How To Design Tank Heating Coils - Parte1

Diunggah oleh

Morteza SepehranJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

How To Design Tank Heating Coils - Parte1

Diunggah oleh

Morteza SepehranHak Cipta:

Format Tersedia

Boiler Water Carryover

Technical Bulletin 1-004

Boiler Systems

Updated 09/21/11

Carryover Defined

Carryover is any contaminant that leaves the boiler with the steam. It can be in a solid, liquid, or vapor form. The

most common form of carryover is boiler water droplets that contain dissolved and suspended solids.

Related Terms

Steam purity refers to the amount of solid, liquid, or vaporous contamination in the steam. High purity steam

contains only trace amounts of carryover. Steam quality is a measure of the amount of moisture in the steam. It

is the weight of dry steam in a mixture of water and steam. For example, steam of 98% quality would contain 2%

moisture. Since steam containing entrained boiler water is by definition wet, both steam purity and steam quality

are reduced by the presence of boiler water carryover.

Effects of Carryover

Boiler water carryover can cause deposits to form in non-return and stop valves,

control valves, heat exchangers, turbines, and superheaters. If the deposits are

significant, heat transfer and/or turbine efficiency damage may occur. Additionally,

carryover can strip away the protective film formed by filming amine programs,

cause erosion induced corrosion, and result in product quality problems in

processes using live steam.

Turbines are particularly prone to damage by carryover. Solid particles in the

steam will erode turbine parts while deposition on turbine blades will reduce

efficiency, cause vibration, and result in turbine failure. The thermal and

mechanical shock associated with large slugs of boiler water carryover can cause

rapid turbine damage.

Steam Line Deposit

An often overlooked consequence of boiler water carryover is the efficiency loss Caused by Carryover

due to wet steam. Since water at a given pressure has lower heat content than

steam, wet steam has lower heat content than dry steam.

Causes of Carryover

The causes of carryover are generally classified as either mechanical or chemical. Mechanical causes include

boiler design, high water level, firing method, and load characteristics. Chemical causes include high solids

concentration (dissolved and suspended), excessive alkalinity, grease, oil, and other contamination.

Mechanical Causes

Boiler design directly influences steam purity. Design factors that affect carryover include design pressure, steam

drum size, design steam generating rate, circulation rate, and the type of mechanical separating equipment used.

Operating characteristics also directly influence steam purity. If a boiler is operated at loads in excess of its design

rating or is subject to sudden increases in load, the potential for carryover dramatically increases.

Chemical Causes

Foaming and selective vaporous carryover are the two main mechanisms of chemical carryover. High suspended

solids, high dissolved solids, high alkalinity, and process contamination from the condensate system can all cause

foaming. In some plants, the dissolved solids level is the primary factor controlling whether carryover occurs while

in others it is the alkalinity level. While suspended solids on a part-per-part basis tend to have a more pronounced

impact on carryover than dissolved solids, the widespread use of external treatment has substantially reduced

carryover due to suspended matter. Oil, grease, and other organic contaminants can also cause carryover due to

©2011 Chem-Aqua, Inc.

foaming. Selective vaporous carryover occurs due to the solvent properties of steam. At high pressures,

steam actually dissolves a portion of the mineral salts in the boiler water. While this is not a concern

with most common minerals at pressures less than 1,000 psi, vaporous carryover of silica can occur at

pressures as low as 600 psig. Consequently, the boiler water silica level must be carefully limited in higher

pressure systems, especially if turbines are present.

Prevention of Carryover

The prevention of carryover can also be divided into mechanical and chemical means.

Mechanical Prevention

Low capacity and low pressure boilers (typically firetube boilers) primarily rely on simple gravity separation

of the water and steam. At higher pressures and/or high steaming rates (typically water tube boilers) it

is necessary to install internal mechanical steam separating devices to provide acceptable purity steam.

These devices may consist of baffles, screens, chevron separators, or centrifugal separators. It is

important that each element of steam separation equipment be kept clean and tight. Even a quarter inch

gap between sections of cover baffles over the generating tubes can negate their operation. Likewise,

the presence of deposits on screens or mesh demisters can prevent them from functioning properly. If the

steam load is consistently at or above the rated capacity, a steam flow regulator (orifice) can be installed on

the outlet of the steam drum, usually between the non-return valve and the steam drum.

Chemical Prevention

The principle chemical factors causing carryover are the dissolved solids, suspended solids, alkalinity,

silica (vaporous carryover), and oil contents of the boiler water. In many cases, limiting the concentration

of these components will satisfactorily control carryover. The actual levels that can be maintained without

carryover problems can only be determined based on operating experience with each boiler system.

Chemical Antifoams

It is often possible to add a treatment chemical to the boiler water that will counteract foaming. These

chemicals, called antifoams, can control carryover to a tolerable level without increased blowdown or

additional external treatment. Their use can even reduce fuel consumption by permitting lower blowdown

rates while maintaining high purity steam. While antifoams will not control all types of boiler water foaming,

they should be considered whenever foaming is a problem.

Testing for Carryover

The occurrence of boiler water carryover can usually be verified by testing the condensate. As a general

rule, low conductivity condensate indicates high purity steam is being produced, while high conductivity

condensate indicates the presence of carryover.

Note that high conductivity alone does not necessarily indicate the presence of boiler water solids in

the steam. In systems using highly alkaline makeup water, the carbon dioxide gas generated by the

breakdown of the natural alkalinity in the makeup water can cause large amounts of carbonic acid to form

in the condensate. Whether neutralized or not, carbonic acid will contribute significantly to the conductivity

of the condensate. When highly alkaline makeup water is used, it is possible to have high condensate

conductivity, although no boiler water solids are present. Also, if a leaking heat exchanger allows hard

water into the condensate, the conductivity of the condensate may increase.

If boiler water carryover is suspected, it can be verified by testing the condensate for such parameters as

phosphate, alkalinity, silica, or sulfite. If significant levels of these contaminants are detected, boiler water

is being “carried over” into the steam. The trace hardness test will confirm the presence of a leaking heat

exchanger.

Conclusion

Even the most well-designed and operated boiler with a controlled water treatment program will produce

at least minor amounts of carryover. The key is to know how much carryover can be tolerated and then

operate the boiler system as required to provide the desired steam purity. Consult your Chem-Aqua

representative to determine acceptable operating parameters.

©2011 Chem-Aqua, Inc.

Anda mungkin juga menyukai

- UOP 826-81 Carbon Dioxide in Ammine SolutionDokumen7 halamanUOP 826-81 Carbon Dioxide in Ammine SolutionMorteza Sepehran100% (1)

- UOP 989-14 Trace Sulfur in LPG and Gaseous Hydrocarbons by Oxidative Combustion With UltravioletDokumen7 halamanUOP 989-14 Trace Sulfur in LPG and Gaseous Hydrocarbons by Oxidative Combustion With UltravioletMorteza SepehranBelum ada peringkat

- UOP 304-08 Bromine Number and Bromine Index of Hydrocarbons by Potentiometric TitrationDokumen13 halamanUOP 304-08 Bromine Number and Bromine Index of Hydrocarbons by Potentiometric TitrationMorteza SepehranBelum ada peringkat

- UOP 99-07 Pentane-Insoluble Matter in Petroleum Oils Using A Membrane FilterDokumen10 halamanUOP 99-07 Pentane-Insoluble Matter in Petroleum Oils Using A Membrane FilterMorteza SepehranBelum ada peringkat

- UOP 555-10 Trace Impurities in Benzene by GCDokumen11 halamanUOP 555-10 Trace Impurities in Benzene by GCMorteza SepehranBelum ada peringkat

- UOP 212-05 - Hydrogen Sulfide, Mercaptan Sulfur, and Carbonyl Sulfide in Hydrocarbon Gases by Po PDFDokumen25 halamanUOP 212-05 - Hydrogen Sulfide, Mercaptan Sulfur, and Carbonyl Sulfide in Hydrocarbon Gases by Po PDFMorteza Sepehran100% (5)

- UOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCDokumen6 halamanUOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCMorteza SepehranBelum ada peringkat

- EE4CL4 Lecture31 PDFDokumen16 halamanEE4CL4 Lecture31 PDFMorteza SepehranBelum ada peringkat

- UOP 1005-14 Trace Metals in Organics by ICP-MSDokumen11 halamanUOP 1005-14 Trace Metals in Organics by ICP-MSMorteza SepehranBelum ada peringkat

- Handout Jacobs CSS - Claus ProcessDokumen1 halamanHandout Jacobs CSS - Claus ProcessMorteza SepehranBelum ada peringkat

- Large-Scale Sulfur Recovery: AS RocessingDokumen3 halamanLarge-Scale Sulfur Recovery: AS RocessingMorteza SepehranBelum ada peringkat

- Process Analytics in ClausDokumen9 halamanProcess Analytics in ClausMorteza SepehranBelum ada peringkat

- Elec Eng 4Cl4:: Control System DesignDokumen12 halamanElec Eng 4Cl4:: Control System DesignMorteza SepehranBelum ada peringkat

- Elec Eng 4Cl4:: Control System DesignDokumen20 halamanElec Eng 4Cl4:: Control System DesignMorteza SepehranBelum ada peringkat

- Metallurgy and Corrosion Control in Oil and Gas ProductionDokumen1 halamanMetallurgy and Corrosion Control in Oil and Gas ProductionMorteza SepehranBelum ada peringkat

- Pages From 08 - Condensate and LPG DehydrationDokumen1 halamanPages From 08 - Condensate and LPG DehydrationMorteza SepehranBelum ada peringkat

- Refining Industry Solutions: Experience, Knowledge, and Technology... in RefiningDokumen44 halamanRefining Industry Solutions: Experience, Knowledge, and Technology... in RefiningMorteza SepehranBelum ada peringkat

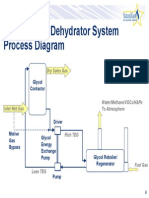

- Basic Glycol Dehydrator System Process Diagram: Dry Sales GasDokumen1 halamanBasic Glycol Dehydrator System Process Diagram: Dry Sales GasMorteza SepehranBelum ada peringkat

- 8-Dehydrations 1 PDFDokumen1 halaman8-Dehydrations 1 PDFMorteza SepehranBelum ada peringkat

- 8-Dehydrations 10 PDFDokumen1 halaman8-Dehydrations 10 PDFMorteza SepehranBelum ada peringkat

- The Leader In: Gas Dehydration & FiltrationDokumen8 halamanThe Leader In: Gas Dehydration & FiltrationMorteza SepehranBelum ada peringkat

- Lessons Learned From Natural Gas STAR PartnersDokumen21 halamanLessons Learned From Natural Gas STAR PartnersMorteza SepehranBelum ada peringkat

- 8-Dehydrations 2 PDFDokumen1 halaman8-Dehydrations 2 PDFMorteza SepehranBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Ch-13 Fluid MechanicsDokumen24 halamanCh-13 Fluid MechanicsDeenul AsmiBelum ada peringkat

- Regenerative Circuit General EquationsDokumen2 halamanRegenerative Circuit General EquationsSwaminath BarmanBelum ada peringkat

- Cavity Vent in Gate ValvesDokumen10 halamanCavity Vent in Gate ValvesSyed Ahsan50% (2)

- Shear Rheology - SpringerLinkDokumen5 halamanShear Rheology - SpringerLinkArjav ThakkarBelum ada peringkat

- Numerical Analysis of Turbojet EnginesDokumen20 halamanNumerical Analysis of Turbojet EnginesvidyaamarBelum ada peringkat

- Manual de ElectrovalvulaDokumen108 halamanManual de ElectrovalvulaAriel MalleaBelum ada peringkat

- Instruction Manual: Fluid Friction C6Dokumen54 halamanInstruction Manual: Fluid Friction C6MI Pedro ZBBelum ada peringkat

- Lubricant List WPK-0304-MD-608Dokumen9 halamanLubricant List WPK-0304-MD-608Jalal NorriBelum ada peringkat

- Bent Axis Piston Pump 34-108ccDokumen3 halamanBent Axis Piston Pump 34-108ccKari MohamedBelum ada peringkat

- HP/LP Bypass Automation: Function DescriptionDokumen14 halamanHP/LP Bypass Automation: Function DescriptionMohit GohilBelum ada peringkat

- Process System Engineers (India) Pvt. LTD.: Marketing, Distribution & System Building ByDokumen13 halamanProcess System Engineers (India) Pvt. LTD.: Marketing, Distribution & System Building ByvuongBelum ada peringkat

- Understanding Valve & Their FunctionsDokumen30 halamanUnderstanding Valve & Their FunctionsMan ThiBelum ada peringkat

- Eneos Sustina AllDokumen2 halamanEneos Sustina Alldan0410Belum ada peringkat

- Elautomation Pumps PricelistDokumen7 halamanElautomation Pumps Pricelistsolo7651Belum ada peringkat

- ANSYS CFX-Solver Theory GuideDokumen362 halamanANSYS CFX-Solver Theory GuideSuri Kens MichuaBelum ada peringkat

- Heat Transfer. Finned Tubes. Heat Flow - U Factor - Fin EfficiencyDokumen79 halamanHeat Transfer. Finned Tubes. Heat Flow - U Factor - Fin EfficiencyvyrgoBelum ada peringkat

- Fluid Mechanics ManualDokumen41 halamanFluid Mechanics ManualrajmaljatBelum ada peringkat

- Plumbing - Water Sypply DesignDokumen7 halamanPlumbing - Water Sypply DesignmadanegBelum ada peringkat

- Differential Analysis of Fluid FlowDokumen49 halamanDifferential Analysis of Fluid FlowKareem HeshamBelum ada peringkat

- Chapter 16Dokumen15 halamanChapter 16Aeromoon AeroseekBelum ada peringkat

- MC20005-WHP-WI-P-0114 Liquid Seal Pot Datasheet Work Instruction - RevD1Dokumen8 halamanMC20005-WHP-WI-P-0114 Liquid Seal Pot Datasheet Work Instruction - RevD1nguyenmainamBelum ada peringkat

- Jawaban Plan and Schedule OperationDokumen2 halamanJawaban Plan and Schedule OperationAhmad NaswianBelum ada peringkat

- Flare Network Calculation Report Hammar Mishrif DGS: Eni - Iraq Zubair Oil Field Development ProjectDokumen20 halamanFlare Network Calculation Report Hammar Mishrif DGS: Eni - Iraq Zubair Oil Field Development ProjectEslam ShiblBelum ada peringkat

- Introduction To Irrigation DesignDokumen40 halamanIntroduction To Irrigation DesignEifa Mat LazimBelum ada peringkat

- Yamuna RiverDokumen2 halamanYamuna Riverpravin963Belum ada peringkat

- CPLT Combinable Production Logging ToolDokumen1 halamanCPLT Combinable Production Logging ToolTruecaller CallerBelum ada peringkat

- Seawater Intake Optimization Study - MWWD2016Dokumen6 halamanSeawater Intake Optimization Study - MWWD2016MVBelum ada peringkat

- Nycolube 127 TDSDokumen1 halamanNycolube 127 TDSpokleBelum ada peringkat

- Mechanical Interview Questions and Answers Fluid MechanicsDokumen2 halamanMechanical Interview Questions and Answers Fluid Mechanicsjk50% (2)