Carbon Steel Belt Biscuits Line Bakery Oven

Diunggah oleh

Lavender ShenJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Carbon Steel Belt Biscuits Line Bakery Oven

Diunggah oleh

Lavender ShenHak Cipta:

Format Tersedia

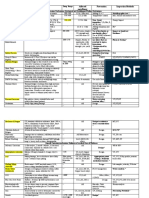

Consol CS1300

Static strength Physical property Corrosion resistance

CS1300 steel belt is tempered carbon steel,which has follow Standard strength (room temperature) General corrosion

Modulus of elasticity, E 201000MPa 29100ksl

steel belt characteristics: Yield Tensile Weld Although there is a layer of oxide on surface,but CS1300 is still

Elongation Hardness Density, ρ 7 850 kg/m3 0.284lb/in3

●Good static strength strength strength factor corroded easily in the water solution,especially acid solution.The

Position

●Outstanding fatigue resistance Mpa corrosion of CS1300 is accelerated by increasing temperature,

Mpa ksi A5(%) Rm/Rm HV5

●Great thermal conductivity ksi Thermal Conductivity,λ velocity of flow,acidity, and salt content in solution Chromate

●Excellent fatigue and wear resistance Parent (CrO4-2) and nitrate(NO3-) will inhibit corrosion in neutral solution.

1200 174 1280 186 11 400 Temperature,°C 20 100 200 300 400

●Easy to maintain and repair material

CS1300 has the hard and smooth surface,which has a layer °F 68 212 392 572 752

Transverse weld Pitting and crevice corrosion

of oxide on it.This steel belt is widely used in many fields

880 128 990 144 3 0.77 * W/mK 38 39 39 40 39

(not heat treated) The carbon steel may be sensitive to pitting and cracking in solutions

with low causticity environment.Because of the outstanding Btu/ft h°F 22 22 22 23 23

of a relative low oxide content.

thermal conductivity,CS1300 is very suitable for baking

Standard strength trend with temperature change

process,it also performs well in heating and drying Hydrogen embrittlement

Yield Tensile Specific heat capacity,Cp

liquid,paste and particle. Temperature Elongation

strength strength Consol CS1300 steel belt is susceptible to hydrogen embrittlement ,

Chemical component % Temperature,°C 20 100 200 300 400

°C °F MPa ksi Mpa ksi A5(%) special heat treatment of the steel belt is required if the steel belt is

°F 68 212 392 572 752

Element C Si Mn P S Cr 100 212 980 142 1220 177 10 exposed to hydrogen embrittlement envirment.

kJ/kgK 0.46 0.50 0.53 0.56 0.61

200 392 950 138 1210 175 12

Btu/ft h°F 0.11 0.12 0.13 0.13 0.14

Content 0.17 1.56 2.79 0.01 0.003 0.016 300 572 890 129 1170 170 28 Welding

400 752 720 104 850 123 28 CS1300 has good welding property, a suitable fusion welding

Thermal expansion,α method is gas-shielded arc welding,with the TIG method as first

International standards

At about 450°C (840°F) chromium carbide precipitates, resulting in deteriorating choice.

Werkstoff Nr. 1.1231 Temperature,°C 20-100 20-200 20-300 20-400

mechanical properties and hardness resistance.Hence the following Before welding,heat treatment should be applied evenly to ensure the

AISI 1070 °F 68-212 68-392 68-572 68-752 mechanical property(static and dynamic) of welding joint.More

recommendation: If an operation temperature of or above 350°C(660°F) is

kJ/kgK 11.1 12 12.8 13.5 information please contact CONSOL office.

considered, your Consol office should be contacted for technical assistance.

Btu/ft h°F 6.2 6.6 7.1 7.5

Specification

The belts are, as standard,delivered in a specially selected Impact properties

hot rolled temper finish and have well-rounded edges. If This steel belt is not suitable for low temperature environment,like freezing

required practically any surface finish can be supplied. process.

Perforated belts are also available.

The belts are leveled and straightened to obtain optimal Dynamic strength

flatness and straightness. The belts can be supplied in The fatigue limit is defined as the reverse bending stress at which 50% of the test

open lengths, with the ends prepared for welding on site, specimen withstand a minimum of 2x106 load cycles.These values refer to 20°C

or in endless condition with a welded joint. (68°F), a normal dry atmosphere and standard prepared specimen. The fatigue

For tracking, the belts can be provided with V-ropes, limit for the parent material is approximately ±460 MPa (68 ksi).

either rubber or in the form of a specially designed steel

Resistivity,ρ 0.2 µΩm

spiral. If required, the product side of the belt can be

fitted with retaining strips to keep the conveyed material Magnetic property

on the belt or with transverse flights to prevent material Remanence,Br 1.5 Wb/m2

from sliding backwards when the belt is steeply Coercive force,Hc 1500 A/m

inclined.Different tolerance grades are available to ensure Max relative permeability,μr 400

that the best belt can be selected from an economic point Due to relative high thermal conductivity and low thermal expansion for carbon

of view. steels,it is little effect that cause by deformation of uneven temperature. Consol Machinery (Canton) Co.,Ltd.

Add:No.6,Longgu Rd.,Shawan towm,Panyu Dist.Guangzhou

Mobile:+86 18820135908 www.consolbelts.com

Anda mungkin juga menyukai

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionDari EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionBelum ada peringkat

- Data Sheet CuZn20Al2AsDokumen1 halamanData Sheet CuZn20Al2AsJean Carlos Reyna PascualBelum ada peringkat

- Steel Belt Cooler Cooling Belt Stainless Steel Belt Sandvik Belt Berndorf BandDokumen1 halamanSteel Belt Cooler Cooling Belt Stainless Steel Belt Sandvik Belt Berndorf BandLavender ShenBelum ada peringkat

- Rust and Acid-Resistant Steels, Ferritic-AusteniticDokumen3 halamanRust and Acid-Resistant Steels, Ferritic-AusteniticKiranBelum ada peringkat

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Dokumen1 halamanMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraBelum ada peringkat

- CuZn38Pb2 CW608N ENDokumen4 halamanCuZn38Pb2 CW608N ENTaner DemirelBelum ada peringkat

- 306 - Dogal 600 and 780 CPDokumen2 halaman306 - Dogal 600 and 780 CPMartin O'NeillBelum ada peringkat

- ASTM C90700 - CuSn11 - Tin Bronze AlloysDokumen1 halamanASTM C90700 - CuSn11 - Tin Bronze Alloysİrem Şebnem SorucuBelum ada peringkat

- 875 Datasheet 16Dokumen1 halaman875 Datasheet 16Fred Duarte CaldeiraBelum ada peringkat

- Aisi E50100, E52100: 154/amoyDokumen6 halamanAisi E50100, E52100: 154/amoyahmad hafizBelum ada peringkat

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Dokumen1 halamanMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraBelum ada peringkat

- Api 571 CorrosionDokumen5 halamanApi 571 CorrosionArun GuptaBelum ada peringkat

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDokumen5 halamanHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızBelum ada peringkat

- PS-SB-499 EngDokumen2 halamanPS-SB-499 EngaylinaykanBelum ada peringkat

- Stainless Steel 321 Technical DataDokumen2 halamanStainless Steel 321 Technical Datasmith willBelum ada peringkat

- 903 Datasheet 17Dokumen1 halaman903 Datasheet 17Fred Duarte CaldeiraBelum ada peringkat

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDokumen1 halamanThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiBelum ada peringkat

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Dokumen3 halamanAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouBelum ada peringkat

- Steel PropertiesDokumen22 halamanSteel PropertiesMOHD SALMANBelum ada peringkat

- API 571 Quick ReviewDokumen32 halamanAPI 571 Quick ReviewMahmoud Hagag100% (1)

- Kme STOL76 C19010 enDokumen1 halamanKme STOL76 C19010 enMattia Terri TerrandoBelum ada peringkat

- Cu ZN 10Dokumen1 halamanCu ZN 10Sara RiddleBelum ada peringkat

- Alloy 030Dokumen2 halamanAlloy 030Nookang SeaSunBelum ada peringkat

- Article Pump Engineer Aluminium Bronze enDokumen3 halamanArticle Pump Engineer Aluminium Bronze enSatrio Agung WijonarkoBelum ada peringkat

- Stellite 21 Alloy: Stellite Cobalt-Based AlloysDokumen2 halamanStellite 21 Alloy: Stellite Cobalt-Based AlloysMehrdad NejatiBelum ada peringkat

- CuZn40 01 2019 PDFDokumen7 halamanCuZn40 01 2019 PDFMisaelBelum ada peringkat

- Quick View For Damage MechanismsDokumen7 halamanQuick View For Damage MechanismsRamniza Mat RaniBelum ada peringkat

- Stellite 21Dokumen2 halamanStellite 21Mohsen ParpinchiBelum ada peringkat

- 301 Stainless SteelDokumen1 halaman301 Stainless SteelDanielBelum ada peringkat

- 1 MaterialsDokumen1 halaman1 Materialsapi-3699282Belum ada peringkat

- AW - Datasheet - ALLOY 20 CB 3Dokumen2 halamanAW - Datasheet - ALLOY 20 CB 3.xBelum ada peringkat

- CABLOFILDokumen60 halamanCABLOFILMon suBelum ada peringkat

- Acronal PRO 7600: Exemplary Applications Performance Highlights Key Technical DataDokumen1 halamanAcronal PRO 7600: Exemplary Applications Performance Highlights Key Technical DataDuodo NguyenBelum ada peringkat

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDokumen2 halamanDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangBelum ada peringkat

- COPPER-110: Nearest StandardDokumen3 halamanCOPPER-110: Nearest StandardPS Pinturas pinturasBelum ada peringkat

- Rti Brochure Astm Compliance Chart Na enDokumen2 halamanRti Brochure Astm Compliance Chart Na enMiguel Martinez GuerreroBelum ada peringkat

- ASTM C91000 - CuSn15 - Tin Bronze AlloysDokumen1 halamanASTM C91000 - CuSn15 - Tin Bronze Alloysİrem Şebnem SorucuBelum ada peringkat

- Stellite 12Dokumen2 halamanStellite 12xy2zjgBelum ada peringkat

- 3CR12 Data Sheet 2021Dokumen1 halaman3CR12 Data Sheet 2021Elcio VilanculoBelum ada peringkat

- Armco Pure Iron PDFDokumen12 halamanArmco Pure Iron PDFsmith willBelum ada peringkat

- Bronze C86300 SpecificationsDokumen2 halamanBronze C86300 SpecificationsDoss MartinBelum ada peringkat

- API RP 571 Ref CardDokumen7 halamanAPI RP 571 Ref Cardzainulabedine100% (1)

- Thermaline 450Dokumen2 halamanThermaline 450gowtham_venkat_4100% (1)

- Section 2 - Nikko Welding ConsumablesDokumen9 halamanSection 2 - Nikko Welding Consumablesangga franugrahaBelum ada peringkat

- A Duplex Stainless Steel With PREN 24 SPDokumen2 halamanA Duplex Stainless Steel With PREN 24 SPFarhad MalikBelum ada peringkat

- Structural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanDokumen153 halamanStructural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanJohn Philip Neri BesedillasBelum ada peringkat

- C95500 ASTM - Nickel Aluminum BronzeDokumen2 halamanC95500 ASTM - Nickel Aluminum BronzethuykvBelum ada peringkat

- API-571 Reference CardDokumen7 halamanAPI-571 Reference CardLaith SalmanBelum ada peringkat

- Stellite 12 Technical DataDokumen2 halamanStellite 12 Technical DataJakeTheSnake69Belum ada peringkat

- Data MP35N Rev-2Dokumen2 halamanData MP35N Rev-2Nishant MehtaBelum ada peringkat

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDokumen3 halamanStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulBelum ada peringkat

- AMP16609P61Dokumen1 halamanAMP16609P61Gutha Giribabu NaiduBelum ada peringkat

- Damage Mechanism Temperature Deg C Affected Materials Appearance Prevention What HappensDokumen2 halamanDamage Mechanism Temperature Deg C Affected Materials Appearance Prevention What HappensBilalBelum ada peringkat

- Cold Drawn PDFDokumen1 halamanCold Drawn PDFAna Emily PrentissBelum ada peringkat

- Bitumastic 300 M PDSDokumen2 halamanBitumastic 300 M PDSMuhammad RizwanBelum ada peringkat

- Screw CharacteristicsDokumen18 halamanScrew CharacteristicsJaokBelum ada peringkat

- 17-7 PH Stainless SteelDokumen2 halaman17-7 PH Stainless Steelzain malikBelum ada peringkat

- Cu-HCP: C10300 Industrial RolledDokumen7 halamanCu-HCP: C10300 Industrial RolledpierocarnelociBelum ada peringkat

- Thermomechanical Processing of High-Strength Low-Alloy SteelsDari EverandThermomechanical Processing of High-Strength Low-Alloy SteelsBelum ada peringkat

- SOP - 03 - Shop FabricationDokumen23 halamanSOP - 03 - Shop FabricationSuci YatiningtiyasBelum ada peringkat

- Tools and Machines Used in Carpentry Lab Part 5Dokumen10 halamanTools and Machines Used in Carpentry Lab Part 5Lo M'hBelum ada peringkat

- Paper From Coconut HuskDokumen3 halamanPaper From Coconut HuskLuke kenneth MacalawaBelum ada peringkat

- AAC Blocks Manufacturers - MagnaDokumen6 halamanAAC Blocks Manufacturers - MagnaMagna GreenBelum ada peringkat

- Fish GlazingDokumen3 halamanFish GlazingBishoyYousifBelum ada peringkat

- Se-dcf-En-05 11 Crossflow Filter PrayefsDokumen4 halamanSe-dcf-En-05 11 Crossflow Filter Prayefslimim56582Belum ada peringkat

- IKA RV 10 Service ManualDokumen11 halamanIKA RV 10 Service Manualco2captureBelum ada peringkat

- Standard Cleaning Procedures of Nail Care ToolsDokumen3 halamanStandard Cleaning Procedures of Nail Care ToolsIrish Nicole PacionBelum ada peringkat

- A Milling Machine Is A Machine Tool Used To Machine Solid MaterialsDokumen7 halamanA Milling Machine Is A Machine Tool Used To Machine Solid MaterialsMD Mahmudul Hasan MasudBelum ada peringkat

- Assignment WeldingDokumen3 halamanAssignment WeldingsritaranBelum ada peringkat

- Cec 198 PDFDokumen9 halamanCec 198 PDFsandip doshiBelum ada peringkat

- Nitoseal MS600Dokumen3 halamanNitoseal MS600Balasubramanian AnanthBelum ada peringkat

- Etching and Intaglio ToolsDokumen4 halamanEtching and Intaglio Toolsmhilet_chi100% (1)

- Compressor Wash System RB211Dokumen15 halamanCompressor Wash System RB211masdikaBelum ada peringkat

- Sino Pipe Fitting Co., LTD: Inspection CertificateDokumen1 halamanSino Pipe Fitting Co., LTD: Inspection CertificateIndra burnamaBelum ada peringkat

- Weld Map For Rotor Weldment AssemblyDokumen2 halamanWeld Map For Rotor Weldment AssemblyMohammad AdilBelum ada peringkat

- Food Packaging Migration - enDokumen4 halamanFood Packaging Migration - enahadsajjadiBelum ada peringkat

- Safco Welding SummryDokumen148 halamanSafco Welding SummryRichard PeriyanayagamBelum ada peringkat

- Planar ReviewDokumen21 halamanPlanar Reviewhawraa amhazBelum ada peringkat

- 03 en PSI Kebu Anti Corrosion TapesDokumen13 halaman03 en PSI Kebu Anti Corrosion Tapesmechanical_engineer11Belum ada peringkat

- CHG 55B2Dokumen1 halamanCHG 55B2Nhien ManBelum ada peringkat

- Hempadur Avantguard 550Dokumen4 halamanHempadur Avantguard 550bondsivamaniBelum ada peringkat

- Press WorkDokumen42 halamanPress WorkanilBelum ada peringkat

- Introduction Drilling Operations and FacilitiesDokumen57 halamanIntroduction Drilling Operations and FacilitiesDinesh Kanesan100% (1)

- ASTM - d-1730-03 Standard Practices For Preparation of Aluminum and Aluminum Alloy Surfaces For Painting PDFDokumen3 halamanASTM - d-1730-03 Standard Practices For Preparation of Aluminum and Aluminum Alloy Surfaces For Painting PDFAdrian OrtizBelum ada peringkat

- Universal Rutile Electrode: Tip ColourDokumen1 halamanUniversal Rutile Electrode: Tip Colourmohamed AdelBelum ada peringkat

- Kr274atl - e Ga8731 PartsDokumen276 halamanKr274atl - e Ga8731 Partsomar100% (1)

- Astm A 681Dokumen14 halamanAstm A 681talhadikenBelum ada peringkat

- Ar 1064Dokumen2 halamanAr 1064georgiBelum ada peringkat

- 제14주차 - Chapter09 - 몸체미세가공, 고종횡비 MEMS 가공Dokumen11 halaman제14주차 - Chapter09 - 몸체미세가공, 고종횡비 MEMS 가공K SiriusBelum ada peringkat