Is 456 M15 Minimum Cement Content

Diunggah oleh

Shuvro Chakravorty0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

6 tayangan1 halamanhi

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inihi

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

6 tayangan1 halamanIs 456 M15 Minimum Cement Content

Diunggah oleh

Shuvro Chakravortyhi

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 1

I 456 : 2000

8.25 Mix Constituents

For concrete to be durable, careful selection ofthe mix.

and materials is necessary, so that deleterious

‘constituents do not exceed the limits.

8.28.2 Chlorides in concrete

Whenever there is chloride in concrete there is an

increased risk of corrosion of embedded metal. The

higher the chloride content, orf subsequently exposed

to warm moist conditions, the greater the risk of

corrosion. All constituents may contain chlorides and

conerete may be contaminated by chlorides from the

external environment. To minimize the chances of

deterioration of concrete from harmful chemical salts,

the levels of such harmful salts in concrete coming

from concrete materials, that is, cement, aggregates

water and admixtures, as wel a by diffusion from the

environment should be limited. The total amount of

chloride content (as Cl) in the concrete atthe time of

placing shal be as given in Table 7.

‘The total acid soluble chloride content should be

calculated from the mix proportions and the measured

chloride contents ofeach ofthe constituents. Wherever

possible, the total chloride content of the concrete

should be determined.

8.2.5.3 Sulphates in concrete

Sulphates are present in most cements and in some

aggregates; excessive amounts of water-soluble

sulphate from these or other mix constituents can cause

‘expansion and disruption of concrete. To prevent this,

the total water-soluble sulphate content of the concrete

‘mix, expressed as SO,, should not exceed 4 percent by

‘mass of the cement in the mix. The sulphate content

should be calculated as the total from the various

‘constituents of the mix.

‘The4 percent limit does not apply to concrete made

with supersulphated cement complying with IS 6909,

8284 Alkalicaggregate reaction

Some aggregates containing particular varieties of

silica may be susceptible (0 attack by alkalis (Na,O

and K,0) originating from cement or other sources,

producing an expansive reaction which can cause

cracking and disruption of concrete. Damage to

concrete from this reaction will normally only occur

‘when all the following are present together:

a) A high moisture level, within the concrete;

b) A cement with high alkali content, or another

source of alkali;

©) Aggregate containing an alkali reactive

constituent.

Where the service records of particular cement

aggregate combination are well established, and do not

include any instances of cracking due to alkali-

‘aggregate reaction, no further precautions should be

necessary. When the materials are unfamiliar,

precautions should take one or more of the following

forms:

8) Use of non-reactive aggregate from alternate

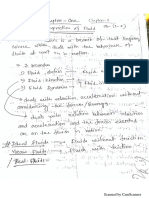

‘Table 5 Minimum Cement Content, Maximum Water-Cement Ratio and Minimum Grade of Concrete

for Different Exposures with Normal Weight Aggregates of 20 mm Nominal Maximum Size

(Clauses 6.12, 824.1 and9.1.2)

= Plata Concrete Relaforced Concrete

Ne

a —_————_.

Minimo Maxima Minimum Minima = Maximum = Minima.

CCenest Free Warr. Grea Cement’ «Free Water. Gnd of

Content Cement Rao —Conerte = Content Cement Ratio Concrete

tein tent

» o o o o o o o

Mie no 080 7 30 oss M20

iy Moderate 0 080 mas sao 050 as

in Severe 20 030 M20 m0 04s M30

iy Verysevere 260 04s Mx Mo 4s mas

Esra 0 ow Mas 60 oo Man

NOTES

1 Cement conten prescribed in thi tbl is imeapecive ofthe grades of cement and itis inclsive of ations mentioned a 82. The

Addon such uly ach or ground ranlated lat fermace slag may be ken ito count n the concrete composition with respect ©

the cement conten nd wate-cereat tof the mtb is eablished and a fog tthe maemo runt taken int acount do

‘ot exceed the lnitof przaloe and sag speciied a 1S 1489 (Pat |) and 1543S rapectivly.

2. Minimum grade for pain concrete der mid exporue condition i ot pei.

20

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Lecture 4 SF and BM Full PageDokumen77 halamanLecture 4 SF and BM Full Pageapi-368340382100% (1)

- SureCash Agent List PDFDokumen18 halamanSureCash Agent List PDFShuvro ChakravortyBelum ada peringkat

- Rules and Regulation of Transmission and Distribution of Natural Gas and Its Application in BangladeshDokumen11 halamanRules and Regulation of Transmission and Distribution of Natural Gas and Its Application in BangladeshShuvro ChakravortyBelum ada peringkat

- Description Total Bazar (TK.) "+/-" Meal Rate (TK.)Dokumen1 halamanDescription Total Bazar (TK.) "+/-" Meal Rate (TK.)Shuvro ChakravortyBelum ada peringkat

- Sheet 1-4Dokumen3 halamanSheet 1-4Shuvro ChakravortyBelum ada peringkat

- at The End of Its First Month of Operations, Watson Answering Services Has The Following UnadjustedDokumen11 halamanat The End of Its First Month of Operations, Watson Answering Services Has The Following UnadjustedShuvro Chakravorty100% (1)

- The Recording Process: Reference Book: Weygandt Kimmel Keiso (9 Edition)Dokumen21 halamanThe Recording Process: Reference Book: Weygandt Kimmel Keiso (9 Edition)Shuvro ChakravortyBelum ada peringkat

- Weygandt Kimmel Keiso 9 EditionDokumen11 halamanWeygandt Kimmel Keiso 9 EditionShuvro ChakravortyBelum ada peringkat

- Lecture CE401 RH 2 TeamsDokumen39 halamanLecture CE401 RH 2 TeamsShuvro ChakravortyBelum ada peringkat

- Code No ListDokumen11 halamanCode No ListShuvro ChakravortyBelum ada peringkat

- Ad. Entry PRB 2Dokumen3 halamanAd. Entry PRB 2Shuvro ChakravortyBelum ada peringkat

- Elixir 93201639468 39471 Published1Dokumen5 halamanElixir 93201639468 39471 Published1Shuvro ChakravortyBelum ada peringkat

- Non-Woven Geotextile Code No: TDF-NW-350-1Dokumen4 halamanNon-Woven Geotextile Code No: TDF-NW-350-1Shuvro ChakravortyBelum ada peringkat

- Fluid Mechanics Sheet PDFDokumen47 halamanFluid Mechanics Sheet PDFShuvro ChakravortyBelum ada peringkat

- Ground Water Table MeasurementDokumen9 halamanGround Water Table MeasurementShuvro ChakravortyBelum ada peringkat