RAX

Diunggah oleh

Zona Educación Especial ZacapaoaxtlaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

RAX

Diunggah oleh

Zona Educación Especial ZacapaoaxtlaHak Cipta:

Format Tersedia

TRANSMISSION & DRIVELINE

RAX

A

B

SECTION

REAR AXLE C

RAX

E

CONTENTS

C200 M226 F

SERVICE INFORMATION ............................ 2 SERVICE INFORMATION ........................... 15

G

PRECAUTIONS ................................................... 2 PRECAUTIONS ................................................. 15

Precaution for Supplemental Restraint System Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- (SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................... 2 SIONER" .................................................................15 H

Precaution ................................................................. 2 Precaution ...............................................................15

PREPARATION ................................................... 3 PREPARATION ................................................. 16 I

Special Service Tool ................................................. 3 Special Service Tool ................................................16

Commercial Service Tool .......................................... 3 Commercial Service Tool ........................................16

NOISE, VIBRATION AND HARSHNESS NOISE, VIBRATION AND HARSHNESS J

(NVH) TROUBLESHOOTING ............................. 5 (NVH) TROUBLESHOOTING ........................... 17

NVH Troubleshooting Chart ...................................... 5 NVH Troubleshooting Chart ....................................17

K

ON-VEHICLE SERVICE ...................................... 6 ON-VEHICLE SERVICE .................................... 18

Rear Axle Parts ......................................................... 6 Rear Axle Parts .......................................................18

Rear Axle Bearing ..................................................... 6 Rear Axle Bearing ...................................................18

L

AXLE SHAFT ...................................................... 7 AXLE SHAFT .................................................... 19

Removal and Installation ........................................... 7 Removal and Installation .........................................19

M

AXLE BEARING .................................................12 AXLE BEARING ................................................ 23

Removal and Installation ......................................... 12 Removal and Installation .........................................23

AXLE OIL SEAL .................................................13 AXLE OIL SEAL ................................................ 24 N

Removal and Installation ......................................... 13 Removal and Installation .........................................24

SERVICE DATA AND SPECIFICATIONS SERVICE DATA AND SPECIFICATIONS

O

(SDS) ..................................................................14 (SDS) ................................................................. 25

Axle Specification .................................................... 14 Axle Bearing ............................................................25

Shim Washers ......................................................... 14

P

Revision: August 2015 RAX-1 2016 Frontier NAM

PRECAUTIONS

< SERVICE INFORMATION > [C200]

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000012566370

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution INFOID:0000000012566371

• When installing rubber parts, final tightening must be carried out under unladen condition* with tires

on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated posi-

tions.

• After installing removed suspension parts, check wheel alignment and adjust if necessary.

Revision: August 2015 RAX-2 2016 Frontier NAM

PREPARATION

< SERVICE INFORMATION > [C200]

PREPARATION

A

Special Service Tool INFOID:0000000012566372

The actual shape of the tools may differ from those illustrated here. B

Tool number Description

(TechMate No.)

Tool name

C

KV40106500 Removing wheel bearing, wheel bearing lock

(J-45073) nut and wheel sensor rotor

Rear axle bearing remover

RAX

E

LPD022

— Installing rear axle bearing

(J-46215)

Rear axle bearing installation kit F

A: ABS sensor mount repair kit J-

46215-8

B: Plastic plugs and nuts kit J-46215-4

G

LDIA0045E

LDIA0047E

J

LDIA0048E

L

— Removing rear axle seal

(J-23907)

Seal and bushing puller M

N

LDIA0046E

Commercial Service Tool INFOID:0000000012566373 O

Revision: August 2015 RAX-3 2016 Frontier NAM

PREPARATION

< SERVICE INFORMATION > [C200]

Tool name Description

1 Flare nut crowfoot Tightening brake tube flare nuts

2 Torque wrench a: 10 mm (0.39 in)/12 mm (0.47 in).

S-NT360

Bearing cage oil seal drift Installing oil seal

a: 74 mm (2.91 in) dia.

b: 68 mm (2.68 in) dia.

NT115

Rear axle oil seal drift Installing oil seal

a: 54.5 mm (2.15 in.)

b: 34.5 mm (1.36 in.)

NT115

Power tool Loosening nuts, screws and bolts

PIIB1407E

Revision: August 2015 RAX-4 2016 Frontier NAM

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SERVICE INFORMATION > [C200]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

A

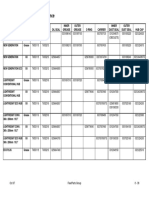

NVH Troubleshooting Chart INFOID:0000000012566374

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts. B

DLN-150, "NVH Troubleshooting Chart"

DLN-250, "NVH Troubleshooting Chart"

WT-44, "NVH Troubleshooting Chart"

WT-44, "NVH Troubleshooting Chart"

FSU-5, "NVH Troubleshooting Chart"

BR-6, "NVH Troubleshooting Chart"

C

RAX

RAX-7

RAX-7

RAX-7

Reference page

Improper installation, looseness

G

Wheel bearing damage

PROPELLER SHAFT

REAR FINAL DRIVE

Parts interference

Possible cause and SUSPECTED PARTS H

ROAD WHEEL

SUSPENSION

BRAKES

TIRES

I

Noise × × × × × × × ×

Shake × × × × × × × J

Vibration × × × × ×

Symptom

Shimmy × × × × × ×

K

Shudder × × × × ×

Poor quality ride or handling × × × × × ×

×: Applicable L

Revision: August 2015 RAX-5 2016 Frontier NAM

ON-VEHICLE SERVICE

< SERVICE INFORMATION > [C200]

ON-VEHICLE SERVICE

Rear Axle Parts INFOID:0000000012566375

• Check the axle parts for excessive play, wear and damage. Replace as necessary.

• Shake each rear wheel to check for excessive play. Repair as nec-

essary.

• Retighten all nuts and bolts to the specified torque. Refer to RAX-

7.

SMA525A

Rear Axle Bearing INFOID:0000000012566376

• Check that the axle shaft bearing operates smoothly. Replace as necessary.

• Check axial end play. Refer to RAX-14, "Axle Specification".

Revision: August 2015 RAX-6 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [C200]

AXLE SHAFT

A

Removal and Installation INFOID:0000000012566377

RAX

WDIA0280E

N

1. Axle shaft 2. Grease catcher 3. Wheel stud

4. Axle bearing stud 5. Back plate 6. Axle bearing

7. Bearing ring retainer 8. Shim washer 9. Snap ring O

10. Wheel sensor rotor 11. O-ring 12. Axle oil seal

13. Breather 14. Rear final drive

CAUTION: P

Before removing the rear axle, disconnect the wheel sensor from the assembly. Then move it away

from the axle. Failure to do so may result in damage to the sensor wires and the sensor becoming

inoperative.

• Wheel bearing does not require maintenance.

• If growling noise is emitted from wheel bearing during operation, replace wheel bearing assembly.

• If the wheel bearing assembly is removed, it must be replaced. The old assembly must not be re-used.

Revision: August 2015 RAX-7 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [C200]

REMOVAL

1. Remove the wheel sensor from the axle case and reposition out of the way. Refer to BRC-142, "Removal

and Installation" (Type 1), BRC-292, "Removal and Installation" (Type 2).

2. Remove the wheel and tire from the vehicle using power tool. Refer to WT-48, "Adjustment".

3. Without disassembling the hydraulic lines, remove the brake caliper using power tool. Position it aside

with wire. Refer to BR-44, "Removal and Installation of Brake Caliper and Disc Rotor".

4. Put alignment marks on the disc rotor and wheel hub and bearing assembly, then remove the disc rotor.

5. Remove the parking brake assembly from the back plate and torque member. Refer to PB-6, "Removal

and Installation".

6. Remove the axle bearing nuts securing the axle shaft assembly to the axle case.

7. Draw the axle shaft assembly out of the axle case using suitable tool.

8. Remove the O-ring.

CAUTION:

Do not reuse O-ring.

9. Remove the axle oil seal using Tools as shown. Apply a constant

pressure on the slide hammer while turning the slide hammer

180° degrees periodically while pulling the axle oil seal out.

Tool number (A): — (J-26941 part of J-46215)

(B): — (J-23907)

CAUTION:

Do not reuse the axle oil seal.

LDIA0030E

10. Remove the wheel sensor rotor using Tool. Discard the wheel

sensor rotor.

Tool number : KV40106500 (J-45073)

CAUTION:

Do not reuse the wheel sensor rotor.

LDIA0031E

11. Remove the snap ring and shim washer. Discard the snap ring and shim washer.

CAUTION:

Do not reuse the snap ring and shim washer.

12. Remove the bearing ring retainer from the axle shaft using Tool

as shown. Discard the bearing ring retainer.

Tool number : KV40106500 (J-45073)

CAUTION:

Do not reuse the bearing ring retainer.

LDIA0031E

13. Remove the back plate and torque member with the axle bearing attached from the axle shaft using a suit-

able press.

14. Remove the axle bearing studs to release the axle bearing from the back plate and torque member using

a suitable hammer or press.

Revision: August 2015 RAX-8 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [C200]

15. Remove the wheel studs using a suitable hammer or press.

16. Remove the grease catcher from the axle shaft. A

INSPECTION AFTER REMOVAL

Axle Shaft B

• Check axle shaft for straightness, cracks, damage, wear and distortion. Replace if necessary.

Axle Case

• Check axle case for yield, deformation and cracks. Replace if necessary. Refer to DLN-225, "Disassembly C

and Assembly".

INSTALLATION

RAX

1. Install the grease catcher on the axle shaft.

2. Install the wheel studs through the grease catcher into the axle shaft using a suitable press.

NOTE:

All six wheel studs must be pressed on at the same time and are flush with the grease catcher when E

installed.

3. Position the axle bearing on the back plate and torque member.

4. Install the axle bearing studs using a suitable press to attach the axle bearing to the back plate and torque F

member.

CAUTION:

Do not reuse the axle bearing. G

5. Install the back plate and torque member, new axle bearing and

new bearing ring retainer on the axle shaft using a suitable

press. H

Maximum press load “P1” : 98 kN (10 ton, 11.0 US

ton, 9.8 Imp ton) I

J

LDIA0038E

CAUTION: K

• Press the new bearing ring retainer on the axle shaft with

the taper side positioned as shown.

• Do not reuse the bearing ring retainer. L

N

LDIA0189E

6. Select the correct size shim washer. Refer to RAX-14, "Shim Washers". O

• Select the size of shim washer so that the installed snap ring to shim washer clearance is within specifi-

cation.

P

Snap ring to shim washer clearance : Refer to RAX-14, "Axle Specification".

7. Install a new snap ring on the axle shaft.

• Do not over spread the snap ring when installing, measure the outer diameter of the snap ring after

installation and replace if the snap ring outer diameter exceeds specification.

Snap ring outer diameter installed : Refer to RAX-14, "Axle Specification".

CAUTION:

Revision: August 2015 RAX-9 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [C200]

Do not reuse the snap ring.

8. Check the snap ring to shim washer clearance, repeat steps 7 and 8 as necessary until the installed snap

ring to shim washer clearance is within specification.

9. Perform break-in rotation of the wheel bearing.

a. Rotate the wheel bearing in the forward direction for a minimum of 10 revolutions at 50-70 RPM.

b. Rotate the wheel bearing in the reverse direction for a minimum of 10 revolutions at 50-70 RPM.

10. Measure the rotational torque of the wheel bearing.

Rotational speed : 8-12 RPM

Rotational torque : 1.8 N·m (0.18 kg-m, 16 in-lb)

11. Inspect that the wheel bearing is free from axial play relative to the axle shaft.

12. Install a new wheel sensor rotor on the axle shaft using a suit-

able press.

CAUTION:

• Press the new wheel sensor rotor on the axle shaft with

the notch side positioned as shown.

• Do not reuse the wheel sensor rotor.

LDIA0190E

13. Install a new O-ring.

CAUTION:

Do not reuse the O-ring.

14. Install the new axle seal into the axle case using Tool as shown.

• After installing the new oil seal, coat the sealing lip with oil.

• Install the new oil seal with the seal facing outwards and the

so that the seal is fully seated in the axle case.

Tool number : — (J-34115 part of J-46215)

CAUTION:

Do not reuse the axle oil seal.

WDIA0243E

15. Apply multi-purpose grease to the recess of axle case end as

shown.

16. Apply gear oil to the spline of axle shaft. Coat the axle oil seal

surface of axle shaft with multi-purpose grease as shown.

SRA652A

Revision: August 2015 RAX-10 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [C200]

17. Insert Tool into the new axle oil seal as a guide.

CAUTION: A

When inserting axle shaft, be careful not to damage oil seal.

NOTE:

The split ends of the Tool must butt up together and not overlap

B

as shown.

Tool number : — (J-34296-1 part of J-46215)

C

WDIA0240E

RAX

18. Insert the axle shaft assembly. Tighten the axle shaft nuts evenly in a criss-cross pattern to specification.

• Remove the Tool when the axle shaft assembly is approximately 90% inserted to protect the new axle oil

seal.

E

Tool number : — (J-34296-1 part of J-46215)

19. Install the parking brake assembly on the back plate and torque member. Refer to PB-6, "Removal and F

Installation".

20. Install the rear brake caliper assembly. Refer to BR-44, "Removal and Installation of Brake Caliper and

Disc Rotor".

G

21. Install the wheel sensor into the axle case. Refer to BRC-142, "Removal and Installation" (Type 1), BRC-

292, "Removal and Installation" (Type 2).

22. Check rear differential gear oil level. Refer to DLN-220, "Checking Differential Gear Oil". H

23. Install the wheel and tire. Refer to WT-48, "Adjustment".

Revision: August 2015 RAX-11 2016 Frontier NAM

AXLE BEARING

< SERVICE INFORMATION > [C200]

AXLE BEARING

Removal and Installation INFOID:0000000012566378

The axle bearing must be replaced every time the axle shaft is removed and installed. Refer to RAX-7,

"Removal and Installation".

CAUTION:

Do not reuse the axle bearing.

Revision: August 2015 RAX-12 2016 Frontier NAM

AXLE OIL SEAL

< SERVICE INFORMATION > [C200]

AXLE OIL SEAL

A

Removal and Installation INFOID:0000000012566379

The axle oil seal must be replaced every time the axle shaft is removed and installed. Refer to RAX-7, B

"Removal and Installation".

CAUTION:

Do not reuse the axle oil seal.

C

RAX

Revision: August 2015 RAX-13 2016 Frontier NAM

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION > [C200]

SERVICE DATA AND SPECIFICATIONS (SDS)

Axle Specification INFOID:0000000012566380

Unit: mm (in)

Axial end play 0 - 0.07 (0 - 0.003)

Snap ring to shim washer clearance 0.2 (0.008) or less

Snap ring outer diameter installed 47.5 (1.87) maximum

Shim Washers INFOID:0000000012566381

Unit: mm (in)

Total end play 0.02 - 0.15 (0.0008 - 0.0059)

ID Paint Dot Color Thickness Part Number*

Pink 2.5 (0.098) 43086-EB08C

Black 2.4 (0.094) 43086-EB07C

Purple 2.3 (0.091) 43086-EB06C

Available shim washers Yellow 2.2 (0.087) 43086-EB05C

Green 2.1 (0.083) 43086-EB04C

Red 2.0 (0.079) 43086-EB03C

White 1.9 (0.075) 43086-EB02C

Blue 1.8 (0.071) 43086-EB01C

*: Always check with the Parts Department for the latest parts information.

Revision: August 2015 RAX-14 2016 Frontier NAM

PRECAUTIONS

< SERVICE INFORMATION > [M226]

SERVICE INFORMATION A

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT B

PRE-TENSIONER" INFOID:0000000012566382

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along C

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted. RAX

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING: E

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

F

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this G

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS H

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a I

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the J

battery and wait at least three minutes before performing any service.

Precaution INFOID:0000000012566383

K

• When installing rubber parts, final tightening must be carried out under unladen condition* with tires

on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated posi-

L

tions.

• After installing removed suspension parts, check wheel alignment and adjust if necessary.

Revision: August 2015 RAX-15 2016 Frontier NAM

PREPARATION

< SERVICE INFORMATION > [M226]

PREPARATION

Special Service Tool INFOID:0000000012566384

The actual shape of the tools may differ from those illustrated here.

Tool number Description

(TechMate No.)

Tool name

205-D002 Removing axle shaft bearing

( — )

Bearing splitter

ZZA0700D

Commercial Service Tool INFOID:0000000012566385

Tool name Description

Power tool Loosening nuts, screws and bolts

PIIB1407E

Revision: August 2015 RAX-16 2016 Frontier NAM

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SERVICE INFORMATION > [M226]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

A

NVH Troubleshooting Chart INFOID:0000000012566386

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts. B

DLN-172, "NVH Troubleshooting Chart"

DLN-250, "NVH Troubleshooting Chart"

RSU-4, "NVH Troubleshooting Chart"

WT-44, "NVH Troubleshooting Chart"

WT-44, "NVH Troubleshooting Chart"

BR-6, "NVH Troubleshooting Chart"

C

RAX

RAX-19

RAX-19

RAX-19

Reference page

Improper installation, looseness

G

Wheel bearing damage

PROPELLER SHAFT

REAR FINAL DRIVE

Parts interference

Possible cause and SUSPECTED PARTS H

ROAD WHEEL

SUSPENSION

BRAKES

TIRES

I

Noise × × × × × × × ×

Shake × × × × × × × J

Vibration × × × × ×

Symptom

Shimmy × × × × × ×

K

Shudder × × × × ×

Poor quality ride or handling × × × × × ×

×: Applicable L

Revision: August 2015 RAX-17 2016 Frontier NAM

ON-VEHICLE SERVICE

< SERVICE INFORMATION > [M226]

ON-VEHICLE SERVICE

Rear Axle Parts INFOID:0000000012566387

• Check the axle parts for excessive play, wear, and damage. Replace as necessary.

• Shake each rear wheel to check for excessive play. Repair as nec-

essary.

• Retighten all nuts and bolts to the specified torque. Refer to RAX-

19.

SMA525A

Rear Axle Bearing INFOID:0000000012566388

• Check that the axle shaft bearing operates smoothly. Replace as necessary.

• Check for excessive axial end play.

Revision: August 2015 RAX-18 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [M226]

AXLE SHAFT

A

Removal and Installation INFOID:0000000012566389

RAX

WDIA0181E

P

1. Axle shaft 2. Snap ring 3. Bearing ring retainer

4. Axle shaft bearing 5. Axle oil seal 6. Axle shaft bearing cage

7. Wheel sensor rotor 8. Back plate 9. Axle shaft bearing cup

10. Breather 11. Rear final drive

CAUTION:

Revision: August 2015 RAX-19 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [M226]

Before removing the axle shaft, remove the wheel sensor to reposition the wheel sensor out of the

way. Failure to do so may result in damage to the wheel sensor and cause the wheel sensor to become

inoperative.

REMOVAL

1. Remove the wheel sensor and position out of the way. Refer to BRC-142, "Removal and Installation"

(Type 1), BRC-292, "Removal and Installation" (Type 2).

2. Remove the wheel and tire from the vehicle using power tool. Refer to WT-48, "Adjustment".

3. Without disassembling the hydraulic lines, remove the brake caliper using power tool. Position it aside

with wire. Refer to BR-44, "Removal and Installation of Brake Caliper and Disc Rotor".

4. Put alignment marks on the disc rotor and wheel hub and bearing assembly, then remove the rotor.

5. Remove the parking brake assembly from the back plate and torque member. Refer to PB-4, "On-Vehicle

Service".

6. Remove the four axle shaft bearing cage nuts and lock washers.

LDIA0112E

7. Remove the axle shaft assembly using suitable tool.

CAUTION:

• The axle shaft bearing cup may stay in place in the axle shaft housing. Remove the cup carefully

so as not to damage the inner surface of the axle shaft housing.

• Do not reuse the axle oil seal.

8. Remove the back plate and torque member.

9. Remove the snap ring from the axle shaft using suitable snap ring pliers.

10. Secure the axle shaft in a suitable vise, then use a 1/4 in size

drill bit to drill a hole approximately 3/4 into the thickness of the

bearing ring retainer [3/4 thickness is approximately 6.3 mm

(0.25 in) deep].

CAUTION:

• Mount the axle shaft using a soft jaw vise to avoid damag-

ing the axle shaft.

• Do not drill all the way through the bearing ring retainer,

the drill may damage the axle shaft surface.

LDIA0148E

11. Strike the bearing ring retainer using a suitable chisel and ham-

mer, with the chisel positioned across the drilled hole. Break the

bearing ring retainer to remove it.

CAUTION:

Do not heat or cut the axle shaft bearing or bearing ring

retainer with a torch during removal, doing so will damage

the axle shaft.

LDIA0149E

12. Remove the axle shaft bearing cage studs using a suitable hammer or press.

13. Pull the axle shaft bearing off of the axle shaft using Tool and a suitable press.

Revision: August 2015 RAX-20 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [M226]

Tool number : 205-D002 ( — ) A

CAUTION:

• Do not tighten the Tool against the axle shaft.

• Do not heat or cut the axle shaft bearing or bearing ring retainer with a torch during removal, B

doing so will damage the axle shaft.

14. Remove the axle oil seal and discard.

CAUTION: C

Do not reuse the axle oil seal.

15. Remove the wheel bearing cage.

NOTE: RAX

• If reinstalling the old axle shaft, it may not be necessary to remove the wheel sensor rotor. Inspect the

wheel sensor rotor and replace as necessary. Refer to BRC-143, "Removal and Installation" (Type 1),

BRC-293, "Removal and Installation" (Type 2).

• The wheel sensor rotor cannot be reused after it is removed. If replacing the axle shaft, install a new E

wheel sensor rotor on to the new axle shaft. Refer to BRC-143, "Removal and Installation" (Type 1),

BRC-293, "Removal and Installation" (Type 2).

INSPECTION AFTER REMOVAL F

Axle Shaft

• Clean and remove all nicks and burrs.

• Check for straightness and distortion. Replace if necessary. G

• Inspect machined surfaces for evidence of overheating, damage and wear. Replace if necessary.

• Measure the bearing ring retainer axle journal diameter. Replace if necessary.

H

Bearing ring retainer axle journal diameter (minimum) : Refer to RAX-25, "Axle Bear-

ing".

I

Axle Shaft Bearing and Cup

• Check that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting and wear.

Replace if necessary.

J

Axle Shaft Bearing Cage

• Check for deformation and cracks. Replace if necessary.

Axle Shaft Housing K

• Check the exterior and inner machined surfaces for deformation and cracks. Replace if necessary.

INSTALLATION

1. If installing a new axle shaft, install a new wheel sensor rotor onto the new axle shaft. Refer to BRC-143, L

"Removal and Installation" (Type 1), BRC-293, "Removal and Installation" (Type 2).

CAUTION:

Do not reuse the wheel sensor rotor. M

2. Install the studs in the axle shaft bearing cage using a suitable hammer or press.

3. Install the axle shaft bearing cage.

4. Install a new axle oil seal. N

CAUTION:

Do not reuse the axle oil seal.

5. Install the axle shaft bearing and cup on the axle shaft. O

• Prepare an installer tool from a steel tube measuring 762 mm

(30 in) long with an outside diameter of 53.98 mm (2.125 in)

and an inside diameter of 41.28 mm (1.625 in).

P

• Press the axle shaft bearing and cup onto the axle shaft using

a suitable press and the installer tool, until a 0.038 mm (.0015

in) feeler gauge does not fit in between the axle shaft bearing

cup and seat.

CAUTION:

Make sure the axle shaft bearing and cup, axle oil seal, and

axle shaft bearing cage are installed facing in the correct

LDIA0150E

direction.

Revision: August 2015 RAX-21 2016 Frontier NAM

AXLE SHAFT

< SERVICE INFORMATION > [M226]

6. Install the bearing ring retainer onto the axle shaft.

• Press the bearing ring retainer onto the axle shaft with a minimum force of 31,100 N (3172 kg, 6992 lb)

until a 0.038 mm (.0015 in) feeler gauge does not fit between the bearing inner race and the bearing ring

retainer in at least one point.

CAUTION:

Do not reuse bearing ring retainer.

7. Install the snap ring so it is fully seated into the groove on the axle shaft, using suitable snap ring pliers.

CAUTION:

Do not reuse snap ring.

8. Install the back plate and torque member.

9. Install the axle shaft assembly into the axle shaft housing.

10. Install the axle shaft bearing cage lock washers and nuts. Tighten the axle shaft bearing cage nuts to

specification.

CAUTION:

Do not reuse axle shaft bearing cage lock washers and nuts.

11. Install the parking brake assembly onto the back plate and torque member. Refer to PB-4, "On-Vehicle

Service".

12. Install the rear brake rotor. Refer to BR-44, "Removal and Installation of Brake Caliper and Disc Rotor".

13. Install the wheel sensor. Refer to BRC-142, "Removal and Installation" (Type 1), BRC-292, "Removal and

Installation" (Type 2).

14. Check rear differential gear oil level. Refer to DLN-251, "Checking Differential Gear Oil" (M226), DLN-310,

"Checking Differential Gear Oil" (M226 ELD).

15. Install the wheel and tire. Refer to WT-48, "Adjustment".

Revision: August 2015 RAX-22 2016 Frontier NAM

AXLE BEARING

< SERVICE INFORMATION > [M226]

AXLE BEARING

A

Removal and Installation INFOID:0000000012566390

The axle bearing must be replaced every time the axle shaft is removed and installed. Refer to RAX-19, B

"Removal and Installation".

CAUTION:

Do not reuse the axle bearing.

C

RAX

Revision: August 2015 RAX-23 2016 Frontier NAM

AXLE OIL SEAL

< SERVICE INFORMATION > [M226]

AXLE OIL SEAL

Removal and Installation INFOID:0000000012566391

The axle oil seal must be replaced every time the axle shaft is removed and installed. Refer to RAX-19,

"Removal and Installation".

CAUTION:

Do not reuse the axle oil seal.

Revision: August 2015 RAX-24 2016 Frontier NAM

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION > [M226]

SERVICE DATA AND SPECIFICATIONS (SDS)

A

Axle Bearing INFOID:0000000012566392

B

Bearing ring retainer axle journal diameter (minimum) 39.726 mm (1.5640 in) minimum

RAX

Revision: August 2015 RAX-25 2016 Frontier NAM

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Nissan Sentra 1989-2004-Wiring PDFDokumen12 halamanNissan Sentra 1989-2004-Wiring PDFJorge Antonio Guillen50% (8)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- 2021 ZX10R KMDokumen77 halaman2021 ZX10R KMefrain100% (2)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- AURLTE102 - Written Knowledge Questioning - Assessment Task1 - V2Dokumen34 halamanAURLTE102 - Written Knowledge Questioning - Assessment Task1 - V2MUHAMMAD UMARBelum ada peringkat

- ATG Actual Exam Questions PPLDokumen5 halamanATG Actual Exam Questions PPLGirish Sreeneebus100% (3)

- CRV WiringDokumen308 halamanCRV WiringJATC100% (3)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- K46 Transaxle Parts Breakdown GuideDokumen23 halamanK46 Transaxle Parts Breakdown GuideBrian Parker100% (2)

- KHT Brochure enDokumen7 halamanKHT Brochure enZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Seajphv 3 N 1 P 8Dokumen14 halamanSeajphv 3 N 1 P 8Zona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Quick Guide to Getting Started with MoqDokumen12 halamanQuick Guide to Getting Started with MoqZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Fact SheetDokumen2 halamanFact SheetZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- MqoDokumen30 halamanMqoZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Miniture Glass Fuse GSB-GDGDokumen1 halamanMiniture Glass Fuse GSB-GDGZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Spring 2014Dokumen32 halamanSpring 2014Zona Educación Especial ZacapaoaxtlaBelum ada peringkat

- MqiDokumen22 halamanMqiZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Kyasanur Forest Disease, India, 2011-2012Dokumen4 halamanKyasanur Forest Disease, India, 2011-2012Zona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Investigation of The Influence of Vanadium Compounds Treatment in Nzo Mice Model Ñ Preliminary StudyDokumen8 halamanInvestigation of The Influence of Vanadium Compounds Treatment in Nzo Mice Model Ñ Preliminary StudyZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- History of East Asian Martial ArtsDokumen7 halamanHistory of East Asian Martial ArtsZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- 3-Band Preamp & Direct Box Owner's GuideDokumen2 halaman3-Band Preamp & Direct Box Owner's GuideZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Efficient profile measurement with the KHT ProfileScanDokumen4 halamanEfficient profile measurement with the KHT ProfileScanZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Datenblatt Traxon DotXLQ 8 RGBW 201706ADokumen5 halamanDatenblatt Traxon DotXLQ 8 RGBW 201706AZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- 3-Band Preamp & Direct Box Owner's GuideDokumen2 halaman3-Band Preamp & Direct Box Owner's GuideZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- The World of ZKW 2018Dokumen23 halamanThe World of ZKW 2018Zona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Note Guidance Maximum Shelf Life Sterile Products Human Use After First Opening Following enDokumen2 halamanNote Guidance Maximum Shelf Life Sterile Products Human Use After First Opening Following enZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- DLKDokumen144 halamanDLKJUAN CARLOS PAZBelum ada peringkat

- Info 116 enDokumen87 halamanInfo 116 enZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- LanDokumen90 halamanLanZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- IJP Volume 5 Issue 7 Pages 5391-5400Dokumen10 halamanIJP Volume 5 Issue 7 Pages 5391-5400Zona Educación Especial ZacapaoaxtlaBelum ada peringkat

- 5683Dokumen1 halaman5683Zona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Engine Cooling System: SectionDokumen60 halamanEngine Cooling System: SectionZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Charging System: SectionDokumen30 halamanCharging System: SectionZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- MwiDokumen91 halamanMwiZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Cruise Control System: SectionDokumen3 halamanCruise Control System: SectionZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- RSUDokumen13 halamanRSUJUAN CARLOS PAZBelum ada peringkat

- SEDokumen51 halamanSEZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Ventilation, heater and air conditioner maintenance and repair guideDokumen27 halamanVentilation, heater and air conditioner maintenance and repair guideZona Educación Especial ZacapaoaxtlaBelum ada peringkat

- Suzuki / Alto: Oem Number Oem NumberDokumen15 halamanSuzuki / Alto: Oem Number Oem NumberBobCavBelum ada peringkat

- Ex6 Hyundai Ex6 Double Cab Cargo - Technical Specs.Dokumen3 halamanEx6 Hyundai Ex6 Double Cab Cargo - Technical Specs.manu .mBelum ada peringkat

- Status of System: Log Sheet For Fire Protection SystemDokumen2 halamanStatus of System: Log Sheet For Fire Protection SystemLUTHRASAGAR5927Belum ada peringkat

- Magictilt 2009-2010 Parts GuideDokumen52 halamanMagictilt 2009-2010 Parts GuidesitekcorpBelum ada peringkat

- l2738 Propulsion Tieri PDFDokumen960 halamanl2738 Propulsion Tieri PDFcatalintoader1969Belum ada peringkat

- Pakistan Diesel ServiceDokumen14 halamanPakistan Diesel ServiceAbdul ShakoorBelum ada peringkat

- MT5020 & MT6020 Appendix - Brake Test and Stall Test - VerB - New PLCDokumen6 halamanMT5020 & MT6020 Appendix - Brake Test and Stall Test - VerB - New PLCFrancisco RojasBelum ada peringkat

- CRZ LeafletDokumen16 halamanCRZ LeafletPaul TanBelum ada peringkat

- Cerrar SIS: Backhoe Loader 416B Backhoe Loader 8Sg 416B Backhoe Loader 8SG00001-11999 (MACHINE) POWERED BY 3054 EngineDokumen3 halamanCerrar SIS: Backhoe Loader 416B Backhoe Loader 8Sg 416B Backhoe Loader 8SG00001-11999 (MACHINE) POWERED BY 3054 Enginepedro sanchez100% (1)

- Hydraulic Basics of Automatic TransmissionsDokumen21 halamanHydraulic Basics of Automatic TransmissionsSumanth Vasista100% (2)

- Fasieco PC16R-3 Engine Parts ManualDokumen472 halamanFasieco PC16R-3 Engine Parts ManualTomasBelum ada peringkat

- E20081024286 - 1-Regular Overhaul NoticeDokumen10 halamanE20081024286 - 1-Regular Overhaul NoticeIvanciu Ionut-FabianBelum ada peringkat

- Ct-100 Bs IV Rev 12 Jun 2017Dokumen76 halamanCt-100 Bs IV Rev 12 Jun 2017Satya Prakash PathakBelum ada peringkat

- EP3107776A4Dokumen1 halamanEP3107776A4BubbleBelum ada peringkat

- Mercedes-Benz Econic CNG: Philip Chance Senior Municipal Sales & Special Applications Manager - TruckDokumen9 halamanMercedes-Benz Econic CNG: Philip Chance Senior Municipal Sales & Special Applications Manager - Truckberek96Belum ada peringkat

- D 6593 - 02 - Rdy1otmtmdjbDokumen70 halamanD 6593 - 02 - Rdy1otmtmdjbMatias GiacchinoBelum ada peringkat

- En14765 Child BikeDokumen48 halamanEn14765 Child BikeLung LungBelum ada peringkat

- Section 8 - BPW Quick ReferenceDokumen43 halamanSection 8 - BPW Quick ReferenceSanhory Abd AlgaderBelum ada peringkat

- Passion Pro MaintenanceDokumen31 halamanPassion Pro Maintenancepradeeperd10011988100% (1)

- Parts Catalgoue: DL1000 K7 (VT53A) DL1000 K8 DL1000 K9Dokumen104 halamanParts Catalgoue: DL1000 K7 (VT53A) DL1000 K8 DL1000 K9Nelson SchleifsteinBelum ada peringkat

- 320dl Stick Drift Reduction ValveDokumen3 halaman320dl Stick Drift Reduction ValveDaniel Rhasty-ghee AhmanorBelum ada peringkat

- SuspensionDokumen2 halamanSuspensionSandeep MeenaBelum ada peringkat

- Motor - KarterDokumen1 halamanMotor - KarterMilena TrifunoskaBelum ada peringkat

- OM 2023 Outlander PHEVDokumen613 halamanOM 2023 Outlander PHEVMonica TarnawskiBelum ada peringkat