MBRCatalog 7.00 en

Diunggah oleh

manuelDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MBRCatalog 7.00 en

Diunggah oleh

manuelHak Cipta:

Format Tersedia

MBR Catalog

Membrane/Bag

Rupture Relay

The Membrane/Bag Rupture Relay - MBR is a device capable of detecting the rupture of the rubber

membrane or bag used in oil preservation systems on power transformers and reactors.

The MBR is comprised of an optical sensor that must be mounted on the membrane or inside the rubber

bag (on the air side), and a control unit located in the transformer control cabinet.

The sensor is provided with a polysulfon capsule containing an emitting LED and a trigger circuit. The

control unit has a reversible contact and two LED's, one to signal the membrane or bag rupture, and

another to signal the on status.

The MBR operation is based on the principle of light reflection. When there is no oil present, the light

produced by the emitting-LED is completely reflected internally by the capsule dome and captured by the

optical receiver. If the oil covers the capsule, the reflection effect on the dome limits change. The rupture

causes part of the emitted light to disperse in the oil, and the amount of light that reaches the optical

receiver is reduced. This change in light refection causes the unbalancing of the coupling circuits and the

actuation of the signal contact.

The output contact is reversible, and its operation mode (operate or return to rest mode in case of

membrane failure) is selected by means of an external jumper.

The auxiliary supply voltage to the MBR can be in the range 85 to 265 Vdc/Vac 50/60Hz, covering all

auxiliary voltages commonly found in power plants. Electrical insulation is provided between input, output

and auxiliary supply circuits.

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 1

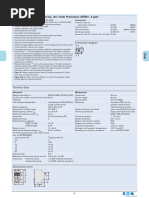

Technical Features:

Power Supply: 85 to 265 Vcc/Vca, 50/60 Hz

Consumption: < 3W

Relay Operation Temperature: -10 to 70°C

Sensor Operation Temperature: -40 to 100°C

Input: 1 MBR-Sensor

Output: 1 Reversible Contact

Maximum Switching Power 60W (dc)/62.5 VA (ac)

Maximum Switching Voltage 220 Vcc/250 Vca (non inductive)

Maximum Switching Current 2,0 A

LED's:

Green: ON

Red: Membrane/Bag rupture

Degree of Protection Relay: IP 20

Degree of Protection Sensor: IP 67

Mounting of Relay: DIN Rail 35mm

Sensor Cable: 4 x 0,5mm², 200°C

Wire Size: 0,3 a 2,5mm², 22 to 12 AWG

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 2

Connection Diagram

85...265

of the output contact

Vdc/Vac

Operation selection

13 1 2 3

NO

15

NC

16

MBR

10 11 12 6 7 8 14

White

Black

Blue

Red

Sensor

Signaling

Contact

Notes:

1) Output contact is shown with MBR de-energized.

2) Connect a jumper wire between terminals 13-15 if the output contact is to operate (close 10-12) in

case of alarm and return to normal position if there is no alarm (close 11-12).

3) Connect a jumper wire between terminals 15-16 if the output contact is to return to normal position

(close 11-12) in case of alarm and to operate if there is no alarm (close 10-12).

4) One of the above jumper wires must be installed. Otherwise the output contact will never change

state.

Test Procedure

The most comprehensive test for the MBR is achieved by connecting the MBR Sensor to the MBR

Relay, energizing it with power supply from 85 to 265 Vdc/Vac and immersing the sensor in insulating

oil or clean water. The Alarm LED at the relay front panel must go on and the output relay must

actuate according to the operation mode selected with the jumper at terminals 13-15 or 15-16. Dry

the sensor after the test.

It is possible also to test the MBR relay without a sensor connected to it. To do that, connect jumper

wires as indicated in the table below and check if the proper output is achieved:

Jumper 1 Jumper 2 Expected Output

7 to 14 6 to 8 No alarm

7 to 14 6 to 7 Alarm

None 6 to 8 Alarm

None 6 to 7 Alarm

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 3

Dimensions

Control Unit

45 110

75

Front View Side View

MBR-Sensor

14

42

Red

White

Blue

Cable (4 X 0,5 mm²)

Black

All dimensions in milimeters

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 4

Accomplished Tests

Immunity to Electrical transients

(IEC 60255-4 / IEC60255-6):

1st cycle peak value 2,5 kV

Frequency: 1,1 MHz

Repeat Time and Rate: 2 seconds, 400 surges/sec

Decay at 50%: 5 cycles

Voltage Impulse (IEC 60255-5):

Wave shape: 1,2/50μs

Amplitude and energy: 5kV

Number of pulses: 3 negative e 3 positive, interval 5s

Voltage Applied (IEC 60255-5): 2 kV 60Hz 1 min against ground

Voltage supportable at industrial frequency

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 5

Optional Accessory

Connection box to MBR – CPMBR

Chain Cable-gland

All dimensions in milimeters

Features

Head: Cast aluminum, painted - KNC

Cable Gland: Nickel plated brass – Thread ½” BSP

Chain: Brass nickel plated

Bolts: Nickel plated brass or stainless steel

Adaptor: Stainless steel

Supportable pressure 0,3 bar

Ordering Information

The Membrane/Bag Rupture Relays MBR have universal power input from 85 to 265Vdc / Vac 50/60 Hz.

The sensor is supplied a with standard cable 5 meters long. Therefore, in purchase orders only the

following need to be informed:

• Membrane/Bag Rupture Relay MBR:

Quantity;

• Sensor for MBR (the MBR sensor is sold separately):

Quantity;

Cable length if different of 5 meters (Upon Request);

• Optional Accessory - Connection Box CP-MBR:

Quantity;

Thread option: 3/4” BSP (British Standard Pipe) or 3/4” NPT (National Pipe Thread).

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 6

Connection instruction MBR-Sensor and CPMBR

1. The sensor is installed in the Transformer Conservator Tank, illustrated in figure 1:

Figure 1

2. The Passing-through fitting CPMBR (figure 2) allows for electrical and signal connections

between the conservator tank and the MBR relay.

1 – Aluminum Head

2 – Adaptor

3 – 4 Pin female connector, sealed

4 – 4 Pin male connector, sealed

5 – Cooper wire 0,5 mm²

6 – Ceramic Terminal Board (4 terminals)

7 – Encapsulating Resine

8 – Identification Plate

Figure 2

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 7

3. In order to connect MBR Sensor, CPMBR and Control Relay Module, 4 wires (shielded) are used,

as shown in figures 3, 4 and 5.

Figure 3

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 8

Figure 4

Figure 5

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 9

4. Finally, figure 6 shows the Electrical Conduit Adapter dimensions for CPMBR.

Figure 6

[ Catalog– MBR | CA–035 | 01-12-2017 | Review: 7.00 ] 10

BRAZIL

Treetech Sistemas Digitais Ltda

Praça Claudino Alves, 141, Centro

CEP 12.940-000 - Atibaia/SP

+ 55 11 2410-1190

comercial@treetech.com.br

www.treetech.com.br

Anda mungkin juga menyukai

- Operational Amplifier Circuits: Analysis and DesignDari EverandOperational Amplifier Circuits: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDari EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsPenilaian: 3.5 dari 5 bintang3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Andrea Elizabeth Shaw - The Embodiment of Disobedience - Fat Black Women's Unruly Political Bodies-Lexington Books (2006)Dokumen162 halamanAndrea Elizabeth Shaw - The Embodiment of Disobedience - Fat Black Women's Unruly Political Bodies-Lexington Books (2006)Mirani Barros100% (1)

- Siemens Transformers Materials Influence Diagnostics Stray GassingDokumen6 halamanSiemens Transformers Materials Influence Diagnostics Stray GassingmanuelBelum ada peringkat

- Agne Vs Director of LandsDokumen7 halamanAgne Vs Director of LandsLee SomarBelum ada peringkat

- Code-It Project ReportDokumen40 halamanCode-It Project Reportm r100% (1)

- Op Amps: Design, Application, and TroubleshootingDari EverandOp Amps: Design, Application, and TroubleshootingPenilaian: 5 dari 5 bintang5/5 (2)

- Service Manual LG L1720 BDokumen28 halamanService Manual LG L1720 Bdidik wahyudionoBelum ada peringkat

- LG L1718S-SDokumen52 halamanLG L1718S-SvideosonBelum ada peringkat

- Business Advantage Pers Study Book Intermediate PDFDokumen98 halamanBusiness Advantage Pers Study Book Intermediate PDFCool Nigga100% (1)

- Software Manual Hydran M2 (DNP) Host (DNP3 Single Protocol)Dokumen218 halamanSoftware Manual Hydran M2 (DNP) Host (DNP3 Single Protocol)manuel0% (1)

- Thesis TopicsDokumen9 halamanThesis TopicsInayath AliBelum ada peringkat

- Openstack Deployment Ops Guide PDFDokumen197 halamanOpenstack Deployment Ops Guide PDFBinank PatelBelum ada peringkat

- People Vs SB - Paredes - Ex Post FactoDokumen2 halamanPeople Vs SB - Paredes - Ex Post FactoMara Aleah CaoileBelum ada peringkat

- Membrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Dokumen7 halamanMembrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Mila CalderónBelum ada peringkat

- LG-LCD-Monitor-Flatron - L1718S-service-manualDokumen35 halamanLG-LCD-Monitor-Flatron - L1718S-service-manualRick MillerBelum ada peringkat

- LG Flatron Monitor l1919sDokumen28 halamanLG Flatron Monitor l1919sDariusz DARCIOBelum ada peringkat

- LG L1730SF, SFKN - eDokumen30 halamanLG L1730SF, SFKN - evideosonBelum ada peringkat

- LG l1755s Chassis Lm72aDokumen31 halamanLG l1755s Chassis Lm72aEmmanuel Dos santosBelum ada peringkat

- LG L1919S-SFQ - eDokumen35 halamanLG L1919S-SFQ - evideosonBelum ada peringkat

- Color Monitor: Service ManualDokumen44 halamanColor Monitor: Service Manualguswir manBelum ada peringkat

- LG L192WS-BNQDokumen37 halamanLG L192WS-BNQAbraham RossBelum ada peringkat

- Color Monitor: Service ManualDokumen22 halamanColor Monitor: Service Manualsergio chagasBelum ada peringkat

- IL55B/ 56B/ MOC8021: Optocoupler, Photodarlington Output, High GainDokumen6 halamanIL55B/ 56B/ MOC8021: Optocoupler, Photodarlington Output, High GainCarlos Arias LuyandoBelum ada peringkat

- Manual LG LCDDokumen41 halamanManual LG LCDHectorisaac_79100% (1)

- LG Flatron Monitor Chlm73a w2241bfDokumen25 halamanLG Flatron Monitor Chlm73a w2241bfDariusz DARCIOBelum ada peringkat

- Color Monitor: MODEL: L200PDokumen36 halamanColor Monitor: MODEL: L200PstevemaddensfBelum ada peringkat

- Color Monitor Service ManualDokumen49 halamanColor Monitor Service ManualAlexandre MagriBelum ada peringkat

- Color Monitor: Service ManualDokumen39 halamanColor Monitor: Service ManualAndres DugarteBelum ada peringkat

- Eaton Afdd Catalog Tech en UsDokumen4 halamanEaton Afdd Catalog Tech en UsjenelbBelum ada peringkat

- In Touch With The Medium: BEDIA Level - Monitoring - Probes Type PLS 10 Type PLS 30 Type PLS 40Dokumen27 halamanIn Touch With The Medium: BEDIA Level - Monitoring - Probes Type PLS 10 Type PLS 30 Type PLS 40ALEJOBelum ada peringkat

- AL3353EV1 User GuideDokumen9 halamanAL3353EV1 User GuideHaze Garcia HechanovaBelum ada peringkat

- 03 Downstream GFB Series Operation ManualDokumen12 halaman03 Downstream GFB Series Operation ManualDamian VillarBelum ada peringkat

- Harmony Analog - RMCN22BDDokumen5 halamanHarmony Analog - RMCN22BDOm Indra NugrahaBelum ada peringkat

- Low-Power, Single-Channel 22-Bit Delta-Sigma Adcs: Features DescriptionDokumen36 halamanLow-Power, Single-Channel 22-Bit Delta-Sigma Adcs: Features Descriptionikaro181083Belum ada peringkat

- MCP4011 Digital PotDokumen60 halamanMCP4011 Digital Potundes100% (1)

- DataSheet VSS Switch Type 1 MinDokumen6 halamanDataSheet VSS Switch Type 1 Minjorgem.mceBelum ada peringkat

- LG W2353S Chassis LM84K Service ManualDokumen22 halamanLG W2353S Chassis LM84K Service ManualLuks BrcBelum ada peringkat

- Zelio Time Re7ra11buDokumen16 halamanZelio Time Re7ra11buRhyan EdwinBelum ada peringkat

- L204WS SDokumen24 halamanL204WS Snei_servieBelum ada peringkat

- Anti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDDokumen7 halamanAnti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDArunava BasakBelum ada peringkat

- Anti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDDokumen7 halamanAnti Pumping Device / Relay (APD or APC) : Inventa Electro Systems (Nasik) PVT .LTDragab abulmagdBelum ada peringkat

- Color Monitor: MODEL: T541 (9512-HWL) T541 (9512-HBL)Dokumen35 halamanColor Monitor: MODEL: T541 (9512-HWL) T541 (9512-HBL)Wasantha MunasinghaBelum ada peringkat

- Color Monitor: Service ManualDokumen28 halamanColor Monitor: Service ManualPareja_Belum ada peringkat

- L1510SDokumen37 halamanL1510SRobert GreenBelum ada peringkat

- 1 Revised MRP Metal 100723Dokumen24 halaman1 Revised MRP Metal 100723Jainam ShahBelum ada peringkat

- MCT2EDokumen3 halamanMCT2ESelva KumarBelum ada peringkat

- Ad5270 5271Dokumen24 halamanAd5270 5271miri10861Belum ada peringkat

- Fire Alarm Control Panel: Product OverviewDokumen3 halamanFire Alarm Control Panel: Product OverviewBharaneeBelum ada peringkat

- DZS900 User Manual-Heyuan IntelligenceDokumen18 halamanDZS900 User Manual-Heyuan IntelligenceAntonio GarciaBelum ada peringkat

- A1350 Flyer Ea3Dokumen2 halamanA1350 Flyer Ea3Bojan IlievBelum ada peringkat

- LG M1721a M1921a BMF Chassis cl-81 PDFDokumen39 halamanLG M1721a M1921a BMF Chassis cl-81 PDFAleluiz LuizBelum ada peringkat

- Roadstar CTN Chassis 1.1 TV SMDokumen33 halamanRoadstar CTN Chassis 1.1 TV SMmarcellobbBelum ada peringkat

- Data Sheet: The Sca103T Differential Inclinometer SeriesDokumen18 halamanData Sheet: The Sca103T Differential Inclinometer SeriesJonathan MatsonBelum ada peringkat

- Semiconductor Technical DataDokumen6 halamanSemiconductor Technical DataAnonymous oEoCVNhu7HBelum ada peringkat

- Dell 1800FP - Chassis CL-29Dokumen35 halamanDell 1800FP - Chassis CL-29msicoie1851Belum ada peringkat

- Service Manual: SDM-X52Dokumen42 halamanService Manual: SDM-X52cinematic3006Belum ada peringkat

- Service Manuals LG TV PLASMA 42PB4D 42PB4D Service ManualDokumen59 halamanService Manuals LG TV PLASMA 42PB4D 42PB4D Service Manual邱政鋒100% (1)

- 3-Phase Sequence and Phase Loss Monitoring Relay: BenefitsDokumen10 halaman3-Phase Sequence and Phase Loss Monitoring Relay: BenefitsZubair RajpootBelum ada peringkat

- Ad 557Dokumen6 halamanAd 557TWChan69Belum ada peringkat

- AV02 1646EN - DS - HDSM 29xB - 2019 05 17Dokumen10 halamanAV02 1646EN - DS - HDSM 29xB - 2019 05 17EduardoBelum ada peringkat

- KY8T1SYBDokumen4 halamanKY8T1SYBTamilarasan KBelum ada peringkat

- AD5259Dokumen22 halamanAD5259greencubesindiaBelum ada peringkat

- 2.5 Amp Output Current IGBT Gate Drive Optocoupler With Rail-to-Rail Output Voltage, High CMRDokumen14 halaman2.5 Amp Output Current IGBT Gate Drive Optocoupler With Rail-to-Rail Output Voltage, High CMRNae CarBelum ada peringkat

- Re 2554Dokumen4 halamanRe 2554Brian MirandaBelum ada peringkat

- Operating-Instruction Nivel de AceiteDokumen20 halamanOperating-Instruction Nivel de AceitemanuelBelum ada peringkat

- Cpr-3 - Catalouge Rele RubberDokumen2 halamanCpr-3 - Catalouge Rele Rubbermanuel100% (1)

- 01 Micafil Bushings Overview English PDFDokumen6 halaman01 Micafil Bushings Overview English PDFanurag_jay12464100% (1)

- Method Statement Free Download: How To Do Installation of Suspended False CeilingsDokumen3 halamanMethod Statement Free Download: How To Do Installation of Suspended False Ceilingsmozartjr22100% (1)

- Distribution IDokumen28 halamanDistribution IsruthiBelum ada peringkat

- Math Studies Financial MathsDokumen7 halamanMath Studies Financial MathsGirish MishraBelum ada peringkat

- Job Board Week WhituDokumen5 halamanJob Board Week WhituAnonymous MZh1KUUXBelum ada peringkat

- Rawson Homes Duplex DesignsDokumen16 halamanRawson Homes Duplex DesignsJhondy TibubosBelum ada peringkat

- Name: - Date: - Week/s: - 2 - Topic: Examining Trends and FadsDokumen3 halamanName: - Date: - Week/s: - 2 - Topic: Examining Trends and FadsRojelyn Conturno100% (1)

- Apy1 Kinematics Review - 2015 - KeyDokumen13 halamanApy1 Kinematics Review - 2015 - KeyemadBelum ada peringkat

- Errors Affecting The Trial BalanceDokumen3 halamanErrors Affecting The Trial BalanceDarwin Lopez100% (1)

- Markets and Commodity Figures: Total Market Turnover StatisticsDokumen6 halamanMarkets and Commodity Figures: Total Market Turnover StatisticsTiso Blackstar GroupBelum ada peringkat

- STAS 111 - Information AgeDokumen20 halamanSTAS 111 - Information AgeMayeee GayosoBelum ada peringkat

- Installing Hyperledger Fabric and Composer: Ser/latest/installing/development-To Ols - HTMLDokumen13 halamanInstalling Hyperledger Fabric and Composer: Ser/latest/installing/development-To Ols - HTMLVidhi jainBelum ada peringkat

- PRP RationaleDokumen12 halamanPRP Rationalemarquezjayson548Belum ada peringkat

- Shyla Jennings Ebook FinalDokumen17 halamanShyla Jennings Ebook FinalChye Yong HockBelum ada peringkat

- BoSY CRLA Grade 1 MT Administration GuideDokumen13 halamanBoSY CRLA Grade 1 MT Administration GuideJOCELYN SANANO100% (1)

- Es PS 0614Dokumen6 halamanEs PS 0614陳相如Belum ada peringkat

- Activity 9 Let's Check and Let's AnalyzeDokumen3 halamanActivity 9 Let's Check and Let's AnalyzeJean Tronco100% (5)

- Statistics and Data CollectionDokumen11 halamanStatistics and Data CollectionRichimon LicerioBelum ada peringkat

- Alcatel 9400 PDFDokumen4 halamanAlcatel 9400 PDFNdambuki DicksonBelum ada peringkat

- How To Read Research PaperDokumen7 halamanHow To Read Research Papertuigauund100% (1)

- Buyer Behavior ModelDokumen1 halamanBuyer Behavior ModelraihanulhasanBelum ada peringkat

- Case Digest 2 S.C. MEGAWORLD CONSTRUCTIONDokumen3 halamanCase Digest 2 S.C. MEGAWORLD CONSTRUCTIONRomualdo CabanesasBelum ada peringkat

- 100 Cases Ethics NotesDokumen16 halaman100 Cases Ethics Noteskoki74Belum ada peringkat

- Tutorial 2 - Financial EnvironmentDokumen5 halamanTutorial 2 - Financial EnvironmentShi ManBelum ada peringkat