Self Consolidating Concretet PCA

Diunggah oleh

jijo800Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Self Consolidating Concretet PCA

Diunggah oleh

jijo800Hak Cipta:

Format Tersedia

Concrete Technology | Self-Consolidating Concrete | Portland Cement Association (PCA)

Type Keywords Here Submit Query

Concrete

Self-Consolidating Concrete

Concrete Technology Home > Concrete Design and Production > Self-Consolidating Concrete

Technology

Home

Cement Basics

Flow with Show: Self-Consolidating Concrete Offers New Opportunities for

Architectural Concrete

Concrete Design

& Production

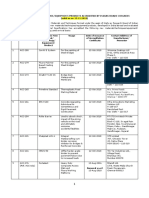

Architectural concrete is a hot topic. Defined by the American Concrete Institute as “concrete

Concrete which will be permanently exposed to view and which therefore requires special care in

Construction selection of the concrete materials, forming, placing and finishing to obtain the desired

architectural appearance,” it’s showing its face everywhere. Examples of applications are

PCA Research buildings and transportation structures like bridges and highway sound/barrier walls. Delivery

Durability methods include cast-in-place, precast, and tilt-up, and in every case, good appearance is

essential because the concrete is to be left exposed. Achieving good surface characteristics

Tech Support requires thorough consolidation of the fresh concrete and thoroughly filled forms.

Fortunately, this also leads to a durable material because water, precipitation, and

Stay Informed

aggressive chemicals/ions are shed by the surface skin.

Resources

CTT Newsletter

FAQs

Stockholm Airport Tower Stockholm Airport Tower close-up

Slim and accurate architectural constructions are much easier to realize with SCC, such as this 83-m

high Stockholm Airport tower, which is decorated with excerpts from the work of Antoine de Saint-

Exupéry. Reduced noise levels made construction during nighttime hours possible. Photo courtesy:

HeidelbergCement

Conventional concrete is placed using vibrators to fill the forms. SCC is a big step forward in

fool-proofing that procedure. SCC technology has the potential to revolutionize the concrete

industry, and architectural concrete stands to benefit from easier construction techniques and

improved surfaces.

Self-Consolidating Concrete

The construction industry has always longed for a high-performance concrete that can flow

easily into tight and constricted spaces without requiring vibration. The need for this

technology has grown over the years as designers specify more heavily reinforced concrete

http://www.cement.org/tech/cct_SCC.asp (1 of 4)30/09/2010 11:03:01

Concrete Technology | Self-Consolidating Concrete | Portland Cement Association (PCA)

members and ever more complex formwork. Honeycombing or exposed reinforcement in

structural walls or columns is a constant concern in these structures.

Until recently, the industry used superplasticizing

admixtures (also known as high-range water

reducers) in conventional mixtures in an attempt to

achieve flowable concrete and duplicate the

advantages of a true self-consolidating concrete. This

allowed the use of concrete having an 8-in. or greater

Placment of white-cement SCC

slump; however, some vibration was still required for

adequate consolidation. While high doses of

superplasticizers can create a very fluid concrete that

flows readily, the concrete will segregate if the

mortar is too thin to support the weight of the coarse Placement of white cement SCC. Photo

aggregate. The key to creating self-consolidating courtesy of Aalborg White.

concrete (SCC), also referred to as self-compacting,

self-leveling, or self-placing concrete, is to produce a very flowable mortar that retains a

viscosity great enough to support the coarse aggregate. Today, advances in admixtures and

mix proportioning are making SCC a practical reality around the world.

SCC Formulated with White Cement

Architectural expression in concrete means different things to different people. Some

designers appreciate concrete for its unadorned appearance. So gray portland cement

concrete can receive architectural treatment. Some designers want to use color to express

aesthetics, and white portland cement is available to create white or colored concrete. Much

of the experimental work to date on SCC has focused on gray cement, but there are

opportunities for white cement formulations.

Concrete producers know that there is quite a bit of

development associated with any mix design. When

SCC is brought into the equation, the fresh properties

are the most important characteristic of the mixture.

The concrete has to flow easily (slump flow) including

passing through obstructions like rebar (measured by

the J-ring test), but has to do so without bleeding or

segregating. See “Testing SCC” below or click here for

Slump flow test - white SCC

a description of the ASTM tests for assessing fresh

SCC properties.

If a mixture is designed with gray portland cement, it

can be modified to use white portland cement, but the

mixture will most likely change somewhat. Testing

done by Aalborg Portland A/S identified several

suggestions for converting a gray SCC formulation to

Slump flow test of white SCC.

Photo courtesy of Aalborg White. white cement SCC. (1, 2) They take into account the

difference in chemistry of white cement and gray

cement, dosages of cement, water and admixtures, etc. Alternately, a mixture can be initially

designed in white portland cement.

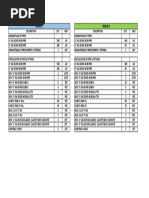

Testing SCC: New ASTM Standards Are Approved

Flowability, passing ability, and stability are three of the most

important characteristics of SCC. In 2001, ASTM started

development of test methods that would assess these

characteristics. In 2005, the first SCC standard was published:

ASTM C1611, Test Method for Slump Flow of Self-Consolidating ASTM C 1621

Concrete, which assesses the flowability of SCC. This was

followed in March of 2006 by ASTM C1621, Test Method for

Passing Ability of Self-Consolidating Concrete by J-Ring. Test

methods to assess static and dynamic stability are currently

under development. These standards will be used in the mix

design process of SCC as well as a quality control tool.

Click here for more information.

References

http://www.cement.org/tech/cct_SCC.asp (2 of 4)30/09/2010 11:03:01

Concrete Technology | Self-Consolidating Concrete | Portland Cement Association (PCA)

(1) Thrysøe, Jacob, and Hansen, Tommy Bæk, “Self compacting concrete based on white

portland cement,” Concrete Plant International, #1, Concrete Plant International Worldwide,

February 2006, pages 84 to 93.

(2) Self Compacting Concrete Based on AALBORG WHITE®

Resources

Self-Consolidating Concrete (IS546B)

Self-Compacting Concrete: Bibliography of Resources (LB06)

Self-Consolidating Concrete Takes Concrete Sustainability to a New Level

Concrete is inherently a sustainable material. Some of

its many sustainable properties and applications are

further enhanced with the use of self-consolidating

concrete (SCC). SCC provides benefits beyond those of

conventional concrete in all three aspects of sustainable

development: economic, social, and environmental. National Museum of the

American Indian

The most important benefit of SCC is the increase in

durability. The uniformity of an SCC mixture reduces the

permeability and enhances the overall durability of the

concrete. This, in turn, enhances the lifespan of the SCC

beyond that of conventional concrete (Corinaldesi

2005); thereby reducing the environmental footprint on a unit time basis.

The use of SCC has been adopted by a large number of precast operations. This has been

done primarily due to the economic benefit of SCC. The self-consolidating property eliminates

the need for vibration, which reduces the labor requirement for SCC placement. In some

cases, the labor requirement can be half that for conventional concrete (Baumgartner 2003).

The energy consumption associated with vibration is also removed. Additionally, the

formwork no longer is subject to the stresses of vibration, which can reduce formwork initial

cost, maintenance costs, or both. These benefits apply to precast operations as well as cast-

in-place operations.

Another benefit associated with the elimination of vibration is the noise reduction. This

improves the working environment and safety. This can increase employee productivity by

reducing noise-induced and vibration-induced illnesses (Daczko 2006). Additionally,

operations located within or near residential or commercial centers may experience less

noise-based negative feedback from the neighbors.

The aesthetic quality of SCC formed surfaces allows the bare concrete to be the finish

surface. Additional material, such as paint, is not needed. This in turn reduces maintenance

requirements and improves air quality.

Additional environmental concerns can be addressed using benefits already highlighted for

the economic and social aspects of sustainable development. The reduction in energy

consumption can be directly translated to reduced fossil fuel usage. On top of the reduction

in energy due to elimination of vibration, the rapid discharge rate of SCC allows for shorter

dwell times of trucks at the job site. Again, this directly translates to a reduction of fossil fuel

usage.

Glavind (2005) states that the industry “has suffered from an image of being dirty, noisy,

and environmentally unfriendly.” SCC in combination with the sustainable principles of

concrete in general can be used to refute this image and show that concrete is the choice for

sustainable development.

References

Baumgartner, J., “Application of the Zero Energy System: Self-Compacting Concrete in the

Swiss Precast Concrete Industry,” Betonwerk- und Fertigteil-Technik (Concrete Plant and

Precast Technology), Vol. 69, No. 9, 2003, pages 58-66.

Corinaldesi, V. and G. Moriconi, “Rheological Study of Blended Cement Concrete,” Cement

Combinations for Durable Concrete, Thomas Telford, London, 2005, pages 211-218.

Daczko, J. A., and M. Vachon, "Self-Consolidating Concrete (SCC)," Significance of Tests and

Properties of Concrete and Concrete-Making Materials, STP169D, ASTM International, West

Conshohocken, Pennsylvania, 2006, pages 637-645.

http://www.cement.org/tech/cct_SCC.asp (3 of 4)30/09/2010 11:03:01

Concrete Technology | Self-Consolidating Concrete | Portland Cement Association (PCA)

Glavind, M., D. Mathiesen, and C.V. Nielsen, “Sustainable Concrete Structures: A Win-Win

Situation for Industry and Society,” Achieving Sustainability in Construction, Thomas Telford,

London, 2005, pages 1-14.

Careers | Sitemap | Disclaimer | Privacy Policy | © 2010 Portland Cement

Association - All Rights Reserved

http://www.cement.org/tech/cct_SCC.asp (4 of 4)30/09/2010 11:03:01

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Fire Resistance Ratings - ANSI/UL 263: Design No. U311Dokumen3 halamanFire Resistance Ratings - ANSI/UL 263: Design No. U311DavidBelum ada peringkat

- Nobel 2022 - CabinetDokumen10 halamanNobel 2022 - CabinetLynn ChiaBelum ada peringkat

- PIPE LAYING PROJECT (Sent To Ms. Analyn) PDFDokumen1 halamanPIPE LAYING PROJECT (Sent To Ms. Analyn) PDFJamaica RolloBelum ada peringkat

- EVS en ISO 16137 2006 en PreviewDokumen11 halamanEVS en ISO 16137 2006 en PreviewMohamed MOUKHTARIABelum ada peringkat

- Science of Materials Science of Materials C: Dr. Andres MarquezDokumen45 halamanScience of Materials Science of Materials C: Dr. Andres MarquezAPBelum ada peringkat

- Work Progress Report of Pegasus DT 03.02.22Dokumen42 halamanWork Progress Report of Pegasus DT 03.02.22pankarvi6Belum ada peringkat

- Astm B 505 PDFDokumen8 halamanAstm B 505 PDFRio WitcandraBelum ada peringkat

- Aluminium in Zinc BathDokumen5 halamanAluminium in Zinc BathTravis Wood100% (1)

- BHEL (Bharat Heavy Electricals Limited) Haridwar Block 2 Heavy FabricationDokumen27 halamanBHEL (Bharat Heavy Electricals Limited) Haridwar Block 2 Heavy FabricationUdit Soni100% (1)

- FQP For Civil WorkDokumen15 halamanFQP For Civil WorkManoj ShahBelum ada peringkat

- Punchlist: Area Comments / Remarks Contractor Fig. No. Completion Date ItemsDokumen10 halamanPunchlist: Area Comments / Remarks Contractor Fig. No. Completion Date ItemsJan Lawrence AlbertoBelum ada peringkat

- Materials As Per IRCDokumen7 halamanMaterials As Per IRCAyyanna HabalBelum ada peringkat

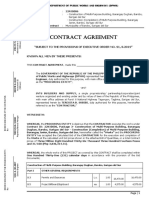

- Contract Agreement: Department of Public Works and Highways (DPWH)Dokumen7 halamanContract Agreement: Department of Public Works and Highways (DPWH)Christian ConsignaBelum ada peringkat

- Hardness TestDokumen2 halamanHardness TestGurdeep KohliBelum ada peringkat

- ASTM A53 Data Sheet PDFDokumen3 halamanASTM A53 Data Sheet PDFmarcelomaster88Belum ada peringkat

- Corrosion Protection For Reinforced Concrete Highway Structures PDFDokumen43 halamanCorrosion Protection For Reinforced Concrete Highway Structures PDFLvisionBelum ada peringkat

- Catalogue Perforated Metal 201501enDokumen44 halamanCatalogue Perforated Metal 201501enRahul MohiteBelum ada peringkat

- Portakabin 03 S033Dokumen12 halamanPortakabin 03 S033AaronBelum ada peringkat

- Portland Cement: Wednesday, March 25, 2015Dokumen35 halamanPortland Cement: Wednesday, March 25, 2015EFRA BINIBelum ada peringkat

- Semana 09 O - Cold Weather Concreting - PCA Chapter 17Dokumen18 halamanSemana 09 O - Cold Weather Concreting - PCA Chapter 17Ernesto Morán OrtizBelum ada peringkat

- Alat OrtoDokumen6 halamanAlat OrtoRangga BahadarBelum ada peringkat

- Technical Information Technical Information: General Information R2 R15Dokumen42 halamanTechnical Information Technical Information: General Information R2 R15safat parBelum ada peringkat

- Injection MouldinDokumen32 halamanInjection MouldinKarthick KarthickBelum ada peringkat

- Welding Procedure Specification ExampleDokumen2 halamanWelding Procedure Specification ExampleShajahan ShagulBelum ada peringkat

- DS 1663ZJDokumen1 halamanDS 1663ZJAgung BachtiarBelum ada peringkat

- Machine Design Final Coaching ShuffledDokumen385 halamanMachine Design Final Coaching Shuffledkristan7Belum ada peringkat

- High-Strength Low-Alloy Columbium-Vanadium Structural Steel: Standard Specification ForDokumen4 halamanHigh-Strength Low-Alloy Columbium-Vanadium Structural Steel: Standard Specification ForCarlosBelum ada peringkat

- Instructions For Installation, Operation, Care and MaintenanceDokumen10 halamanInstructions For Installation, Operation, Care and MaintenanceAdi HardiansyahBelum ada peringkat

- An Overview Of: Piping Material SpecificationDokumen60 halamanAn Overview Of: Piping Material SpecificationNeeraj Bora100% (10)

- Bolt Load Capacity TableDokumen1 halamanBolt Load Capacity Tableezarul fitri100% (3)