Instrumentation and Control: Pressure Measurement

Diunggah oleh

bigbang0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

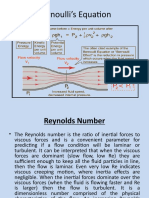

20 tayangan23 halamanThere are three main types of pressure measurement scales: gage pressure, absolute pressure, and vacuum. Pressure can be measured using instruments with liquid columns, mechanical gauges like Bourdon tubes, diaphragm gauges and bellow gauges, and electronic methods using strain gauges and variable capacitors. Mechanical gauges operate using physical deformation under pressure while electronic methods detect pressure through resistive changes in strain gauges or capacitive changes between conductive plates.

Deskripsi Asli:

Pressure Measurement 08-20-18

Judul Asli

Pressure Measurement 08-20-18

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThere are three main types of pressure measurement scales: gage pressure, absolute pressure, and vacuum. Pressure can be measured using instruments with liquid columns, mechanical gauges like Bourdon tubes, diaphragm gauges and bellow gauges, and electronic methods using strain gauges and variable capacitors. Mechanical gauges operate using physical deformation under pressure while electronic methods detect pressure through resistive changes in strain gauges or capacitive changes between conductive plates.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan23 halamanInstrumentation and Control: Pressure Measurement

Diunggah oleh

bigbangThere are three main types of pressure measurement scales: gage pressure, absolute pressure, and vacuum. Pressure can be measured using instruments with liquid columns, mechanical gauges like Bourdon tubes, diaphragm gauges and bellow gauges, and electronic methods using strain gauges and variable capacitors. Mechanical gauges operate using physical deformation under pressure while electronic methods detect pressure through resistive changes in strain gauges or capacitive changes between conductive plates.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 23

Instrumentation and

Control

PRESSURE MEASUREMENT

Instrumentation and Control

Pressure Measurement Scale

There are three scales for pressure measurement

• Gage pressure (PSIG)

• Absolute pressure (PSIA)

• Vacuum

Pressure Measurement Scale

PRESSURE

MEASUREMENT

INSTRUMENTS

Pressure Instruments with a Liquid Column

• Measuring pressure is possible by

monitoring the height of a liquid in a

column

• These gauges are very accurate and

may be used as a calibration tools to

other instruments

• A barometer is an example of a liquid

column gauge

Pressure Instruments: Mechanical gauge

Major types of mechanical gauges

• Bourdon tube

• Diaphragm gauge

• Bellow Gauge

Mechanical Gauge: Bourdon Tube

• The bourdon tube is a C shaped metal tube

• As pressure increase, the tube coil unwinds

• As it unwinds, a needle attached to the end will move to indicate a higher pressure

reading

• The gauge range depends on the type of material

Mechanical Gauge: Bourdon Tube

Mechanical Gauge: Bourdon Tube

Mechanical Gauge: Bourdon Tube

Mechanical Gauge: Diaphragm Gauge

• Diaphragm gauges are typically spring-loaded as a mean of setting the range

and sensitivity.

• Diaphragm gauges can be used to measure absolute pressure and gauge

pressure.

Mechanical Gauge: Diaphragm Gauge

Mechanical Gauge: Diaphragm Gauge

Mechanical Gauge: Diaphragm Gauge

Mechanical Gauge: Bellow Gauge

• Bellows gauges have wider ranges of operation than to the diaphragm

gauges because of the pleated sides of the bellows

• An opposing spring is used to control range and sensitivity

Mechanical Gauge: Bellow Gauge

ELECTRONIC PRESSURE

MEASUREMENT

Strain Gauge

• Strain gauges measure pressure by detecting the strain on an object caused

by pressure

• Strain gauges are typically constructed of piezoelectric semiconductor

material

• Pressure on the elements of a strain gauge causes the elements to expand or

contract

• Strain gauges are used as part of Wheatstone Bridge to measure pressure

• Strain gauges can be bonded to the surface of a pressure diaphragm. The

change in the process pressure will cause a resistive change in the strain

gauges, which is then used to produce a 4-20 mA signal.

Strain Gauge

Variable Capacitor Pressure Detector

• Uses two conductive plates oriented adjacent to one another and separated

by air

• One plate is fixed, and the other is attached to a bellows

• The charge of the capacitor is influenced by the distance between the plates,

and therefore, the pressure being exerted on the bellows

Variable Capacitor Pressure Detector

Anda mungkin juga menyukai

- MMM Lecture - Unit 2 - Pressure MeasurementDokumen24 halamanMMM Lecture - Unit 2 - Pressure MeasurementAlanka BhanuBelum ada peringkat

- MM Unit 3Dokumen45 halamanMM Unit 3Subodh DanaoBelum ada peringkat

- Metrology Unit 3 PPT 3Dokumen34 halamanMetrology Unit 3 PPT 3Punith RajBelum ada peringkat

- Process Instrumentation & Control GuideDokumen24 halamanProcess Instrumentation & Control GuideAwais JavaidBelum ada peringkat

- University of Engineering and Technology Taxila Mechanical Engineering DepartmentDokumen32 halamanUniversity of Engineering and Technology Taxila Mechanical Engineering DepartmentAsad ullahBelum ada peringkat

- Psycheometric ChartDokumen35 halamanPsycheometric ChartMuzzamil AbbasiBelum ada peringkat

- Manometers Notes 1Dokumen13 halamanManometers Notes 1Sri Kiran ThunuguntlaBelum ada peringkat

- Measuring Fluid Pressure with Manometers and Bourdon TubesDokumen23 halamanMeasuring Fluid Pressure with Manometers and Bourdon TubesMohammed Al-OdatBelum ada peringkat

- Material Handling & Auxiliaries - Day 3Dokumen58 halamanMaterial Handling & Auxiliaries - Day 3smendozaBelum ada peringkat

- Manometerics: - Prepared By:-Rajnish Khanduri&Vipin Kumar TomarDokumen17 halamanManometerics: - Prepared By:-Rajnish Khanduri&Vipin Kumar TomarNimish JoshiBelum ada peringkat

- Screenshot 2021-04-28 at 2.58.28 AMDokumen19 halamanScreenshot 2021-04-28 at 2.58.28 AMSyairazi FahmiBelum ada peringkat

- Gas Flow MeasurementDokumen72 halamanGas Flow MeasurementJunaid Mazhar100% (1)

- Pressure MeasurementDokumen37 halamanPressure MeasurementSaumya GoelBelum ada peringkat

- Unit III NotesDokumen73 halamanUnit III NotesShubham SharmaBelum ada peringkat

- Fluid EngineeringDokumen31 halamanFluid Engineeringابو حنيف100% (1)

- How to use Energy Audit Instruments EffectivelyDokumen65 halamanHow to use Energy Audit Instruments EffectivelyUlhas VajreBelum ada peringkat

- FluidKinematics Lesson5 FlowMeasurement HandoutDokumen22 halamanFluidKinematics Lesson5 FlowMeasurement HandoutYou Know WhoBelum ada peringkat

- Chapter 1-4 Process Measurement and Devices Flow MeasurementDokumen123 halamanChapter 1-4 Process Measurement and Devices Flow Measurementamin shukriBelum ada peringkat

- Intro ManometerDokumen8 halamanIntro ManometerSaumya GoelBelum ada peringkat

- Ventilation Survey Lecture-IIIDokumen33 halamanVentilation Survey Lecture-IIIKUNUSOTH SAIKUMARBelum ada peringkat

- Measure Fluid Pressure Differences Using ManometersDokumen6 halamanMeasure Fluid Pressure Differences Using ManometersAssociates zBelum ada peringkat

- Pressure Measurements Techniques To Measure PressureDokumen17 halamanPressure Measurements Techniques To Measure PressureAnonymous PuEyutLBelum ada peringkat

- Assignment - 4: 2K18/ECE/163 Shubham Gupta Electronic Instrumentations and MeasurementDokumen9 halamanAssignment - 4: 2K18/ECE/163 Shubham Gupta Electronic Instrumentations and MeasurementShubham GuptaBelum ada peringkat

- Pressure Sensor Experiment GuideDokumen19 halamanPressure Sensor Experiment GuideVineeth Valiyaveedu VijayanBelum ada peringkat

- 001 Pressure Measurement PDFDokumen22 halaman001 Pressure Measurement PDFMorteza AmirlooBelum ada peringkat

- Module v. Calibration and Uses of Pressure & Temperature Measuring InstrumentsDokumen25 halamanModule v. Calibration and Uses of Pressure & Temperature Measuring InstrumentsDomingo NoverasBelum ada peringkat

- Pressure Measurement FundamentalsDokumen52 halamanPressure Measurement FundamentalsAirish AirishBelum ada peringkat

- Pressure Measurement: Objective of LessonDokumen49 halamanPressure Measurement: Objective of LessonMohammad TahaBelum ada peringkat

- Chapter 1-1 Process Measurement and Devices Pressure MeasurementDokumen81 halamanChapter 1-1 Process Measurement and Devices Pressure Measurementamin shukriBelum ada peringkat

- Lecture # 17: Pressure Sensors Cont & Mass and Force SensorsDokumen24 halamanLecture # 17: Pressure Sensors Cont & Mass and Force SensorsHuzaifa ImtiazBelum ada peringkat

- Pressure Gauge and Transmitter GuideDokumen35 halamanPressure Gauge and Transmitter GuideTHEOPHILUS ATO FLETCHERBelum ada peringkat

- BMEDokumen33 halamanBMEBinita DashBelum ada peringkat

- Diesta, Martinez (Sensors Pressure and Temperature)Dokumen30 halamanDiesta, Martinez (Sensors Pressure and Temperature)Rodolfo Rey TorresBelum ada peringkat

- Pressure Measurement Techniques and DevicesDokumen29 halamanPressure Measurement Techniques and DevicesBhavik PrajapatiBelum ada peringkat

- Pressure Measurements Techniques To Measure PressureDokumen17 halamanPressure Measurements Techniques To Measure PressureIbonBelum ada peringkat

- Transportation and Metering of FluidsDokumen50 halamanTransportation and Metering of FluidsDedipya100% (2)

- AB502 ST U4 RotameterDokumen9 halamanAB502 ST U4 RotameterHARSH MALVIYABelum ada peringkat

- Free Flow Air GaugeDokumen11 halamanFree Flow Air GaugeKARAN KHANNABelum ada peringkat

- Free Flow Air GuageDokumen17 halamanFree Flow Air Guageshubham100% (1)

- 2k17che17 AssignmentDokumen6 halaman2k17che17 AssignmentMishi KhanBelum ada peringkat

- (Course Code:18ME36B) : Mechanical Measurements and MetrologyDokumen38 halaman(Course Code:18ME36B) : Mechanical Measurements and MetrologyVishal PatilBelum ada peringkat

- Fluid Pressure Measuring DevicesDokumen31 halamanFluid Pressure Measuring DevicesM Kafeel Khan100% (1)

- Pricinples of Measurement of PressureDokumen18 halamanPricinples of Measurement of PressureSohail NawabBelum ada peringkat

- FlowDokumen62 halamanFlowbapita roy100% (1)

- CH 2001 Fluid Mechanics Video Lectures: Module 33: Flow MeasurementDokumen34 halamanCH 2001 Fluid Mechanics Video Lectures: Module 33: Flow MeasurementSai KumarBelum ada peringkat

- Pressure Measurement 1Dokumen12 halamanPressure Measurement 1Imran TahirBelum ada peringkat

- 4 Pressure and Level MeasurementDokumen127 halaman4 Pressure and Level MeasurementJincy K AbhrahamBelum ada peringkat

- Units & Measurement Part-1Dokumen23 halamanUnits & Measurement Part-1PremKumarBelum ada peringkat

- Transducers U2Dokumen64 halamanTransducers U2R NAVEEN KUMAR MECHBelum ada peringkat

- Pressure Measurement MethodsDokumen181 halamanPressure Measurement MethodsIsulaBelum ada peringkat

- Hydraulics Micro-Project: Topic: Study of Pressure Measuring DevicesDokumen18 halamanHydraulics Micro-Project: Topic: Study of Pressure Measuring DevicesGvanBelum ada peringkat

- ManometerDokumen16 halamanManometerHaris ShahidBelum ada peringkat

- Measurement of Pressure: Static and Dynamic PressureDokumen10 halamanMeasurement of Pressure: Static and Dynamic PressureTarun VarshneyBelum ada peringkat

- II Mod 2Dokumen20 halamanII Mod 2SARATH R.THOPPILBelum ada peringkat

- Notes Tee801 Inst Pressure Measurement 2010-11Dokumen17 halamanNotes Tee801 Inst Pressure Measurement 2010-11S DivyaBelum ada peringkat

- INinDUSTRIAL INSTRUMENTATION Pewssure SensorDokumen53 halamanINinDUSTRIAL INSTRUMENTATION Pewssure SensorAmna EhsanBelum ada peringkat

- NGE Lectures 25-26Dokumen25 halamanNGE Lectures 25-26Zain GillaniBelum ada peringkat

- Process Measurement and Control InstrumentDokumen121 halamanProcess Measurement and Control InstrumentEvans HopeBelum ada peringkat

- Handbook of Mechanical and Materials EngineeringDari EverandHandbook of Mechanical and Materials EngineeringPenilaian: 5 dari 5 bintang5/5 (4)

- Prevention of Actuator Emissions in the Oil and Gas IndustryDari EverandPrevention of Actuator Emissions in the Oil and Gas IndustryBelum ada peringkat

- 7 Famous Female Engineers in HistoryDokumen6 halaman7 Famous Female Engineers in HistorybigbangBelum ada peringkat

- Board of Electrical Engineering-Code of EthicDokumen2 halamanBoard of Electrical Engineering-Code of Ethicraul_bsuBelum ada peringkat

- 7 Famous Female Engineers in HistoryDokumen10 halaman7 Famous Female Engineers in HistorybigbangBelum ada peringkat

- Multidirectional GroundDokumen3 halamanMultidirectional GroundbigbangBelum ada peringkat

- Measuring and Controlling TemperatureDokumen21 halamanMeasuring and Controlling TemperaturebigbangBelum ada peringkat

- Methods For Calculating IlluminationDokumen27 halamanMethods For Calculating Illuminationreca4520100% (1)

- Qualification Standard for Instrumentation and Control PersonnelDokumen273 halamanQualification Standard for Instrumentation and Control PersonnelHumberto Enrique Oyaga Barrios100% (4)

- LinearTubular Fluourescent LampsDokumen39 halamanLinearTubular Fluourescent LampsbigbangBelum ada peringkat

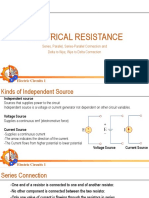

- Electrical Resistance Lecture 2Dokumen5 halamanElectrical Resistance Lecture 2bigbang0% (1)

- Nervous System of AnimalsDokumen10 halamanNervous System of AnimalsbigbangBelum ada peringkat

- Previews IES RP-6-01 PreDokumen10 halamanPreviews IES RP-6-01 Prebigbang0% (1)

- ELECTRICAL CIRCUITS: SERIES, PARALLEL, AND DELTA-WYE TRANSFORMATIONSDokumen16 halamanELECTRICAL CIRCUITS: SERIES, PARALLEL, AND DELTA-WYE TRANSFORMATIONSbigbangBelum ada peringkat

- Recommended Illuminance For MallsDokumen1 halamanRecommended Illuminance For MallsbigbangBelum ada peringkat

- 7 Famous Female Engineers in HistoryDokumen6 halaman7 Famous Female Engineers in HistorybigbangBelum ada peringkat

- ElecromagsDokumen1 halamanElecromagsbigbangBelum ada peringkat

- Engineering Management Ch1Dokumen21 halamanEngineering Management Ch1bigbangBelum ada peringkat

- Environmental and Health Problems in LivestockDokumen8 halamanEnvironmental and Health Problems in LivestockbigbangBelum ada peringkat

- Philippine Electrical Code Guide to Electrical Safety StandardsDokumen124 halamanPhilippine Electrical Code Guide to Electrical Safety StandardsbigbangBelum ada peringkat

- Hazardous Waste ManagementDokumen12 halamanHazardous Waste ManagementbigbangBelum ada peringkat

- Format For The Report DocuDokumen5 halamanFormat For The Report DocubigbangBelum ada peringkat

- Mechatronics: Basic Automation and PLCDokumen29 halamanMechatronics: Basic Automation and PLCbigbangBelum ada peringkat

- The History of Electronics PioneersDokumen32 halamanThe History of Electronics PioneersbigbangBelum ada peringkat

- WS Circuits 3Dokumen2 halamanWS Circuits 3bigbangBelum ada peringkat

- Introduction To Environmental EngineeringDokumen38 halamanIntroduction To Environmental EngineeringbigbangBelum ada peringkat

- The History of Electronics PioneersDokumen32 halamanThe History of Electronics PioneersbigbangBelum ada peringkat

- Electrical Safety and Strategic SolutionsDokumen63 halamanElectrical Safety and Strategic SolutionsboltgingerkoppyBelum ada peringkat

- RMTechU Laboratory Borrower's SlipDokumen2 halamanRMTechU Laboratory Borrower's Slipbigbang60% (5)

- Chapter - 1Dokumen19 halamanChapter - 1api-314267144Belum ada peringkat

- Multi-Phase, Multi-Voltage Surge Protective Devices SPD - Leviton - PK-93699-10-02-0B PDFDokumen2 halamanMulti-Phase, Multi-Voltage Surge Protective Devices SPD - Leviton - PK-93699-10-02-0B PDFsomeontorrenteBelum ada peringkat

- Bornay AeconDokumen2 halamanBornay AeconAlexandre Boullot100% (2)

- NLS3000-Manual Version 0.4 - ENGDokumen27 halamanNLS3000-Manual Version 0.4 - ENGJan Der VarBelum ada peringkat

- Saic M 1005Dokumen2 halamanSaic M 1005Hussain Nasser Al- NowiesserBelum ada peringkat

- Power Quality Issues Produced by Embedded Storage Technologies in Smart Grid EnvironmentDokumen5 halamanPower Quality Issues Produced by Embedded Storage Technologies in Smart Grid Environmentdog123Belum ada peringkat

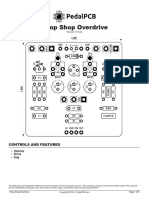

- ChopShop-PedalPCB V1Dokumen5 halamanChopShop-PedalPCB V1nghtlghtBelum ada peringkat

- A QUASI-Z-SOURCE Converter Using A Single-Stage Switched-Inductor Boost DC-DC ConverterDokumen14 halamanA QUASI-Z-SOURCE Converter Using A Single-Stage Switched-Inductor Boost DC-DC ConverterIJRASETPublicationsBelum ada peringkat

- SIMATIC S7-200: Digital ModulesDokumen3 halamanSIMATIC S7-200: Digital ModuleszeeshanBelum ada peringkat

- Finals Physics SummDokumen3 halamanFinals Physics SummGio Rico Naquila EscoñaBelum ada peringkat

- Mod. C20-E2/EV: Testing Module of Electricity 2Dokumen1 halamanMod. C20-E2/EV: Testing Module of Electricity 2lusoegyi 1919Belum ada peringkat

- Footprint Expert Solder Joint Goal Tables: Updated: June 2020 © 2014 - 2021 - PCB Libraries, IncDokumen35 halamanFootprint Expert Solder Joint Goal Tables: Updated: June 2020 © 2014 - 2021 - PCB Libraries, IncANANDBelum ada peringkat

- MEK-2500 Datasheet PDFDokumen2 halamanMEK-2500 Datasheet PDFhenryhariyadiBelum ada peringkat

- Perform New FRAMIT Transformer TestDokumen2 halamanPerform New FRAMIT Transformer TestMajid ArabahmadiBelum ada peringkat

- Class 7 Light NotesDokumen5 halamanClass 7 Light Noteschotu bhanuBelum ada peringkat

- Energy Saving Switch MANUALDokumen2 halamanEnergy Saving Switch MANUALRicardogcBelum ada peringkat

- A1xv (Mbaw56 SMDDokumen3 halamanA1xv (Mbaw56 SMDjavier venturaBelum ada peringkat

- Eagle TutorialDokumen6 halamanEagle Tutorialgenuinelycool100% (1)

- D 229 - 96 - Rdiyos1sruqDokumen20 halamanD 229 - 96 - Rdiyos1sruqValeria Orannel Lopez MorilloBelum ada peringkat

- SPC1 Series: Single Phase, Power ControllerDokumen6 halamanSPC1 Series: Single Phase, Power ControllerFadhil IskandarBelum ada peringkat

- Sensors: Microfluidic EBG Sensor Based On Phase-Shift Method Realized Using 3D Printing TechnologyDokumen14 halamanSensors: Microfluidic EBG Sensor Based On Phase-Shift Method Realized Using 3D Printing TechnologyAnonymous 5AmJ13mLkBelum ada peringkat

- Manual Fmu860Dokumen130 halamanManual Fmu860David González RodríguezBelum ada peringkat

- 6MD63 UsDokumen232 halaman6MD63 UsngocanhvyBelum ada peringkat

- Maintenance For Motors and Generators TFjelldalen ABBDokumen20 halamanMaintenance For Motors and Generators TFjelldalen ABBRoni EnjelaniBelum ada peringkat

- PDS Nytro Taurus enDokumen2 halamanPDS Nytro Taurus enLee RoBelum ada peringkat

- Om 407 Operation RepairDokumen90 halamanOm 407 Operation RepairJacksonBelum ada peringkat

- Astm D 1729-96 Visual Appraisal For Colour DifferencesDokumen2 halamanAstm D 1729-96 Visual Appraisal For Colour Differencesamittal111100% (1)

- M.tech Syllabus 2nd Year MtuDokumen15 halamanM.tech Syllabus 2nd Year MturakeshgnitBelum ada peringkat

- Module 19: Transformers and Circuit BreakersDokumen67 halamanModule 19: Transformers and Circuit BreakersDipayan DasBelum ada peringkat

- Data Sheet: BZV90 SeriesDokumen12 halamanData Sheet: BZV90 SeriesZoltán ÁgostonBelum ada peringkat