Dhi-Ehs-Hsm-031 Permit To Work Rev0

Diunggah oleh

khoahuyen_89Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Dhi-Ehs-Hsm-031 Permit To Work Rev0

Diunggah oleh

khoahuyen_89Hak Cipta:

Format Tersedia

HEALTH AND SAFETY MANUAL

DHI-EHS-HSM-031

PERMIT TO WORK

Copyright This document is the property of Doosan Heavy Industries and Construction and all rights are

reserved in respect of it. This document may not be reproduced or disclosed in any manner what so ever, in

whole or in part, without the prior written consent of Doosan.

Doosan expressly disclaims any responsibility for or liability arising from the use

of this document by any third party. Copies printed are UNCONTROLLED.

Revision Details Next Review: January 2015

Rev. Date Revision Status Checked Approved

00 31/03/2014 Draft Yonghyun Kim Seungmin Park

DHI-EHS-HSM-031 (March 2014), Page 1 of 21

PURPOSE AND SCOPE

This manual describes system of control potentially high risk operations through the issue of a Permit to Work

(PTW).

DEFINITIONS

Permit to Work (PTW): Is a system which ensures that all essential precautions have been taken

and where necessary, physical safe guards are in place to allow particular

high risk work to proceed.

PROCEDURE

Operations that involve, but are not limited to the use of toxic materials or explosive devices, confined space

entry, on or near live electrical equipment or other similar hazardous work shall require a Permit to Work to be

used.

Safe working depends on trained people strictly applying and adhering to all appropriate company and legislative

procedures.

Permit to Work systems and procedures constitute the most formal method of ensuring safe working practices.

The responsible Permit Holder shall ensure that the safe work practices outlined on the permit and all other

requirements of the Work Permit are strictly adhered to during the task being performed.

The EHS department is responsible for keeping a copy of Permit to Work issued.

Hazardous work to be carried out under the Permit to Work must have risk assessment conducted prior to issue

of Work Permit. The necessary control measures must also be indicated in the Work Permit. The Work Permit

should also be displayed at the Work Area.

1.0 Hazard Identification and Risk Assessment

Identification of Hazards in Relation to Work Permits will depend upon the purpose of the Permit e.g.

Hot Works

Excavation

Lifting more than 10t, twin lifts or complicated lifts

Night Work/ Holiday Work

Confined Spaces

Ionizing Radiation Work

Working over Water

Diving

A specific Risk Assessment Form and Job Safety Analysis Form must be attached to the Permit.

DHI-EHS-HSM-031 (March 2014), Page 2 of 21

2.0 Risk Checklist

Carry out preliminary survey of work and work area to ascertain dangers.

Analyze the work and level of exposure to hazards.

Appoint competent personnel to execute the work.

Carry out any specific training prior to commencement.

Ensure all necessary PPE is provided.

Ensure necessary Emergency back-up/support measures are in place prior to commencement.

Ensure others who are in the vicinity of the work are notified and protected against the hazards.

Ensure a copy of the Permit is posted at the work area and times strictly complied with.

DHI-EHS-HSM-031 (March 2014), Page 3 of 21

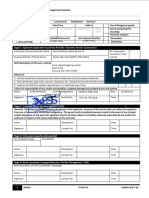

Attachment 1

HOT WORK PERMIT

Project Name Date:

PERMIT REQUIRED FOR WELDING GAS CUTTING BRAZING GRINDING Others

Location:

Section – I DETAILS OF THE PERMIT RECIVER (SC = Sub Contractor, DHI = DOOSAN)

Permit Receiver (SC) Contact Number

Engineer Responsible (DHI) Contact Number

Name of the Welder (or worker) Gate Pass ID number

Safety In charge (DHI) Contact Number

Section – II PERMIT VALIDATIONS

Date issued Valid Till (Not more than a week)

Time Issued Valid Till (Expires after 0001 hrs)

Extended Date Valid Till (Not more than a week)

Extended Time Valid Till (Expires after 0001 hrs)

Permit Contents: 1) Permit to Hot Work (Two copies one for site one for EHS file)

2) Method Statement and JSEA (Copy for Site)

3) Personnel Training Record Sheet (To be placed in EHS file)

HOT work permit shall not exceed its duration for more than seven (7) days.

Work Permit shall be renewed on the Eighth (8th) day WITHOUT FAIL

Section – III PREREQUISITE (Work May be stopped if one of the following is not complied with)

Yes/ Yes/

for YES and X for No NA for YES and X for No NA

No No

A Flammable Materials removed from location K Appropriate Working Platform

B Welding Gensets terminal insulation L Safety/Warning Signs in place

C Adequate Earthing M Adequate Ventilation

D Area of work clean and dry N Condition of the welding cables

E Appropriate Fire Extinguisher Provided O Adequate illumination

F Operatives trained in using fire extinguisher P Flash Back arrestors - Gas Cylinders

G Fire Blankets (non flammable) Provided Q Cylinders Kept in trolley and secured

H Fire Watch Personal R Regulators in good condition

I Area barricaded S Gas test required

J Appropriate PPE Provided T Isolation of Equipments required

Declaration by the Permit Receiver Name and address of Permit Receiver

I_________________ representing _________________ hereby declare that I Company Name: ………………………………………………………

have checked the location and the welder has been briefed about the emergency Nature of Job: ………………………………………………. ………

procedure and a toolbox talk given on using the fire extinguisher to ALL involved

Tel.No…………………………………………………………………

in the activity.

Email…………………………………………………………………

Date: ……/……/…… Name; ……………. Signature;

Contact Number (Site Safety Rep)………………………..

DHI-EHS-HSM-031 (March 2014), Page 4 of 21

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date …….../…..…./……..

Comments.

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected from

the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date …….../…..…./……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Doosan Civil/ Doosan Electrical/ Doosan QA/ QC

Project Director ( )

Architecture Manager Mechanical Manager Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 5 of 21

Attachment 2

PERMIT TO EXCAVATE

Project Name Date:

PERMIT REQUIRED FOR Excavation LOCATION:

Section – I DETAILS OF THE PERMIT RECEIVER (SC = Sub Contractor, DHI = DOOSAN)

Task Supervisor/Foreman(SC) Contact Number

Engineer Responsible (DHI) Contact Number

Safety Advisor on Site (DHI) Contact Number

Section – II (Eng. Responsible) PERMIT VALIDATIONS

PERMIT ISSUE DETAILS Date ____________________ Time ________________ NO EXTENSION WILL BE GIVEN

PERMIT EXPIRY DETAILS Date ____________________ Time ________________ ON THIS PERMIT

Permit Contents: 1) Permit to Excavate (Two copies one for site one for EHS file)

2) Method Statement and JSEA (Copy for Site)

3) Personnel Training Record Sheet (To be placed in EHS file)

ALL EXCAVATIONS IN EXCESS OF 1.2M DEEP SHOULD BE APPROVED THIS PERMIT.

THIS PERMIT IS ONLY TO BE USED BY THE PERSONS TO WHOM IT IS ISSUED. ON COMPLETION OF THE TASK OR ON EXPIRY THE

PERMIT IS TO BE RETURNED TO THE ISSUER FOR CANCELATION

Section – III (By SubContractor) PREREQUISITE (Work May not commence if one of the following is not complied with)

for YES and X for No Yes/No NA for YES and X for No Yes/No NA

Is the Work Area Clearly Defined? Have the Latest DOC Services indicated by walk through with

A

drawings been Consulted? H operatives designated to the task and safe

B Has the Area been Checked Underground Utilities? exclusion zones been indicated by barriers.

Water / Sewer / Irrigation / Drainage

C Are All Service Locations Clearly Marked? I

( 1m Exclusion)

D Have All necessary Trial Trenches been Excavated? Electrical 11 Kv or Higher Voltage

J

(3m Exclusion)

Has a Risk Assessment been Completed for the Task of

E

Excavating Near the Services? K Electrical Lower than 11 Kv (1m Exclusion)

Have The Operatives for the task been briefed on the Risk L Telecommunication (1m Exclusion)

F

Assessment. Is this Signed for? M Oil/Gas (10m Exclusion)

Are the Required Controls in Place as per the Risk N Overhead Services (Contact Service owner)

G Assessment?

O Other (including Structures)

Attended Briefing 1 5

2 6

Details of Employees working 3 7

in the Excavation 4 8

Name, Company

Planned Equipment For

Declaration by the Permit Receiver (SC) Allowed / Disallowed

Excavation

I_________________ representing _________________ hereby declare that I have

checked the location and all the employees have been briefed about the emergency

procedure and services associated with this area of excavation.

Date: ……/……/…… Name; ……………. Signature; …………….. PTW CANCELLED: By:

DHI-EHS-HSM-031 (March 2014), Page 6 of 21

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date …….../…..…./……..

Comments.

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected from

the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date …….../…..…./……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Doosan Civil/ Doosan Electrical/ Doosan QA/ QC

Project Director ( )

Architecture Manager Mechanical Manager Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 7 of 21

Attachment 3

CRANE OPERATING PERMIT

Project Name Date:

PERMIT REQUIRED FOR Crane Operation LOCATION:

Section – I DETAILS OF THE PERMIT RECEIVER (SC = Sub Contractor, DHI = DOOSAN)

Task Supervisor/Foreman(SC) Contact Number

Engineer Responsible (DHI) Contact Number

Safety Advisor on Site (DHI) Contact Number

Section – II PERMIT VALIDATIONS

Date issued Valid Till (Not more than a week)

Time Issued Valid Till (Expires after 0001 hrs)

Extended Date Valid Till (Not more than a week)

Extended Time Valid Till (Expires after 0001 hrs)

Section – III PREREQUISITE (Work May be stopped if one of the following is not complied with)

for YES and X for No Yes/No NA for YES and X for No Yes/No NA

A Lifting procedure/prepared/planned? K Main brake system functioning?

B Crane inspected/Jibs good condition? L Safety/Warning Signs in place?

C Work area in safe-condition? M Winch brake system functioning?

D Lifting calculation completed/Load Test/Charts? N Ground stability checked?

E Height clearance completed? O Stability of crane outriggers?

Dedicated signalman (one person only) with

F Shackles inspected? P

vest?

G Slings inspected with certificates? Q Weather in good condition?

Area supervisor/safety personnel

H Spreader bar inspected? R

supervision?

I Reverse alarm & lights functioning? S Fire extinguisher in place?

J Doors & windscreen good condition? T Steel plates (where required)?

Crane : Type : Model No. : Vehicle No.:

Year of Manufacturing Crane :

Operator Name: Operator Certificate No.:

Maximum Weight of the Load:

Declaration by the Permit Receiver Name and address of Permit Receiver

I_________________ representing _________________ hereby declare that I Company Name: ………………………………………………………

have checked the location and the welder has been briefed about the Nature of Job: ………………………………………………. ………

emergency procedure and a toolbox talk given on using the fire extinguisher to

Tel.No…………………………………………………………………

ALL involved in the activity.

Email…………………………………………………………………

Date: ……/……/…… Name; ……………. Signature;

Contact Number (Site Safety Rep)………………………..

DHI-EHS-HSM-031 (March 2014), Page 8 of 21

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date …….../…..…./……..

Comments.

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected

from the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date …….../…..…./……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Doosan Civil/

Project Doosan Electrical/ Doosan QA/ QC

Architecture ( )

Director Mechanical Manager Manager

Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 9 of 21

Attachment 4

ELECTRICAL WORK PERMIT

Project Name Date:

Description of

Work

PERMIT REQUIRED FOR Electrical Work LOCATION:

Section – I PERMIT RECIVER DETAILS

Permit Receiver (SC) Contact Number

Engineer Responsible (DHI) Contact Number

Safety In charge (SC) Contact Number

Safety Advisor on Site (DHI) Contact Number

Section – II PERMIT VALIDATIONS

Date issued Valid Till

Time Issued Valid Till

Extended Date Valid Till

Extended Time Valid Till

Section – III PREREQUISITE (Work will be stopped if one of the following is not complied with)

Details of the 220 volt power tool for YES and X for No Yes NA

ELCB Tested and

1 Type of Power Tool A

Drill Breaker Others certified

2 Reason for using the equipment ; Industrial Sockets

B

……………………………………………………………………………………………………………………………………………………………………………………………………………… (Blue) in use

C Armoured cable

Toolbox talk on use of

D

220 volt elec.

Equipment is

3 Manufacture E

adequately earthed

Serial Safety Warning Signs

4 F

Number in place

5 Electricians Declaration Dead Mans Switch

G

I_________________ representing _________________ hereby declare that I have checked the functioning

location/machine mentioned above and confirm that it is in line with all safety requirements and is Double Insulated

safe to be used. H

casings

I Area of work kept dry

J Cables appropriately

Date :……/……/…… Name; ……………. Signature ;…………….. protected

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date ………/…..…./……..

Comments.

Section IV PERMIT APPROVAL

DHI-EHS-HSM-031 (March 2014), Page 10 of 21

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected

from the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date ………/…..…./

……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Project Doosan Civil/ Doosan Electrical/ Doosan QA/ QC

( )

Director Architecture Manager Mechanical Manager Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 11 of 21

Attachment 5

NIGHT WORK/ HOLIDAY WORK PERMIT

Project Name Date:

Description of

Work

PERMIT REQUIRED FOR Night Work Holiday Work LOCATION:

Section – I DETAILS OF THE PERMIT RECEIVER (SC = Sub Contractor, DHI = DOOSAN)

Task

Contact Number

Supervisor/Foreman(SC)

Engineer Responsible (DHI) Contact Number

Safety Advisor on Site (DHI) Contact Number

Section – II (Eng. Responsible) PERMIT VALIDATIONS

PERMIT ISSUE DETAILS Date ____________________ Time ________________ NO EXTENSION WILL BE GIVEN

PERMIT EXPIRY DETAILS Date ____________________ Time ________________ ON THIS PERMIT

IN CASE OF NIGHT WORK PERMIT, THE PERMIT SHOULD BE SUBMITTED AND DISCUSSED BEFORE 4 PM. ALL REQUIRED SAFETY

WORK PREPARATION BEFORE 5 PM and IT HAS TO BE CONFIRMED WITH Doosan EHS MANAGER.

IN CASE OF HOLIDAY WORK, THE PERMIT SHOULD BE SUBMITTED AND DISCUSSED AT LEAST ONE DAY BEFORE.

Section – III PREREQUISITE (Work May be stopped if one of the following is not complied with)

for YES and X for No Yes/No NA for YES and X for No Yes/No NA

A Sufficient illumination provided? D Are additional permit need?

Is security notified of the night

B Are all employees equipped with clear safety glasses? E

work/holiday work?

Are all employees trained emergency

C Is there an ambulance and nurse present? F

responses?

Attended Briefing 1 5

2 6

Details of Employees 3 7

working in the night/ holiday 4 8

Name, Company

Planned Equipment For Night

Declaration by the Permit Receiver (SC) Allowed / Disallowed

Work/ Holiday Work

I_________________ representing _________________ hereby declare that I have

checked the location and all the employees have been briefed about the emergency

procedure and services associated with this area of excavation

Date: ……/……/…… Name; ……………. Signature; …………….. PTW CANCELLED: By:

DHI-EHS-HSM-031 (March 2014), Page 12 of 21

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date …….../…..…./……..

Comments.

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected

from the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date …….../…..…./……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Project Doosan Civil/ Doosan Electrical/ Doosan QA/ QC

( )

Director Architecture Manager Mechanical Manager Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 13 of 21

Attachment 6

CONFINED SPACE ENTRY PERMIT

Project Name Date:

ENTRY REQUIRED FOR PAINTING FINISHING HOT WORKS Others (Specify) ……………………..

Location(s) :

Section – I DETAILS OF THE PERMIT RECIVER (SC = Sub Contractor, DHI = DOOSAN)

Permit Receiver (SC) Contact Number

Engineer Responsible (DHI) Contact Number

Safety In charge (SC) Contact Number

Safety Advisor on Site (DHI) Contact Number

Section – II PERMIT VALIDATIONS

PERMIT ISSUE DETAILS Date ____________________ Time ________________ NO EXTENSION WILL BE

PERMIT EXPIRY DETAILS Date ____________________ Time ________________ GIVEN ON THIS PERMIT

Permit Contents: 1) Permit to Confined Space Entry (Two copies one for site one for EHS file)

2) Method Statement and JSEA (Copy for Site)

3) Personnel Training Record Sheet (To be placed in EHS file)

This permit covers ENTRY ONLY to a confined space.

All work entailed in effecting entry and after entry shall be covered by the appropriate WORK PERMIT.

Section – III PREREQUISITE (Work May be stopped if one of the following is not complied with)

Yes/ Yes/

for YES and X for No NA for YES and X for No NA

No No

A Atmosphere in the Confined Space Tested? K If so, are the equipments isolated?

B Oxygen level is 19.5% (Should not be less/more) L Is the main source of supply tagged?

C Will the atmosphere be monitored during work? M Has the toolbox talk been given?

D Continuously/Periodically Specify Interval N Air intake system located free from fume?

E Has the space been ventilated before entry? O Preparedness for emergency response?

F Will ventilation be continued during work? (LEV) P Work Method Statements submitted?

G Was the space found unacceptable? Q Will any Chemicals be used in the space?

H If so, after ventilation was the area retested? R Adequate illumination to carry out the job?

I Are there any other equipment running? S Appropriate PPE Provided?

J Will any other equipment be used in the space? T Watcher(s) required?

1 5

Details of Employee working 2 6

in the confined space

Name, Company 3 7

4 8

Details of Equipment and/or

Material being used

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date ………/…..…./……..

Comments.

Section IV PERMIT APPROVAL

DHI-EHS-HSM-031 (March 2014), Page 14 of 21

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected

from the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date ………/…..…./

……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Project Doosan Civil/ Doosan Electrical/ Doosan QA/ QC

( )

Director Architecture Manager Mechanical Manager Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 15 of 21

Attachment 7

IONIZING RADIATION WORK PERMIT

Project Name Date:

Location(s)

Section – I DETAILS OF THE PERMIT RECIVER (SC = Sub Contractor, DHI = DOOSAN)

Permit Receiver (SC) Contact Number

Engineer Responsible (DHI) Contact Number

Safety In charge (SC) Contact Number

Safety Advisor on Site (DHI) Contact Number

Section – II PERMIT VALIDATIONS

PERMIT ISSUE DETAILS Date ____________________ Time ________________ NO EXTENSION WILL BE

PERMIT EXPIRY DETAILS Date ____________________ Time ________________ GIVEN ON THIS PERMIT

Permit Contents: 1) Permit to Ionizing Radiation Work Permit (Two copies one for site one for EHS file)

2) Method Statement and JSEA (Copy for Site)

3) Personnel Training Record Sheet (To be placed in EHS file)

Section – III PREREQUISITE (Work May be stopped if one of the following is not complied with)

Yes/ Yes/

for YES and X for No NA for YES and X for No NA

No No

A Radiation areas barricaded? E Rad. meters checked & calibrated?

B Caution notice posted? F Remote handling equip. checked?

C Radiation area boundaries monitored? G Sealed source container checked?

D Warning lights etc. positioned? K Other Necessary Precautions?

Detail of Radiation Source

(a) X-ray apparatus (manufacturing year / type ) :

(b) Max tube voltage: (kv)

(c) Sealed source type:

(d) Strength: curies

(e) Serial No.:

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date …….../…..…./……..

Comments.

DHI-EHS-HSM-031 (March 2014), Page 16 of 21

Section IV PERMIT APPROVAL

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected

from the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date …….../…..…./……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Project Doosan Civil/ Doosan Electrical/ Doosan QA/ QC

( )

Director Architecture Manager Mechanical Manager Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 17 of 21

Attachment 8

WORKING OVER WATER (MARINE) WORK PERMIT

Project Name Date:

Location(s)

Section – I DETAILS OF THE PERMIT RECIVER (SC = Sub Contractor, DHI = DOOSAN)

Permit Receiver (SC) Contact Number

Engineer Responsible (DHI) Contact Number

Safety In charge (SC) Contact Number

Safety Advisor on Site (DHI) Contact Number

Section – II PERMIT VALIDATIONS

PERMIT ISSUE DETAILS Date ____________________ Time ________________ NO EXTENSION WILL BE

PERMIT EXPIRY DETAILS Date ____________________ Time ________________ GIVEN ON THIS PERMIT

Permit Contents: 1) Permit to Marine Work Permit (Two copies one for site one for EHS file)

2) Method Statement and JSEA (Copy for Site)

3) Personnel Training Record Sheet (To be placed in EHS file)

Section – III PREREQUISITE (Work May be stopped if one of the following is not complied with)

Yes/ Yes/

for YES and X for No NA for YES and X for No NA

No No

A Approved Work Method Statement attached? H Life boat with crew standing by?

B Wind/Waves checked? I Fist aid kit available?

C Visibility checked? J Oil/fuel spillage prevention provided?

D Crane operator possesses a valide certificate? K Fire extingushers maintained operable?

E Hoist wire and clam checked? L Search light furnished for emergency?

F Emergency communication maintained/available? M Sufficient food stocks & drinking water reserved?

G Life Jackets available and worn by all crew? N Other necessary precautions?

Special Note.

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date …….../…..…./……..

Comments.

Section IV PERMIT APPROVAL

DHI-EHS-HSM-031 (March 2014), Page 18 of 21

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected

from the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date …….../…..…./……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Project Doosan Civil/ Doosan Electrical/ Doosan QA/ QC

( )

Director Architecture Manager Mechanical Manager Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 19 of 21

Attachment 9

DIVING WORK PERMIT

Project Name Date:

Location(s)

Section – I DETAILS OF THE PERMIT RECIVER (SC = Sub Contractor, DHI = DOOSAN)

Permit Receiver (SC) Contact Number

Engineer Responsible (DHI) Contact Number

Safety In charge (SC) Contact Number

Safety Advisor on Site (DHI) Contact Number

Section – II PERMIT VALIDATIONS

PERMIT ISSUE DETAILS Date ____________________ Time ________________ NO EXTENSION WILL BE

PERMIT EXPIRY DETAILS Date ____________________ Time ________________ GIVEN ON THIS PERMIT

Permit Contents: 1) Permit to Diving Work Permit (Two copies one for site one for EHS file)

2) Method Statement and JSEA (Copy for Site)

3) Personnel Training Record Sheet (To be placed in EHS file)

Section – III PREREQUISITE (Work May be stopped if one of the following is not complied with)

Yes/ Yes/

for YES and X for No NA for YES and X for No NA

No No

A Approved Work Method Statement attached? K Two way communication established and known?

B Wind/Waves checked? L Emergency communication maintained available?

C Velocity and direction of the current confirmed? M Emergency transportation maintained ready?

D In-water Visibility checked? N Operational Compression chamber available?

E Diving equipment checked? O Compressor for respiratory air chcecked?

F Depth guage properly calibrated as required? P Respiratory air clean device provided?

An air flow meter provided and properly

G Diving record maintained? Q

function?

H Diving dresses free of defects? R Watch man (look out) assigned and maintained

I Dive Logs available? S Search light furnished for emergency

J Stand by Diver dressed? T Life Jackets available and worn by all crew

Special Note.

Section IV PERMIT APPROVAL

Reviewed by Doosan Manager: ………………………………………………………… Signature …………………………… Date …….../…..…./……..

Comments.

DHI-EHS-HSM-031 (March 2014), Page 20 of 21

Section IV PERMIT APPROVAL

Work shall be carried out ONLY after complying with the precautions given in Section – III of this Permit.

The permit is valid up to _______ hrs. On / / . It has to be ensured that the employee executing the Job has a copy of the permit at all times during

work. No equipments shall be left unattended at any time whatsoever the reason may be. Prior to any accessory replacement the tool must be disconnected

from the main source of power supply.

Name of the Doosan EHS Manager:………………………………..…………………….. Signature …………………………… Date …….../…..…./……..

Comments

PERMIT COPY DISTRIBUTION (tick appropriate boxes):

Project Doosan Civil/ Doosan Electrical/ Doosan QA/ QC

( )

Director Architecture Manager Mechanical Manager Manager

Subcontractor Subcontractor Area

( ) ( ) Security

Site Manager Manger

DHI-EHS-HSM-031 (March 2014), Page 21 of 21

Anda mungkin juga menyukai

- Hot Work PermitDokumen1 halamanHot Work PermitManesh MBelum ada peringkat

- Confined Space - Permit To WorkDokumen5 halamanConfined Space - Permit To WorkNgel EvnsBelum ada peringkat

- Hot Work PermitDokumen1 halamanHot Work PermitbahrianroyalBelum ada peringkat

- Confined Space PermitDokumen2 halamanConfined Space Permitrizal azizanBelum ada peringkat

- Permit To Work: Utracon Construction SDN BHD Utracon Structural Systems SDN BHDDokumen2 halamanPermit To Work: Utracon Construction SDN BHD Utracon Structural Systems SDN BHDChe ZahirBelum ada peringkat

- EHSWP004 - Hot Work Permit PDFDokumen2 halamanEHSWP004 - Hot Work Permit PDFRand raiBelum ada peringkat

- Form 0004: Confined Space Permit: Section - I Details of The Permit Issuer & ReciverDokumen1 halamanForm 0004: Confined Space Permit: Section - I Details of The Permit Issuer & Reciverasem sawalmehBelum ada peringkat

- Hindustan Urvarak and Rasayan Limited Confined Space Entry PermitDokumen2 halamanHindustan Urvarak and Rasayan Limited Confined Space Entry PermitThakur Vikash SharmaBelum ada peringkat

- PCD-OSH-SF-35 PTW For Confine SpaceDokumen2 halamanPCD-OSH-SF-35 PTW For Confine Spacerizal azizanBelum ada peringkat

- Excavation permit-1-GREENDokumen2 halamanExcavation permit-1-GREENAravind Babu Dasari100% (1)

- General Work PermitDokumen2 halamanGeneral Work PermitJareem PeesBelum ada peringkat

- General Electric Work PermitDokumen2 halamanGeneral Electric Work PermitFaiqah AzmirBelum ada peringkat

- EHSWP004 - Hot Work PermitDokumen1 halamanEHSWP004 - Hot Work PermitloganathanBelum ada peringkat

- EM - EHS - PTW - General UpdatedDokumen1 halamanEM - EHS - PTW - General UpdatedMushfiqur ChowdhuryBelum ada peringkat

- Nippon Paint (Coatings) Philippines, Inc. Hot Work Permit: General InformationDokumen1 halamanNippon Paint (Coatings) Philippines, Inc. Hot Work Permit: General InformationFrancis Jade PutisBelum ada peringkat

- HOT WORK PERMIT Revisi 1Dokumen8 halamanHOT WORK PERMIT Revisi 1hse bsjBelum ada peringkat

- IDI-FRM-HSE-32-01 Permit To Work - Electrical WorkDokumen1 halamanIDI-FRM-HSE-32-01 Permit To Work - Electrical Workaulia chaniaBelum ada peringkat

- Excavation Permit FormDokumen2 halamanExcavation Permit FormazozinlcBelum ada peringkat

- Excavation Work PermitDokumen2 halamanExcavation Work Permitmuhammad.younisBelum ada peringkat

- Permit HWDokumen1 halamanPermit HWsurya adi wijayaBelum ada peringkat

- ATT 3 Hot Works PermitDokumen2 halamanATT 3 Hot Works PermitSamsu Usup SudiarsonoBelum ada peringkat

- Excavation Safety ChecklistDokumen2 halamanExcavation Safety Checklistsindarth raveendrakrishnanBelum ada peringkat

- Cold Work PermitDokumen3 halamanCold Work Permitnakul kushwahaBelum ada peringkat

- HSE Permit ManagementDokumen2 halamanHSE Permit ManagementDesign Xess EventsBelum ada peringkat

- 001 - Safe Work Permit Form - R2Dokumen2 halaman001 - Safe Work Permit Form - R2John Renz Caling RetiroBelum ada peringkat

- 47.HDEC-HSE-F0047 Pressure Test PermitDokumen1 halaman47.HDEC-HSE-F0047 Pressure Test PermitRonn CaiBelum ada peringkat

- Hot Work Permit Format (HSE-CTN-HPP-FMT-009)Dokumen2 halamanHot Work Permit Format (HSE-CTN-HPP-FMT-009)Radha BuildtechBelum ada peringkat

- Hot Work Permit To WorkDokumen3 halamanHot Work Permit To WorkMorris M.Belum ada peringkat

- Confined Space Entry Permit FormDokumen2 halamanConfined Space Entry Permit FormYounis Khan100% (1)

- Permit For Working at HeightDokumen1 halamanPermit For Working at HeightMohit Bhadauria100% (1)

- Form 0005: Hot Work Permit: Section - I Details of The Permit ReciverDokumen1 halamanForm 0005: Hot Work Permit: Section - I Details of The Permit Reciverasem sawalmehBelum ada peringkat

- Hot Work Permit: 1. General PrecautionsDokumen3 halamanHot Work Permit: 1. General PrecautionsAbu Syeed Md. Aurangzeb Al MasumBelum ada peringkat

- SA-924-2 Red PrintDokumen2 halamanSA-924-2 Red PrintAbdus SamadBelum ada peringkat

- Pressure Test PermitDokumen2 halamanPressure Test PermitRajesh KumarBelum ada peringkat

- PermitDokumen7 halamanPermitdeepak bhagatBelum ada peringkat

- Lifting and Shifting of Heavy ObjectsDokumen5 halamanLifting and Shifting of Heavy ObjectsChaitanya MyneniBelum ada peringkat

- SC-03 Hot Work Jan 2006 - Rev 2 Nov 07Dokumen2 halamanSC-03 Hot Work Jan 2006 - Rev 2 Nov 07Sumit NarayanBelum ada peringkat

- Agreement by Permit Holder: I Understand and Agree That No Work Is Permitted Accept That Shown On The Permit. IDokumen1 halamanAgreement by Permit Holder: I Understand and Agree That No Work Is Permitted Accept That Shown On The Permit. ISameer YadavBelum ada peringkat

- Confined Space Entry PermitDokumen15 halamanConfined Space Entry PermitSyed Amjad100% (2)

- Hot Work PermitDokumen1 halamanHot Work PermitrajamohamdedhanaBelum ada peringkat

- Hot Work Safety ChecklistDokumen2 halamanHot Work Safety ChecklistAravind Babu Dasari100% (1)

- Hot Work Permit ChecklistDokumen1 halamanHot Work Permit ChecklistAryan DashBelum ada peringkat

- One Punggol - General Work Permit FormDokumen3 halamanOne Punggol - General Work Permit FormSelvamBelum ada peringkat

- Safety DocumentsDokumen42 halamanSafety Documentsdan sealzaBelum ada peringkat

- Electrially Energized Area Entry PermitDokumen1 halamanElectrially Energized Area Entry PermitShahrukh Faizan AhmedBelum ada peringkat

- F. 44 Hot Work PermitDokumen1 halamanF. 44 Hot Work PermitksadisBelum ada peringkat

- 02 Hot Work PermitDokumen2 halaman02 Hot Work PermitFaisal Abdul GhaffarBelum ada peringkat

- Heigh Work Pemit - BlueDokumen2 halamanHeigh Work Pemit - BlueAravind Babu Dasari100% (6)

- HSE Work PermitDokumen3 halamanHSE Work PermitNajmal AmanBelum ada peringkat

- Permit WAHDokumen1 halamanPermit WAHsurya adi wijayaBelum ada peringkat

- Ptw6 Hot WorkDokumen2 halamanPtw6 Hot WorkPradeepBelum ada peringkat

- Method Statement WeldingDokumen9 halamanMethod Statement Weldingkiki270977Belum ada peringkat

- HOT WORK SAFETYDokumen2 halamanHOT WORK SAFETYsindarth raveendrakrishnan100% (4)

- Confined Space Work PermitDokumen2 halamanConfined Space Work PermitDimas Dwi SwarnaBelum ada peringkat

- HSE Work PermitDokumen3 halamanHSE Work PermitNajmal Aman100% (1)

- Confine Space Entry PermitDokumen4 halamanConfine Space Entry Permitmirwinsoner sonsanddaughterBelum ada peringkat

- Excavation Permit FormDokumen2 halamanExcavation Permit FormKarim KachourBelum ada peringkat

- Lifting Operation PermitDokumen2 halamanLifting Operation PermitFMU KSA100% (2)

- Safety - Form-SAF019-HotWorkPermitDokumen5 halamanSafety - Form-SAF019-HotWorkPermitEdwin MofokengBelum ada peringkat

- 25 OPF Safety Program Manual - Lockout TagoutDokumen2 halaman25 OPF Safety Program Manual - Lockout Tagoutkhoahuyen_89Belum ada peringkat

- LOTO Safety ProceduresDokumen5 halamanLOTO Safety ProceduresBố Đăng KhánhBelum ada peringkat

- Dhi-Ehs-Hsm-008 Harness and Belts Rev0Dokumen12 halamanDhi-Ehs-Hsm-008 Harness and Belts Rev0khoahuyen_89Belum ada peringkat

- Dhi-Ehs-Hsm-008 Harness and Belts Rev0Dokumen4 halamanDhi-Ehs-Hsm-008 Harness and Belts Rev0khoahuyen_89Belum ada peringkat

- Health and Safety Manual: Ehs Accicent and IncidentDokumen9 halamanHealth and Safety Manual: Ehs Accicent and Incidentkhoahuyen_89Belum ada peringkat

- Clarif-JGCS-EVN-CVL-ECOBA - From JGCS (Zone-2) - Ecoba Addition - JGCS ReplyDokumen6 halamanClarif-JGCS-EVN-CVL-ECOBA - From JGCS (Zone-2) - Ecoba Addition - JGCS Replykhoahuyen_89Belum ada peringkat

- Electrical Safety ManualDokumen63 halamanElectrical Safety Manualsuryavenkat_79Belum ada peringkat

- Dhi-Ehs-Hsm-001 Ehs Risk Management Rev0Dokumen22 halamanDhi-Ehs-Hsm-001 Ehs Risk Management Rev0khoahuyen_89Belum ada peringkat

- Dhi-Ehs-Hsm-008 Harness and Belts Rev0Dokumen4 halamanDhi-Ehs-Hsm-008 Harness and Belts Rev0khoahuyen_89Belum ada peringkat

- X550AJ Operation and Safety ManualDokumen78 halamanX550AJ Operation and Safety Manualkhoahuyen_89Belum ada peringkat

- 009 Fire Engineering and Emergency PlanningDokumen3 halaman009 Fire Engineering and Emergency Planningkhoahuyen_89Belum ada peringkat

- X550AJ Operation and Safety Manual PDFDokumen136 halamanX550AJ Operation and Safety Manual PDFZenon Nuñonca ZapataBelum ada peringkat

- Fire Engineering PDFDokumen642 halamanFire Engineering PDFABELWALIDBelum ada peringkat

- Hazard IdDokumen52 halamanHazard IdKarenBelum ada peringkat

- WKS 4 Excavations Excavation Safety Guide PDFDokumen84 halamanWKS 4 Excavations Excavation Safety Guide PDFAbinesh ABBelum ada peringkat

- X550AJ Operation and Safety Manual PDFDokumen136 halamanX550AJ Operation and Safety Manual PDFZenon Nuñonca ZapataBelum ada peringkat

- Review of Design Methods For ExcavationsDokumen2 halamanReview of Design Methods For Excavationskhoahuyen_89Belum ada peringkat

- Review of Design Methods For ExcavationsDokumen196 halamanReview of Design Methods For ExcavationsDoan Duy Thinh100% (1)

- Work at Height Assessor Course CentreDokumen7 halamanWork at Height Assessor Course Centrekqgcnxejd100% (1)

- Hazard Assessment Safety Action Plan (Hasap)Dokumen25 halamanHazard Assessment Safety Action Plan (Hasap)Mohamed HadjkacemBelum ada peringkat

- MS Welding in Confined SpaceDokumen12 halamanMS Welding in Confined Spacemithun dutta100% (1)

- SafetygoldenrulesDokumen28 halamanSafetygoldenrulesCLIFFBelum ada peringkat

- Excavation Working in Trenches Swms 10281-6Dokumen17 halamanExcavation Working in Trenches Swms 10281-6JamesBelum ada peringkat

- Cljoc Fac WPK 40 0158Dokumen24 halamanCljoc Fac WPK 40 0158chuminhBelum ada peringkat

- Contractor Safety Orientation EssentialsDokumen68 halamanContractor Safety Orientation EssentialsdethscrimBelum ada peringkat

- USAMRICD AHA Underground UtilitiesDokumen14 halamanUSAMRICD AHA Underground UtilitiesKenneth Bia Martin100% (2)

- SWC RoleCardsTemplatesDokumen3 halamanSWC RoleCardsTemplatesAbdus SamadBelum ada peringkat

- Upstream Excavation Procedure Highlights Key StepsDokumen37 halamanUpstream Excavation Procedure Highlights Key StepsabbBelum ada peringkat

- Ansi Z88.2Dokumen40 halamanAnsi Z88.2EdwinMauricioMacabeo100% (1)

- MSH TB ElectricalHazardAwarenessDokumen54 halamanMSH TB ElectricalHazardAwarenesstuBelum ada peringkat

- PTW Training Module CCP NaamaDokumen29 halamanPTW Training Module CCP NaamaHSE CERIBelum ada peringkat

- Excavations SHE Risk AssessmentDokumen4 halamanExcavations SHE Risk AssessmentMuhammed yahiyaBelum ada peringkat

- Rescue Plan For CSADokumen5 halamanRescue Plan For CSABrian Gidudu100% (1)

- Survey and Examination of Ships' Lifting AppliancesDokumen24 halamanSurvey and Examination of Ships' Lifting Applianceshpss77100% (1)

- Excavation and Sewer ConnectionDokumen8 halamanExcavation and Sewer ConnectionMustafa SütcüoğluBelum ada peringkat

- Oxygen Deficient AtmospheresDokumen17 halamanOxygen Deficient Atmospheresshahef9Belum ada peringkat

- Gadzoom Sample Activity Hazard Analysis TemplateDokumen8 halamanGadzoom Sample Activity Hazard Analysis TemplateΝικολιδάκης ΒαγγέληςBelum ada peringkat

- Sigma Zinc 102en-US - 7702 PDFDokumen5 halamanSigma Zinc 102en-US - 7702 PDFaselabollegalaBelum ada peringkat

- Amerlock-2K - TDSDokumen7 halamanAmerlock-2K - TDSGiovanny SotoBelum ada peringkat

- UKF COLLEGE CIVIL ENGINEERING SAFETY Q&ADokumen8 halamanUKF COLLEGE CIVIL ENGINEERING SAFETY Q&AGoogle AccountBelum ada peringkat

- Expert Trainers Academy - Hse Interview Questions V1Dokumen14 halamanExpert Trainers Academy - Hse Interview Questions V1greewin88Belum ada peringkat

- Cosh ReviewerDokumen4 halamanCosh ReviewerJamie Amanda FaderonBelum ada peringkat

- Annex 06 - UNOPS Minimum Health and Safety Requirements For ContractorsDokumen57 halamanAnnex 06 - UNOPS Minimum Health and Safety Requirements For Contractorsabdu al enabBelum ada peringkat

- Contractor Safety GuidelineDokumen21 halamanContractor Safety GuidelinepankajBelum ada peringkat

- M1 Legal RequirementsDokumen39 halamanM1 Legal RequirementsArif izzuddinBelum ada peringkat

- Technical Advisory Confined Spaces PDFDokumen93 halamanTechnical Advisory Confined Spaces PDFJustin ChongBelum ada peringkat

- Stoving Paint MsdsDokumen9 halamanStoving Paint MsdsrajangangarBelum ada peringkat

- JSA Blasting and Coating KP 69.4Dokumen5 halamanJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)