Luong Minh Tue

Diunggah oleh

LinhXuânPhạmDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Luong Minh Tue

Diunggah oleh

LinhXuânPhạmHak Cipta:

Format Tersedia

石油学会誌 Sekiyu Gakkaishi, 42, (6), 403-410 (1999) 403

[Techical Paper]

A Fundamental Study on Vietnamese Crude Oil Refining

-Normal Paraffin Separation and Utilization-

Koichi KATO†1)* and Pham Quang DU†2)

†1) Nikko Consulting & Engineering Co., Ltd., 4-1-40 Toranomon, Minato-ku, Tokyo 105-0001

†2) Research & Development Center for Petroleum Processing, Petro Vietnam, 4 Nguyen Thong St. Dist. 3, Ho Chi Minh City, Vietnam

(Received February 4, 1999)

Vietnamese crude oil such as Bach Ho has a high paraffin content, and it must be processed in a different man-

ner from ordinary crudes to obtain maximum fuel products. In this paper, we discuss the following: characteris-

tics of Vietnamese crudes and distillates; experimental data on normal paraffin removal from distillates (mainly

gas-oil fraction) to meet product specifications; and the applications of recovered normal paraffins. Design

analysis and economics study are also conducted to illustrate the feasibility of the projects. In order to produce

on-spec gas-oil from Bach Ho crude, normal paraffin extraction process using molecular sieve has been selected,

and LAB (Linear Alkyl Benzene) and SAS (Sodium Alkane Sulfonate) productions from the recovered normal

paraffins are discussed.

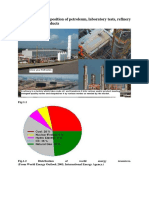

1. Introduction pies are low in sulfur, nitrogen, vanadium, nickel, and

asphaltene resin constituent elements (cf. Table 1)3).

The need for establishing oil refineries and petro- Because of high paraffin contents, pour points of

chemical complex in Vietnam has long been recog- Vietnamese crudes are about 30℃ causing much diffi-

nized by the Vietnamese Government. PetroVietnam culties in production, transportation and storage. The

intends to set up the first oil refinery with a processing high pour point suggests that some technical methods

capacity of 120,000 BSD of Vietnamese crude oil per of pour-point reduction are required to minimize the

year, and to start up its operation from the beginning of above difficulties.

next century. Vietnamese crude oils, such as Bach Ho In Table 2 the basic assays and some general refin-

(White Tiger) and Dai Hung (Big Bear) crudes, have ing properties of Vietnam Bach Ho crude distillates are

high paraffin contents, so they must be processed in a shown1)-3). For example, the kerosene fraction has

different manner from ordinary Middle Eastern crudes properties suitable for light kerosene. However, if

to obtain maximum fuel products. Because of the intended to produce jet fuel, some technical characteris-

high normal paraffin contents in the crude oil fractions, tics, such as freezing point, must be considered further.

paraffin separation processes and processes to convert The gas-oil fraction has high-quality characteristics

the paraffin to petrochemical feedstocks must be con- for diesel fuel. The cetane index, for instance, is 61.3-

sidered for future Vietnamese petroleum and petro- 69.8. However, its pour point, 7.5℃, is rather high.

chemical industries. In this paper we discuss the fol- From the 240-360℃ fraction, the normal paraffin yield

lowing topics: (1) characteristics of Vietnamese crudes can be as high as 51.7wt% of the fraction, or about

and distillates; (2) normal paraffin removal from distil- 23.2wt% of the whole crude. Liquid normal paraffins

lates (mainly gas-oil fraction) to meet the product spec- are particularly valuable feeds for downstream chemi-

ifications; and (3) applications of recovered normal cals production.

paraffins. The heavy fuel oil fraction, approximately 55wt%

yield, has a low sulfur content 0.12-0.20wt%, making

2. Characteristics and Refining of Vietnamese it a good fuel from environmental standpoint and a suit-

Crude Oils able feed for residual catalytic cracking. However, its

high pour point, 48-51℃, creates difficulties in storage

Vietnamese crudes, according to the samples from and handling.

the Bach Ho and other fields show high paraffin con- Because of the high normal paraffin content of the

tents (greater than 17wt% paraffins)1),2). All the sam- gas-oil fraction, and the high wax content of the fuel

oil, paraffin separation processes and the processes to

* To whom correspondence should be addressed.

convert the paraffin wax to petrochemical feedstocks

(Present) Japan Energy Research Center Co., Ltd., 3-17-35 Niizo-

Minami, Toda, Saitama 335-8502 must be considered.

石油学会誌 Sekiyu Gakkaishi, Vol. 42, No. 6, 1999

404

Table 1 The Properties of Vietnamese Crude Oils

Refining sweet Vietnamese crudes requires neither A 1000cc flask with a rotating mixer is used for

high quality anti-corrosive plant materials nor deep kerosene (100g) and urea (200g) reaction. After 4

desulfurization processes. However, their high pour hours of agitation at room temperature, solid urea

points cause more difficulties in the use of the product adduct produced is separated by filtration and washed

oil fractions. As stated before, this means that other thoroughly by solvent and then dried. The dried urea

methods for pour-point reduction are required. adduct is then decomposed with hot water into normal

Examples of such methods are summarized in Table 3. paraffins and urea. Dewaxed oil is recovered by elim-

Of the methods, normal paraffin removal was chosen inating the solvent using an evaporator. For the

because it best meets the objectives of maximum pro- gas-oil fraction, separation is carried out in the same

duction and cost effectiveness. manner but on a double scale.

The basis of the following study on normal paraffin Normal paraffin distributions in feedstock kerosene

distribution in the Bach Ho crude was our gas-chro- and gas-oil and the distribution in the recovered normal

matographic analysis (Fig. 1)4). It shows smooth dis- paraffin are shown in Fig. 3.

tribution, compared with the previously reported data The properties of the sample fractions are then mea-

which had clearly shown a minimum at carbon number sured using an authorized method.

around 102). 3.2. Effects of Normal Paraffin Contents

3.2.1. On Freeze/Cloud Points of Kerosene Frac-

3. Effects of Normal Paraffin Removal tion

The relationship between freezing and cloud points

3.1. Experimental of kerosene fraction and normal paraffin contents are

Normal paraffin removal experiments have been car- shown in Table 5 and Fig. 4.

ried out using the urea adduction method5) to investi- The freezing point of virgin kerosene is -40℃. In

gate the relationship between freeze/cloud points of order to produce on-spec jet fuel, certain amount of

kerosene fraction and normal paraffin content. The normal paraffin should be removed to meet the specifi-

relationship between the pour point of gas-oil and nor- cation, which is below -47℃.

mal paraffin content was also investigated. The prop- 3.2.2. On Pour/Cloud Points of Gas-Oil Fraction

erties of feedstocks for the experiments are shown in The relationship between pour point and cloud point

Table 4. Experimental procedure is shown in Fig. 2. with respect to the normal paraffin content in gas-oil is

Normal paraffin free oil thus obtained is re-mixed shown in Table 6 and Fig. 5.

with the virgin distillate fraction to obtain changeable For gas-oil fraction when its normal paraffin content

paraffin contents in the sample fractions. decreases, its pour point also decreases, as shown in

石油学会誌 Sekiyu Gakkaishi, Vol. 42, No. 6, 1999

405

Table 2 The Properties of Bach Ho Crude Distillates

a) OGJ 1989. b) OGJ 1990. c) PEC Report.

Table 3 Pour Point Reduction Methods

Fig. 5. However, the degree of the effect is not as point (below 0℃), normal paraffins in the fraction

dramatic in the range of normal paraffin content above should be kept less than 35wt%. Also shown in Fig.

20%. 5 is the relationship between normal paraffins content

In order to meet the specification of diesel oil pour and pour point obtained by mixing with Dubai crude

石油学会誌 Sekiyu Gakkaishi, Vol. 42, No. 6, 1999

406

Fig. 1 Normal Paraffin Distribution of Bach Ho Crude Oil

Table 4 The Properties of Kerosene and Gas-Oil Used for the

Study

Fig. 2 Separation of Normal Paraffins from Bach Ho Distillate

by Adduction of Urea

distillate3). The difference between the slopes of two

curves suggets that Dubai gas-oil contains normal

paraffins of higher solubility.

4. Evaluation and Selection of Normal Paraffin

Removal Technology

A study has been carried out for processes to sepa-

rate and recover normal paraffins from a wide range

gas-oil fraction of Bach Ho crude oil. The reason as

to why gas-oil fraction, not kerosene, has been taken up

for this study is that gas oil pour point improvement is

Fig. 3 The Result of Separation by Adduction of Urea:

much more crucial than that of the freeze point of

Normal Paraffin from Kerosene and Diesel Fraction of

kerosene. Processes evaluated are those of Molex and Bach Ho Crude Oil

Nurex. The former is a liquid phase separation of n-

paraffins from iso-paraffins using molecular sieve and

the latter is that based on urea adduction about which numbers, in which carbon numbers 10 to 15 (contained

has already been mentioned. The Molex process has in kerosene and gas-oil fraction) are important raw

been selected mainly because of its cost advantage materials for production of linear alkylbenzene deter-

(Table 7)4). Sources of the data are published infor- gents (LABs). As shown in Fig. 1, substantial

mation and consultant's data files. amounts of normal paraffins are found in this carbon

range. According to the forecast of demand on nor-

5. Normal Paraffin Application mal paraffins in the world, some shortage is expected

now and in the near future4).

Normal paraffins are widely used in various chemi- As stated before, it is better to consider a normal

cal industries as basic raw materials, and their major paraffin application in the refinery to make the project

application is the production of detergents. more profitable, taking the future domestic market of

Their application depends on normal paraffin carbon normal paraffins into consideration.

石油学会誌 Sekiyu Gakkaishi, Vol. 42, No. 6, 1999

407

Table 5 Relationship between NP Contents and Freeze/Cloud Pts in Kerosene

NP: Normal paraffin.

Table 6 Relationship between NP Contents and Pour/Cloud Pts in Gas-Oil

NP: Normal paraffin.

Fig. 4 Relationship between NP Contents and Freeze/Cloud Fig. 5 Relationship between NP Contents and Pour Point in

Pts in Kerosene Gas-Oil

Table 7 Normal Paraffin Separation Process Comparison

Linear alkylbenzene sulfonate (LAS) production has The demand for normal paraffins with carbon num-

already been started in Vietnam. There are four facto- bers larger than 16 is rather limited. SAS (Sodium

ries as of 1998 producing LAS using around 50,000 Alkane Sulfonate) production is, however, recommend-

tons/year of LAB, and their expansion will be consid- ed and realized because of its high biodegradability3),4)

ered.

石油学会誌 Sekiyu Gakkaishi, Vol. 42, No. 6, 1999

408

Fig. 6 Material Balance for Normal Paraffin Separation from 120,000 BSD Refinery

6. Process Design and Economics

In a Bach Ho fed 120,000 BSD refinery, conditions

to produce the maximum amount of on-spec diesel oil

(pour point 0℃) and normal paraffin feedstocks for

LAB and SAS are being studied. The properties of

feedstock gas-oil are shown in Table 4.

The resulting material balance is shown in Figs. 6

and 7. The Molex feed capacity is ca. 14,000 BSD,

and on-spec diesel oil of 20,145 BSD can be produced

as shown in the scheme, while the feedstocks for LAB

and SAS are 100,890 and 115,745 tons/year, respec-

tively. In LAB production, Pacol plus HF Alkylation

and Pacol plus Detal processes are considered. Pacol

is a catalytic dehydrogenation process using a platinum Fig. 7 Material Balance for LAB and SAS Production

catalyst, and Detal process is a direct alkylation of ben-

zene with olefins using a solid heterogeneous catalyst.

Both processes were developed by UOP. normal paraffins that results in better kerosene

Using the material balance, production costs of nor- smoke point, better diesel cetane number, and high-

mal paraffins for LAB and SAS are estimated. The er freezing point in jet fuel and higher pour point in

results shown in Table 8 indicate that commercial pro- the gas-oil fraction. Normal paraffin distribution

duction of LAB and SAS at current market prices is of Bach Ho crude has also been investigated.

feasible. (2) In order to reduce the pour point of the above frac-

tion, several methods are reviewed. Of the meth-

7. Conclusions ods normal paraffin removal from the fraction is

found effective and is recommended.

As a result of this investigation, the following con- (3) Experiments on normal paraffin separation using

clusions have been obtained. urea are carried out to establish a relationship

(1) Vietnamese crude oil such as Bach Ho crude con- between normal paraffin content and pour point of

tains a low content of sulfur, but a high content of gas-oil (or freezing point of kerosene).

石油学会誌 Sekiyu Gakkaishi, Vol. 42, No. 6, 1999

409

Table 8 Summary of Economic Results

Basis

Bach Ho crude price 17.0US$/BBL.

Price of utilities: Fuel 10US$/MMkcal, Electricity 0.1US$/kWh, Steam 16.5US$/ton, Water 2US$/ton.

Depreciation period: 15 year. As of March 1998 in Japan.

(4) Normal paraffin removal processes are reviewed. International Trade and Industry of Japan.

Molex is found to be suitable for gas-oil fraction.

(5) For normal paraffin application, in which the degree References

of pour point reduction of gas oil and that of carbon

distribution are both taken into consideration, LAB 1) Du, P. Q., Oil & Gas J., Nov. 6, 39 (1989).

2) Du, P. Q., Oil & Gas J., July 16, 58 (1990).

and SAS are selected. Economic studies suggest

3) Research report, No.1996-I-50, Petroleum Energy Center, Japan

that their commercial production is feasible.

(1997).

4) Research report, No. 1997-I-52, Petroleum Energy Center, Japan

Acknowledgments (1998).

Part of this work has been sponsored by Petroleum 5) Yata, N., Bull. of Jpn. Petrol. Inst., 4, March, 35 (1962).

Energy Center, which is supported by The Ministry of

石油学会誌 Sekiyu Gakkaishi, Vol. 42, No. 6, 1999

410

要 旨

ベ トナ ム 原 油 の 精 製 に関 す る基 礎 的 研 究

-ノ ル マル パ ラ フ ィン の分 離 と有 効 利 用-

加 藤 恒 一†1), Pham Quang DU†2)

†1) 日鉱 エ ン ジ ニ ア リ ン グ (株), 105-0001東 京 都 港 区 虎 ノ 門4-1-40

†2)Research & Development Center for Petroleum Processing, Petro Vietnam, 4 Nguyen Thong St. Dist. 3, Ho Chi Minh City, Vietnam

ベ トナ ム に お い て は 国 産 原 油 を主 と して 処 理 す る製 油 所 計 画 ル パ ラ フ ィ ン の 量 を 分 離 実 験 に よ り 求 め た。 同 時 に 得 ら れ る ノ

が 進 ん で い る。 バ ッ クホ ー 等 の ベ トナ ム 原 油 は 高 濃 度 の ノ ルマ ル マ ル パ ラ フ ィ ン の 用 途 に つ い て 検 討 しLAB (Linear Alkyl

ル パ ラ フ ィ ン を含 む た め, 留 分 を も含 め て 流 動 点 が 高 く, 規 格 Benzene) とSAS (Sodium Alkane Sulfonate) を 選 定 し た。

に 合 致 す る 製 品 を効 率 的 に 得 る た め には 中 東 原 油 と異 な った 精 120,000BSDの 製 油 所 に 対 す る 本 ス キ ー ム の プ ロ セ ス 設 計, 設

製 法 が 必 要 とな る。 備 検 討 を 行 いLABお よ びSAS生 産 の 経 済 的 可 能 性 を確 認 し

バ ッ クホ ー 原 油 お よび そ の 留 分 の 性 質 を検 討 し, 軽 油 の 流 動 た。

点 を規 格 (0℃) に合 わせ る た め 同 留 分 か ら抽 出 す べ きノ ル マ

Keywords

Crude oil, Normal paraffin, Dewaxing, Linear alkylbenzene, Pour point, Separation

石 油 学 会誌 Sekiyu Gakkaishi, Vol. 42, No. 6, 1999

Anda mungkin juga menyukai

- UniversityPhysicsVolume3 OPDokumen616 halamanUniversityPhysicsVolume3 OPSamuel Ciorap100% (2)

- Oxford Six Class Science NotesDokumen15 halamanOxford Six Class Science NotesLisha92% (12)

- Petroleum Refining Technology DR Ram Prasad 1st Editionpdf PDFDokumen210 halamanPetroleum Refining Technology DR Ram Prasad 1st Editionpdf PDFMahesh ChoudharyBelum ada peringkat

- Revamping An Integrated Hydrocracker and Lube Base Oil UnitDokumen5 halamanRevamping An Integrated Hydrocracker and Lube Base Oil UnitVyacheslavBelum ada peringkat

- Mini Oil RefineryDokumen20 halamanMini Oil Refinerygochi bestBelum ada peringkat

- Petroleum Refining ProcessesDokumen21 halamanPetroleum Refining ProcessesJimBelum ada peringkat

- Mini RefineryDokumen12 halamanMini RefinerySaraAwad100% (1)

- Cylinder Lubrication Marine Engines ArticleDokumen10 halamanCylinder Lubrication Marine Engines ArticleVijay Geddada100% (2)

- PCS#176, Low-Capital Crude Unit Revamp Increases Product YieldDokumen4 halamanPCS#176, Low-Capital Crude Unit Revamp Increases Product YieldJeffrey Ryan LindmarkBelum ada peringkat

- PTQ Efficient Crude BlendingDokumen7 halamanPTQ Efficient Crude BlendingArpit SharmaBelum ada peringkat

- High-Pour-Point and Asphaltic Crude Oils and CondensatesDokumen5 halamanHigh-Pour-Point and Asphaltic Crude Oils and CondensatesarispriyatmonoBelum ada peringkat

- Varnish in Turbine OilsDokumen6 halamanVarnish in Turbine OilsToppy Toppy100% (1)

- Isomerization Process, Reactions, Effects of Process Variables. IsomerizationDokumen6 halamanIsomerization Process, Reactions, Effects of Process Variables. IsomerizationAlaa El-sherbinBelum ada peringkat

- StructuralMechanicsModuleUsersGuide PDFDokumen1.160 halamanStructuralMechanicsModuleUsersGuide PDFKamran PanaghiBelum ada peringkat

- Heavy and Extra-heavy Oil Upgrading TechnologiesDari EverandHeavy and Extra-heavy Oil Upgrading TechnologiesPenilaian: 4 dari 5 bintang4/5 (2)

- Upgrading of Heavy Crude Oils - CastillaDokumen7 halamanUpgrading of Heavy Crude Oils - Castillapks24886Belum ada peringkat

- Lecture 3: Petroleum Refining Overview: 3.1 Crude OilDokumen66 halamanLecture 3: Petroleum Refining Overview: 3.1 Crude OilKumar AyushBelum ada peringkat

- DR FCC PDFDokumen7 halamanDR FCC PDFAle SanzBelum ada peringkat

- FDP-Zubara Gas FieldDokumen86 halamanFDP-Zubara Gas FieldLinhXuânPhạmBelum ada peringkat

- Refinery Configurations For Maximizing Middle DistillatesDokumen9 halamanRefinery Configurations For Maximizing Middle DistillatesramiarenasBelum ada peringkat

- 03 Road Map Presentation ItalyDokumen26 halaman03 Road Map Presentation ItalyKURAF MUHENDISLIK AŞ.Belum ada peringkat

- PTP-13.1 HandoutDokumen14 halamanPTP-13.1 HandoutJayBelum ada peringkat

- Extraction of Aromatic Hydrocarbons From Lube Oil Using Different Co-SolventDokumen13 halamanExtraction of Aromatic Hydrocarbons From Lube Oil Using Different Co-Solventchirag jainBelum ada peringkat

- CrudeoilDokumen34 halamanCrudeoilr_nagpalBelum ada peringkat

- Elar Be 2021Dokumen10 halamanElar Be 2021Ilham PutraBelum ada peringkat

- Petroleum Refining (Compatibility Mode)Dokumen37 halamanPetroleum Refining (Compatibility Mode)Sri GowthamBelum ada peringkat

- Methaforming Process Description en A4Dokumen16 halamanMethaforming Process Description en A4ruhayemBelum ada peringkat

- Canola Oil ExtractedDokumen5 halamanCanola Oil ExtractedJorge CopadoBelum ada peringkat

- Lube Oil: D 1747-89 Standard Test Method For Refractive Index of Viscous MaterialsDokumen3 halamanLube Oil: D 1747-89 Standard Test Method For Refractive Index of Viscous MaterialsmahsaBelum ada peringkat

- Fractio of Crude Oil 2Dokumen4 halamanFractio of Crude Oil 2KORAMA KIENBelum ada peringkat

- Paper Nr101Dokumen6 halamanPaper Nr101SterlingBelum ada peringkat

- Extraction of Aromatic Hydrocarbons From Lube Oil Using Different Co-SolventDokumen12 halamanExtraction of Aromatic Hydrocarbons From Lube Oil Using Different Co-Solventn.hartonoBelum ada peringkat

- Review of Visbreaking (2008)Dokumen45 halamanReview of Visbreaking (2008)Axel Morales Piñón.Belum ada peringkat

- ResumoAlargado SaraSousaDokumen10 halamanResumoAlargado SaraSousaHồng ÂnBelum ada peringkat

- Waste OBMDokumen9 halamanWaste OBMmeteBelum ada peringkat

- Control de Parafinas y AsfaltenosDokumen11 halamanControl de Parafinas y AsfaltenosJesus Ponce GBelum ada peringkat

- Production of Biolubricant From Parkiabiglobosa Seed Oil Through TransesterificationDokumen5 halamanProduction of Biolubricant From Parkiabiglobosa Seed Oil Through TransesterificationINUWA LAMIDOBelum ada peringkat

- CHAPTER No. 2 (ADU AND VDU)Dokumen5 halamanCHAPTER No. 2 (ADU AND VDU)snow ivoryBelum ada peringkat

- Hart2014 Article TheNovelTHAICAPRITechnologyAndDokumen11 halamanHart2014 Article TheNovelTHAICAPRITechnologyAndalejandro Altamirano QuirogaBelum ada peringkat

- Classificationof Crude Oilsandits Fractionsonthe Basisof ParaffinicDokumen9 halamanClassificationof Crude Oilsandits Fractionsonthe Basisof ParaffinicShradhhaBelum ada peringkat

- Performance of Synthesized Rice Husk Ash (Rha-Based) Adsorbent As A Palm Oil Bleaching MaterialDokumen6 halamanPerformance of Synthesized Rice Husk Ash (Rha-Based) Adsorbent As A Palm Oil Bleaching MaterialAli MulhakimBelum ada peringkat

- Castor Oil Biodiesel Production and OptimizationDokumen6 halamanCastor Oil Biodiesel Production and OptimizationKyraBelum ada peringkat

- Refinery Processing of Asphalt Cement: Luke W. CorbettDokumen5 halamanRefinery Processing of Asphalt Cement: Luke W. CorbettFarrukh ChoksiBelum ada peringkat

- Petrotech 2009 Paper1Dokumen7 halamanPetrotech 2009 Paper1rvsingh100% (1)

- Chemcon 2013: Modeling, Simulation and Optimization of Naphtha Reforming Process On ASPEN Plus PlatformDokumen5 halamanChemcon 2013: Modeling, Simulation and Optimization of Naphtha Reforming Process On ASPEN Plus PlatformArash AbbasiBelum ada peringkat

- SPE 65382 Study and Application of The Viscosity Reducer Used in Production of The Viscous Crude OilDokumen7 halamanSPE 65382 Study and Application of The Viscosity Reducer Used in Production of The Viscous Crude OilJuan Sebastian Eslava HerreraBelum ada peringkat

- Terpolymers As Flow Improvers For Mexican Crude Oils PDFDokumen6 halamanTerpolymers As Flow Improvers For Mexican Crude Oils PDFAfzal AktharBelum ada peringkat

- Introduction To RefineryDokumen6 halamanIntroduction To RefinerydyarBelum ada peringkat

- Study of The Effect of The Temperature of Caustic Tower Operation On Red Oil Formation in Olefin UnitsDokumen6 halamanStudy of The Effect of The Temperature of Caustic Tower Operation On Red Oil Formation in Olefin UnitsLux Olan ReyesBelum ada peringkat

- Egyptian Journal of Petroleum: S.T. Keera, S.M. El Sabagh, A.R. TamanDokumen6 halamanEgyptian Journal of Petroleum: S.T. Keera, S.M. El Sabagh, A.R. TamanABDULLAH BONOBelum ada peringkat

- Introduction RFCCDokumen2 halamanIntroduction RFCCJiana Nasir100% (1)

- PDFDokumen8 halamanPDFgobiksBelum ada peringkat

- Article - Care and Maintenance of Quench OilsDokumen6 halamanArticle - Care and Maintenance of Quench OilsLuiz guilherme OliveiraBelum ada peringkat

- Crude Oil CharacterisationDokumen7 halamanCrude Oil CharacterisationSwiftTGSolutionsBelum ada peringkat

- 2014 ICEES CalcinationsofPetroleumcokeDokumen4 halaman2014 ICEES CalcinationsofPetroleumcokekirboikaladBelum ada peringkat

- A More Efficient Palm Oil Extraction MethodDokumen19 halamanA More Efficient Palm Oil Extraction MethodnfkryhBelum ada peringkat

- Production of Biodiesel From Jatropha Oil (Jatropha Curcas) in Pilot PlantDokumen8 halamanProduction of Biodiesel From Jatropha Oil (Jatropha Curcas) in Pilot PlantDebasishBelum ada peringkat

- Performance Test of Palm Fatty Acid Biodiesel On Compression Ignition EngineDokumen9 halamanPerformance Test of Palm Fatty Acid Biodiesel On Compression Ignition EngineTimotius Candra KusumaBelum ada peringkat

- Geospatial Visualization For Second-Generation Renewable Diesel Feedstock From Palm Oil Value Chain in Indonesia-RevisionDokumen60 halamanGeospatial Visualization For Second-Generation Renewable Diesel Feedstock From Palm Oil Value Chain in Indonesia-RevisionYori Timotius BangunBelum ada peringkat

- Cdu 3Dokumen76 halamanCdu 3Duong PhamBelum ada peringkat

- Naphthenic Base Lube Oil Manufactured Via Hydrogenation Process Naphthenic Base Lube Oil Manufactured Via Hydrogenation ProcessDokumen30 halamanNaphthenic Base Lube Oil Manufactured Via Hydrogenation Process Naphthenic Base Lube Oil Manufactured Via Hydrogenation ProcessDaniel DaiaBelum ada peringkat

- Reactive AdsorptionDokumen9 halamanReactive AdsorptionLinhXuânPhạmBelum ada peringkat

- Additives For Petroleum Products: Pham Thi Linh Xuan K4-Refining and PetrochemicalDokumen15 halamanAdditives For Petroleum Products: Pham Thi Linh Xuan K4-Refining and PetrochemicalLinhXuânPhạmBelum ada peringkat

- Mon Mar 11 15:28:18 2019 Case: Case 1.hsc Flowsheet: Case (Main)Dokumen1 halamanMon Mar 11 15:28:18 2019 Case: Case 1.hsc Flowsheet: Case (Main)LinhXuânPhạmBelum ada peringkat

- Bể chứaDokumen18 halamanBể chứaLinhXuânPhạmBelum ada peringkat

- MSDS Catridge HPDokumen7 halamanMSDS Catridge HPdp abdullahBelum ada peringkat

- D 5088 - 90 - RduwodgtotaDokumen3 halamanD 5088 - 90 - RduwodgtotaPrakash MakadiaBelum ada peringkat

- Dfe 4 B 043 Bcca 419825Dokumen11 halamanDfe 4 B 043 Bcca 419825Sarvesh DubeyBelum ada peringkat

- Electric Charges and FieldDokumen42 halamanElectric Charges and FieldKunal ChaudharyBelum ada peringkat

- Dielectric Loaded Horn Feed For Radiometer AntDokumen4 halamanDielectric Loaded Horn Feed For Radiometer Antవేలుసామి లింగాసామిBelum ada peringkat

- MODULE 2 Electric FieldsDokumen12 halamanMODULE 2 Electric FieldsVenus CaringalBelum ada peringkat

- Quantum Mechanics JEST 2012-2019 PDFDokumen37 halamanQuantum Mechanics JEST 2012-2019 PDFjhansiBelum ada peringkat

- Pure Biology Chapter 7 Nutrition in PlantsDokumen38 halamanPure Biology Chapter 7 Nutrition in Plantshamsterish100% (2)

- Tutorial Test 3 QPDokumen3 halamanTutorial Test 3 QPMohan Kumar100% (1)

- General Relativity and Cosmology : Martin Bucher and Wei-Tou NiDokumen15 halamanGeneral Relativity and Cosmology : Martin Bucher and Wei-Tou NiashishBelum ada peringkat

- Us4560481 - Co-Polymer Hps-1 Aa - AhpseDokumen6 halamanUs4560481 - Co-Polymer Hps-1 Aa - AhpseKhanh Nguyen TuanBelum ada peringkat

- Physics 1 Week 9Dokumen16 halamanPhysics 1 Week 9Santos, Alexsandria PaulaBelum ada peringkat

- R.T.-1 P-08-05-2011 Paper-1 12th (ABCD) (English) Code-B WADokumen12 halamanR.T.-1 P-08-05-2011 Paper-1 12th (ABCD) (English) Code-B WASushmit GuptaBelum ada peringkat

- Science 9 Q2W1-2Dokumen19 halamanScience 9 Q2W1-2Tito BadangBelum ada peringkat

- Final PrEN 16782Dokumen23 halamanFinal PrEN 16782App Protecţia PatrimoniuluiBelum ada peringkat

- End Group 2Dokumen22 halamanEnd Group 2Sabha Khalid shafiqBelum ada peringkat

- Clasification Torbanite and Cannel Coal IDokumen22 halamanClasification Torbanite and Cannel Coal IJulian De Bedout OrdoñezBelum ada peringkat

- CHEM 210 Karty Exam 2Dokumen19 halamanCHEM 210 Karty Exam 2nm100% (1)

- Medicel® Oxygen (O2) Gas SensorDokumen5 halamanMedicel® Oxygen (O2) Gas SensorShtomaBelum ada peringkat

- INDUSTRIAL HAZARDS AND THEIR SAFETY NotesDokumen15 halamanINDUSTRIAL HAZARDS AND THEIR SAFETY NotesSimna RamesanBelum ada peringkat

- Exact Solutions of The Ising Model in 1 and 2 Dimensions PDFDokumen5 halamanExact Solutions of The Ising Model in 1 and 2 Dimensions PDFLeonardo Suárez SánchezBelum ada peringkat

- VCMDokumen1 halamanVCMLearners DotcomBelum ada peringkat

- AG Gauge Valves AEDokumen51 halamanAG Gauge Valves AEbaladiroyaBelum ada peringkat

- CHEN 3001 Transport Phenomena: Week 5: Lecture 1 Basic ConceptsDokumen50 halamanCHEN 3001 Transport Phenomena: Week 5: Lecture 1 Basic ConceptsRashveenaBelum ada peringkat

- Performance Comparison of New and Conventional Water RepellentsDokumen6 halamanPerformance Comparison of New and Conventional Water RepellentsQuyen Tran Thi AnhBelum ada peringkat

- Planets in The Solar SystemDokumen11 halamanPlanets in The Solar SystemYeshalyn IrogBelum ada peringkat

- PH127 Lectures Nov. 2022 4Dokumen212 halamanPH127 Lectures Nov. 2022 4dicksonjohnxpBelum ada peringkat