Gta+sma PQR

Diunggah oleh

Rahul MoottolikandyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gta+sma PQR

Diunggah oleh

Rahul MoottolikandyHak Cipta:

Format Tersedia

PROCEDURE QUALIFICATION RECORD

Reference :ASME B31.3,ASME Sec IX and E.S.5.14.0010RA

KRANTZ ENGINEERS W.L.L

Project Name: Ras Laffan Emergency and Safety College

Company Name: Krantz Engineers W.L.L

Procedure Qualification Record No: PQR-KE-001 Date : 09.04.2011

WPS No:WPS-KE-001(NON-IMPACT)

Welding Process: GTAW + SMAW

Types (Manual, Automatic, Semi-Auto): MANUAL

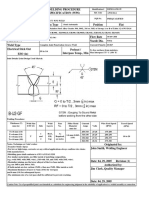

Joints (QW-402)

PQR TEST COUPEN: 6” Ø

SCH80 (API5L.Gr.B to

API5L.Gr.B) PIPE to PIPE

Groove Design Test Coupon

BASE METAL (QW-403) Also as per QW 420.2 POSTWELD HEAT TREATMENT (QW-407)

Material Spec : API5L.Gr.B to API5L.Gr.B Temperature: NA

Type of Grade : Time : NA

P.No 1 Group 1 to P.No 1 Group 1 Other : NA

Thickness of Test Coupon : 10.97 mm

Diameter of Test Coupon : 6” NB 10.97 mm GAS (QW-408) Percent Composition

Other : NA Gas(es) (Mixture) Flow Rate

Shielding Argon 99.99% 8-12 LPM

FILLER METALS(QW-404) Trailing NA NA NA

GTAW SMAW Backing NA NA NA

SFA Specification: SFA 5.18 SFA5.1

AWS Classification ER70-S3 E7018 ELECTRICAL CHARACTERISTICS (QW-409)

Filler Metal F.No F6 F4 Current: DC

Weld Metal Analysis A.No A1 A1 Polarity: GTAW-EN, SMAW –EP

Size of Filler Metal 2.4 mm 2.5 mm Amps: GTAW 70-135Amps SMAW 60-160Amps

Other: OK Tigrod 12.60 OK 55 Volts: GTAW 8-14 Volts SMAW 20-32 Volts

Weld Metal Thickness: 4 mm 6.97 mm Tungsten Electrode Size:2.4 mm

POSITION (QW-405) TECHNIQUE (QW-410)

Travel Speed: GTAW 63-128mm/min SMAW 67-

Position of Groove:2G & 5G

120mm/min

String of Weave Bead:String on Root Pass, Weave-Hot,

Weld Progression (Uphill, Downhill): Uphill

Fill & Cap

Other: NA Oscillations: NA

Multipass or single pass(per side): Multiple Passes

PREHEAT(QW-406) Single or Multiple Electrodes: Single Electrode

Preheat Temp : 25 0C (Ambient Temperature) Other: NA

Interpass Temp: 1800C Max

Other: NA

PROCEDURE QUALIFICATION RECORD

Reference :ASME B31.3,ASME Sec IX and E.S.5.14.0010RA

KRANTZ ENGINEERS W.L.L

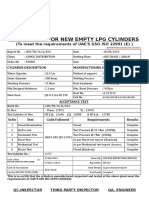

Actual Welding Parameters of Test Coupon

Filter Metal Travel Heat

Weld Current Voltage Remark

Process AWS Speed Input

Pass Brand Name Dia Polarity Amps Volts s

Class (mm/min) kj/mm

Root GTAW ESAB-OK Tigrod 12.60 ER70-S3 2.4 mm DCEN 100-110 9-11 50-90 0.60-0.90

Hot GTAW ESAB-OK Tigrod 12.60 ER70-S3 2.4 mm DCEN 120-140 9-11 90-110 0.60-0.09

Fill SMAW ESAB-OK 55.00 E 7018 2.5 mm DCEP 90-110 23-27 90-115 1.20-2.20

Cap SMAW ESAB-OK 55.00 E 7018 2.5 mm DCEP 90-120 23-27 100-120 1.2-1.4

NDE Results

NDT Method RESULTS Inspection Report Number

Visual Testing Acceptable -

Radiographic Testing Acceptable RT-KE-001A& RT-KE-001B

Magnetic Particle Testing Acceptable MT-KE-001A& MT-KE-001B

Tensile Strength (QW-150)

Thickness UTS Type of Failure &

Specimen No. Width (mm) Area (mm2) UTL (KN)

(mm) (N/mm2) Location

001(2G) 19.11 10.10 193.01 104.10 539 Ductile & PM

002(2G) 19.10 10.10 192.91 106.00 549 Ductile & PM

001(5G) 19.15 10.05 192.46 100.20 521 Ductile & PM

002(5G) 19.15 10.35 198.20 105.00 530 Ductile & PM

Guided-Bend Test (QW160)

Type of Figure No. Result

003,004(2G) Acceptable

005,006(2G) Acceptable

003,004(5G) Acceptable

005,006(5G) Acceptable

Macro result: Satisfactory (Specimen No,007,008) for 2G Deposit Analysis : NA

Satisfactory (Specimen No, 007,008) for 5G

Other Type of Test: Hardness(HV10): Satisfactory (009,010) for 2G

Satisfactory (009,010) for 5G

Welders Name : MURUGESAN

Test Conducted By : EXOVA(QATAR)LLC Report No: for 2G Q 101182

Report No: for 5G Q 101180

We certify that the statement in this record are correct and that the test welds were prepared, welded and tested in

accordance with the requirements of section IX of ASME Ed.2007, ASME B31.3-2008 & ES.5.140.0010 RA

KRANTZ TPI QP

Anda mungkin juga menyukai

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Dokumen2 halamanASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Utoc Preliminary Wps Shell Project 270807 PDFDokumen55 halamanUtoc Preliminary Wps Shell Project 270807 PDFErick HoganBelum ada peringkat

- ASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies PartsDokumen1 halamanASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies Partssathi_mechBelum ada peringkat

- Welding Procedure Qualification Record: Shipyard LogoDokumen4 halamanWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Asme PQR DemoDokumen3 halamanAsme PQR DemoMuthusamy AyyanapillaiBelum ada peringkat

- Welder Qualification CertificateDokumen2 halamanWelder Qualification CertificateNguyen Thanh BinhBelum ada peringkat

- PQRDokumen2 halamanPQRafqzfieBelum ada peringkat

- Is 7310 RequirementsDokumen4 halamanIs 7310 RequirementsRavichandran Tirupattur SubramaniamBelum ada peringkat

- 1035 03Dokumen2 halaman1035 03Anuj ShahiBelum ada peringkat

- P91 Profile WpsDokumen6 halamanP91 Profile WpsManzar KhanBelum ada peringkat

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Dokumen21 halamanTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- HHHHHHHHJJJJJJ: O O O ODokumen1 halamanHHHHHHHHJJJJJJ: O O O OAli MoosaviBelum ada peringkat

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDokumen1 halamanPDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينBelum ada peringkat

- MEI - Aluminium MIG WeldDokumen56 halamanMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- Murex Tig Poster 2008 PDFDokumen1 halamanMurex Tig Poster 2008 PDFPCBelum ada peringkat

- 121 T BW FPDokumen4 halaman121 T BW FPA. ΒρατσισταBelum ada peringkat

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDokumen3 halamanWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEBelum ada peringkat

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Dokumen3 halamanWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Wps Guides 2006Dokumen25 halamanWps Guides 2006BE GBelum ada peringkat

- Specification requirements for CRA/CRA clad pipelines before and during weldingDokumen2 halamanSpecification requirements for CRA/CRA clad pipelines before and during weldingSơn Nguyễn TháiBelum ada peringkat

- Write WPS ISO 15614Dokumen10 halamanWrite WPS ISO 15614Hoang LamBelum ada peringkat

- WPS 316 L PDFDokumen4 halamanWPS 316 L PDFIrinaBelum ada peringkat

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEDokumen18 halamanAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreBelum ada peringkat

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Dokumen2 halaman(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Sabari Engineering PQRDokumen3 halamanSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Dokumen4 halamanPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluBelum ada peringkat

- Weld Checklist PQRDokumen2 halamanWeld Checklist PQRScott Trainor100% (1)

- WPQ WeldCanada PDFDokumen1 halamanWPQ WeldCanada PDFAhmad DanielBelum ada peringkat

- Control Ferrite Content Stainless Steel WeldsDokumen5 halamanControl Ferrite Content Stainless Steel Weldstedmer1Belum ada peringkat

- FCAW Unit TestDokumen4 halamanFCAW Unit TestSatish KeskarBelum ada peringkat

- P-WPS 135 - MAG (GR 316)Dokumen9 halamanP-WPS 135 - MAG (GR 316)Tarun PatelBelum ada peringkat

- Engineer CV Material Specialists Mechanical Piping NDT Coating Inspection Oil Gas AlgeriaDokumen3 halamanEngineer CV Material Specialists Mechanical Piping NDT Coating Inspection Oil Gas Algeriaait.koufiBelum ada peringkat

- CIGWELDDokumen244 halamanCIGWELDrodastrid5653100% (1)

- Welding 11-14%Cr IIW Document - Part 1Dokumen20 halamanWelding 11-14%Cr IIW Document - Part 1Manuel CarreñoBelum ada peringkat

- Welder CertificateDokumen6 halamanWelder CertificateA. ΒρατσισταBelum ada peringkat

- GTAW Welding Process ParametersDokumen12 halamanGTAW Welding Process Parametersmiteshpatel191Belum ada peringkat

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Dokumen60 halaman3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmBelum ada peringkat

- WPQR Welding Procedure QualificationDokumen3 halamanWPQR Welding Procedure QualificationThanasis KyrgiazoglouBelum ada peringkat

- WPS Welding Procedure SpecificationDokumen1 halamanWPS Welding Procedure SpecificationburakBelum ada peringkat

- WPQR6Dokumen3 halamanWPQR6Dimitris NikouBelum ada peringkat

- WPQDokumen10 halamanWPQayoki100% (3)

- I-963 Welder Certificate Smaw-Gtaw-1Dokumen1 halamanI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- GMAWDokumen12 halamanGMAWsushant47Belum ada peringkat

- 1 5 1Dokumen5 halaman1 5 1daemsalBelum ada peringkat

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDokumen5 halamanQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- Quality Alert # 01 Storage of Welding ConsumablesDokumen1 halamanQuality Alert # 01 Storage of Welding ConsumablesGaurav Khamkar100% (1)

- VP16 PDFDokumen13 halamanVP16 PDFKara WhiteBelum ada peringkat

- SMAW DuniDokumen4 halamanSMAW DuniMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Procedure for Radiographic Testing of Welded Steel JointsDokumen30 halamanProcedure for Radiographic Testing of Welded Steel JointsG_ARVALIS8470Belum ada peringkat

- Fillet Weid Break and Macroetch Test PlateDokumen1 halamanFillet Weid Break and Macroetch Test PlatewijiestBelum ada peringkat

- Destructive Test Report for Welding SamplesDokumen14 halamanDestructive Test Report for Welding SamplesMark AnthonyBelum ada peringkat

- Duplex Stainless Steel - Part 2 - TWIDokumen6 halamanDuplex Stainless Steel - Part 2 - TWItuanBelum ada peringkat

- Wps Mma PipeDokumen2 halamanWps Mma PipeDimitris NikouBelum ada peringkat

- Metrode - P92 WPS PDFDokumen3 halamanMetrode - P92 WPS PDFXing ChenBelum ada peringkat

- Qualification of Welding Procedures and WeldersDokumen20 halamanQualification of Welding Procedures and WeldersZanuardi YahyaBelum ada peringkat

- Gmaw Complete Aws d1.6Dokumen1 halamanGmaw Complete Aws d1.6Silvia CardenasBelum ada peringkat

- PWPS Fillet WeldDokumen2 halamanPWPS Fillet WeldUgonnaBelum ada peringkat

- WPS - 023Dokumen10 halamanWPS - 023MAT-LION0% (1)

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- Need of Surface TreatmentDokumen6 halamanNeed of Surface TreatmentRahul MoottolikandyBelum ada peringkat

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Dokumen1 halamanWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyBelum ada peringkat

- OrganicDokumen11 halamanOrganicRahul MoottolikandyBelum ada peringkat

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDokumen3 halamanItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyBelum ada peringkat

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDokumen3 halamanMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyBelum ada peringkat

- Paint GlossaryDokumen18 halamanPaint Glossaryramaraj_37Belum ada peringkat

- 1Dokumen17 halaman1Rahul MoottolikandyBelum ada peringkat

- The Importance of Chemical Treatment for Welding Stainless Steel and AluminiumDokumen6 halamanThe Importance of Chemical Treatment for Welding Stainless Steel and AluminiumRahul MoottolikandyBelum ada peringkat

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDokumen7 halamanMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyBelum ada peringkat

- Report #19aDokumen2 halamanReport #19aRahul MoottolikandyBelum ada peringkat

- Stainless 20Dokumen45 halamanStainless 20k_sivakumar16Belum ada peringkat

- Report #16ADokumen2 halamanReport #16ARahul MoottolikandyBelum ada peringkat

- HYDokumen6 halamanHYRahul MoottolikandyBelum ada peringkat

- Inspection NotesDokumen1 halamanInspection NotesRahul MoottolikandyBelum ada peringkat

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDokumen3 halamanMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyBelum ada peringkat

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDokumen5 halamanMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyBelum ada peringkat

- Guide To Fillet WeldingDokumen7 halamanGuide To Fillet WeldingPeter KyawBelum ada peringkat

- Intresting To KnowDokumen1 halamanIntresting To KnowRahul MoottolikandyBelum ada peringkat

- 026 To 033test ReportsDokumen40 halaman026 To 033test ReportsRahul MoottolikandyBelum ada peringkat

- Safety Relief ValveDokumen1 halamanSafety Relief ValveRahulBelum ada peringkat

- Hydro Test Key PointsDokumen16 halamanHydro Test Key PointsRahulBelum ada peringkat

- Safety Relief ValveDokumen1 halamanSafety Relief ValveRahulBelum ada peringkat

- Pipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )Dokumen3 halamanPipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )Rahul MoottolikandyBelum ada peringkat

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDokumen1 halamanDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyBelum ada peringkat

- Air Density FactorsDokumen23 halamanAir Density FactorsRahul MoottolikandyBelum ada peringkat

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDokumen3 halamanMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyBelum ada peringkat

- 026 To 033test ReportsDokumen40 halaman026 To 033test ReportsRahul MoottolikandyBelum ada peringkat

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDokumen7 halamanMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyBelum ada peringkat

- Report #01Dokumen4 halamanReport #01Rahul MoottolikandyBelum ada peringkat

- Gate Pass Request Form: Requested Date: Reference NoDokumen1 halamanGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyBelum ada peringkat

- Traction CONTROLDokumen18 halamanTraction CONTROLkiransideasBelum ada peringkat

- Bench Scale Jig-Column Test On Network 1 Copper Ore: Mri) Uyrr,."S... I..., C, L. F.3 1': NW .-Lyu ... ,. .. .-, - IDokumen20 halamanBench Scale Jig-Column Test On Network 1 Copper Ore: Mri) Uyrr,."S... I..., C, L. F.3 1': NW .-Lyu ... ,. .. .-, - IAhmed Mohamed RedaBelum ada peringkat

- Pec RulesDokumen2 halamanPec RulesMhayson LpaguipoBelum ada peringkat

- Boiler Feed Water Treatment & BlowdownDokumen6 halamanBoiler Feed Water Treatment & BlowdownnurulBelum ada peringkat

- MSDS Accepta LTD Accepta 3543Dokumen5 halamanMSDS Accepta LTD Accepta 3543mechzarBelum ada peringkat

- PRESSURE DROP CALCULATION FOR DRILL WATER PIPEDokumen9 halamanPRESSURE DROP CALCULATION FOR DRILL WATER PIPEdasubhaiBelum ada peringkat

- Utilities Module 2Dokumen27 halamanUtilities Module 2Celinni DasigBelum ada peringkat

- Seminar Presentation PPT On Reactive Powder Concrete Civil EngineeringDokumen39 halamanSeminar Presentation PPT On Reactive Powder Concrete Civil Engineeringshreekanth bapatBelum ada peringkat

- Cool The Summer - Leaflet - HRDokumen48 halamanCool The Summer - Leaflet - HRPeter Ace John IngelBelum ada peringkat

- Mole ConceptDokumen3 halamanMole Conceptzafarchem_iqbalBelum ada peringkat

- Optimize Diesel Engine Performance with DENSO Common Rail SystemDokumen50 halamanOptimize Diesel Engine Performance with DENSO Common Rail SystemAnonymous yjK3peI793% (15)

- Souvinir AIMTDR PDFDokumen351 halamanSouvinir AIMTDR PDFKushal Singh100% (3)

- Vivax Acp-12ch35gei Service ManualDokumen67 halamanVivax Acp-12ch35gei Service Manualdrm_gBelum ada peringkat

- 55 Emerson Catalog PDFDokumen82 halaman55 Emerson Catalog PDFBRLSwamyBelum ada peringkat

- ASTM Volume 01.01 Steel Piping StandardsDokumen4 halamanASTM Volume 01.01 Steel Piping StandardsPrasanna UmapathyBelum ada peringkat

- NAVEEN Acc LTDDokumen96 halamanNAVEEN Acc LTDNAVEEN DUBEYBelum ada peringkat

- Sensitization of Weld Overlay 308 PDFDokumen12 halamanSensitization of Weld Overlay 308 PDFShoaib AhmedBelum ada peringkat

- Solid Waste Management A Case Study of Jaipur City IJERTCONV4IS23003Dokumen4 halamanSolid Waste Management A Case Study of Jaipur City IJERTCONV4IS23003manjuBelum ada peringkat

- R744 and R290Dokumen7 halamanR744 and R290SURAJ NAGBelum ada peringkat

- Barangay Ordinance On Open Burning 2022Dokumen4 halamanBarangay Ordinance On Open Burning 2022Catherine Parinas100% (4)

- Lanmark FTP Patch 26AWGDokumen3 halamanLanmark FTP Patch 26AWGAnonymous SE7u3C1dBelum ada peringkat

- Waste Heat RecoveryDokumen25 halamanWaste Heat RecoveryJoeb DsouzaBelum ada peringkat

- Computational Modelling for Lithium Extraction from Sea WaterDokumen24 halamanComputational Modelling for Lithium Extraction from Sea WaterShivansh MishraBelum ada peringkat

- Components: Hitec® 536Dokumen2 halamanComponents: Hitec® 536Liliana RodriguezBelum ada peringkat

- Heat Loss CalculationDokumen2 halamanHeat Loss CalculationdsborwankarBelum ada peringkat

- Reactive and Explosive MaterialsDokumen30 halamanReactive and Explosive Materialsicol451Belum ada peringkat

- Fine Woodworking 028Dokumen92 halamanFine Woodworking 028Buliga Alexandra Elena100% (2)

- Braden Bga06 Manual de PartesDokumen24 halamanBraden Bga06 Manual de PartesMauricio Ariel H. OrellanaBelum ada peringkat

- PO format-ACCDokumen17 halamanPO format-ACCSpace designBelum ada peringkat

- IrisDokumen16 halamanIrisvibinkumarsBelum ada peringkat