principle of Laser beam welding process with neat sketch. (2)

Q4. a) Name the common rolling defects and explain how these can be eliminated. (2.5)

b) Describe with neat sketch the hydrostatic extrusion process. (2.5)

Q5. (a) What are the differences between hot working process and cold working process? (3)

(b) Distinguish between drop forging and press forging process (2)

Q6. (a) the voltage arc gap characteristic of a machine is given by equation V= (15+30L) volts. Where L is

arc gap in mm. The machine operates with an open circuit wattage of 70volts and shot circuit current

of 700 amps. Determine the optimum arc length for which power is maximum and the corresponding

power. (3)

(b) discuss briefly resistance projection welding (2)

Q7. (a)Discuss the different sheering operations performed on sheet metal. (3)

(b) Explain the difference between punching, blanking and piercing. (2)

Q8.(a) Compare TIG welding with MIG welding. (2)

(b) Describe the process of submerged arc welding stating its advantages and limitations (3)

Q9(a) Using neat sketch describe briefly the method of extruding a hollow round collapsible tube with help of

drawing process. (3)

(b) What is impact extrusion? Explain this process and state its specific applications. (2)

Anda mungkin juga menyukai

- Important PointsDokumen3 halamanImportant PointssmrutirekhaBelum ada peringkat

- Work, Power and Energy Revision NotesDokumen3 halamanWork, Power and Energy Revision NotessmrutirekhaBelum ada peringkat

- Important PointsDokumen3 halamanImportant PointssmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen3 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Important PointsDokumen3 halamanImportant PointssmrutirekhaBelum ada peringkat

- Important PointsDokumen3 halamanImportant PointssmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen3 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen2 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Work, Power and Energy Revision NotesDokumen2 halamanWork, Power and Energy Revision NotessmrutirekhaBelum ada peringkat

- Important PointsDokumen2 halamanImportant PointssmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen3 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen2 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen2 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen2 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Important PointsDokumen2 halamanImportant PointssmrutirekhaBelum ada peringkat

- Chapter 14 WeldingDokumen22 halamanChapter 14 WeldingRiian ApriansyahBelum ada peringkat

- Important PointsDokumen2 halamanImportant PointssmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen2 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Advantages of Francis Turbines for Medium to High Head RangesDokumen2 halamanAdvantages of Francis Turbines for Medium to High Head RangessmrutirekhaBelum ada peringkat

- Work:-Work Done W Is Defined As The Dot Product of Force F and Displacement SDokumen2 halamanWork:-Work Done W Is Defined As The Dot Product of Force F and Displacement SsmrutirekhaBelum ada peringkat

- Optics 27 YearsDokumen15 halamanOptics 27 YearssmrutirekhaBelum ada peringkat

- Physics 11Dokumen2 halamanPhysics 11smrutirekhaBelum ada peringkat

- Chapter 1thermodynamicsDokumen21 halamanChapter 1thermodynamicssmrutirekhaBelum ada peringkat

- Advantages of Francis Turbines for Medium to High Head RangesDokumen2 halamanAdvantages of Francis Turbines for Medium to High Head RangessmrutirekhaBelum ada peringkat

- Advantages of Francis Turbines for Medium to High Head RangesDokumen2 halamanAdvantages of Francis Turbines for Medium to High Head RangessmrutirekhaBelum ada peringkat

- Metal forming processes overviewDokumen91 halamanMetal forming processes overviewAnonymous 9xvU1F100% (2)

- Optics 27 YearsDokumen15 halamanOptics 27 YearssmrutirekhaBelum ada peringkat

- Advantages of Francis Turbines for Medium to High Head RangesDokumen2 halamanAdvantages of Francis Turbines for Medium to High Head RangessmrutirekhaBelum ada peringkat

- Advantages of Francis Turbines for Medium to High Head RangesDokumen2 halamanAdvantages of Francis Turbines for Medium to High Head RangessmrutirekhaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Tool & Die Design Lecture Jan2011 13mar12Dokumen100 halamanTool & Die Design Lecture Jan2011 13mar12azizmaarof100% (8)

- Sundial TemplateDokumen1 halamanSundial TemplateMark FerneauBelum ada peringkat

- Gamac Series: Grinding Aids For Cement ProductionDokumen2 halamanGamac Series: Grinding Aids For Cement Productionmahreza189Belum ada peringkat

- One step solution for LCD panel applicationDokumen35 halamanOne step solution for LCD panel applicationMicu Adrian DanutBelum ada peringkat

- Fig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsDokumen7 halamanFig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsWilly UioBelum ada peringkat

- Introduction To Welding - 1 GCDokumen66 halamanIntroduction To Welding - 1 GCkr_abhijeet72356587Belum ada peringkat

- Uhdtv 10bitsDokumen6 halamanUhdtv 10bitsNachoBelum ada peringkat

- Field Effect Transistor (FET) : Electronic II Second Year, 2015-2016 Part II LecturesDokumen62 halamanField Effect Transistor (FET) : Electronic II Second Year, 2015-2016 Part II Lecturestareq omarBelum ada peringkat

- PriceListHirePurchase Normal 4 PDFDokumen55 halamanPriceListHirePurchase Normal 4 PDFAbdul SamadBelum ada peringkat

- Dashboard & Gantt ChartDokumen9 halamanDashboard & Gantt Chartarief spartaBelum ada peringkat

- LCD TV: Parts and DiagramsDokumen16 halamanLCD TV: Parts and DiagramsGeovanny SanJuanBelum ada peringkat

- Experiment 2Dokumen5 halamanExperiment 2Vivek Surana40% (5)

- LPPJFF RL - Envi - 2013 04 04Dokumen10 halamanLPPJFF RL - Envi - 2013 04 04Petros IosifidisBelum ada peringkat

- ME6004-Unconventional Machining Processes VETDokumen11 halamanME6004-Unconventional Machining Processes VETPRAKASHBelum ada peringkat

- American Welding SocietyDokumen4 halamanAmerican Welding SocietyFs100% (1)

- Syllabus: Summary of Information On Each Course Metal Fabrication ActivitiesDokumen10 halamanSyllabus: Summary of Information On Each Course Metal Fabrication ActivitiesAhmadFahmiMohdAdniBelum ada peringkat

- Debre Markos University Institute of Technology School of Electrical and Computer Engineering Computer Engineering (PG)Dokumen10 halamanDebre Markos University Institute of Technology School of Electrical and Computer Engineering Computer Engineering (PG)enidegBelum ada peringkat

- SiteCollectionDocuments Outokumpu Stainless Steel Wall ChartDokumen1 halamanSiteCollectionDocuments Outokumpu Stainless Steel Wall ChartPedro PiniaBelum ada peringkat

- Siyath ZonalDokumen43 halamanSiyath ZonalmlmihjazBelum ada peringkat

- AM58330 Fastrans PET Matte Chrome Permanent S2045P BG40Dokumen1 halamanAM58330 Fastrans PET Matte Chrome Permanent S2045P BG40Yashvanth ShettyBelum ada peringkat

- Print Key Characteristics Project 3235Dokumen49 halamanPrint Key Characteristics Project 3235Gokul Prasad ChettiBelum ada peringkat

- The History of Combine HarvestersDokumen16 halamanThe History of Combine Harvesterspop bogdanBelum ada peringkat

- Pages From Asme Sec Ix 2017-3Dokumen1 halamanPages From Asme Sec Ix 2017-3Akhtar AnsariBelum ada peringkat

- Bipolar Transistor Cross-Reference Search - Equivalent TransistorsDokumen3 halamanBipolar Transistor Cross-Reference Search - Equivalent TransistorsDhany SiregarBelum ada peringkat

- Lista Stanley Black & Decker May 23Dokumen31 halamanLista Stanley Black & Decker May 23Fer DehBelum ada peringkat

- 7-Manual Process Planning (AMS May13 - 13) PDFDokumen24 halaman7-Manual Process Planning (AMS May13 - 13) PDFtadele10Belum ada peringkat

- EML 2322L - Welding - MAE Design and Manufacturing LabDokumen21 halamanEML 2322L - Welding - MAE Design and Manufacturing LabBhaiJan59Belum ada peringkat

- Pulp and Paper IndustryDokumen118 halamanPulp and Paper IndustrySYED ASGHAR ALI SULTANBelum ada peringkat

- 2017 Summer Model Answer PaperDokumen18 halaman2017 Summer Model Answer PaperNishant GawadBelum ada peringkat

- Fabrication ProcessDokumen5 halamanFabrication ProcessSeafuri Khairunnisa UntadiBelum ada peringkat