Process Control Plan: Brooks Approval

Diunggah oleh

jaxshahJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Process Control Plan: Brooks Approval

Diunggah oleh

jaxshahHak Cipta:

Format Tersedia

Brooks

Approval:

Process Control Plan Date Approved:

Effectivity Date:

Supplier Name: Part Number: PCP Number Prepared by:

Supplier Number: Part Number Revision: PCP Revision Checked by:

Workcell / Location Part Name: PCP Rev Date: Approval:

Process Machine, Device, Product / Process Characteristics Control Methods/Measurement

Process

Number

Name / Jig, Ref Doc. Number/ Specification Sample Remarks

Step

Key Measurement Reaction Plan

Operation Tools for Specification No Characteristic Description & size& Record (Special Process)

Dim Technique

Description Manufacturing Tolerance Frequency

SCM100113 Rev. A PCP Blank

DCO001668

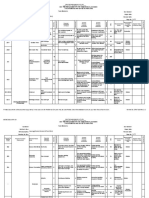

Brooks

Approval:

Process Control Plan Date Approved:

Effectivity Date:

Supplier Name: Part Number: PCP Number Prepared by:

Supplier Number: Part Number Revision: PCP Revision Checked by:

Workcell / Location Part Name: PCP Rev Date: Approval:

Process Machine, Device, Product / Process Characteristics Control Methods/Measurement

Process

Number

Name / Jig, Ref Doc. Number/ Specification Sample Remarks

Step

Key Measurement Reaction Plan

Operation Tools for Specification No Characteristic Description & size& Record (Special Process)

Dim Technique

Description Manufacturing Tolerance Frequency

SCM100113 Rev. A PCP Blank

DCO001668

Process Co

Supplier Name: 1 Part Number:

Supplier Number: 2 Part Number Revision:

Workcell / Location 3 Part Name:

Product / Process Characteristics

Process

Process

Number

Machine, Device, Jig,

Name / Ref Doc. Number/

Step

Tools for

Operation Specification No Characteristic Description

Manufacturing

Description

17 20

16 18 19

1 Supplier Name / Logo Area Supplier to Enter Supplier's Name.

2 Supplier ID# Supplier to enter supplier name and Brooks su

3 Workcell / Location Supplier to enter Workcell or location for prima

4 Part Number Supplier to enter Brooks part number from dra

5 Part Number Revision Supplier to enter Brooks part number revision

6 Part Description Supplier to enter Brooks part Description from

7 PCP Number Supplier to enter their specific PCP number.

8 PCP Revision Supplier to enter PCP revision.

9 PCP Rev Date Supplier to enter PCP revision date.

10 Prepared by Supplier to enter PCP preparer's name.

11 Checked by Supplier to enter PCP checker / reviewer's nam

12 Approval #1 Supplier to enter Approver's signature.

13 Brooks Approval: Brooks SQE to enter their Approval signature.

14 Date Approved Brooks SQE to enter approval date.

15 Effectivity Date Brooks SQE to enter effectivity date.when appr

16 Process Step Number Supplier to enter process numbers from job tra

17 Process Name / Operation Description Supplier to enter process name / operation des

18 Machine, Device, Jig, Tools for Manufacturing Supplier to enter specific Machine, Device, Jig,

19 Ref Doc. Number/ Specification No Supplier to enter work instructions, drawing nu

20 Characteristic Description Supplier to enter specification or feature chara

21 Specification & Tolerance Supplier to enter Product or Process requireme

FM-HW-SQA-042 PCP Map

22 Key DIM Supplier to identify Key dimensions with a K

23 Measurement Technique Supplier to enter measurement technique, gag

24 Sample size & Frequency Supplier to enter Sample size and inspection fr

25 Record Supplier to enter record keeping method.

26 Reaction Plan Supplier to enter Reaction Plan / Corrective act

27 Remarks (Special Process) Supplier to enter remarks / notes / comments r

FM-HW-SQA-042 PCP Map

cess Control Plan

4 PCP Number 7

5 PCP Revision 8

6 PCP Rev Date: 9

t / Process Characteristics Control Methods/Measurement

Specification

Key Sample size&

& Measurement Technique Record

Dim Frequency

Tolerance

21 22 23 24 25

1

pplier's Name.

pplier name and Brooks supplier ID# (ID# identified on Brooks purchase or contract order).

rkcell or location for primary process (optional).

ooks part number from drawing, purchase order or contract order.

ooks part number revision from drawing, purchase order or contract order.

ooks part Description from drawing, purchase order or contract order.

ir specific PCP number.

P revision.

P revision date.

P preparer's name.

P checker / reviewer's name.

prover's signature.

r their Approval signature.

r approval date.

r effectivity date.when approved Process Control Plan is used in production.

ocess numbers from job travelers / routers.

ocess name / operation description.

ecific Machine, Device, Jig, Tool number.

rk instructions, drawing numbers, specifications and inspection procedures.

ecification or feature characteristic.

oduct or Process requirements and tolerances.

FM-HW-SQA-042 PCP Map

Key dimensions with a K

asurement technique, gage, inspection equipment type.

mple size and inspection frequency.

ord keeping method.

action Plan / Corrective action process. Include plan numbers or means of identification.

marks / notes / comments related to the specific process.

FM-HW-SQA-042 PCP Map

Brooks Approval: 13

Date Approved: 14

Effectivity Date: 15

Prepared by: 10

Checked by: 11

Approval: 12

Remarks

Reaction Plan

(Special Process)

26 27

FM-HW-SQA-042 PCP Map

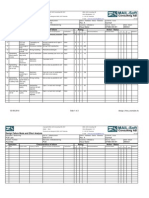

Process Contr

Supplier Name: Part Number:

Supplier Number: Part Number Revision:

Workcell / Location Part Name:

Product / Process Characteristics

Process

Process

Number

Machine, Device, Jig,

Name / Ref Doc. Number/

Step

Tools for

Operation Specification No Characteristic Description

Manufacturing STEEL, CORROSION RESISTING, 304 OR 30

Description

PLATE, UNS S30400/UNS S30403, HOT ROLL

Receive Raw ANNEALID AND PICKLED PER ASTM A240 OR A

Material work instruction xxx- SA-240, WITH NO CALCIUM OR OTHER ADDIT

10 N/A

Incoming xxxx Dimensions

FOR MACHINABILITY

Inspection

diameter

diameter

diameter

CNC Lathe#:xxx

Drawing #:xxx diameter

CNC Program

20 Machining Manufacture work chamfer

#:xxxx Tool#:xxxx

instruction #: xxxx dim

Fixture#:xxxx

dim

dim

Roughness

3rd Process,

Grinding#:xxx 0.02

Manufacture work

30 Bottom plane Tool #:xxx

instruction #: xxxx 0.02B

Fixture#:xxx

Ø0.02B

4th process

Machining Hole

CNC Milling#:xxx dim

Hole, Profile Manufacture work

40 Tool #:xxx

cutting, Tap instruction #: xxxx Tap

Fixture#:xxx

holes

Hole

50 De-Burring De-burring tools work instruction #: xxxx

Tap

Specification #:xxxx Hole

60 Pre-Treatment

Treatment PCP #:xxxxx Roughness

Appearance

Specification #:xxxx

Treatment/Finis

70 Treatment House Treatment PCP #:xxxxx Electroless Nickel Plating

hing

diameter

Post-Treatment Post-treat Inspection

80

Inspection

FM-HW-SQA-042 procedure xxxx PCP Example

hole

tap

Post-Treatment Post-treat Inspection

80

Inspection procedure xxxx roughness

Appearance

work instruction xxx-

90 Packaging

xxxx

Out Going work instruction xxx- Refer to out going inspection

100

Inspection xxxx sheert

FM-HW-SQA-042 PCP Example

s Control Plan

PCP Number

PCP Revision

PCP Rev Date:

t / Process Characteristics Control Methods/Measurement

Specification

Key Sample size&

& Measurement Technique Record

ION RESISTING, 304 OR 304L Dim Frequency

Tolerance

00/UNS S30403, HOT ROLLED,

KLED PER ASTM A240 OR ASME CoC Verification Every lot

ALCIUM OR OTHER ADDITIVES IQC inspection

AQL 1.0 sheet

MACHINABILITY caliper

Every lot

Ø160±1 CMM

Ø130±1 CMM

Ø120 G6 Y CMM 2pcs Every

Ø65±.0.1 CMM machine Set up

In-Process Insp.

C2 CMM 1pcs every two

From CMM

10 -0.1/0 HG hours

5±0.2 HG In-Process

control 19 to19.2 Caliper

63 √ C SRT/Comparator

2pcs Every

Y CMM machine Set up In-Process Insp.

Y CMM 1pcs every hour From CMM

Y CMM In-Process

Ø5H8 PG 2pcs Every

26.5±0.03 Y CMM machine Set up

In-Process Insp.

1pcs every two

M6 Tap hole Thread Gauge From CMM

hours

Ø4.5(all the hole In-Process

CMM

dimension)

Break All Sharp AQL1.0 Record on QA Plan

visual Inspection

Edges and burrs every lot XXXX

M6 Tap hole Thread Gauge

Ø5H8 PG AQL0.65 Pre-treatment

63 √ C SRT/Comparator Every lot inspection record

to Spec XXXX Visual inspection

X-Ray Visual AQL0.65

[0.003-0.005mm] COC from Supplier

inspection Every lot

Ø120 G6 CMM

AQL0.65 for

COC from

critical

supplier and Post

dimensions and

FM-HW-SQA-042 treatment PCP Example

100% for Visual

inspection record

inspection

Ø5H8 PG AQL0.65 for

M6 Tap hole TG COC from

critical

supplier and Post

All surface dimensions and

SRT/Comparator treatment

Roughness 100% for Visual

inspection record

No stain, masking, inspection

Visual inspection

color to sample

Each Lot STD packaging

Visual

Received method

CMM AQL 1.0 Every Review of QA Plan

Visual lot XXXXX

FM-HW-SQA-042 PCP Example

Brooks Approval:

Date Approved:

Effectivity Date:

Prepared by:

Checked by:

Approval:

Remarks

Reaction Plan

(Special Process)

Return to Supplier. Notify production of new

RMA process XXX delivery date.

Stop machining/

Fine-tune the

Notify Supervisor

Setting and re-

inspect

Stop machining/

Fine-tune the Qualified Operator

Setting

Stop machining/

Fine-tune the

Setting

StopDe-

burringRework &

CAR

Rework/CAR send

for rework

Qualified Plater

Rework

(ABC Company)

Raise CAR send for

rework

FM-HW-SQA-042 PCP Example

Raise CAR send for

rework

Repack and

Validate

Raise CAR/Rework

FM-HW-SQA-042 PCP Example

Anda mungkin juga menyukai

- GM 1927 16 Process Control Plan Audit PCPADokumen7 halamanGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemBelum ada peringkat

- Control plan optimizationDokumen11 halamanControl plan optimizationRadhika GuptaBelum ada peringkat

- Customer Complaint RegisterDokumen3 halamanCustomer Complaint RegistermuthuselvanBelum ada peringkat

- Al PSW FormatDokumen2 halamanAl PSW Formatabhayjha1988Belum ada peringkat

- Fmea Sfe47.005 WeldingDokumen8 halamanFmea Sfe47.005 Weldingkumaraswamy.kBelum ada peringkat

- GM Machining CP REV 03Dokumen17 halamanGM Machining CP REV 03Suraj RawatBelum ada peringkat

- Capacity VerificationDokumen4 halamanCapacity VerificationLucinei SantosBelum ada peringkat

- Procedure Name: Amendment RecordDokumen6 halamanProcedure Name: Amendment RecordsubbuBelum ada peringkat

- Change Management Matrix for Vendor Updates in May 2022Dokumen1 halamanChange Management Matrix for Vendor Updates in May 2022nitin rathoreBelum ada peringkat

- 8 D Report FormatDokumen9 halaman8 D Report FormatAlok MehtaBelum ada peringkat

- 48 Point Ppap Check SheetDokumen39 halaman48 Point Ppap Check SheetSanjay KumarBelum ada peringkat

- Company Process Flow and FMEA DiagramsDokumen12 halamanCompany Process Flow and FMEA DiagramsDINESH SHARMA100% (1)

- Packaging Details: Vendor Name & AddressDokumen4 halamanPackaging Details: Vendor Name & AddressPk NimiwalBelum ada peringkat

- Design Fmea ExampleDokumen2 halamanDesign Fmea ExampleSenthil_KBelum ada peringkat

- Vda FmeaDokumen30 halamanVda Fmealalit GuptaBelum ada peringkat

- Production Readiness ChecklistDokumen10 halamanProduction Readiness ChecklistprashanthBelum ada peringkat

- Format For Work Instruction MatrixDokumen2 halamanFormat For Work Instruction MatrixKodhansBelum ada peringkat

- Bgl-Fm-Qa - Red Bin Analysis RuleDokumen1 halamanBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghBelum ada peringkat

- Supplier 8D FormDokumen3 halamanSupplier 8D FormBen DesireBelum ada peringkat

- S ApqpDokumen15 halamanS ApqpIram ChaviraBelum ada peringkat

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDokumen3 halamanDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungBelum ada peringkat

- APQP (27) ElementsDokumen31 halamanAPQP (27) Elementssam1hi5Belum ada peringkat

- FMEADokumen6 halamanFMEANavnath TamhaneBelum ada peringkat

- 06) - Fmea For 11190722 - DDokumen192 halaman06) - Fmea For 11190722 - DMONISHRAJBelum ada peringkat

- APQP Documents and TimelineDokumen72 halamanAPQP Documents and Timelinesaby aroraBelum ada peringkat

- Guidelines For Making PFMEA - A PDFDokumen10 halamanGuidelines For Making PFMEA - A PDFKalimuthu PsBelum ada peringkat

- Apqp FormsDokumen32 halamanApqp FormsAnonymous A2jnZ5MNPxBelum ada peringkat

- First Article Inspection Report: Purchase Order Number Supplier NameDokumen8 halamanFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityBelum ada peringkat

- Setup & Inprocess Inspection Report CaseDokumen19 halamanSetup & Inprocess Inspection Report CaseMURALIDHRABelum ada peringkat

- Part Submission Warrant SummaryDokumen4 halamanPart Submission Warrant Summaryaperezpi26606Belum ada peringkat

- Change Control Management Matrix for Vendors (M/s Sigma vibracoutic India Pvt. Ltd. A Company of the TrelleborgVibracoustic GroupDokumen3 halamanChange Control Management Matrix for Vendors (M/s Sigma vibracoutic India Pvt. Ltd. A Company of the TrelleborgVibracoustic GroupManikandanBelum ada peringkat

- 8DDokumen8 halaman8DRomie CubalBelum ada peringkat

- 6 PFMEA & Control Plan 1 of 7Dokumen8 halaman6 PFMEA & Control Plan 1 of 7P G Suman100% (1)

- FMEA SampleDokumen94 halamanFMEA SampleKaran MalhiBelum ada peringkat

- PFMEA Review PlanDokumen1 halamanPFMEA Review PlanKaran Malhi100% (1)

- Company Name: Quality Management System (QSM) Title: Machine Capability Study (CMK Study) ReportDokumen1 halamanCompany Name: Quality Management System (QSM) Title: Machine Capability Study (CMK Study) ReportSachin RamdurgBelum ada peringkat

- APQP TemplateDokumen7 halamanAPQP TemplateBob ZepfelBelum ada peringkat

- Vendor PPAP Readiness for MEMBER EXTENSION LONGITUDINAL FRONT LH/RHDokumen39 halamanVendor PPAP Readiness for MEMBER EXTENSION LONGITUDINAL FRONT LH/RHSanjay KumarBelum ada peringkat

- APQP Time Plan for 150 X 75 Steel Hollow SectionDokumen4 halamanAPQP Time Plan for 150 X 75 Steel Hollow SectionRakesh PandeyBelum ada peringkat

- Ipc & Ipp Logbook or FlowDokumen8 halamanIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- 1 - Supplier Rating - Including Premium Freight1Dokumen1 halaman1 - Supplier Rating - Including Premium Freight1RAJESH DHOKALEBelum ada peringkat

- ATTRIBUTE MSADokumen2 halamanATTRIBUTE MSADINESHCHOUDHARY880% (1)

- TMT Procedure - Analysis of Data & Continuous Improvement P2Dokumen1 halamanTMT Procedure - Analysis of Data & Continuous Improvement P2sumanBelum ada peringkat

- Special Audit of Key Characteritics in Control Plan FAU-F-PSG-0800-En-4Dokumen1 halamanSpecial Audit of Key Characteritics in Control Plan FAU-F-PSG-0800-En-4KarlBelum ada peringkat

- Today Hoje 5/31/2012 APQP CriteriaDokumen71 halamanToday Hoje 5/31/2012 APQP CriteriaMarco Antonio RamosBelum ada peringkat

- Road Map For IATF 16949 R-6 UpdatedDokumen1 halamanRoad Map For IATF 16949 R-6 UpdatedRavi javaliBelum ada peringkat

- Corrective Actions For Not Ok Charcteristics: Months - July13Dokumen1 halamanCorrective Actions For Not Ok Charcteristics: Months - July13shobha shelarBelum ada peringkat

- Optimize Company Control PlanDokumen6 halamanOptimize Company Control Planazadsingh1Belum ada peringkat

- Procedure For Ppap: Input / Output DiagramDokumen5 halamanProcedure For Ppap: Input / Output DiagrammuthuselvanBelum ada peringkat

- Copy of APQP Check List - Ford (Blank)Dokumen9 halamanCopy of APQP Check List - Ford (Blank)feiraluremaBelum ada peringkat

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDokumen9 halamanGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikBelum ada peringkat

- Control Plan for Flywheel Assembly ProductionDokumen18 halamanControl Plan for Flywheel Assembly ProductionSuraj RawatBelum ada peringkat

- Supplier Control Plan: Audit SummaryDokumen2 halamanSupplier Control Plan: Audit SummaryRay ManBelum ada peringkat

- APQP TrackerDokumen10 halamanAPQP TrackerBharathBelum ada peringkat

- SPC Study Shows Highly Capable ProcessDokumen1 halamanSPC Study Shows Highly Capable ProcessVenkateswaraa InsulationBelum ada peringkat

- PCPDokumen2 halamanPCPpinakinqc3Belum ada peringkat

- Process Control Plan Excel TemplateDokumen13 halamanProcess Control Plan Excel TemplateTalal NajeebBelum ada peringkat

- Plano de Controle de ProcessoDokumen20 halamanPlano de Controle de ProcessoGustavo MollicaBelum ada peringkat

- Control Plan: Prototype Pre-Launch XDokumen1 halamanControl Plan: Prototype Pre-Launch XkishortilekarBelum ada peringkat

- Process Control Plan SCM100113Dokumen20 halamanProcess Control Plan SCM100113Rohit MakhijaBelum ada peringkat

- Is 09 SixSigmaDokumen10 halamanIs 09 SixSigmaLuciana PopoviciBelum ada peringkat

- Excel Pareto Chart TemplateDokumen2 halamanExcel Pareto Chart TemplateLuciana PopoviciBelum ada peringkat

- A3 Toyota 8 Step TemplatesDokumen11 halamanA3 Toyota 8 Step TemplatesBharathBelum ada peringkat

- Gantt Chart LDokumen1 halamanGantt Chart LLuciana PopoviciBelum ada peringkat

- 8D Form - LongDokumen7 halaman8D Form - LongManoj IllangasooriyaBelum ada peringkat

- Six Sigma Book PDF FormDokumen218 halamanSix Sigma Book PDF Formbabudukku100% (24)

- General Format MLADokumen5 halamanGeneral Format MLALuciana PopoviciBelum ada peringkat

- Application Note: Upgrade To ATSC Mobile DTVDokumen30 halamanApplication Note: Upgrade To ATSC Mobile DTVturbo44Belum ada peringkat

- ADJUST FUEL TIMINGDokumen3 halamanADJUST FUEL TIMINGSanjay MadakaBelum ada peringkat

- DTFT Analysis in MATLABDokumen7 halamanDTFT Analysis in MATLABRUTUJA MADHUREBelum ada peringkat

- Wind Load AnalysisDokumen4 halamanWind Load AnalysisNiraj ShindeBelum ada peringkat

- 3UG46161CR20 Datasheet enDokumen4 halaman3UG46161CR20 Datasheet enengmnfBelum ada peringkat

- IEMPOWER-2019 Conference Dates 21-23 NovDokumen2 halamanIEMPOWER-2019 Conference Dates 21-23 Novknighthood4allBelum ada peringkat

- 013 - Engine - Throttle - Pedal Position Sensor - Switch A Circuit MalfunctionDokumen4 halaman013 - Engine - Throttle - Pedal Position Sensor - Switch A Circuit MalfunctionMortada AlsonniBelum ada peringkat

- NPX Series - Npx-25: Data SheetDokumen2 halamanNPX Series - Npx-25: Data SheetCesar AdrianzenBelum ada peringkat

- CDU Basic Engineering Design BasisDokumen12 halamanCDU Basic Engineering Design BasisSampat100% (2)

- Deep Cycle Batteries Solar EbookDokumen27 halamanDeep Cycle Batteries Solar Ebookanakraja11Belum ada peringkat

- Various Types of W.C and Water Supply ConnectionsDokumen12 halamanVarious Types of W.C and Water Supply ConnectionsAtish Kumar100% (1)

- SAN11 Paper Guide 16-17Dokumen4 halamanSAN11 Paper Guide 16-17ghgheBelum ada peringkat

- Software Engineering Course OverviewDokumen2 halamanSoftware Engineering Course OverviewRajatKumarBelum ada peringkat

- Data Science SyllabusDokumen7 halamanData Science SyllabuslucasBelum ada peringkat

- SF - Domestic Water PipingDokumen16 halamanSF - Domestic Water PipingJahat AtencioBelum ada peringkat

- 0 Delphi Labs DataSnap XE CallbacksDokumen7 halaman0 Delphi Labs DataSnap XE Callbacksduna tarimaBelum ada peringkat

- Superior Pipeline EquipmentsDokumen68 halamanSuperior Pipeline Equipmentsaliyildizx17730Belum ada peringkat

- Data MigrationDokumen6 halamanData MigrationsivasivasapBelum ada peringkat

- Flight 60T Turbine Operating ManualDokumen128 halamanFlight 60T Turbine Operating Manualtravieso112Belum ada peringkat

- Market and Influencer Mapping for Orient Bell Ltd in Calicut RegionDokumen12 halamanMarket and Influencer Mapping for Orient Bell Ltd in Calicut RegionJomin PjoseBelum ada peringkat

- Modul Sitem Informasi Managemen (MAN 611)Dokumen13 halamanModul Sitem Informasi Managemen (MAN 611)Locke Holey FristantoBelum ada peringkat

- ANSI E1.50-1 2017 Entertainment Technology - Requirements For The Structural Support of Temporary LED, Video & Display SystemsDokumen19 halamanANSI E1.50-1 2017 Entertainment Technology - Requirements For The Structural Support of Temporary LED, Video & Display SystemsGabriel neagaBelum ada peringkat

- Q603 - Nte159Dokumen2 halamanQ603 - Nte159daneloBelum ada peringkat

- Panel Data Analysis Using EViews Chapter - 3 PDFDokumen49 halamanPanel Data Analysis Using EViews Chapter - 3 PDFimohamed2Belum ada peringkat

- Closed Source DocumentationDokumen12 halamanClosed Source Documentation이즈르엘Belum ada peringkat

- Design of A Manned Vehicle Technical ReportDokumen215 halamanDesign of A Manned Vehicle Technical ReportEstrella de SánchezBelum ada peringkat

- B.O Q Irrigation Items SAQQER ROAD - Xls FINALDokumen1 halamanB.O Q Irrigation Items SAQQER ROAD - Xls FINALDEEPAKBelum ada peringkat

- RICOH Streamline NX Guia de UsuarioDokumen107 halamanRICOH Streamline NX Guia de UsuarioMaria Elena AvilaBelum ada peringkat

- Work Method Statement For Roof Sheeting WorksDokumen8 halamanWork Method Statement For Roof Sheeting WorksRepl microsoft, Pune100% (1)

- QCAI476 LfiltersDokumen11 halamanQCAI476 LfilterscivodulBelum ada peringkat