The Light Soaking Effect - Additional Power Boost in Thin Film CIGS PV Module

Diunggah oleh

Anand JeevaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

The Light Soaking Effect - Additional Power Boost in Thin Film CIGS PV Module

Diunggah oleh

Anand JeevaHak Cipta:

Format Tersedia

SOLARPOWER

The Light Soaking Effect - Additional Power

Boost in Thin Film CIGS PV Module

Mr.Manoj Kumar Sharma, Manager-Sales, Q Cells Systems India

Nearly all PV technologies exhibit changes in device performance under extended

continuous illumination. CIGS modules improve their efficiency after being subjected to

illumination which is known as the Light Soaking Effect. In simple words a 100 Wp rated

module may produce 105 Wp when subjected to illumination. The magnitude of this

increase depends on the cell and module technology, irradiance, temperature, electrical

bias and device structure.

C

opper indium Physically, what happens is that the buffer doping through light soaking to achieve

gallium (di)sele- layer is photo-doped, which means that the ideal heterojunction conditions, while

nide (CIGS) is a the buffer layer becomes highly n-type, others are highly doped from the start and

I-III-VI2 semiconductor pinning the bands to the Fermi level . respond less to light soaking. Variations in

material composed of The effect of the barrier due to the CIGS band gap and the thickness of the

copper, indium, gal- buffer layer manifests itself in a degraded buffer layer also play an important role in

lium, and selenium. fill factor, with a curve shape that looks how quickly the light soaking effect im-

The CIGS modules con- similar to that of excess series resistance proves the module performance.

tain a thin film of a semiconductor called (lower Vmpp and lower slope around Voc).

Cu (In,Ga)Se2 or in short CIGS (Figure 1). The effect on the IV curve of a CIGS mod- Light Soaking In Other Device Types

This absorber layer is the key technology of ule is illustrated in Figure 2. With the ben- Amorphous Silicon

the CIGS module, and enables their smart eficial light soaking effect being connected Amorphous silicon (a-Si) is one of the ear-

looks, efficient energy conversion and high to absorption in the buffer layer, it is driven liest thin film PV technologies and exhib-

energy yield. Compared to conventional Si by the absorption of light at shorter wave- its a well-known light-induced degrada-

lengths. tion effect, in which efficiencies degrade

by ~10-30% in the first several hundred

hours of light soaking. The degradation is

due to the Staebler-Wronski effect (SWE),

first observed as a reduction in the dark

conductivity and photoconductivity of

a-Si:H after light exposure, wherein the

degradation is reversible by annealing at

technology, the CIGS layer is extremely high temperatures. The SWE occurs due

thin and the cells come out of manufac- to the recombination-induced breaking of

turing already connected in series with no weak Si-Si bonds by optically excited carri-

need for tabbing and stringing. ers after thermalization, producing defect

Figure 1: CIGS Device Structure Figure 2: IV curves for module before and after centres that lower carrier lifetime. Device

- Substrate light soaking

recovery occurs upon annealing as defects

are healed.

What is Light Soaking? The extent and time dependence of

The light soaking effect is related to the the light soaking effect depends primar- Cadmium Telluride (CdTe)

buffer layer of the solar cell. At the inter- ily on the dose of the blue light that the CdTe PV devices typically contain an n-type

face between the CIGS and the buffer lay- module receives and the initial state of the CdS buffer layer followed by a p-type CdTe

er a barrier for electrons is created, which buffer layer. Since the buffer layer is defect absorber layer and a back-contact metal-

inhibits transport of carriers from the CIGS doped, as opposed to the impurity doping lization layer for current collection. With

to the TCO Layer (Transparent Conducting used in conventional wafer based tech- long-term light exposure CdTe devices typ-

Oxides) and to the outside circuit. This bar- nologies, there is some variation in dop- ically exhibit performance degradation due

rier can be lowered due to incoming pho- ing within the process window. This means to detrimental permanent changes in the

tons that are absorbed in the buffer layer. that some modules need more photo- device. The diffusion of Cu ions away from

2 JANUARY|FEBRUARY12 energetica india

SOLARPOWER

the back contact metallization in CdTe

devices can explain many of the observed

long-term light soaking effects. The back

contact in CdTe forms a diode junction of

opposite polarity to the main junction, lim-

iting performance. The degradation rate

increases with increased temperature and

is significantly faster at 85-100 °C than at

temperatures observed during normal op-

eration, CdTe degradation during extend-

ed light soaking is strongly affected by the

electrical bias condition with open-circuit-

ed devices showing greater degradation

than those operating at max power. This

is believed to be due at least in part to the

retardation of Cu ion migration by internal

electric fields when the devices operate

near max power.

Conclusion

Metastable behaviour could be observed

in all investigated thin-film technologies

(CdTe, a-Si and CIGS). While a-Si and

CdTe mostly show degradation with light

absorption, CIGS shows improvement in

efficiency and module rated power dur-

ing initial light absorption. The increase in

power output is contributed to phenom-

enon called light soaking effect.

Device structure and buffer layer de-

sign contributes a lot to the light soaking

phenomenon. This feature of light soak-

ing is very useful for higher specific yields

(kWh/kWp). As a result of light soaking

the module output increases after instal-

lation in the field, this is like generating

more units from the same size of system

capacity. This will increase the return on

Investment and decrease the monetary

and energy payback time from a solar PV

plant.

Q-Cells thin-film Q.SMART module

technology is now the first in the entire

thin-film sector to achieve a solar module

efficiency of 17.4% (aperture area) and

harnesses a “light-soaking” effect to gen-

erate an average of 2.5 % power boost

above Nominal Power at Standard Test

Conditions when deployed in the field.

This contributes to higher return on invest-

ments and secures yields. With large scale

CIGS plants performing very well across

the globe, the technology is gaining share

in thin film market. One of the very good

features of CIGS technology is additional

power boost with light soaking.

energetica india JANUARY|FEBRUARY12

Anda mungkin juga menyukai

- Research Advances in Thin Film Solar Cells CIGS and CZTS TechnologiesDokumen8 halamanResearch Advances in Thin Film Solar Cells CIGS and CZTS TechnologiesSai VishalBelum ada peringkat

- Optp Electronics DeviceDokumen6 halamanOptp Electronics Devicekaran007_mBelum ada peringkat

- Multiscale Modeling of Thin-Film Deposition: Applications To Si Device ProcessingDokumen8 halamanMultiscale Modeling of Thin-Film Deposition: Applications To Si Device ProcessingZhou JiaoBelum ada peringkat

- Second Generation Solar CellsDokumen4 halamanSecond Generation Solar CellsAboothahir AfzalBelum ada peringkat

- A Comprehensive Review On Current Performance, Challenges and Progress in Thin Film Solar CellsDokumen21 halamanA Comprehensive Review On Current Performance, Challenges and Progress in Thin Film Solar CellsREMO MosesBelum ada peringkat

- Solar PV Unit 2Dokumen101 halamanSolar PV Unit 2Dhananjay Chandrashekhar KajaleBelum ada peringkat

- Microstructural and Diffusion Properties of CIGS Thin Film Solar Cells Fabricated Using Transparent Conducting Oxide Back ContactsDokumen7 halamanMicrostructural and Diffusion Properties of CIGS Thin Film Solar Cells Fabricated Using Transparent Conducting Oxide Back ContactsmendaburkiwiBelum ada peringkat

- Solar Cell Basics and Future TechnologyDokumen37 halamanSolar Cell Basics and Future TechnologyMuhammad FauzanBelum ada peringkat

- Indoor Light Harvesting Using Dye Sensitized Solar Cell: AbstractDokumen5 halamanIndoor Light Harvesting Using Dye Sensitized Solar Cell: Abstractjose manuel acosta saavedraBelum ada peringkat

- Arc 4Dokumen8 halamanArc 4AnilKumarBelum ada peringkat

- Wu 2013Dokumen4 halamanWu 2013Almouzzam KhanBelum ada peringkat

- Thin Film Solar Cells: A Review: Journal of Information, Knowledge and Research in Electronics and CommunicationDokumen3 halamanThin Film Solar Cells: A Review: Journal of Information, Knowledge and Research in Electronics and CommunicationEndalew kassahunBelum ada peringkat

- 1 s2.0 S0038092X1931031X MainDokumen6 halaman1 s2.0 S0038092X1931031X MainSyed Muhammad Ahsan RizviBelum ada peringkat

- Lecture 15 24Dokumen48 halamanLecture 15 24SAMBHAV GOEL 21104033Belum ada peringkat

- High Efficient CIGS Based Thin Film Solar Cell Performance Optimization Using PC1DDokumen4 halamanHigh Efficient CIGS Based Thin Film Solar Cell Performance Optimization Using PC1DOuarda TerghiniBelum ada peringkat

- An Industry Moving Beyond Sight: Thin Film Quantum Dot Solar CellsDokumen8 halamanAn Industry Moving Beyond Sight: Thin Film Quantum Dot Solar Cellsapi-438135804Belum ada peringkat

- PERECDokumen2 halamanPERECkamaleshsBelum ada peringkat

- CIGSDokumen5 halamanCIGSsasikalasivakumarBelum ada peringkat

- EE6303-Linear Integrated Circuits and Applications Q&ADokumen24 halamanEE6303-Linear Integrated Circuits and Applications Q&AY RohitBelum ada peringkat

- Sensor Techno Logy: Experiment No. - 3Dokumen5 halamanSensor Techno Logy: Experiment No. - 3Shiv GuptaBelum ada peringkat

- Nanotech Solar Cells: Dye, Quantum Dot and PerovskiteDokumen4 halamanNanotech Solar Cells: Dye, Quantum Dot and PerovskiteVishwasBelum ada peringkat

- bhattacharya1999Dokumen2 halamanbhattacharya1999Eman NasirBelum ada peringkat

- 1 - Dye Sensitized Solar Cells For Economically Viable Photovoltaic SystemsDokumen12 halaman1 - Dye Sensitized Solar Cells For Economically Viable Photovoltaic SystemswangwbthuBelum ada peringkat

- Materials:: Thin-Film Technologies Reduce The Amount of ActiveDokumen11 halamanMaterials:: Thin-Film Technologies Reduce The Amount of ActiveParth KumarBelum ada peringkat

- Working Spectrum: Crystalline Silicone Solar Modules Crystalline Silicone Solar ModulesDokumen2 halamanWorking Spectrum: Crystalline Silicone Solar Modules Crystalline Silicone Solar ModulesaimketBelum ada peringkat

- Ini Iya KayaknyaDokumen8 halamanIni Iya KayaknyaRiski RamadaniBelum ada peringkat

- Development of Solar CellsDokumen15 halamanDevelopment of Solar CellsPrithvi HarveBelum ada peringkat

- Research PaperDokumen7 halamanResearch PaperRithi VishwanathanBelum ada peringkat

- 10 5923 J Msse 20120102 04Dokumen6 halaman10 5923 J Msse 20120102 04mohanadBelum ada peringkat

- Taskina Solar Cells Optical and Recombination LossesDokumen19 halamanTaskina Solar Cells Optical and Recombination LossesTaskina NasrinBelum ada peringkat

- Nanostructures For Light Trapping in Thin Film Solar Cells: MicromachinesDokumen18 halamanNanostructures For Light Trapping in Thin Film Solar Cells: MicromachinesПривет УлыбатьсяBelum ada peringkat

- Silicon Solar Cell Parameters - PVEducationDokumen2 halamanSilicon Solar Cell Parameters - PVEducationnaveen reddy MedimalliBelum ada peringkat

- Sustainable Energy Technologies and Assessments: SciencedirectDokumen10 halamanSustainable Energy Technologies and Assessments: SciencedirectSupriya RaiBelum ada peringkat

- Solar Cell Basics ExplainedDokumen1 halamanSolar Cell Basics ExplainedJonas OliverBelum ada peringkat

- Development of Rear Surface Passivated Cu (In, Ga) Se2 Thin Film Solar Cells With Nano-Sized Local Rear Point ContactsDokumen7 halamanDevelopment of Rear Surface Passivated Cu (In, Ga) Se2 Thin Film Solar Cells With Nano-Sized Local Rear Point ContactsmendaburkiwiBelum ada peringkat

- 1 s2.0 S0026271421003899 MainDokumen7 halaman1 s2.0 S0026271421003899 MainSaqib Ali KhanBelum ada peringkat

- PV Cell and Module Degradation, Detection and Diagnostics: Eleni KaplaniDokumen10 halamanPV Cell and Module Degradation, Detection and Diagnostics: Eleni KaplaniAndres PerezBelum ada peringkat

- Investigation On Light-Trapping Schemes in Crystalline Silicon Thin-Film Solar Cell On Glass Superstrate by Ray TracerDokumen9 halamanInvestigation On Light-Trapping Schemes in Crystalline Silicon Thin-Film Solar Cell On Glass Superstrate by Ray TracerMADHIYAH YAHAYA BERMAKAIBelum ada peringkat

- Light Trapping in Thin-Film Cu (Inga) Se Solar CellsDokumen6 halamanLight Trapping in Thin-Film Cu (Inga) Se Solar CellsTikam SuvasiyaBelum ada peringkat

- 2 LectureDokumen48 halaman2 LectureDonavan CheahBelum ada peringkat

- Performance of Different Photovoltaic Technologies For Amorphous Silicon (A-Si) and Copper Indium Gallium Di-Selenide (Cigs) Photovoltaic ModulesDokumen11 halamanPerformance of Different Photovoltaic Technologies For Amorphous Silicon (A-Si) and Copper Indium Gallium Di-Selenide (Cigs) Photovoltaic ModulesOday Ibraheem ABdullahBelum ada peringkat

- Res PresentationDokumen15 halamanRes PresentationKIRUBAHARAN MANIVASAGANBelum ada peringkat

- Solar Power PlantDokumen44 halamanSolar Power Plantgotiwo7723Belum ada peringkat

- Solar CrystallineDokumen6 halamanSolar CrystallineSirsanath BanerjeeBelum ada peringkat

- Novel Methods of Enhancing Solar Photovoltaic Panel Efficiency Using IOT and AutomationDokumen5 halamanNovel Methods of Enhancing Solar Photovoltaic Panel Efficiency Using IOT and AutomationInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Dye Solar Cells: Overview of Mechanism, Limitations & SolutionsDokumen36 halamanDye Solar Cells: Overview of Mechanism, Limitations & SolutionsDevendra KhadeBelum ada peringkat

- Jbire 1960 0036Dokumen12 halamanJbire 1960 0036George AcostaBelum ada peringkat

- Recovery After Potential-Induced Degradation of Cuin Ga Se Solar Cells With Cds and ZN (O, S) Buffer LayersDokumen1 halamanRecovery After Potential-Induced Degradation of Cuin Ga Se Solar Cells With Cds and ZN (O, S) Buffer Layerssouso88Belum ada peringkat

- Physical ChemDokumen8 halamanPhysical Chemshaherbano AwanBelum ada peringkat

- Properties of High-Efficiency Cuingase Thin Film Solar CellsDokumen4 halamanProperties of High-Efficiency Cuingase Thin Film Solar CellsSnowdenn BreddBelum ada peringkat

- Nano-Solar Cells: My Anti Fossil Fuel......Dokumen20 halamanNano-Solar Cells: My Anti Fossil Fuel......mula madeen KumarBelum ada peringkat

- TÜV Rheinland Webinar Potential-Induced Degradation (PID)Dokumen39 halamanTÜV Rheinland Webinar Potential-Induced Degradation (PID)Saul Romero100% (1)

- And9770 DDokumen12 halamanAnd9770 DzoehdiismailBelum ada peringkat

- Ic FabricationDokumen7 halamanIc FabricationphooolBelum ada peringkat

- WP 0412Dokumen2 halamanWP 0412Eydatoulah ShaffeeqBelum ada peringkat

- Analysis of solar PV array configurations under partial shadingDokumen5 halamanAnalysis of solar PV array configurations under partial shadingHddjdjBelum ada peringkat

- Third generation solar cells: Efficiency beyond limitsDokumen6 halamanThird generation solar cells: Efficiency beyond limitsdhivyaBelum ada peringkat

- 516538596-Seminar - PPTX 20231124 092231 0000Dokumen15 halaman516538596-Seminar - PPTX 20231124 092231 0000KIRUBAHARAN MANIVASAGANBelum ada peringkat

- KR Monograph July2013 IEEMA PDFDokumen410 halamanKR Monograph July2013 IEEMA PDFMeetBelum ada peringkat

- LPI and III Lightning Infographic PDFDokumen1 halamanLPI and III Lightning Infographic PDFAnand JeevaBelum ada peringkat

- Ref Guide 2014Dokumen32 halamanRef Guide 2014Anand JeevaBelum ada peringkat

- Merlin Gerin Technical Guide Medium VoltageDokumen80 halamanMerlin Gerin Technical Guide Medium Voltagepavlovicg100% (1)

- PSPDokumen12 halamanPSPsdiamanBelum ada peringkat

- Document Submission Status: For Construction: KDL 120Mw Combined Cyle Power Plant ProjectDokumen28 halamanDocument Submission Status: For Construction: KDL 120Mw Combined Cyle Power Plant ProjectAnand JeevaBelum ada peringkat

- Fault DecrementDokumen2 halamanFault DecrementAnand JeevaBelum ada peringkat

- KR Monograph July2013 IEEMA PDFDokumen410 halamanKR Monograph July2013 IEEMA PDFMeetBelum ada peringkat

- Sweeping Magazine Article 6-08 PDFDokumen4 halamanSweeping Magazine Article 6-08 PDFAnand JeevaBelum ada peringkat

- Lightning Protection Risk Assessment NEWDokumen6 halamanLightning Protection Risk Assessment NEWTigrillo100% (1)

- Lightning Safety and Economic Impact in the U.SDokumen1 halamanLightning Safety and Economic Impact in the U.SAnand JeevaBelum ada peringkat

- IEEE Guide For Direct Lightning Stroke Shielding of SubstationsDokumen227 halamanIEEE Guide For Direct Lightning Stroke Shielding of SubstationsAlcides NetoBelum ada peringkat

- 2.b. LPI Standard Performance Spec Short Form PDFDokumen1 halaman2.b. LPI Standard Performance Spec Short Form PDFAnand JeevaBelum ada peringkat

- 5 EeeDokumen25 halaman5 Eeepramana_gmritBelum ada peringkat

- Quarterly Report On European Electricity Markets q1 2021 Final 0Dokumen49 halamanQuarterly Report On European Electricity Markets q1 2021 Final 0saadounBelum ada peringkat

- Loss DiagramDokumen1 halamanLoss DiagramAahd GhafriBelum ada peringkat

- Advancing Solar Integration in Security and Alarm Systems: A Review of Innovations and ChallengeDokumen13 halamanAdvancing Solar Integration in Security and Alarm Systems: A Review of Innovations and ChallengeucheBelum ada peringkat

- Electrical Power Engineering (EPE)Dokumen1 halamanElectrical Power Engineering (EPE)Fernando CornielleBelum ada peringkat

- PVGIS-5 GridConnectedPV 44.434 25.998 SA Crystsi 112kWp 1.4 35deg 0degDokumen1 halamanPVGIS-5 GridConnectedPV 44.434 25.998 SA Crystsi 112kWp 1.4 35deg 0degMonica IorgulescuBelum ada peringkat

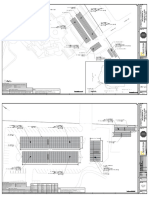

- Mounting StructureDokumen41 halamanMounting StructureAcharan Chandel100% (1)

- China 2050 High Renewable Energy Penetration Scenario and Roadmap StudyDokumen13 halamanChina 2050 High Renewable Energy Penetration Scenario and Roadmap StudyClimateCentralBelum ada peringkat

- NR SSD GCC Rev01Dokumen4 halamanNR SSD GCC Rev01Gulrej VarsiBelum ada peringkat

- Solar Energy Installation in NigeriaDokumen12 halamanSolar Energy Installation in NigeriavicaschendeBelum ada peringkat

- Installation of Solar Street LightsDokumen13 halamanInstallation of Solar Street LightsGeremy Delos Santos SantiagoBelum ada peringkat

- RenewX 2020 Accelerates Growth of South India Renewable EnergyDokumen13 halamanRenewX 2020 Accelerates Growth of South India Renewable Energyiyer34Belum ada peringkat

- Project ProposalDokumen8 halamanProject ProposalLynette CastilarBelum ada peringkat

- Photovoltaic Installation GuideDokumen14 halamanPhotovoltaic Installation GuideCarlos Samaniego100% (2)

- Measuring Soiling Losses at Utility-Scale PV Power PlantsDokumen6 halamanMeasuring Soiling Losses at Utility-Scale PV Power Plantsrhariss97Belum ada peringkat

- Job Description: Solar PV HSSE Manager (Health, Safety, Social and Environment) Location: Project Based, Indonesia Start Date: ASAPDokumen3 halamanJob Description: Solar PV HSSE Manager (Health, Safety, Social and Environment) Location: Project Based, Indonesia Start Date: ASAPYusril Izza MBelum ada peringkat

- Solar Energy Trainer: Salient FeaturesDokumen2 halamanSolar Energy Trainer: Salient FeaturesadtronBelum ada peringkat

- Assessing Industrial Energy Transition in Pakistan's Textile SectorDokumen37 halamanAssessing Industrial Energy Transition in Pakistan's Textile SectorKamran AhmedBelum ada peringkat

- ELECTRICITY SMART GRIDS AND ENERGY SYSTEMSDokumen56 halamanELECTRICITY SMART GRIDS AND ENERGY SYSTEMSRahul raiBelum ada peringkat

- User Manual For Flexible Solar Panel 2021Dokumen3 halamanUser Manual For Flexible Solar Panel 2021DaBelum ada peringkat

- Selina Solutions For Class 9 Physics Chapter 6 Heat and EnergyDokumen22 halamanSelina Solutions For Class 9 Physics Chapter 6 Heat and EnergyAnubrata SarkarBelum ada peringkat

- DGDokumen8 halamanDGJose Huillca VargasBelum ada peringkat

- Mathematical Modeling of Direct-Coupled Photovoltaic Solar Pump System For Small-Scale IrrigationDokumen23 halamanMathematical Modeling of Direct-Coupled Photovoltaic Solar Pump System For Small-Scale IrrigationAfif TeukuBelum ada peringkat

- Solar Proposal For Mr. Nayyer Hussain (New) PDFDokumen14 halamanSolar Proposal For Mr. Nayyer Hussain (New) PDFSuban TasirBelum ada peringkat

- Application For Net Metering Re01Dokumen2 halamanApplication For Net Metering Re01Sisira KumaraBelum ada peringkat

- PDP8 End of The Beginning 1684803400Dokumen6 halamanPDP8 End of The Beginning 1684803400Max NgBelum ada peringkat

- Background of the Study on Impatiens balsamina as Dye for Solar CellsDokumen2 halamanBackground of the Study on Impatiens balsamina as Dye for Solar CellsAlyssum MarieBelum ada peringkat

- 1 MW Soalr Power Plant Project ReportDokumen48 halaman1 MW Soalr Power Plant Project ReportRaghu Kurada79% (19)

- LCOE CalculationDokumen27 halamanLCOE CalculationRadhakrishnan VBelum ada peringkat

- Gwalior Solar City Plan - Ver8.1 - 011213Dokumen366 halamanGwalior Solar City Plan - Ver8.1 - 011213abhishekBelum ada peringkat

- Build Your Own Electric Vehicle, Third EditionDari EverandBuild Your Own Electric Vehicle, Third EditionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Electronics All-in-One For Dummies, 3rd EditionDari EverandElectronics All-in-One For Dummies, 3rd EditionPenilaian: 5 dari 5 bintang5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4.5 dari 5 bintang4.5/5 (542)

- Operational Amplifier Circuits: Analysis and DesignDari EverandOperational Amplifier Circuits: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- The Graphene Revolution: The Weird Science of the Ultra-thinDari EverandThe Graphene Revolution: The Weird Science of the Ultra-thinPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- Understanding Automotive Electronics: An Engineering PerspectiveDari EverandUnderstanding Automotive Electronics: An Engineering PerspectivePenilaian: 3.5 dari 5 bintang3.5/5 (16)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsDari EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsPenilaian: 4 dari 5 bintang4/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesDari EverandThe Rare Metals War: the dark side of clean energy and digital technologiesPenilaian: 5 dari 5 bintang5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDari EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgePenilaian: 5 dari 5 bintang5/5 (8)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemDari EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemBelum ada peringkat

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsDari EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsPenilaian: 5 dari 5 bintang5/5 (3)

- 8051 Microcontroller: An Applications Based IntroductionDari Everand8051 Microcontroller: An Applications Based IntroductionPenilaian: 5 dari 5 bintang5/5 (6)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4 dari 5 bintang4/5 (331)

- Automotive Electronic Diagnostics (Course 2)Dari EverandAutomotive Electronic Diagnostics (Course 2)Penilaian: 4 dari 5 bintang4/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingDari EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingPenilaian: 4 dari 5 bintang4/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Dari EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Penilaian: 5 dari 5 bintang5/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsDari EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovBelum ada peringkat

- Winning in 2025: Digital and Data Transformation: The Keys to SuccessDari EverandWinning in 2025: Digital and Data Transformation: The Keys to SuccessBelum ada peringkat

- A Mind at Play: How Claude Shannon Invented the Information AgeDari EverandA Mind at Play: How Claude Shannon Invented the Information AgePenilaian: 4 dari 5 bintang4/5 (52)

- Electrical Principles and Technology for EngineeringDari EverandElectrical Principles and Technology for EngineeringPenilaian: 4 dari 5 bintang4/5 (4)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsDari EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsPenilaian: 5 dari 5 bintang5/5 (2)