2016-06-20 ACX-APL5 Installation Time Schedule Rev06

Diunggah oleh

julio arroyo0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

86 tayangan17 halamanThis document outlines the preliminary erection and commissioning schedule for a cold annealing and pickling line from November 2017 to March 2018. It includes timelines for the erection of equipment and electrical systems, functional tests, processing the first coil, hot commissioning, proving performance guarantees, and provisional reception. It also lists obligations of Acerinox such as ensuring site preparations like access, storage, cranes and utilities are ready to allow for equipment delivery, unloading, and storage between February and May 2017.

Deskripsi Asli:

1221221

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document outlines the preliminary erection and commissioning schedule for a cold annealing and pickling line from November 2017 to March 2018. It includes timelines for the erection of equipment and electrical systems, functional tests, processing the first coil, hot commissioning, proving performance guarantees, and provisional reception. It also lists obligations of Acerinox such as ensuring site preparations like access, storage, cranes and utilities are ready to allow for equipment delivery, unloading, and storage between February and May 2017.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

86 tayangan17 halaman2016-06-20 ACX-APL5 Installation Time Schedule Rev06

Diunggah oleh

julio arroyoThis document outlines the preliminary erection and commissioning schedule for a cold annealing and pickling line from November 2017 to March 2018. It includes timelines for the erection of equipment and electrical systems, functional tests, processing the first coil, hot commissioning, proving performance guarantees, and provisional reception. It also lists obligations of Acerinox such as ensuring site preparations like access, storage, cranes and utilities are ready to allow for equipment delivery, unloading, and storage between February and May 2017.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 17

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

1 Contract Schedule Erection & Commissioning 01.02 01.03

2 Erection of Equipment 01.02 31.07

3 Functional Tests 01.08 01.11

4 1st Coil 01.11

5 Hot Commissioning 02.11 12.01

6 Proof of Performance Guarantees 16.01 01.03

7 Provisional Reception 01.03

8 Target Schedule Erection & Commissioning 01.02 01.03

9 Erection of Mechanical Equipment 01.02 30.06

10 Erection of Electrical Equipment 01.03 29.07

11 Functional Tests 15.07 01.11

12 1st Coil 01.11

13 Hot Commissioning 02.11 12.01

14 Proof of Performance Guarantees 16.01 01.03

15 Provisional Reception 01.03

16 ACERINOX OBLIGATIONS 30.12 26.10

17 Road Access for Truck Deliveries and Mobile Cranes 30.12

18 Sufficient Site Storage Area Open for Equipment Available 30.12

19 Sufficient Site Storage Area with roof for Equipment Available 30.12

20 Bay Cranes Ready for Use by Supplier 31.01

21 temporary low voltage power supply 31.01

22 medium voltage available 31.01

23 Building Columns ready for cable tray installation 31.01

24 Building with roof, side walls ready 31.01

25 Foundation ready incl. acid/oil protection 31.01

26 MCC/electrical rooms complete (painted, e-installation, floor) 31.01

27 CAPL Exit electrical room complete 31.01

28 CAPL Entry electrical room complete 31.01

29 Utilities for Installation (water, air, current) 01.02

30 Water 01.02

31 Air 01.02

32 Current 01.02

33 Gas 01.02

34 Utilities, consumables for Start Up of CAPL 15.07 26.10

35 raw water 15.07

36 potable water 15.07

37 compressed air / instrument air 15.07

38 demineralized water 15.07

39 direct cooling water 15.07

40 indirect cooling water 15.07

41 saturated steam 15.07

42 LNG 15.07

43 sodium hydroxide solution 26.10

44 degreasing agent - powder, liquid 26.10

45 make-up (fresh) nitric acid 26.10

46 make-up (fresh) hydroflouric acid 26.10

47 sodium sulfate powder, solution 26.10

48 sodium bisulfite powder, solution 26.10

49 urea – solid granulate, solution 26.10

50 DELIVERY EQUIPMENT DDP 02.01 31.05

51 Unloading and Storage 02.01 31.07

52 Site preparation 16.01 10.02

53 Arrival of SV 16.01

54 Establish of job side 16.01 18.01

55 Check foundations 31.01 03.02

56 Check/ establish main axes & level bench marks 04.02 07.02

2016-06-20 Page 1 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

57 Check/ establish auxilliary axis 08.02 10.02

58 ERECTION 31.01 10.08

59 Erection Mechanical Equipment 01.02 09.08

60 1516 Steel structure Terminal Equipment 11.02 03.06

61 -026 Steel Structure Entry 30.03 05.04

62 -027 Operator platform entry 06.04 12.04

63 -028 Steel structure for belt conveyor and leader end handling 06.04 12.04

64 -029 Steel structure Entry Looper 11.02 03.03

65 -032 Operator platform Entry Looper 04.03 17.03

66 -035 Steel Structure Exit Looper 04.03 24.03

67 -038 Operation Platform Exit Looper 25.03 07.04

68 -041 Steel Structure Exit 12.04 25.04

69 -042 Operator Platform Exit 26.04 04.05

70 -043 Operation Platform Paper Unwinder 05.05 13.05

71 -044 Misc- Structures / Platforms 15.05 03.06

72 Entry No. 1 11.02 04.05

73 2101 Coil Storage Skid No.1, 3 places 25.02 03.03

74 2115 -021 Rail for Coil Car No.1 11.02 17.02

75 2115 -100 Coil Car No.1, L type 18.02 24.02

76 2131 Coil centering system no. 1 04.03 07.03

77 2132 Sleeve Unloading Unit No.1 04.03 09.03

78 2134 Paper Winder No.1 04.03 08.03

79 2136 Paper Coil Handling No. 1 09.03 15.03

80 -026 Jib Crane 11.03 15.03

81 -100 Paper coil handling 09.03 10.03

82 2138 Outboard bearing no. 1 04.03 07.03

83 2140 Uncoiler No. 1 25.02 03.03

84 2140 -980 Strip Position Control 09.03 09.03

85 2150 -100 Coil peeler no. 1 04.03 08.03

86 2154 -020 drive for pinch roll unit no.1 13.03 15.03

87 2154 -100 Pinch roll unit no.1 09.03 11.03

88 2155 -020 Drive for flattener no. 1 16.03 18.03

89 2155 -100 Flattener no. 1 13.03 15.03

90 2161 Bending Device No. 1 16.03 18.03

91 2165 -020 Drive for auxiliary pinch roll no. 1 20.03 20.03

92 2165 -100 Auxiliary pinch roll no. 1 16.03 18.03

93 2170 Crop shear no. 1 20.03 22.03

94 2171 Swiveling table no. 1 06.04 08.04

95 2175 Scrap Removal System No. 1 11.02 22.02

96 2175 -021 rails for scrap removal system no. 1 11.02 17.02

97 2175 -058 Scrap box no. 1 22.02 22.02

98 2175 -100 Scrap removal system no. 1 18.02 21.02

99 2180 -020 Drive for belt conveyor no. 1 17.04 18.04

100 2180 -026 Lifting roll for belt conveyor no. 1 19.04 22.04

101 2180 -100 Belt conveyor no. 1 13.04 15.04

102 2185 Dide guide no. 1 24.04 25.04

103 2187 Dide guide no. 2 26.04 27.04

104 2195 Strip junction 28.04 04.05

105 Entry No. 2 11.02 02.06

106 2201 Coil Storage Skid No.2, 3 places 25.02 03.03

107 2215 -021 Rail for Coil Car No.2 11.02 17.02

108 2215 -100 Coil Car No.2, L type 18.02 24.02

109 2231 Coil centering system no. 2 04.03 07.03

110 2232 Sleeve Unloading Unit No.2 08.03 13.03

111 2234 Paper Winder No.2 08.03 11.03

112 2236 Paper Coil Handling No. 2 06.04 12.04

2016-06-20 Page 2 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

113 -026 Monorail Crane 06.04 10.04

114 -100 Paper Coil Handling 11.04 12.04

115 2238 Outboard bearing no.2 04.03 07.03

116 2240 Uncoiler No. 2 25.02 03.03

117 2240 -980 Strip Position Control 16.03 16.03

118 2250 -100 Coil peeler no.2 11.03 15.03

119 2254 -020 Drive for pinch roll unit no.2 11.03 14.03

120 2254 -100 Pinch roll unit no.2 08.03 10.03

121 2255 -020 Drive for flattener no.2 20.03 22.03

122 2255 -100 Flattener no.2 16.03 18.03

123 2261 Bending Device No. 2 20.03 22.03

124 2265 -020 Drive for auxiliary pinch roll no.2 27.03 27.03

125 2265 -100 Auxiliary pinch roll no.2 23.03 25.03

126 2270 Crop shear no. 2 27.03 29.03

127 2271 Swiveling table no.2 30.03 01.04

128 2275 Scrap Removal System No. 2 18.02 01.03

129 2275 -021 Rails for scrap removal system no.2 18.02 24.02

130 2275 -058 Scrap box no.2 01.03 01.03

131 2275 -100 Scrap removal system no.2 25.02 28.02

132 2280 Belt Conveyor No. 2 (Upper pasline) 13.04 02.05

133 2280 -020 Drive for belt conveyor no.2 24.04 25.04

134 2280 -026 Lifting roll for belt conveyor no.2 26.04 28.04

135 2280 -027 Lifting roll for belt conveyor no.2 29.04 02.05

136 2280 -030 Steel Structure for belt conveyor no.2 13.04 19.04

137 2280 -100 Belt conveyor no.2, upper passline 20.04 22.04

138 2281 Belt Conveyor No. 3 (Lower pasline) 24.03 05.04

139 2281 -020 drive for belt conveyor no.3 28.03 29.03

140 2281 -026 lifting roll for belt conveyor no.3 30.03 01.04

141 2281 -027 lifting roll for belt conveyor no.3 03.04 05.04

142 2281 -100 belt conveyor no.3, Lower passline 24.03 27.03

143 2283 Moveable carriage for leader ends 22.03 23.03

144 2287 Leader End Carriage 25.02 08.03

145 2287 -021 Rail for Lead End Car 25.02 03.03

146 2287 -026 Storage frame for leader ends, 2 piece 04.03 06.03

147 2287 -027 Leader ends Car 04.03 07.03

148 2287 -100 Leader ends Storage 07.03 08.03

149 2289 Side guide no.3 28.03 30.03

150 2317 -020 Drive for Steering Pinch Roll No.1 09.05 11.05

151 2317 -100 Steering Pinch Roll No.1 05.05 08.05

152 2317 -980 Strip Position Control 09.05 10.05

153 2326 Looper Table No.1 11.05 12.05

154 2330 Welding Machine and Side Notcher 13.05 02.06

155 2343 Looper Table No.2 11.05 12.05

156 2350 -020 Drive for Steering Pinch Roll No.2 17.05 19.05

157 2350 -100 Steering Pinch Roll No.2 13.05 16.05

158 2350 -980 Strip Position Control 17.05 18.05

159 Degreasing Section Complete 01.02 05.06

160 1515-110 Steel Structure Degreasing Section 08.02 14.02

161 2710 DEGREASING SECTION 1 15.02 17.03

162 -100 CASING 15.02 28.02

163 -221 SQUEEZE ROLL SET 01.03 10.03

164 -321 DRIVE SQUEEZE ROLL SET 11.03 17.03

165 2720 DEGREASING SECTION 2SCBM NO.1 01.03 23.03

166 SCBM 01.03 14.03

167 -300 DRIVE SCRUB BRUSH MACHINE 15.03 23.03

168 2725-221 SQUEEZE ROLL SET 15.03 18.03

2016-06-20 Page 3 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

169 -321 DRIVE SQUEEZE ROLL SET 20.03 21.03

170 2730 RINSING SECTION SCBM NO.2 20.03 11.04

171 SCBM 20.03 01.04

172 -300 DRIVE SCRUB BRUSH MACHINE 03.04 11.04

173 2740 RINSING SECTION AFTER DEGREASING SECTION 03.04 25.04

174 -100 CASING 03.04 08.04

175 -221 SQUEEZE ROLL SET 10.04 18.04

176 -331 DRIVE SQUEEZE ROLL SET 19.04 25.04

177 2750 CIRCULATION PRE-TREATMENT SECTION 01.02 13.05

178 -410 PUMP FOR DEGR. SECT. 1 01.02 01.02

179 -420 PUMP FOR DEGR. SECT. 2 02.02 02.02

180 -440 PUMP FOR PRE-TREATMENT RINSE 03.02 03.02

181 -480 SUMP PUMP PRE-TREATMENT SECTION 17.02 17.02

182 -482 FRAME FOR SUMP PUMPS 16.02 16.02

183 -510 HEAT EXCHANGER NO.1 DEGREASING SECTION 1 04.02 06.02

184 -520 HEAT EXCHANGER NO.2 DEGREASING SECTION 2 07.02 08.02

185 -610 CIRCULATION TANK NO.1 DEGREASING SECTION 1 09.02 10.02

186 -620 CIRCULATION TANK NO.2 DEGREASING SECTION 2 11.02 11.02

187 -630 CIRCULATION TANK for SCBM 13.02 13.02

188 -640 STORAGE TANK FOR DEGREASING AGENT 14.02 14.02

189 -640 TANK FOR SUMP (CL01) 15.02 15.02

190 -710 ARCHED STRAINER 16.02 16.02

191 -730 OIL AND SLUDGE SEPARATOR 17.02 17.02

192 -910 PIPING PROCESS - PRE-TREATMENT SECT. 10.04 13.05

193 -911 PIPING UTILITY - STEAM, WATER, COND. 10.04 13.05

194 -950 PIPE SUPPORTS DEGREASING SECTION 10.04 13.05

195 2770 EDGE BLOW OFF COMPLETE 10.04 12.04

196 -100 EDGE BLOW-OFF DEVICE 10.04 12.04

197 2775 STRIP DRIER COMPL. 13.04 20.04

198 -100 HOUSING STRIP DRIER 13.04 18.04

199 -200 SUPPORT ROLL SET STRIP DRIER 19.04 20.04

200 2775 CIRCULATION STRIP DRIER 19.04 05.05

201 -110 DUCTWORK STRIP DRIER 19.04 05.05

202 -450 FAN STRIP DRIER 20.04 21.04

203 -451 FRAME FAN STRIP DRIER 19.04 19.04

204 -510 AIR HEATER STRIP DRIER 22.04 24.04

205 2792 PNEUMATIC SYSTEM 18.02 11.05

206 -900 PIPING SYSTEM PNEUMATIC 19.04 11.05

207 -910 VALVE STANDS PNEUMATIC 18.02 23.02

208 2791 HYDRAULIC SYSTEM 24.02 25.04

209 -900 PIPING SYSTEM HYDRAULIC 03.04 25.04

210 -910 VALVE STANDS HYDRAULIC 24.02 01.03

211 2795 EXHAUST SYSTEM NO.1 PRE-TREATMENT SECT. 20.04 05.06

212 -110 DUCTWORK EXHAUST SYSTEM NO.1 26.04 05.06

213 -115 DUCT SUPPORTS EXHAUST SYSTEM NO.1 26.04 05.06

214 -120 STACK EXHAUST SYSTEM NO.1 19.05 30.05

215 -450 FAN EXHAUST SYSTEM NO.1 22.04 25.04

216 -451 FRAME FAN EXHAUST SYSTEM NO.1 20.04 21.04

217 -810 DROP SEPARATOR AFTER FAN 22.04 25.04

218 Mechanical Equipment Entry Looper Area 11.02 08.06

219 2354 -020 Drive for Bridle No.1 05.06 08.06

220 2354 -100 Bridle No. 1 31.05 03.06

221 2357 -100 Steering Roll No. 1 26.05 30.05

222 -980 Strip Position Control 31.05 01.06

223 2791 -910 Hydraulic Control Entry / Pickling 11.02 14.02

224 2820 Entry Looper 04.03 06.06

2016-06-20 Page 4 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

225 2820 -020 entry looper drive 31.05 06.06

226 2820 -021 Rails 04.03 24.03

227 2820 -040 entry looper car 08.04 14.04

228 2820 -043 Power Rails 09.05 22.05

229 2820 -045 entry looper strip support rolls 25.03 07.04

230 2820 -046 entry looper folding doors, 12 pairs 08.04 08.05

231 2820 -047 Steering Roll No. 2 09.05 11.05

232 2820 -048 Steering Roll No. 3 12.05 15.05

233 2820 -980 Strip Position Control 15.04 15.04

234 2820 -981 Strip Position Control 17.04 17.04

235 2820 -982 Strip Position Control 18.04 18.04

236 2820 -983 Strip Position Control No. 2 12.05 12.05

237 2820 -984 Strip Position Control No. 3 16.05 16.05

238 2836 -100 Steering Roll No. 4 16.05 18.05

239 2836 -980 Strip Position Control No. 4 19.05 19.05

240 2865 Deflector Roll No. 1 20.05 23.05

241 2870 -020 Drive for Bridle No.2.1 29.05 01.06

242 2870 -100 Bridle No. 2.1 24.05 27.05

243 2875 -020 Drive for Bridle No.2.2 02.06 06.06

244 2875 -100 Bridle No. 2.2 29.05 01.06

245 2905 Dismounting Devices Entry 15.04 28.04

246 Entry Hydraulic 10.02 30.06

247 2911 Hydraulic Unit Entry 17.02 20.02

248 2912 Hydraulic Contol Entry 21.02 23.02

249 2922 -100 Pneumatic Control Entry 28.04 04.05

250 2940 Piping Terminal Equipment Entry 10.02 30.06

251 2940 -026 Piping LP Hydraulic 25.02 03.06

252 2940 -027 Piping lubrication 10.02

253 2940 -028 Piping cooling water 11.02 24.02

254 2940 -029 Piping Pneumatic 05.05 20.06

255 Cleaning Hydraulic Pipe System Entry 01.06 21.06

256 Functiontest per Hand 22.06 30.06

257 FURNACE and COOLING SECTION 01.02 09.08

258 setup site facilities 01.02 02.02

259 inspection alignment of encasted foundation steel 03.02 06.02

260 installation of handrails on +8.2m level 03.02 16.02

261 installation of staircases to +8.2m level 17.02 02.03

262 Erection Furnace 08.02 02.08

263 Chamber #1 08.02 16.02

264 installation section A chamber #1 08.02 08.02

265 installation section B chamber #1 09.02 09.02

266 installation section C chamber #1 10.02 10.02

267 welding + alignment of chamber #1 11.02 16.02

268 Chamber #2 17.02 06.03

269 installation section A chamber #2 17.02 17.02

270 installation section B chamber #2 18.02 18.02

271 installation section C chamber #2 20.02 20.02

272 welding + alignment of chamber #2 21.02 25.02

273 Install lower burners #2 27.02 27.02

274 Assembly of walkway #2 28.02 04.03

275 Install upper burners #2 06.03 06.03

276 Chamber #3 27.02 11.03

277 installation section A chamber #3 27.02 27.02

278 installation section B chamber #3 28.02 28.02

279 welding + alignment of chamber #3 01.03 03.03

280 Install lower burners #3 04.03 04.03

2016-06-20 Page 5 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

281 Assembly of walkway #3 06.03 10.03

282 Install upper burners #3 11.03 11.03

283 Chamber #4 04.03 18.03

284 installation section A chamber #4 04.03 04.03

285 installation section B chamber #4 06.03 06.03

286 welding + alignment of chamber #4 07.03 10.03

287 Install lower burners #4 11.03 11.03

288 Assembly of walkways #4 13.03 17.03

289 Install upper burners #4 18.03 18.03

290 instal. Rails between chambers 20.03 30.03

291 Furnace insulation (by refractory contractor) 18.02 22.05

292 Chamber 1 18.02 28.03

293 Floor; corner bricks #1 18.02 20.02

294 Wall; installation blocks, board and bricks #1 20.02 25.02

295 Wall; installation anchors and ramming material #1 27.02 07.03

296 Prepare roof for concrete pooring #1 08.03 11.03

297 Roof; concrete pooring layer 1 #1 13.03 14.03

298 Roof; concrete pooring layer 2 #1 15.03 16.03

299 Roof; concrete pooring layer 3 #1 17.03 18.03

300 Removal of roof supports #1 20.03 20.03

301 Floor; installation of board #1 21.03 23.03

302 Floor; installation of bricks 3 layers #1 24.03 28.03

303 Chamber 2 08.03 14.04

304 Floor; corner bricks #2 08.03 09.03

305 Wall; installation blocks, board and bricks #2 09.03 15.03

306 Wall; installation anchors and ramming material #2 16.03 24.03

307 Prepare roof for concrete pooring #2 25.03 29.03

308 Roof; concrete pooring layer 1 #2 30.03 31.03

309 Roof; concrete pooring layer 2 #2 01.04 03.04

310 Roof; concrete pooring layer 3 #2 04.04 05.04

311 Removal of roof supports #2 06.04 06.04

312 Floor; installation of board #2 07.04 10.04

313 Floor; installation of bricks 2 layers #2 11.04 14.04

314 Chamber 3 25.03 02.05

315 Floor; corner bricks #3 25.03 27.03

316 Wall; installation blocks, board and bricks #3 27.03 01.04

317 Wall; installation anchors and ramming material #3 03.04 11.04

318 Prepare roof for concrete pooring #3 12.04 15.04

319 Roof; concrete pooring layer 1 #3 17.04 18.04

320 Roof; concrete pooring layer 2 #3 19.04 20.04

321 Roof; concrete pooring layer 3 #3 21.04 22.04

322 Removal of roof supports #3 24.04 24.04

323 Floor; installation of board #3 25.04 27.04

324 Floor; installation of bricks 3 layers #3 28.04 02.05

325 Chamber 4 13.04 22.05

326 Floor; corner bricks #4 13.04 14.04

327 Wall; installation blocks, board and bricks #4 15.04 21.04

328 Wall; installation anchors and ramming material #4 22.04 01.05

329 Prepare roof for concrete pooring #4 02.05 05.05

330 Roof; concrete pooring layer 1 #4 06.05 08.05

331 Roof; concrete pooring layer 2 #4 09.05 10.05

332 Roof; concrete pooring layer 3 #4 11.05 12.05

333 Removal of roof supports #4 13.05 13.05

334 Floor; installation of board #4 15.05 17.05

335 Floor; installation of bricks 3 layers #4 18.05 22.05

336 Instal. Temporary gaspipe for dy-out 15.05 24.05

2016-06-20 Page 6 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

337 Pre-dry-out sequence (by refractory contractor) 01.06 01.08

338 Gas available (by ACX) 01.06

339 Chamber 1 03.07 17.07

340 Set up dry-out equipment 03.07 03.07

341 dry-out 04.07 10.07

342 cooldown 11.07 17.07

343 Chamber 2 01.06 15.06

344 Set up dry-out equipment 01.06 01.06

345 dry-out 02.06 08.06

346 cooldown 09.06 15.06

347 Chamber 3 18.07 01.08

348 Set up dry-out equipment 18.07 18.07

349 dry-out 19.07 25.07

350 cooldown 26.07 01.08

351 Chamber 4 17.06 01.07

352 Set up dry-out equipment 17.06 17.06

353 dry-out 19.06 24.06

354 cooldown 26.06 01.07

355 Remove temporary gaspipe 02.08 02.08

356 Installation other equipment 03.04 09.08

357 insulation of hot air duct (by refractory contractor) 03.04 15.04

358 insulation flue gas exhaust ducts (by refractory contractor) 17.04 27.04

359 instal. Flue gas exhaust ducts to flue gas fan 01.05 13.05

360 instal. of flue gas exhaust fan 15.05 16.05

361 instal. of flue gas stack 17.06 20.06

362 install. of ducting between flue gas fan / stack 21.06 22.06

363 Install. Recuperator and welding 15.05 18.05

364 install. of carousels and alignment (3 pcs.) 03.08 09.08

365 install. of Hot Air ducts and supports 19.05 30.05

366 install. of dilution air duct 23.06 24.06

367 install. of cold comb. air ducting incl. Supports 26.06 29.06

368 installation of hot air piping incl. Supports 05.06 17.06

369 external insulation Hot Air piping 13.06 29.06

370 installation of threading coilers + system 01.06 06.06

371 install of gasstation 01.06 01.06

372 install. gas piping 02.06 15.06

373 leaktest gaspiping 16.06 17.06

374 install. of strip retraction cooler 07.06 08.06

375 Install. Cooling water stations 08.05 09.05

376 Install. Roll cooling water 10.05 23.05

377 Install. lift roll unit + exit doors 03.07 05.07

378 install. drainpipe under platform 24.05 08.06

379 install. emergency cooling piping near cooling exit 12.06 20.06

380 Erection Cooling section 31.03 30.06

381 Floatation cooling 31.03 30.06

382 Assembly of hot floatation cooling section 31.03 11.04

383 Insulation of hot floatation cooling section 12.04 22.04

384 install. Hot floatation cooling section 24.04 26.04

385 install floatation cooling section 27.04 27.05

386 install sound insulation floatation cooling 29.05 13.06

387 erection floatation exhaust stack 14.06 15.06

388 install floatation cool exhaust fans 2x 16.06 19.06

389 install ducting between fans and stack 20.06 30.06

390 install ducting between inlet and floatation cooling unit 29.05 10.06

391 Terminal Equipment between furnace and pickling sections 11.02 30.06

392 2990 Pin Hole Detector No. 1 Entry 03.06 05.06

2016-06-20 Page 7 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

393 3081 -100 Steering Roll No. 5 17.02 21.02

394 3081 -980 Strip position control No. 5 22.02 22.02

395 3085 -020 Drive for Bridle No.3.1 27.02 02.03

396 3085 -100 Bridle No. 3.1 22.02 25.02

397 3090 -020 Drive for Bridle No.3.2 03.03 07.03

398 3090 -100 Bridle No. 3.2 27.02 02.03

399 5881 -100 Steering Roll No. 6 02.03 06.03

400 5881 -980 Strip Position Control No. 6 07.03 07.03

401 5884 -020 Drive for Bridle No.4 18.05 22.05

402 5884 -100 Bridle No. 4 13.05 17.05

403 5905 Dismounting Devices Treatment 10.06 30.06

404 5910 -910 Hydraulic Control Pickling Exit 11.02 14.02

405 5980 Tension Measuring Device No. 1 Treatment 02.06 03.06

406 5981 Tension Measuring Device No. 2 Treatment 05.06 06.06

407 5982 Tension Measuring Device No. 3 Treatment 03.03 04.03

408 5990 Pin Hole Detector No. 2 Treatment 07.06 08.06

409 5991 Pin Hole Detector No. 3 Treatment 06.03 07.03

410 Pickling Section 02.02 30.06

411 1515-200 Steel Structure for Pickling Section 08.02 08.03

412 4030 ULTRASONIC GRAIN SIZE MEASURING SYSTEM 09.05 17.05

413 -110 TANK FOR GRAIN SIZE MEASURING SYSTEM 09.05 10.05

414 -200 DEFLECTOR ROLL 11.05 12.05

415 -221 DEFLECTOR ROLL WITH SQUEEZE ROLL 13.05 15.05

416 -300 DRIVE FOR DEFLECTOR ROLL 16.05 16.05

417 -310 DRIVE FOR DEFLECTOR ROLL / SQUEEZE ROLL 17.05 17.05

418 4050 CIRCULATION GRAIN SIZE MEASUREMENT 18.05 26.05

419 -410 PUMP FOR GRAIN SIZE MEASURING 18.05 19.05

420 -510 HEAT EXCHANGER GRAIN SIZE MEASURING 20.05 20.05

421 PIPING SYSTEM 22.05 26.05

422 4210 ELECTROLYTIC PICKLING SECT. NA2SO4 09.03 15.06

423 -110 PICKLING TANK 09.03 22.03

424 WELDING JOINTS 21.03 03.04

425 RUBBER LINING JOINTS 01.04 17.04

426 -120 BRICK LINING 14.04 12.05

427 -130 COVER 17.05 25.05

428 -135 COVER LIFTING DEVICE 04.04 12.04

429 -140 BUILT IN PARTS 13.05 18.05

430 -150 ANODES 19.05 01.06

431 -155 CATHODES 02.06 15.06

432 -221 SQUEEZE ROLL SET 02.05 05.05

433 -222 SQUEEZE ROLL WITH EARTHING ROLL 06.05 09.05

434 -224 SEALING ROLL SET 10.05 12.05

435 -227 SUPPORT ROLL SET 13.05 16.05

436 -321 DRIVE SQUEEZE ROLL SET 06.05 09.05

437 -322 DRIVE SQUEEZE ROLL WITH EARTHING ROLL 10.05 11.05

438 -324 DRIVE SEALING ROLL SET 13.05 15.05

439 -327 DRIVE SUPPORT ROLL SET 17.05 18.05

440 4250 CIRCULATION ELECTROL. PICK. SECT. NA2SO4 23.03 28.06

441 -410 PUMP FOR ELECTROLYT PICK. NEOLYTE 23.03 24.03

442 -480 SUMP PUMP ELECTROLYT. PICK. NEOLYT 28.03 29.03

443 -481 FRAME SUMP PUMP 25.03 27.03

444 -510 HEAT EXCHANGERS E. PICKL. 30.03 31.03

445 -511 FRAME HEAT EXCHANGER 28.03 29.03

446 -520 HEAT EXCHANGERS E. PICKL. 04.04 05.04

447 -521 FRAME HEAT EXCHANGER 01.04 03.04

448 -610 CIRCULATION TANK 1 06.04 07.04

2016-06-20 Page 8 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

449 -620 CIRCULATION TANK 2 08.04 10.04

450 -630 CIRCULATION TANK 3 11.04 12.04

451 -640 CIRCULATION TANK 4 13.04 14.04

452 -680 TANK FOR SUMP 15.04 17.04

453 -900 PIPING SYSTEM ELECTROLYTIC P.S. 25.03 28.06

454 4286 CIRCULATION RECTIFIER 18.04 27.04

455 -410 PUMP FOR RECTIFIER COOLING 18.04 19.04

456 -510 HEAT EXCHANGER FOR RECTIFIER COOLING 20.04 20.04

457 -510 TANK FOR RECTIFIER COOLING 21.04 21.04

458 -900 PIPING SYSTEM 22.04 27.04

459 4300 RINSE AFTER ELECTROL. PICKL. SECT. 23.03 19.04

460 4320, 4330 SCRUB BRUSH MACHINE NO.3 + 4 complete 23.03 05.04

461 -300 DRIVE SCRUB BRUSH MACHINE 06.04 08.04

462 -221 SQUEEZE ROLL SET 10.04 15.04

463 -331 DRIVE SQUEEZE ROLL SET 17.04 19.04

464 4350 CIRCULATION RINSE SCBM NO.3+4 25.03 19.05

465 -410 PUMP FOR RINSE AND SCBM 25.03 27.03

466 -610 CIRCULATION TANK 1 28.03 29.03

467 -620 CIRCULATION TANK 2 30.03 30.03

468 -630 CIRCULATION TANK 3 31.03 31.03

469 -900 PIPING SYSTEM SCBM NO.3+4 28.04 19.05

470 4410 ELECTROLYTIC PICKLING SECT. WITH HNO3 20.04 13.06

471 -110 PICKLING TANK 20.04 24.04

472 PP-WELDING HNO3 PICKLING TANKS 22.04 01.05

473 -130 COVER 04.05 12.05

474 -135 COVER LIFTING DEVICE 25.04 03.05

475 -140 BUILT IN PARTS 25.04 29.04

476 -150 ANODES 01.05 13.05

477 -155 CATHODES 15.05 27.05

478 -221 SQUEEZE ROLL SET 29.05 31.05

479 -222 SQUEEZE ROLL WITH EARTHING ROLL 01.06 03.06

480 -224 SEALING ROLL SET 05.06 07.06

481 -227 SUPPORT ROLL SET 08.06 10.06

482 -321 DRIVE SQUEEZE ROLL SET 01.06 02.06

483 -322 DRIVE SQUEEZE ROLL WITH EARTHING ROLL 05.06 06.06

484 -324 DRIVE SEALING ROLL SET 08.06 09.06

485 -327 DRIVE SUPPORT ROLL 12.06 13.06

486 4450 CIRCULATION ELECTR. P. S. NITRIC ACID 01.04 16.06

487 -410 PUMP FOR ELECTROLYT PICK. NITRIC 01.04 03.04

488 -510 HEAT EXCHANGER E. PICKL. NITRIC 06.04 07.04

489 -511 FRAME HEAT EXCHANGER 04.04 05.04

490 -610 CIRCULATION TANK ELECTR. P. S. NITRIC 08.04 10.04

491 -620 CIRCULATION TANK ELECTR. P. S. NITRIC 11.04 12.04

492 -900 PIPING SYSTEM ELECTROLYTIC P.S. HNO3 02.05 16.06

493 4610 MIXED ACID PICKLING SECTION NO.1 09.03 03.05

494 -110 PICKLING TANK MIXED ACID 09.03 27.03

495 PP-WELDING MIXED ACID PICKLING TANKS 24.03 11.04

496 -130 COVER 18.04 28.04

497 -135 COVER LIFTING DEVICE 12.04 17.04

498 -140 BUILT IN PARTS 12.04 17.04

499 -221 SQUEEZE ROLL SET 18.04 22.04

500 -228 IMMERSION ROLL 24.04 28.04

501 -321 DRIVE SQUEEZE ROLL SET 24.04 28.04

502 -328 DRIVE IMMERSION ROLL 29.04 03.05

503 4615 STRIP CENTERING DEVICE 18.04 21.04

504 -100 STRIP CENTERING DEVICE 18.04 21.04

2016-06-20 Page 9 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

505 4650 CIRCULATION SYSTEM MIXED ACID SYSTEM NO.1 + 2 02.02 30.06

506 -410 PUMP FOR MIXED ACID 13.04 17.04

507 -480 SUMP PUMP MIXED ACID 20.04 21.04

508 -481 FRAME SUMP PUMP 18.04 19.04

509 -485 SUMP PUMP PNEUMATIC 22.04 24.04

510 -510 HEAT EXCHANGER NO.5 + 6 MIXED ACID 24.04 27.04

511 -511 FRAME HEAT EXCHANGER 20.04 22.04

512 -610 CIRCULATION TANK NO.1 MIXED ACID 28.04 29.04

513 -620 CIRCULATION TANK NO.2 MIXED ACID 01.05 02.05

514 -630 CIRCULATION TANK NO.3 MIXED ACID 03.05 04.05

515 -640 CIRCULATION TANK NO.4 MIXED ACID 05.05 06.05

516 -650 CIRCULATION TANK NO.5 MIXED ACID 08.05 09.05

517 -660 CIRCULATION TANK NO.6 MIXED ACID 10.05 11.05

518 -680 TANK FOR SUMP (CL03) 12.05 13.05

519 -900 PIPING SYSTEM MIXED ACID P.S. NO.1 + 2 02.02 30.06

520 4800 FINALE RINSE 04.05 31.05

521 4820, 4830 SCRUB BRUSH MACHINE NO.5 + 6 complete 04.05 17.05

522 -300 DRIVE SCRUB BRUSH MACHINE 18.05 20.05

523 -221 SQUEEZE ROLL SET 22.05 27.05

524 -331 DRIVE SQUEEZE ROLL SET 29.05 31.05

525 4850 CIRCULATION RINSE SCBM NO.5+6 15.05 30.06

526 -410 PUMP FOR RINSE AND SCBM 15.05 16.05

527 -610 CIRCULATION TANK 1 17.05 18.05

528 -620 CIRCULATION TANK 2 19.05 19.05

529 -620 CIRCULATION TANK 3 20.05 20.05

530 -900 PIPING SYSTEM SCBM NO.3+4 08.06 30.06

531 STRIP DRYING AFTER FINAL RINSE 01.06 27.06

532 4870 EDGE BLOW OFF COMPLETE 01.06 03.06

533 -100 EDGE BLOW-OFF DEVICE 01.06 03.06

534 4875 STRIP DRIER COMPL. 05.06 12.06

535 -100 HOUSING STRIP DRIER 05.06 09.06

536 -200 SUPPORT ROLL SET STRIP DRIER 10.06 12.06

537 4877 CIRCULATION STRIP DRIER 10.06 27.06

538 -110 DUCTWORK STRIP DRIER 16.06 27.06

539 -450 FAN STRIP DRIER 12.06 13.06

540 -451 FRAME FAN STRIP DRIER 10.06 10.06

541 -510 AIR HEATER STRIP DRIER 14.06 15.06

542 4930 EXHAUST SYSTEM NO.2 (NEOLYTE) 26.05 29.06

543 -110 DUCTWORK EXHAUST SYSTEM NO.2 26.05 29.06

544 -120 STACK EXHAUST SYSTEM NO.2 31.05 10.06

545 -450 FAN EXHAUST SYSTEM NO.2 14.06 16.06

546 -451 FRAME FOR FAN EXHAUST SYSTEM NO.2 12.06 13.06

547 -810 DROP SEPARATOR BEFORE FAN 17.06 20.06

548 -820 DROP SEPARATOR AFTER FAN 21.06 23.06

549 4940 EXHAUST SYSTEM NO.3 15.04 23.06

550 -110 DUCTWORK EXHAUST SYSTEM NO.3 15.04 12.06

551 -120 STACK EXHAUST SYSTEM NO.3 12.06 22.06

552 -450 FAN EXHAUST SYSTEM NO.3 16.06 19.06

553 -451 FRAME FOR FAN EXHAUST SYSTEM NO.3 14.06 15.06

554 -610 GAS SCRUBBER 20.06 22.06

555 -810 DROP SEPARATOR BEFORE FAN 20.06 21.06

556 -820 DROP SEPARATOR AFTER FAN 22.06 23.06

557 4945 CIRCULATION EXHAUST SYSTEM NO.3 23.06 28.06

558 -410 PUMP GAS SCRUBBER 23.06 24.06

559 -420 DOSING PUMP NAOH 26.06 26.06

560 -620 TANK NAOH 27.06 28.06

2016-06-20 Page 10 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

561 4950 CIRCULATION STEAM, WATER CONDENSATE 04.05 30.06

562 -410 PUMP FOR CONDENSATE 29.06 30.06

563 -610 TANK - CONDENSATE 23.06 24.06

564 -900 PIPING SYSTEM UTILITY PIPING (STEAM,...) 04.05 30.06

565 -950 PIPE SUPPORTS AND DUCT SUPPORTS 04.05 30.06

566 NEOLYTE RECOVERY 11.02 30.06

567 1515-300 Steel Structure for Neolyte Recovery 11.02 24.02

568 5511 REACTION 18.04 04.05

569 -510 COOLER REACTION TANK 18.04 20.04

570 -610 REACTION TANK 21.04 24.04

571 -620 REDUCTION TANK CR6+ 25.04 27.04

572 -710 AGITATOR REACTION TANK 28.04 01.05

573 -720 AGITATOR REDUCTION TANK Cr6+ 02.05 04.05

574 5533 SLUDGE TREATMENT 05.05 06.05

575 -610 STORAGE TANK FOR FILTER PRESS 05.05 06.05

576 5541 FILTER PRESS 05.05 27.05

577 -100 FILTER PRESS 13.05 24.05

578 -110 FUNNEL F. FILTER PRESS 08.05 12.05

579 -410 PUMP FILTERPRESS 05.05 06.05

580 -610 CONTAINER FOR FILTERCAKE 25.05 27.05

581 5562 PREPARATION NAHSO3 28.04 05.05

582 -510 HEAT EXCHANGER 28.04 29.04

583 -610 PREPARATION TANK NaHSO3 01.05 03.05

584 -710 AGITATOR NaHSO3 PREPARATION TANK 04.05 05.05

585 5563 PREPARATION NAOH 06.05 12.05

586 -510 HEAT EXCHANGER 06.05 08.05

587 -610 PREPARATION TANK NaOH 09.05 10.05

588 -710 AGITATOR NaOH PREPARATION TANK 11.05 12.05

589 5564 PREPARATION H2SO4 11.05 12.05

590 -410 DOSING TANK H2SO4 11.05 12.05

591 5571 STORAGE OF FILTRATE 13.05 17.05

592 -410 PUMP FOR TRANSFER FILTRATE 13.05 15.05

593 -610 TANK FOR FILTRATE 16.05 17.05

594 5580 SUMP NEOLYTE RECOVERY (CL05) 18.05 24.05

595 -480 SUMP PUMP 19.05 20.05

596 -481 FRAME FOR SUMP PUMPS 18.05 18.05

597 -485 SUMP PUMP PNEUMATIC 22.05 22.05

598 -680 TANK FOR SUMP (CL05) 23.05 24.05

599 5590 PIPING 03.04 30.06

600 -900 PIPING 03.04 30.06

601 -950 PIPE SUPPORTS 03.04 30.06

602 5600 DENOX 02.06 30.06

603 5611 DENOX 05.06 21.06

604 -900 PIPING NH3, PRE-HEATING 02.06 30.06

605 5700 TANK FARM 15.04 06.06

606 5721-610 STORAGE TANK FRESH HNO3 FOR PICKLING S. 15.04 17.04

607 5722-610 STORAGE TANK FRESH HF FOR PICKLING S. 18.04 19.04

608 5713-610 STORAGE TANK REG. MIXED ACID 20.04 21.04

609 5714-610 STORAGE WASTE MIXED ACID 22.04 24.04

610 5724-610 STORAGE WASTE H2SO4 25.04 26.04

611 5721-410 TRANSFER PUMP FOR HNO3 27.04 27.04

612 5722-410 TRANSFER PUMP FOR HF 28.04 28.04

613 5713-410 TRANSFER PUMP FOR REGENERATED MIXED ACID 29.04 29.04

614 5714-410 TRANSFER PUMP FOR WASTE MIXED ACID 01.05 01.05

615 5724-410 TRANSFER PUMP FOR H2SO4 02.05 02.05

616 5780 SUMP ACID STORAGE (CL06) 03.05 09.05

2016-06-20 Page 11 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

617 -480 SUMP PUMP 04.05 05.05

618 -481 FRAME FOR SUMP PUMPS 03.05 03.05

619 -485 SUMP PUMP PNEUMATIC 06.05 06.05

620 -680 TANK FOR SUMP (CL05) 08.05 09.05

621 PIPING CIRCULATION TANK FARM 03.05 06.06

622 PIPING GENERAL 09.03 30.06

623 ACID PIPING 30.03 30.06

624 INTERCONNECTING PIPING 30.03 30.06

625 STEEL PIPING 30.03 30.06

626 INTERCONNECTION PIPING 30.03 30.06

627 Gas piping 13.04 30.06

628 Gas piping 13.04 04.05

629 pipe support 17.04 04.05

630 Interconnecting piping 04.05 30.06

631 5920 Pneumatic pickling section 17.03 06.05

632 valve stands pneumatic 17.03 24.03

633 piping pneumatic 25.03 06.05

634 5910 Hydraulic pickling section 09.03 22.05

635 valve stands hydraulic 09.03 16.03

636 piping hydraulic 06.04 22.05

637 6020 Looper Exit 25.03 23.06

638 6020 -020 Exit looper drive 10.06 16.06

639 6020 -021 Rails 25.03 14.04

640 6020 -040 Exit looper car 29.04 05.05

641 6020 -043 Power Rails 27.05 09.06

642 6020 -045 Exit looper strip support rolls 15.04 28.04

643 6020 -046 Exit looper folding doors, 7 pairs 29.04 26.05

644 6020 -047 Car return winch 17.06 23.06

645 6020 -048 Steering Roll No. 7 06.05 09.05

646 6020 -049 Steering Roll No. 8 10.05 12.05

647 6020 -980 Strip Position Control 06.05 06.05

648 6020 -981 Strip Position Control 08.05 08.05

649 6020 -982 Strip Position Control 09.05 09.05

650 6020 -983 Strip Position Control No. 7 10.05 10.05

651 6020 -984 Strip Position Control No. 8 13.05 13.05

652 6035 -100 Steering Roll No. 9 18.05 20.05

653 6035 -980 Strip Position Control No.9 22.05 22.05

654 6068 Deflector Roll No. 2 22.05 24.05

655 6070 -020 Drive for Bridle No.5.1 30.05 02.06

656 6070 -100 Bridle No. 5.1 25.05 29.05

657 6075 -020 Drive for Bridle No.5.2 03.06 07.06

658 6075 -100 Bridle No. 5.2 30.05 02.06

659 4-High Mill 11.02 17.05

660 1124 -026 Safety fence 02.05 08.05

661 1517 -032 Steel Structure Mill Exit 18.04 24.04

662 6150 Platform 25.04 01.05

663 6160 -100 Shapemetre roll 28.03 29.03

664 6180 Mill Table RH 18.03 24.03

665 6180 -026 Mill Table 18.03 20.03

666 6180 -029 Deflector Roll 23.03 24.03

667 6180 -039 Passline Roll 21.03 22.03

668 6180 Mill Table LH 25.03 31.03

669 6181 -026 Mill Table 25.03 27.03

670 6181 -029 Deflector Roll 30.03 31.03

671 6180 -039 Passline Roll 28.03 29.03

672 6200 Rolling Mill 20.02 17.04

2016-06-20 Page 12 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

673 -020 Gear box 02.03 04.03

674 -021 Drive Line 06.03 08.03

675 -026 Mill Housing 27.02 01.03

676 -027 Roll Arrangement 02.03 04.03

677 -028 Work Roll 17.04 17.04

678 -030 Back up Roll 15.04 15.04

679 -033 Passline Adjustment 09.03 09.03

680 -034 Hydraulic Adjustment 01.03

681 -036 Holding Claws 01.03

682 -037 Roll Coupling Clamping 24.03 27.03

683 -042 Roll Retracting Device 06.03 08.03

684 -046 Base Plate 20.02 25.02

685 -047 CL-Guiding Plate 14.03 15.03

686 -048 Roll Cleaning Device 16.03 17.03

687 -049 Anti Crimping Roll 10.03 13.03

688 -051 Dust Exhaust System 18.03 31.03

689 6280 -010 Roll changing device 06.03 14.03

690 -026 Roll Changing Car 15.03 23.03

691 6375 Fire Extinguishing System 01.04 14.04

692 6390 Masroll 28.03 30.03

693 Erection Piping 11.02 17.05

694 6952 Hydraulic Unit HP 11.02 14.02

695 6912 Hydraulic Contol 15.02 16.02

696 6953 Hydraulic Contol HP 17.02 18.02

697 6922 Pneumatic Contol 20.02 21.02

698 6955 Scheme CL Supply System 22.02 24.02

699 6966 Spraying System 25.02 28.02

700 6941 -026 Pipinig LP Hydraulic 17.02 23.03

701 -027 Piping HP Hydraulic 24.03 27.04

702 -028 Piping Cooling Water 21.04 27.04

703 -029 Piping Pneumatic 24.03 20.04

704 -030 Piping Grease Lubrication 06.03 18.03

705 Flushing 28.04 09.05

706 Functiontest per Hand 10.05 17.05

707 6972 Dust Exhaust System 01.04 21.04

708 -026 Blowing and Exhaust Aggregates 01.04 07.04

709 -100 Exhaust System 08.04 21.04

710 6973 Strip Drier 31.03 06.04

711 6400 RINSE AFTER TL and strip drier 08.02 09.05

712 Steel Structure for rinsing Section 08.02 11.02

713 6420 RINSING SECTION 13.02 02.03

714 -100 CASING 13.02 18.02

715 -221 SQUEEZE ROLL SET 20.02 25.02

716 -321 DRIVE SQUEEZE ROLL SET 27.02 02.03

717 6430 CIRCULATION RINSE AFTER MILL 03.03 21.03

718 -410 PUMPS RINSE AFTER MILL 03.03 03.03

719 -480 SUMP PUMP RINSE AFTER MILL 06.03 07.03

720 -482 FRAME SUMP PUMP 04.03 04.03

721 -485 SUMP PUMP PNEUMATIC 08.03 08.03

722 -680 TANK FOR SUMP (CL04) 09.03 09.03

723 -901 PIPING RINSE AFTER MILL 10.03 21.03

724 -950 PIPE SUPPORTS 10.03 21.03

725 6440 EDGE BLOW OFF COMPLETE 03.03 06.03

726 -100 EDGE BLOW-OFF DEVICE 03.03 06.03

727 6475 STRIP DRIER COMPL. 07.03 13.03

728 -100 HOUSING STRIP DRIER 07.03 10.03

2016-06-20 Page 13 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

729 -200 SUPPORT ROLL SET STRIP DRIER 11.03 13.03

730 6475 CIRCULATION STRIP DRIER 11.03 28.03

731 -110 DUCTWORK STRIP DRIER 11.03 28.03

732 -450 FAN STRIP DRIER 13.03 14.03

733 -451 FRAME FAN STRIP DRIER 11.03 11.03

734 -510 AIR HEATER STRIP DRIER 15.03 16.03

735 6492 PNEUMATIC SYSTEM 17.03 14.04

736 -900 PIPING SYSTEM PNEUMATIC 23.03 14.04

737 -910 VALVE STANDS PNEUMATIC 17.03 22.03

738 6495 EXHAUST SYSTEM NO.4 13.03 09.05

739 -110 DUCTWORK EXHAUST SYSTEM 18.03 27.04

740 -120 STACK EXHAUST SYSTEM 28.04 09.05

741 -450 FAN EXHAUST SYSTEM 15.03 17.03

742 -451 FRAME FAN EXHAUST SYSTEM 13.03 14.03

743 -810 DROP SEPARATOR AFTER FAN 15.03 17.03

744 Terminal Equipment 4 High and Tension Leveller Area 02.03 26.05

745 6402 -020 Drive for Bridle No.6 07.03 10.03

746 -100 Bridle No. 6 02.03 06.03

747 6410 -100 Tension Leveller 07.03 10.03

748 -026 Bending Cartridge 24.03 24.03

749 -027 Leveling Cartridge 24.03 24.03

750 -028 Spraying Equipment 11.03 17.03

751 6415 -021 Rail for Cassette Changing Device 11.03 17.03

752 6415 -100 Cassette Changing Device 18.03 21.03

753 6416 Cassette Turing Device 22.03 23.03

754 6450 -020 Drive for Bridle No.7.1 16.03 20.03

755 -100 Bridle No. 7.1 11.03 15.03

756 6453 -020 Drive for Bridle No.7.2 21.03 24.03

757 -100 Bridle No. 7.2 16.03 20.03

758 6458 -020 Drive for Bridle No.7.3 25.03 29.03

759 -100 Bridle No. 7.3 21.03 24.03

760 6460 Creep Looper 25.03 25.04

761 6460 -020 Creep looper drive 19.04 25.04

762 6460 -021 Rails for creep looper 25.03 07.04

763 6460 -040 Creep looper car 15.04 18.04

764 6460 -045 creep looper strip support rolls 08.04 14.04

765 6475 -100 Steering Roll No. 10 19.04 21.04

766 6475 -980 Strip Position Control No. 10 22.04 24.04

767 6500 -100 Steering Roll No. 11 25.04 28.04

768 -980 Strip Position Control No. 11 29.04 29.04

769 6543 Edge Trimmer 19.04 02.05

770 -030 Edge Scrap Guide Channel 26.04 28.04

771 6543 -031 Antiflutter Roll for Edge Trimmer 29.04 02.05

772 -100 Edge Trimmer 19.04 25.04

773 6545 -100 Scrap Winder 26.04 02.05

774 6545 -020 Drive for Scrap Baller 03.05 05.05

775 6554 Scrap Removal Equipment 06.05 26.05

776 -021 Rails 06.05 12.05

777 6554 -058 scrap box no. 3 13.05 19.05

778 6554 -100 scrap disposal system/ chute 20.05 26.05

779 Exit Area No 1 11.02 07.06

780 6560 -020 Drive for Bridle No.8 08.05 11.05

781 -100 Bridle No. 8 03.05 06.05

782 6561 Inspection Stand 08.05 13.05

783 6562 Deflector Roll No. 6 08.05 10.05

784 6563 Deflector Roll No. 7 11.05 13.05

2016-06-20 Page 14 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

785 6564 Deflector Roll No. 8 15.05 17.05

786 6565 -100 Auxiliary Pinch Roll Unit No. 3 18.05 20.05

787 -020 Drive Aux. Pinch Roll No. 3 22.05 24.05

788 6568 -100 Excentre Shear 22.05 24.05

789 -020 Drive Excentre Shear 25.05 27.05

790 6571 swiveling table no. 3 25.05 27.05

791 6575 Scrap Removal System No. 3 26.04 25.05

792 6575 -021 rails for scrap disposal 26.04 09.05

793 6575 -058 Scrap box 24.05 25.05

794 6575 -100 Scrap removal system, blade type 10.05 23.05

795 6598 Strip Transfer Table 29.05 31.05

796 6610 -100 Strip threading device No.1 01.06 03.06

797 -020 Drive Strip Threading Device No. 1 05.06 07.06

798 6620 -100 Recoiler No. 1 25.02 03.03

799 6620 -980 Strip Position Control 04.03 04.03

800 6628 Outboard bearing no. 3 04.03 07.03

801 6630 Double Paper unwinder No. 1 03.05 09.05

802 6632 Paper Coil Handling No. 1 10.05 30.05

803 -026 Jib Crane 24.05 30.05

804 -027 Paper Coil Storage 10.05 16.05

805 -100 Paper Coil Handling 17.05 23.05

806 6634 Sleeve Loading Unit 21.03 23.03

807 6635 Sleeve Storage 18.03 20.03

808 6640 belt wrapper no.1 08.03 14.03

809 6650 Exit Coil Car No. 1 18.02 03.03

810 6650 -021 Rails for Coil Car No.3 18.02 24.02

811 6650 -100 Coil Car No.3, L type 25.02 03.03

812 6655 Coil Storage Skid No.3, 3 places 04.03 10.03

813 6670 -100 weighing station for coil scale no.1 11.02 14.02

814 6670 -026 frame for coil scale no.1 15.02 17.02

815 6672 Strapping Device No. 1 11.03 17.03

816 6705 Belt Conveyor 26.04 02.05

817 Exit Area No 2 04.03 10.06

818 6710 -100 Strip threading device No. 2 03.05 05.05

819 6710 -020 drive for strip threading device no.1 06.05 09.05

820 6720 -100 Recoiler No. 2 25.03 31.03

821 -980 Strip Position Control 06.05 06.05

822 6728 Outboard Bearing No. 2 01.04 04.04

823 6730 Double Paper unwinder no.2 15.05 20.05

824 6732 Paper Coil Handling No. 2 22.05 10.06

825 -026 Jib Crane 05.06 10.06

826 -027 Paper Coil Storage 22.05 27.05

827 -100 Paper Coil Handling 29.05 03.06

828 6734 Sleeve Unloading Unit 04.04 06.04

829 6735 Sleeve Storage 01.04 03.04

830 6740 Belt wrapper no.2 05.04 11.04

831 6750 Exit Coil Car No. 2 11.03 24.03

832 6750 -021 Rail for Coil Car No.4 11.03 17.03

833 6750 -100 Coil Car No.4, L type 18.03 24.03

834 6755 Coil Storage Skid No.4, 3 places 25.03 31.03

835 6770 -100 Weighing station for coil scale no.2 04.03 07.03

836 6770 -026 Frame for coil scale no.2 08.03 10.03

837 6772 Strapping Device No. 2 01.04 07.04

838 6905 Dismounting Devices Exit 22.05 10.06

839 Hydraulic Exit 21.02 01.07

840 6911 Hydraulic Unit Exit 21.02 23.02

2016-06-20 Page 15 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

841 6912 Hydraulic Control Exit 24.02 27.02

842 6922 Pneumatic System Exit 05.05 10.05

843 6940 Piping Terminal Equipment Exit 24.02 01.07

844 -026 Piping Hydraulic 28.02 06.06

845 -027 Piping Lubrication 28.02

846 -028 Piping Colling Water 24.02 09.03

847 -029 Piping Pneumatic 11.05 14.06

848 Cleaning Hydraulic Pipework 07.06 22.06

849 Functiontest per Hand 23.06 01.07

850 Auxiliary Equipment 11.02 29.05

851 6980 Tension Measuring Device No. 4 Exit 25.05 26.05

852 6981 Tension Measuring Device No. 5 Exit 11.02 13.02

853 6982 Tension Measuring Device No. 6 Exit 14.02 15.02

854 6983 Tension Measuring Device No. 7 Exit 11.03 13.03

855 6984 Tension Measuring Device No. 8 Exit 18.05 19.05

856 6990 Pin Hole Detector No. 4 Exit 27.05 29.05

857 6991 Pin Hole Detector No. 5 Exit 01.05 02.05

858 6992 Pin Hole Detector No. 6 Exit 03.05 04.05

859 Preconditions for electrical installation 31.01 29.03

860 Main building completed 31.01

861 E-Building Entry completed 31.01

862 E-Building Process completed 31.01

863 E-Building Exit completed 31.01

864 Steel structure completed 31.01 06.03

865 Heavy machinery work completed 31.01 29.03

866 ELECTRICAL INSTALLATION CAPL 31.01 10.08

867 CAPL General Electrical Equipment 31.01 10.08

868 Main Cable Trays on Building Columns 31.01 05.05

869 Installation of MV-Switchgear and Transformers 31.01 15.02

870 Installation of MCC Cubicles 31.01 23.02

871 Installation of PLC Cubicles 20.03 04.04

872 Installation of Drive Cubicles 23.02 29.03

873 Installation of RIO Cubicles 24.03 15.04

874 Setup-Up of PLC Network 03.05 26.05

875 Installation of Intercom System 19.06 20.07

876 Installation of ITV System 10.07 10.08

877 CAPL Entry Section - BR 1 (Terminal Equipment) 12.04 05.07

878 Local Control Desks, Panels and Boxes 29.04 02.06

879 Cable Trays and Conduits in Line 12.04 16.05

880 Cabling 06.05 23.06

881 Cable and Wire Checks 24.06 05.07

882 Installation of Terminal Equipment Sensors 11.05 14.06

883 APL Degreasing Section (Process) 02.05 21.06

884 Local Control Desks, Panels and Boxes 02.05 08.05

885 Cable Trays and Conduits in Line 02.05 24.05

886 Cabling 25.05 09.06

887 Cable and Wire Checks 10.06 21.06

888 Installation of Instrumentation and Sensors 13.05 05.06

889 APL Entry Looper 15.05 14.06

890 Local Control Desks, Panels and Boxes 22.05 25.05

891 Cable Trays and Conduits in Line 15.05 10.06

892 Cabling 15.05 27.05

893 Cable and Wire Checks 29.05 02.06

894 Installation of Terminal Equipment Sensors 22.05 29.05

895 Installation of Power and Signal Rails 07.06 14.06

896 APL Furnace and Cooling Section 20.03 08.07

2016-06-20 Page 16 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

ACERINOX EUROPE COLD ANNEALING AND PICKLING LINE

PRELIMINARY ERECTION & COMMISSIONING SCHEDULE

ID WBS-Nr WBS-S.O.Task Name 2017

Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Apr

897 Local Control Desks, Panels and Boxes 23.05 08.07

898 Cable Trays and Conduits in Line 20.03 27.05

899 Chamber 1 - Cabling & Terminations 12.05 25.05

900 Chamber 2, Cabling & Terminations 18.05 31.05

901 Chamber 3, Cabling & Terminations 24.05 06.06

902 Chamber 4, Cabling & Terminations 01.06 14.06

903 Cooling Sctn., Cabling & Terminations 30.05 12.06

904 Cable and Wire Checks 26.05 04.07

905 Installation of Sensors and Instrumentation 28.04 01.06

906 APL Pickling Section 09.03 14.07

907 Local Control Desks, Panels and Boxes 15.04 05.05

908 Cable Trays and Conduits in Line 22.04 13.06

909 Cabling 06.06 23.06

910 Cable and Wire Checks 24.06 14.07

911 Installation of Sensors and Instrumentation 09.03 30.05

912 APL Tension Leveler 19.05 12.06

913 Local Control Desks, Panels and Boxes 19.05 23.05

914 Cable Trays and Conduits in Line 19.05 25.05

915 Cabling 26.05 06.06

916 Cable and Wire Checks 07.06 12.06

917 APL SPM 02.05 28.06

918 Local Control Desks, Panels and Boxes 02.05 09.05

919 Cable Trays and Conduits in Line 18.05 31.05

920 Cabling 01.06 16.06

921 Cable and Wire Checks 17.06 28.06

922 APL Exit Section 19.05 20.07

923 Local Control Desks, Panels and Boxes 24.05 30.05

924 Cable Trays and Conduits in Line 19.05 03.06

925 Cabling 05.06 08.07

926 Cable and Wire Checks 10.07 20.07

927 Installation of Terminal Equipment Sensors 19.05 22.06

928 Commissioning 06.07 01.03

929 IO-Tests 06.07 26.08

930 Functional Tests 15.07 01.11

931 1st Coil 01.11

932 Hot Commissioning 02.11 12.01

933 Proof of Performance Guarantees 16.01 01.03

934 Provisional Reception 01.03

2016-06-20 Page 17 of 17 2016-06-20 ACX-APL5 Installation Time Schedule Rev06.mpp

MERi/EP

Anda mungkin juga menyukai

- Pipeline StandardDokumen50 halamanPipeline Standardsofianina05Belum ada peringkat

- Monthly Cash Flow: Inflows Total AverageDokumen3 halamanMonthly Cash Flow: Inflows Total AverageDahlan MuksinBelum ada peringkat

- Labour Schedule For Sefwi-WiawsoDokumen1 halamanLabour Schedule For Sefwi-WiawsoNana BarimaBelum ada peringkat

- Misfa 2Dokumen28 halamanMisfa 2Delwar HossainBelum ada peringkat

- Submittal Sheet: From: CCDokumen2 halamanSubmittal Sheet: From: CCCaberte JohnnyBelum ada peringkat

- Template (Electrical Works)Dokumen10 halamanTemplate (Electrical Works)Anonymous Qu7LeEBelum ada peringkat

- Rev. F Update 30 Sept 2013Dokumen5 halamanRev. F Update 30 Sept 2013amesbBelum ada peringkat

- 3 - WaterfloodingDokumen68 halaman3 - Waterfloodingpermanahend100% (1)

- 01-Operating Manual For 1200 MTPD Ammonia Plant PDFDokumen315 halaman01-Operating Manual For 1200 MTPD Ammonia Plant PDFAbdulla100% (4)

- ML 07 WeldingDokumen11 halamanML 07 WeldingDeepakBelum ada peringkat

- Lifting - SAMPLE-Method of StatmentDokumen1 halamanLifting - SAMPLE-Method of Statmentsudeesh kumarBelum ada peringkat

- Coiled Tubing Emergency ProceduresDokumen46 halamanCoiled Tubing Emergency Proceduresazareiforoush0% (1)

- Common 1 General Safety Precaution in WeldingDokumen49 halamanCommon 1 General Safety Precaution in WeldingEgghead YTCBelum ada peringkat

- WP 010813Dokumen7 halamanWP 010813Mohammad Syourkam ZakariaBelum ada peringkat

- Overall Pre-Contract Report 2008-6-13Dokumen13 halamanOverall Pre-Contract Report 2008-6-13Daniel EvansBelum ada peringkat

- CC Road A-B-C-D-E WARD - 111CR (12-2-2020 LD) BOQ PDFDokumen15 halamanCC Road A-B-C-D-E WARD - 111CR (12-2-2020 LD) BOQ PDFSwapnil PalavBelum ada peringkat

- Daily Construction ReportDokumen8 halamanDaily Construction ReportkamalalifBelum ada peringkat

- Time Schedule - Aug 8, 2014 PDFDokumen1 halamanTime Schedule - Aug 8, 2014 PDFFikret DavudovBelum ada peringkat

- Solving Gas Plant Operation ProblemsDokumen6 halamanSolving Gas Plant Operation Problemsadeel_jamel100% (1)

- Fundamentals of Enhanced Oil RecoveryDokumen270 halamanFundamentals of Enhanced Oil RecoveryLuis Vallejo EstrellaBelum ada peringkat

- Commissioning of A FurnaceDokumen2 halamanCommissioning of A FurnaceyogacruiseBelum ada peringkat

- Pipelining Liquefied Petroleum GasDokumen8 halamanPipelining Liquefied Petroleum GasSaurabh Sengar100% (1)

- Concrete Pre-Placement Checklist BackupDokumen1 halamanConcrete Pre-Placement Checklist Backuphermano balbonBelum ada peringkat

- Sample Template For Procurement Progress Calculation SheetDokumen10 halamanSample Template For Procurement Progress Calculation SheetAkmal MuliawanBelum ada peringkat

- Air VaporizerDokumen33 halamanAir VaporizerGolfkung Pairoj100% (1)

- Architect & Engineer Instruction Variation OrderDokumen4 halamanArchitect & Engineer Instruction Variation OrderaimiBelum ada peringkat

- 6-BIM Models - (127-131)Dokumen6 halaman6-BIM Models - (127-131)samriddh25Belum ada peringkat

- Daily Report As of 05-03-2022Dokumen82 halamanDaily Report As of 05-03-2022Abd Elrahman AmeenBelum ada peringkat

- 3 Delay Analysis - 25 March 2014Dokumen3 halaman3 Delay Analysis - 25 March 2014Zitheeq UmarBelum ada peringkat

- Daily Program Nov-2011Dokumen19 halamanDaily Program Nov-2011Mahibul HasanBelum ada peringkat

- Type of BoilersDokumen10 halamanType of BoilersZaheer Ahmad Raza100% (1)

- Key Points: EPC4 Weekly Report 22 February 2011 Teamwork at Its HighestDokumen7 halamanKey Points: EPC4 Weekly Report 22 February 2011 Teamwork at Its HighestMarkyBelum ada peringkat

- EXP 12 Molar Mass of A Volatile LiquidDokumen8 halamanEXP 12 Molar Mass of A Volatile LiquidMau TenBelum ada peringkat

- Job Procedure For Hydrotest/Water Fillup Test: 1. ScopeDokumen3 halamanJob Procedure For Hydrotest/Water Fillup Test: 1. ScopeRebecca SchultzBelum ada peringkat

- Coal Based Sponge Iron IndustryDokumen4 halamanCoal Based Sponge Iron IndustrychaitanyabhansaliBelum ada peringkat

- Attachment A - Scope of WorkDokumen12 halamanAttachment A - Scope of WorkJhoBelum ada peringkat

- Jetty Modification - Upd 250417Dokumen86 halamanJetty Modification - Upd 250417Deni Yudha PermanaBelum ada peringkat

- Daily Site Progress ReportDokumen15 halamanDaily Site Progress ReportOmoge Oluwole TemitopeBelum ada peringkat

- CW Pump Station Rev01Dokumen3 halamanCW Pump Station Rev01karna@Belum ada peringkat

- Installation Method StatementDokumen6 halamanInstallation Method StatementgururajBelum ada peringkat

- Boq Piping Materials RaDokumen4 halamanBoq Piping Materials RaHerruSetiawanBelum ada peringkat

- LWM - MEP-ProgramDokumen2 halamanLWM - MEP-ProgramAburvarajBelum ada peringkat

- Mobilization Checklist 1Dokumen3 halamanMobilization Checklist 1MuslimkarimjeeBelum ada peringkat

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDokumen8 halamanMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaBelum ada peringkat

- Equipment Mobilization PlanDokumen1 halamanEquipment Mobilization Planlucio444Belum ada peringkat

- Pre-Feasibility Report: Tata Steel LimitedDokumen10 halamanPre-Feasibility Report: Tata Steel LimitedLokendra Singh RathoreBelum ada peringkat

- Installation Armstrong Ceiling SystemsDokumen24 halamanInstallation Armstrong Ceiling Systemsmelgarcia829Belum ada peringkat

- Ms 03 Fit Out WorksDokumen18 halamanMs 03 Fit Out WorksHichem ZerradBelum ada peringkat

- Final - Commercial & SOR-Vol IDokumen86 halamanFinal - Commercial & SOR-Vol IengharshBelum ada peringkat

- Daily Construction Report (DCR) : Project ManagerDokumen5 halamanDaily Construction Report (DCR) : Project ManagerMoath AlhajiriBelum ada peringkat

- Request For Information (Rfi) : Company (Contractor) Contract/ Purchase NoDokumen2 halamanRequest For Information (Rfi) : Company (Contractor) Contract/ Purchase NoResearcherBelum ada peringkat

- Procedure Installation of Lighting - LABUAN BAJO PDFDokumen6 halamanProcedure Installation of Lighting - LABUAN BAJO PDFWika Djoko OBelum ada peringkat

- DS 40 Full SubmittalDokumen50 halamanDS 40 Full Submittalahmed100% (1)

- MOS-SRWSE-20220329-Distribution Pump InstallationDokumen58 halamanMOS-SRWSE-20220329-Distribution Pump InstallationKhit MakaraBelum ada peringkat

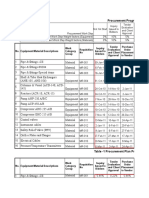

- Procurement Plan: Epc Project New Effluent Water Treatment Plant (Ewtp) Di Pertamina BalonganDokumen10 halamanProcurement Plan: Epc Project New Effluent Water Treatment Plant (Ewtp) Di Pertamina BalonganHolid AzhariBelum ada peringkat

- Site Diary: Italian-Thai Development Public Company LimitedDokumen4 halamanSite Diary: Italian-Thai Development Public Company LimitedjackcoolsBelum ada peringkat

- Welder 2Dokumen1 halamanWelder 2Fahad AhmadBelum ada peringkat

- BOQ of Pipe Sleepers-SwccDokumen2 halamanBOQ of Pipe Sleepers-SwccjatinBelum ada peringkat

- (Client Name/logo) (Contractor Name/logo) : List of Documents / DrawingsDokumen1 halaman(Client Name/logo) (Contractor Name/logo) : List of Documents / DrawingsDeoBelum ada peringkat

- E&I Tool Box ContentsDokumen1 halamanE&I Tool Box ContentsChandan RayBelum ada peringkat

- Schedule NarrativeDokumen298 halamanSchedule NarrativetabtawanBelum ada peringkat

- MS of Tower Facade - 2016-05-30Dokumen126 halamanMS of Tower Facade - 2016-05-30Nguyễn SơnBelum ada peringkat

- Besmm4f PDFDokumen2 halamanBesmm4f PDFGodwin JohnBelum ada peringkat

- Typical Organization ChartDokumen1 halamanTypical Organization ChartJaved MiandadBelum ada peringkat

- MOS-SRWSE-20220405-Mechanical Steel & Gavalnized Steel PipeDokumen28 halamanMOS-SRWSE-20220405-Mechanical Steel & Gavalnized Steel PipeKhit MakaraBelum ada peringkat

- Construction Daily Report 03-10-2018Dokumen3 halamanConstruction Daily Report 03-10-2018Saddem HadfiBelum ada peringkat

- Site Progress Report SampleDokumen12 halamanSite Progress Report SampleBadrul HishamBelum ada peringkat

- Method Statement For Workshop Activities RevDokumen4 halamanMethod Statement For Workshop Activities RevEmadHassanBelum ada peringkat

- LTS3000 - DPR (Draft) - 01-01-11Dokumen9 halamanLTS3000 - DPR (Draft) - 01-01-11SivaramkumarBelum ada peringkat

- Ssec Profile 2010Dokumen47 halamanSsec Profile 2010Syaiful AzliBelum ada peringkat

- Capital BudgetingDokumen67 halamanCapital BudgetingBhargavi DoddaBelum ada peringkat

- Joost Siteur Vector - WTE in ThailandDokumen8 halamanJoost Siteur Vector - WTE in ThailandBimo Nuswantoro SugardoBelum ada peringkat

- Green House EffectDokumen6 halamanGreen House EffectVir PatelBelum ada peringkat

- Aligning Carbon Pricing With National Priorities of Pakistan. Saadullah AyazDokumen16 halamanAligning Carbon Pricing With National Priorities of Pakistan. Saadullah AyazSaadullah AyazBelum ada peringkat

- ENERGY EFFICIENCY IntroductionDokumen13 halamanENERGY EFFICIENCY IntroductionAzmi HashimBelum ada peringkat

- Afes MCQ BankDokumen20 halamanAfes MCQ BankPrabhu GovindBelum ada peringkat

- Shell Mysella S2 Z 40 Old Name R 40 PDFDokumen2 halamanShell Mysella S2 Z 40 Old Name R 40 PDFhananBelum ada peringkat

- PPL Su 1050 O.1Dokumen56 halamanPPL Su 1050 O.1olalekanBelum ada peringkat

- Uni of DuhokDokumen14 halamanUni of Duhokaa zzBelum ada peringkat

- Pyro Catalogue-MiccDokumen16 halamanPyro Catalogue-Micckprasad_56900Belum ada peringkat

- STORENGY - Optimizing Gas StorageDokumen3 halamanSTORENGY - Optimizing Gas StorageIslemBelum ada peringkat

- FuelsDokumen47 halamanFuelsSheeraz Junejo100% (1)

- 39.0046 - Issue7 - July2002 - FMQ 10&FMQ 8 36&FMQ 7 42 - Install&OperateInstructionsDokumen30 halaman39.0046 - Issue7 - July2002 - FMQ 10&FMQ 8 36&FMQ 7 42 - Install&OperateInstructionsSubuk T. RathodBelum ada peringkat

- A 1836 CintaDokumen2 halamanA 1836 Cintasatria jayaBelum ada peringkat

- Advisory Memorandum On Ensuring Essential Critical Infrastructure Workers' Ability To Work During The Covid-19 ResponseDokumen23 halamanAdvisory Memorandum On Ensuring Essential Critical Infrastructure Workers' Ability To Work During The Covid-19 ResponseGisele ChagasBelum ada peringkat

- Entrained-Bed Gasification Processes: Koppers-Totzek (K-T) ProcessDokumen8 halamanEntrained-Bed Gasification Processes: Koppers-Totzek (K-T) ProcessSarita ShitBelum ada peringkat

- CHEMCAD As A Tool When Teaching Chemical Engineering: January 2011Dokumen52 halamanCHEMCAD As A Tool When Teaching Chemical Engineering: January 2011LucianoBelum ada peringkat

- ACCDokumen20 halamanACCDARK DANGERBelum ada peringkat

- Clair OilfieldDokumen3 halamanClair OilfieldJabir JammyBelum ada peringkat