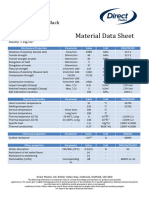

TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PET

Diunggah oleh

Feby Shyntia AfirantiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PET

Diunggah oleh

Feby Shyntia AfirantiHak Cipta:

Format Tersedia

TECAPET® PET and 1400® PET

(Polyethylene Terephthalate)

TECAPET®/1400® are both unreinforced, semi-crystalline thermoplastic polyester derived from polyethylene terephthalate. Their excellent

wear resistance, low coefficient of friction, high flexural modulus, and superior dimensional stability make it a versatile material for designing

mechanical and electro- mechanical parts. Because TECAPET®/1400® has no centerline porosity, the possibility of fluid absorption and

leakage is virtually eliminated.

• Excellent wear resistance • Low coefficient of friction • Good electrical insulator

• Very good chemical resistance • Excellent hardness and stiffness • Low water absorption

• High mechanical strength • Good weather resistance • Good resistance to high-energy radiation

• In compliance with FDA regulations CFR 177.1630 for use in contact with food

• No centerline porosity eliminates the possibility of fluid absorption and leakage

TECAPET®/1400® both have superior wear resistance and lack of centerline porosity give it an advantage over other materials for

applications involving solvents, chemicals, and food products. TECAPET®/1400® can also be used in water purification systems, printing

equipment, textile components, food-handling equipment, and valves.

Primary Specification (Resin) (Typical): ASTM-D-5927 TPES0211 Shapes Specification (Typical): ASTM-D-6261 S-TPES0211

ASTM Test TECAPET® 1400HI®

Property Units

Method PET PET

Physical

3

Density D792 lbs/in 0.0499 0.051

Specific Gravity D792 g/cc 1.38 1.4

Water Absorption,

@24 hours, 73°F D570 % 0.1 0.1

@Saturation, 73°F D570 % 0.5 0.9

Mechanical

Tensile Strength @ Yield, 73°F D638 psi 12,500 12,330

Tensile Modulus D639 psi 470,000 471,000

Elongation @ Break, 73°F D638 % 20 23

Flexural Strength, 73°F D790 psi 17,600 -

Flexural Modulus, 73°F D790 psi 430,000 -

Compressive Strength D695 psi - 15,450

Izod Impact Strength, 73°F D256 ft-lbs/in 0.7 -

Rockwell Hardness, 73°F D785 R Scale 94 -

Shore Hardness - D Scale - 84

3

Wear Factor Against Steel, in /hr x -10

D3702 210 x 10 -

40 psi, 50 fpm 1/PV

Static Coefficient of Friction D3702 - 0.19 0.18-0.25

Dynamic Coefficient of Friction,

D3702 - 0.25 0.23-0.29

40 psi, 50 fpm

Thermal

Heat Deflection Temperature,

D648 °F 240 -

@ 66 psi

@264 psi D648 °F 175 175

Coefficient of Linear Thermal -5 -5

D696 in/in/°F 3.9 x 10 3.9 x 10

Expansion

Maximum Servicing Temperature,

- °F 320 320

Intermittent

Long Term - °F 230 212

Specific Heat UL746B BTU/lb-°F 0.28 -

Thermal Conductivity - - 2.01 2.0

Vicate Softening Point - °F - -

Melting Point D2133 °F 490 490

Flammability UL94 - HB HB

ASTM Test TECAPET® 1400®

Property Units

Method PET PET

Electrical

15

Volume Resistivity D257 ohm-cm 10 -

Dielectric Strength D149 V/mil 400 -

Dielectric Constant, @ 60 Hz,

D150 - 3.4 -

73°F, 50% RH

Dissipation Factor, @ 60 HZ, 73°F D150 - 0.002 -

NOTE: The information contained herein are typical values intended for reference and comparison purposes only. They should NOT be

used as a basis for design specifications or quality control. Contact us for manufacturers' complete material property datasheets. All

values at 73°F (23°C) unless otherwise noted.

Anda mungkin juga menyukai

- MBADokumen3.270 halamanMBAPranpath NarupantawartBelum ada peringkat

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDari EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsPenilaian: 5 dari 5 bintang5/5 (1)

- UntitledDokumen396 halamanUntitledMr BigBelum ada peringkat

- Caustic Soda Flakes 5 x20'5522895882301297069 PDFDokumen2 halamanCaustic Soda Flakes 5 x20'5522895882301297069 PDFYair ZayaBelum ada peringkat

- Pharmaceutical Drug AnalysisDokumen554 halamanPharmaceutical Drug AnalysisMuriel Bellizzi100% (8)

- Curly Wurly Teddy BearDokumen3 halamanCurly Wurly Teddy BearFeby Shyntia AfirantiBelum ada peringkat

- SN1 SN2Dokumen54 halamanSN1 SN2Feby Shyntia AfirantiBelum ada peringkat

- Technology 1Dokumen9 halamanTechnology 1Prabhu KalpakkamBelum ada peringkat

- BS EN 13765 2010 - Mangueiras Termoplásticas para Transferecia de Hidrocarb, Solventes e QuimicosDokumen28 halamanBS EN 13765 2010 - Mangueiras Termoplásticas para Transferecia de Hidrocarb, Solventes e QuimicosJoice100% (3)

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Dokumen1 halamanTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngBelum ada peringkat

- TecamidDokumen2 halamanTecamidTejas HuddarBelum ada peringkat

- Delrin Mat PDFDokumen2 halamanDelrin Mat PDFyajneshwaradixitBelum ada peringkat

- Delrin PDFDokumen2 halamanDelrin PDFA. Kumar RaiBelum ada peringkat

- Delrin MaterialDokumen2 halamanDelrin MaterialyajneshwaradixitBelum ada peringkat

- Craftechind PtfeDokumen2 halamanCraftechind PtfeZubair AamirBelum ada peringkat

- CHRAFTECHIND Pai Bearing GradeDokumen2 halamanCHRAFTECHIND Pai Bearing GradeZubair AamirBelum ada peringkat

- MC 907 Natural NylonDokumen2 halamanMC 907 Natural NylonJunior TaHuaBelum ada peringkat

- TOTAL Polystyrene 1441: Material DatasheetDokumen3 halamanTOTAL Polystyrene 1441: Material DatasheetAlbert FortunatoBelum ada peringkat

- NorylDokumen1 halamanNorylAnonymous P8Bt46mk5IBelum ada peringkat

- Nylatron® 4.6 - BoedekerDokumen6 halamanNylatron® 4.6 - BoedekerMas ZuhadBelum ada peringkat

- Polye PDokumen2 halamanPolye PFranco Gabriel MercadoBelum ada peringkat

- MSS PJ PJMaterialsDataSheetDokumen2 halamanMSS PJ PJMaterialsDataSheetAndreBelum ada peringkat

- Physical Properties of PVC CPVC PipeDokumen1 halamanPhysical Properties of PVC CPVC PipeBimal DeyBelum ada peringkat

- LdpeDokumen1 halamanLdpeArdy WiyogoBelum ada peringkat

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDokumen1 halamanTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamBelum ada peringkat

- Nylon 6.6 Data SheetDokumen2 halamanNylon 6.6 Data SheetAshish Mohurle100% (1)

- Delrin SpecsDokumen1 halamanDelrin SpecsGrimmo1979Belum ada peringkat

- Delrin SpecsDokumen1 halamanDelrin SpecsabhijitBelum ada peringkat

- Delrin - Mechanical PropertyDokumen1 halamanDelrin - Mechanical PropertyGovarthanan GovaBelum ada peringkat

- Hojas TécnicasDokumen2 halamanHojas TécnicasalejandrocharlescollBelum ada peringkat

- Nylon 6Dokumen1 halamanNylon 6luuiissBelum ada peringkat

- Technical Data Sheet Polyimide: Benefits ApplicationsDokumen3 halamanTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkBelum ada peringkat

- RTP 102 Polypropylene (PP) Glass Fiber: Product Data Sheet & General Processing ConditionsDokumen1 halamanRTP 102 Polypropylene (PP) Glass Fiber: Product Data Sheet & General Processing ConditionsarmandoBelum ada peringkat

- Polypropylene PDFDokumen2 halamanPolypropylene PDFSabuj SaikiaBelum ada peringkat

- Tds Ral 7037 Haa Hfhr02s8Dokumen1 halamanTds Ral 7037 Haa Hfhr02s8Jaskaran SinghBelum ada peringkat

- HDHR-242U: High Density PolyethyleneDokumen1 halamanHDHR-242U: High Density Polyethylenefrancisca ulloa riveraBelum ada peringkat

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Dokumen1 halamanTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PBelum ada peringkat

- Ge Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Dokumen2 halamanGe Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Ionut DeaconuBelum ada peringkat

- Data Sheet: 2205 Duplex Stainless SteelDokumen2 halamanData Sheet: 2205 Duplex Stainless SteelJandri JacobBelum ada peringkat

- PolystyreneDokumen1 halamanPolystyrenejoshkajasmineBelum ada peringkat

- Pei 0270 RTP 2183Dokumen2 halamanPei 0270 RTP 2183Vincent NguyenBelum ada peringkat

- Acetal Natural Data SheetDokumen1 halamanAcetal Natural Data SheetvijayBelum ada peringkat

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDokumen2 halamanTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanBelum ada peringkat

- Toray Btcy-1: Description FeaturesDokumen6 halamanToray Btcy-1: Description FeaturesAkhil HebbarBelum ada peringkat

- Current Material - 5323-70-Epdm-Seals - 020217Dokumen2 halamanCurrent Material - 5323-70-Epdm-Seals - 020217Brent TairaBelum ada peringkat

- Infineum V534Dokumen1 halamanInfineum V534Hiram GarciaBelum ada peringkat

- Arkema PEKK Kkepstan 8001 TDSDokumen3 halamanArkema PEKK Kkepstan 8001 TDSstartionlilBelum ada peringkat

- PEEKDokumen2 halamanPEEKHugorong WongBelum ada peringkat

- Teflon® FEP (Fluorinated Ethylene Propylene)Dokumen1 halamanTeflon® FEP (Fluorinated Ethylene Propylene)mohammed goudaBelum ada peringkat

- Astm Lupol gp3156f - EngDokumen2 halamanAstm Lupol gp3156f - EngYo ABelum ada peringkat

- Exhaust Rim E722 - Epoxy - PDSDokumen5 halamanExhaust Rim E722 - Epoxy - PDSSpace MuskBelum ada peringkat

- Ptfe SpecificationsDokumen1 halamanPtfe SpecificationsiN00bBelum ada peringkat

- SABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)Dokumen3 halamanSABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)MRC RailBelum ada peringkat

- Technical Product Data: Autofroth® 100-B-1704 Resin/Autofroth 10000A Isocyanate Rigid Urethane Foam SystemDokumen2 halamanTechnical Product Data: Autofroth® 100-B-1704 Resin/Autofroth 10000A Isocyanate Rigid Urethane Foam SystemKhin Sandi KoBelum ada peringkat

- Slide Plate Selection ChartDokumen1 halamanSlide Plate Selection ChartLovebinBelum ada peringkat

- Shear Flat SlabDokumen1 halamanShear Flat Slabadnan-651358Belum ada peringkat

- Ptfe PDFDokumen1 halamanPtfe PDFXiwen CloudBelum ada peringkat

- ABS (Acrylonitrile-Butadiene-Styrene) : Property ASTM Test Method UnitsDokumen1 halamanABS (Acrylonitrile-Butadiene-Styrene) : Property ASTM Test Method UnitsFong Ka YengBelum ada peringkat

- PolycarbonateDokumen2 halamanPolycarbonatepuvitta sudeshilaBelum ada peringkat

- PolycarbonateDokumen2 halamanPolycarbonateAdnan KhanBelum ada peringkat

- PolycarbonateDokumen2 halamanPolycarbonateROHIT SHARMABelum ada peringkat

- Wonderloy PC 540Dokumen2 halamanWonderloy PC 540Phung LucBelum ada peringkat

- ABS HI 121 MaterialDokumen2 halamanABS HI 121 Materiallenderahul1705Belum ada peringkat

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDokumen2 halamanMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloBelum ada peringkat

- B-1003 HDPE GDB50 PE4710 Natural Gas Distribution PipeDokumen2 halamanB-1003 HDPE GDB50 PE4710 Natural Gas Distribution PipeZulfikar NoerBelum ada peringkat

- Abs Pa777dDokumen1 halamanAbs Pa777djdstore99Belum ada peringkat

- Fluteck P7500 CA v01.19Dokumen2 halamanFluteck P7500 CA v01.19fprovitaliBelum ada peringkat

- Styro Lution Tds 400900240714Dokumen3 halamanStyro Lution Tds 400900240714vrjrBelum ada peringkat

- Harvest Moon - Back To Nature - 2000 - Natsume, Inc PDFDokumen32 halamanHarvest Moon - Back To Nature - 2000 - Natsume, Inc PDFFeby Shyntia AfirantiBelum ada peringkat

- DIY Rotating CalenderDokumen9 halamanDIY Rotating CalenderFeby Shyntia AfirantiBelum ada peringkat

- Doll Graduation D e A4Dokumen1 halamanDoll Graduation D e A4Feby Shyntia AfirantiBelum ada peringkat

- Ticagrelor Versus Aspirin in Acute Stroke or Transient Ischemic AttackDokumen9 halamanTicagrelor Versus Aspirin in Acute Stroke or Transient Ischemic AttackTara WandhitaBelum ada peringkat

- Ex IrDokumen7 halamanEx IrVinh HoangBelum ada peringkat

- 09 Craft0010 e A4Dokumen0 halaman09 Craft0010 e A4TitaS@Belum ada peringkat

- Effects of The Spreading Inflammatory ReactionDokumen5 halamanEffects of The Spreading Inflammatory ReactionFeby Shyntia AfirantiBelum ada peringkat

- Tugas BiokimiaDokumen1 halamanTugas BiokimiainnamuthiBelum ada peringkat

- Optical Imaging Fact SheetDokumen2 halamanOptical Imaging Fact SheetFeby Shyntia AfirantiBelum ada peringkat

- Tabel Student's T-TestDokumen5 halamanTabel Student's T-TestFeby Shyntia AfirantiBelum ada peringkat

- Subtitusi NukleofilikDokumen8 halamanSubtitusi NukleofilikFeby Shyntia AfirantiBelum ada peringkat

- Blood Type Diet FQADokumen8 halamanBlood Type Diet FQAFeby Shyntia AfirantiBelum ada peringkat

- Nutraceuticals 1 EditDokumen25 halamanNutraceuticals 1 EditFeby Shyntia AfirantiBelum ada peringkat

- Polymer Blends and CompositesDokumen23 halamanPolymer Blends and Compositesjacky hansdahBelum ada peringkat

- Lab Report 1 Sku 3043Dokumen9 halamanLab Report 1 Sku 3043Nelviana NahBelum ada peringkat

- Product List Additives For Coatings - SynthronDokumen20 halamanProduct List Additives For Coatings - SynthronbexigaobrotherBelum ada peringkat

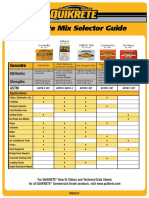

- Concrete Mix Selector GuideDokumen1 halamanConcrete Mix Selector GuideTerry McManamanBelum ada peringkat

- Jet - Lube Industrial CatalogDokumen25 halamanJet - Lube Industrial CatalogJeremias UtreraBelum ada peringkat

- Din 5402-2Dokumen2 halamanDin 5402-2Dule JovanovicBelum ada peringkat

- Concrete Slab TypesDokumen6 halamanConcrete Slab TypesMukovhe MuvhaliBelum ada peringkat

- Density of Materials & Comparison of Ss 304 Vs Ss316LDokumen4 halamanDensity of Materials & Comparison of Ss 304 Vs Ss316LShino UlahannanBelum ada peringkat

- L125Dokumen15 halamanL125Gilorie RuizBelum ada peringkat

- Nedal Alloy Datasheet EN AW 7108ADokumen1 halamanNedal Alloy Datasheet EN AW 7108ANico VazquezBelum ada peringkat

- 003 PDFDokumen52 halaman003 PDFengsonikaBelum ada peringkat

- Guidelines From MSRDC PDFDokumen15 halamanGuidelines From MSRDC PDFSreekanth SattirajuBelum ada peringkat

- 15A04506 MEMS & MicrosystemsDokumen1 halaman15A04506 MEMS & Microsystemsyoga anandhygBelum ada peringkat

- Highway Pavement DesignDokumen28 halamanHighway Pavement DesignJannin GeronimoBelum ada peringkat

- Composition of Ceramic and Its UsesDokumen28 halamanComposition of Ceramic and Its UsesManveer SinghBelum ada peringkat

- Basic Material Pipe PriceDokumen3 halamanBasic Material Pipe PricesmithBelum ada peringkat

- Sandvik SX PDFDokumen1 halamanSandvik SX PDFLéo FreitasBelum ada peringkat

- 1591 EC2213 SignedDokumen5 halaman1591 EC2213 SignedDeepak HoleBelum ada peringkat

- PW 07TexFilmCharDokumen2 halamanPW 07TexFilmCharMiguel ArriecheBelum ada peringkat

- Comparison of Wood Fiber and Cotton FiberDokumen6 halamanComparison of Wood Fiber and Cotton FiberpalajinggaBelum ada peringkat

- Indexing Plungers: Steel / Stainless Steel Without Rest PositionDokumen2 halamanIndexing Plungers: Steel / Stainless Steel Without Rest PositionClecio FelixBelum ada peringkat

- 1) The Physical Structure of FiberDokumen9 halaman1) The Physical Structure of Fiberlutfur nomanBelum ada peringkat

- Week 6 (1) - CombinedDokumen150 halamanWeek 6 (1) - CombinedAdelisa AdrovicBelum ada peringkat

- CBC - Design Assisstant - June 2019Dokumen36 halamanCBC - Design Assisstant - June 2019G. S. YadavBelum ada peringkat

- RD218 Gardan 3110 Ob2226657 NDokumen1 halamanRD218 Gardan 3110 Ob2226657 Nopen hartigBelum ada peringkat