26 Civ Su 4747 A

Diunggah oleh

BhattJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

26 Civ Su 4747 A

Diunggah oleh

BhattHak Cipta:

Format Tersedia

CIV-SU-4747-A

CONSTRUCTION OF UNDERGROUND DRAINAGE SYSTEMS

This document can be downloaded from the following

Technical Standards website:

http://techstds.ric100.chevron.net

Electronic files may be ordered by phone (510-242-7241),

e-mail (TechStds@Chevron.com),

or fax (510-242-2157).

December 2005 © Chevron Corporation 1 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

CONTENTS

1.0 SCOPE .........................................................................................................................3

2.0 REFERENCES .............................................................................................................3

3.0 EXCAVATION ..............................................................................................................3

3.1 ......Trench Excavation ............................................................................................3

3.2 ......Excavation/Bedding for Appurtenances ...........................................................6

3.3 ......Slopes, Sheeting, and Shoring .........................................................................6

3.4 ......Considerations for Existing Facilities ................................................................6

3.5 ......Dewatering .......................................................................................................7

3.6 ......Excavation in Contaminated Ground ................................................................7

4.0 CONSTRUCTION OF APPURTENANCES .................................................................7

4.1 ......General .............................................................................................................7

4.2 ......Protection of Appurtenances ............................................................................7

5.0 PIPE AND FITTING INSTALLATION ..........................................................................7

5.1 ......General .............................................................................................................7

5.2 ......Protection and Care of Pipe, Fittings, and Trench ...........................................8

5.3 ......Alignment and Grade .......................................................................................8

5.4 ......Bell and Spigot or Similar Pipe .........................................................................8

5.5 ......Suspended Pipe Laying ...................................................................................8

5.6 ......HDPE pipe ........................................................................................................8

6.0 JOINTING ....................................................................................................................8

6.1 ......Pipe ..................................................................................................................8

6.2 ......Field Joints and Repairs in Corrosion Coating .................................................9

7.0 TESTING ......................................................................................................................9

7.1 ......Procedure .........................................................................................................9

7.2 ......Water Source and Disposal ..............................................................................9

7.3 ......Test Duration ....................................................................................................9

7.4 ......Allowable Leakage .........................................................................................10

8.0 BACKFILL .................................................................................................................10

8.1 ......Compaction ....................................................................................................10

8.2 ......Trenches ........................................................................................................10

8.3 ......Appurtenances ...............................................................................................12

9.0 TIE-IN TO EXISTING SYSTEM .................................................................................12

10.0 MISCELLANEOUS ....................................................................................................12

10.1 ....Keep System Clean ........................................................................................12

10.2 ....Plug Openings into System ............................................................................12

10.3 ....Embedment of Flexible Pipe ..........................................................................12

December 2005 © Chevron Corporation 2 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

1.0 SCOPE

This specification covers the requirements for construction of underground drainage systems.

2.0 REFERENCES

Process Industry Practices (PIP)

PIP CVC01015 Civil Design Criteria, October 2004

PIP CVS02100 Site Preparation, Excavation, and Backfill Specification, August 2003

PIP CVS02700 Underground Gravity Sewer Specification, October 2004

PIP CVI02720 Sewer Details, June 2004

American Society for Testing and Materials (ASTM)

ASTM C969 Standard Practice for Infiltration and Exfiltration Acceptance Testing of

Installed Precast Concrete Pipe Sewer Lines

ASTM D422 Standard Test Method for Particle - Size Analysis of Soils

Code of Federal Regulations: Safety and Health Regulations for Construction

29 CFR 1926 Subpart P - Excavations

3.0 EXCAVATION

3.1 Trench Excavation

3.1.1 General

All excavation and trenching shall be made in accordance with PIP CVS02100, OSHA

standards, and Company's local requirements and guidelines for the following:

1. Shoring, bracing, and/or sloping wall construction.

2. Marking, flagging, and protecting open excavations.

3. Permitting and confined space entry requirements.

4. Employing excavation-competent person (ECP).

5. Handling and storing excavated materials.

3.1.2 Trench Alignment

The trench shall be correctly aligned to permit pipe laying without straining the pipe and

pipe joints.

3.1.3 Trench Width

1. The trench shall be excavated to the smallest width sufficient to allow proper assem-

bly of pipe joints and compaction of fill material.

2. If practical, maximum trench width from bottom of the trench to 12 inches (305 mm)

above the pipe shall be 4/3 the nominal diameter of the pipe plus 8 inches (203 mm).

December 2005 © Chevron Corporation 3 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

3.1.4 Trench Depth

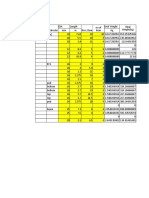

Table 1: Typical Trench Widths

Outside Diameter (O.D.) Trench Width

Less than or equal to 30 inches (762 mm) O.D. + 20 inches (508 mm)

Greater than 30 inches (762 mm) O.D. + 24 inches (610 mm)

The trench depth shall be based on the specified invert of the pipe plus the bedding

requirements as specified in this Specification and in the contract documents.

3.1.5 Excavated Material

1. Stockpiling and disposal requirements shall be in accordance with Company require-

ments.

2. Excavated material shall not be stockpiled on roads.

3. Excavated material must not be stockpiled alongside the trence excavation. A clear

distance, as directed by the project, must be maintained between the trench edge and

the bottom of the heap of excavated material to prevent collapse of the trench side due

to local surcharging.

3.1.6 Preparation of Trench Bottom

1. General

The bottoms of trenches shall be firm, flat throughout its width, and graded to provide

uniform bearing of the pipe.

2. Rock

a. If ledge rock, hard pan, shale, or other unyielding material, cobbles, rubble,

debris, boulders, or stones larger than 1.5 (38 mm) inches are encountered in the

trench bottom, the trench shall be over-excavated to a distance below the pipe of 8

inches or 1/6 of the pipe diameter, whichever is greater.

b. The over-excavation shall be centered about the pipe and at least 12 inches

(305 mm) wider than the outside diameter of the pipe barrel.

c. The excavated materials shall be replaced with proper embedment material.

3. Unsuitable Material

Unsuitable material such as muck, peat, or similar material shall be over-excavated

throughout the width of the trench to a distance below the pipe of 12 inches (305 mm)

or ½ of the pipe internal diameter, whichever is greater.

4. Over-excavation

a. If a trench is over-excavated, the over-excavated portion shall be replaced with

compacted backfill.

b. Backfill material and compaction shall be in accordance with Section 8.1.1 and

8.2.2.

December 2005 © Chevron Corporation 4 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

3.1.7 Bedding

1. Bedding Material

a. Bedding material shall be granular and well graded. All material shall pass a

½-inch sieve and shall be at least 90% retained on No. 200 (75 microns) sieve as

determined in accordance with ASTM D422.

b. Bedding material shall be compacted to a density approximately that of the undis-

turbed site soil materials.

2. Basic Requirements

a. Compacted bedding shall cover the full width of the trench with a minimum thick-

ness equal to 6 inches (152 mm) or ¼ of the outside diameter of the pipe barrel,

whichever is greater.

b. The pipe bed shall provide uniform bearing for the bottom of the pipe.

c. Localized loading and differential settlement shall be minimized where the pipe

crosses other utilities or subsurface structures or in areas having special founda-

tions such as pile caps or sheeting. A cushion of bedding shall be provided

between the pipe and any such point of localized loading.

3. Bedding Classes

a. Bedding in general shall conform to one of the classes in accordance with

PIP CVS02700 Section 4.3.4.6.

b. Bedding for box culverts shall conform to one of the classes in accordance with

PIP CVS02700 Section 4.3.4.7.

3.1.8 Pipe with Projections

1. The Contractor shall make holes for each bell, coupling, or projection.

2. A clearance of at least 2 inches (50 mm) shall be provided between the bottom of the

projecting piece and the bottom of the hole.

3.1.9 Bell Holes

If pipe joint diameter exceeds pipe outside diameter (e.g., bell and spigot piping), bell

holes shall be manually excavated after the trench bottom has been graded.

3.1.10 Flexible Pipe

1. Only as much trench shall be opened as can be safely maintained by available equip-

ments.

2. The space between the pipe and trench wall shall be wider than the compaction equip-

ment used in the conduit zone; however, in no case shall it be wider than the conduit

diameter times 1.5 plus 12 inches (305 mm).

3.1.11 Wall Supports

1. If trench wall supports such as sheeting are required, these supports must be left in

place to preclude loss of support for the pipe.

2. If sheeting is to be cut off, cuts shall be made a minimum of 1.5 ft. (457 mm) above

the crown of the pipe.

December 2005 © Chevron Corporation 5 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

3. Rangers, whalers, and braces shall be left in place as required to support cutoff sheet-

ing.

4. If timber sheeting is used, it shall be treated as a permanent structure and treated

against biological degradation.

3.2 Excavation/Bedding for Appurtenances

1. Excavations for appurtenances shall be large enough for correct placement of the item true and

plumb, and adequately supported on firm material.

2. Bedding, if required, shall be as shown on the construction drawing.

3. Appurtenances include manholes, valve boxes, and large catch basins.

3.3 Slopes, Sheeting, and Shoring

The Contractor shall submit a procedure to show how the excavation is safely supported and the

pipes are installed. This shall include design calculations where appropriate.

1. The Contractor shall meet the minimum requirements for shoring and bracing of excavations

given in the 29 CFR 1926 Subpart P.

2. The Contractor shall take adequate measures to prevent slips, cave-ins, and slides.

a. The Contractor shall install trench bracing, sheeting, or shoring as necessary to perform

the work and protect the excavation.

b. If trenches must have side slopes for stability, the slope shall not be carried below a plane

level with the top of the pipe barrel.

3.4 Considerations for Existing Facilities

1. The Contractor shall use caution to avoid damaging existing facilities (e.g., foundations, ser-

vices, pipelines, etc.) on, above, or below the surface of the area where excavation and backfill

operations are to be performed.

2. The Contractor shall adequately support all existing underground lines that are excavated and

all existing footings, foundations, or pipe supports near any excavation.

3. Any excavation within 2 feet (610 mm) of operating lines shall be done by hand until the lines

are completely exposed.

4. Trial hole shall be made where the excavation is to take place. These shall be carried out by

hand until undisturbed rock or soil is encountered. When all existing services are located,

marked and notified on the excavation permit the contractor may start mechanical excavation

in undisturbed material. It is recommended that any excavation in fill continue to be carried

out by hand unless it is known that there are no underground services

5. The Contractor shall immediately report to the Company any underground facilities discov-

ered during excavation that are not shown on the construction drawings, and suspend work on

this section until given authority by the Company representative to continue.

6. If construction of new sewers interferes with existing sewers, satisfactory temporary bypass

facilities shall be provided. Open ends of existing sewers that are cut shall be temporarily

blocked to prevent escape of liquid or gas into the excavation.

7. Open ends of existing sewers that are cut or abandoned in place shall be securely closed with a

plug or wall of concrete having a minimum thickness of 3 pipe diameters.

December 2005 © Chevron Corporation 6 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

3.5 Dewatering

3.5.1 General

1. Dewatering shall be carried out continuously (24 hrs/day) while work is being carried

out.

2. Water shall not be allowed to accumulate in excavations. Subsurface water flowing

into excavations shall be removed by pumping or if possible by gravity drainage.

3. Liquids which accumulate in trenches shall be removed. Disposal of liquids removed

from trenches shall be in accordance with Company instructions.

4. The length of open trench shall be limited to that which can be dewatered with meth-

ods and equipment available.

3.5.2 Equipment

Equipment necessary to collect and discharge water away from excavations, such as

pumps, sumps, suction and discharge lines, and all other dewatering system components,

shall be provided, installed, and maintained.

3.5.3 Dewatering Methods

Dewatering methods shall be used to minimize softening of the soil supporting the pipe

and changes in soil characteristics that are detrimental to subgrade stability.

3.6 Excavation in Contaminated Ground

1. Known contaminated soils within the construction limits shall be managed in accordance with

a contaminated soil management plan provided by the Project before the start of excavation.

2. If unexpected soil contamination is encountered during the work, the Contractor shall stop

work and notify the Company immediately.

4.0 CONSTRUCTION OF APPURTENANCES

4.1 General

1. Manholes, catch basins, dry boxes, etc., shall be constructed in accordance with

PIP CVI02720.

2. The Contractor shall construct manholes, catch basins, area drains, drainage sumps, and other

appurtenances as shown on the construction drawings.

4.2 Protection of Appurtenances

The Contractor shall protect drain hubs and other projecting or exposed appurtenances against

physical damage, settlement, misalignment, or entry of dirt and debris.

5.0 PIPE AND FITTING INSTALLATION

5.1 General

1. Nothing shall be installed in water or other liquids.

a. Pipe shall be laid true to line and grade and kept clean and sound.

b. Pipe laying and joining shall be carried out in a dry trench.

December 2005 © Chevron Corporation 7 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

2. Each fitting and piece of pipe shall bear uniformly along its entire length or barrel. Where the

Contractor has had to wedge or block up pipes, the sections of pipe between the wedges shall

be fully surrounded by backfill and compacted fully, the wedges or blocks removed and the

remaining sections of pipe fully surrounded with compacted backfill.

3. Pipe and fittings shall be carefully installed so that the completed system has a smooth invert.

5.2 Protection and Care of Pipe, Fittings, and Trench

1. Components which are bruised, loosed, cracked, or otherwise damaged shall not be installed.

The inside of each piece shall be examined, and all dirt, construction tools or equipment, and

other foreign material shall be removed prior to and after installation.

2. Components shall be protected during installation against impact, shock, and free fall. Proper

facilities and equipment shall be used during installation to prevent disturbance of the bed and

sides of the trench.

3. Components damaged by the Contractor during or after installation shall be removed and

replaced.

5.3 Alignment and Grade

1. Pipe shall be laid beginning at the lowest point in trenches.

2. Components shall be installed to the line and set firmly to the grade shown on the construction

drawings.

a. The Contractor shall survey, record, and submit to the Company the system alignment and

grade.

b. The Contractor shall follow a Contractor-prepared plan that is acceptable to the Company.

5.4 Bell and Spigot or Similar Pipe

1. Pipes with tongue or spigot end shall be laid with spigot end pointing in the direction of flow.

The bell or coupling shall not bear on the trench. See also Section 2.1.8.

2. Bell and spigot joints shall be clean and dry.

a. A lubricant recommended by the pipe manufacturer shall be applied to the joint materials.

b. The spigot shall have full bell penetration.

5.5 Suspended Pipe Laying

If pipe laying is suspended, the ends of the pipe shall be kept closed and sealed to keep out soil and

foreign materials.

5.6 HDPE pipe

1. HDPE pipe shall be welded by experienced, qualified welders.

2. All welds shall be fusion welds except at manholes, where extrusion welds are permitted.

6.0 JOINTING

6.1 Pipe

Jointing shall be in accordance with the methods recommended by the joint manufacturers.

December 2005 © Chevron Corporation 8 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

6.2 Field Joints and Repairs in Corrosion Coating

Field joints in corrosion coatings, if applicable, shall be installed, tested, and repaired in accor-

dance with the manufacturer's recommendations.

7.0 TESTING

7.1 Procedure

7.1.1 General

1. The entire system shall be hydrotested according to a Company-approved plan pre-

pared by the Contractor.

2. The Contractor shall submit the plan to the Company for review at least 5 days prior to

testing.

3. The Contractor's plan shall include at least the following:

a. Schedule including at what points of completion the system will be tested.

b. Test procedures.

c. Re-test procedures (in case there are leaks).

4. Each section of the system shall be tested before that section is completely backfilled

so leaks can be spotted. Joints, couplings, bells, etc., shall remain completely exposed.

5. In systems with mortar joints, testing shall be done after the joints have developed suf-

ficient strength (at least 24 hours).

6. The entire system shall meet the allowable leakage requirement.

7.1.2 Process and Sanitary Sewers

Procedure for Process and Sanitary Sewers shall be in accordance with PIP CVS 02700

Section 4.4.2.

7.1.3 Storm Sewers

Exfiltration testing of storm sewers shall be done in accordance with ASTM C969.

7.2 Water Source and Disposal

1. Testing water shall be supplied at a location designated by the Company.

2. The Contractor shall be responsible for all hoses, connections, valves, etc., necessary to move

the test water to the test location.

3. Test water shall be disposed of by the Contractor at a location designated by the Company.

7.3 Test Duration

1. Specify duration here. "The test duration shall be ___________. The test shall start no sooner

than ___ hours after completion of filling."

2. Choose the test duration considering:

a. The size of the system being tested. How long it will take to walk the system, find and

record leaks, etc.

December 2005 © Chevron Corporation 9 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

b. The system material. Concrete or cement components will absorb water, so the Contractor

shall fill the system and let it stand for 12 to 24 hours before topping off and testing.

c. The climate. In hot climates, either allow enough time for the (hot) pipe and (cool or

warm) water temperatures to come to equilibrium, or test in early morning or late evening

when the temperature difference might not be as large.

d. The sensitivity of your measuring system and test pressure.

7.4 Allowable Leakage

Specify allowable leakage here. "The maximum allowable leakage shall be __ gal/hr."

8.0 BACKFILL

8.1 Compaction

8.1.1 General

1. All fill material shall be brought to an optimum moisture content range and compacted

to obtain a dry density of, unless specified otherwise, at least 90% of the maximum

dry density.

2. Backfill under roads shall be in accordance with the road construction specification

and be compacted to at least 95% of the max dry density.

3. The maximum dry density shall be obtained by the method of test for moisture-density

relations of soils (ASTM D422).

4. The maximum loose depth of any lift shall be 8 inches (203 mm).

8.1.2 Water Jetting or Flooding

Compaction by water jetting or flooding shall not be permitted.

8.2 Trenches

1. The trench shall be backfilled and compacted to a density equal to that specified on the con-

tract documents or equal to that of the adjacent in situ material.

2. Bedding and backfill for flexible pipe (for example, Spirolite and other plastics, corrugated

steel) must be placed and compacted with special care since the soil and pipe act together to

support loads. Be sure to follow manufacturer's instructions.

8.2.1 Protection of Pipe

1. No machinery or vehicles shall be allowed to pass over the trench until the trench is

completely backfilled and compacted sufficiently to prevent damage to the pipe.

2. The Contractor shall take care to avoid damaging or dislocating the system during

backfilling.

8.2.2 Backfill Material

1. Backfill and compaction material shall be in accordance with PIP CVS02100 and this

Specification and shall be similar to in-situ material.

2. In general, backfill material shall be one of the following:

a. Excavated material, if suitable and agreed to by the Company;

December 2005 © Chevron Corporation 10 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

b. Sand with a maximum particle size of 1/4 inch;

c. Gravel with a minimum grain size of 1/4 inch;

d. Pea gravel;

e. Gravel mixed with sand; or

f. Well-graded compactable material, free from stones exceeding 3 inches (76 mm)

in the largest dimension, chunks of highly plastic clay, or other deleterious mate-

rial.

8.2.3 Placement

1. Initial Backfill

a. As soon as possible after making up joints, the Contractor shall place and compact

lifts in the space between the pipe and sides of the trench, with care to prevent

movement of the line or grade, until the compacted backfill reaches halfway up

the pipe.

b. All couplings, bells, joints, etc., shall remain exposed (for observation during

hydrotesting).

c. After hydrotesting, these areas shall be backfilled.

d. To avoid misalignment or damage to the pipe and joints, the Contractor shall work

on both sides at the same time while placing and compacting lifts.

e. Lifts shall be placed and compacted as follows:

Nominal Pipe Maximum Lift Compaction

Diameter (Loose Depth) Method

12 inches and less 4 inches Hand

Over 12 inches 8 inches Hand or machine tamping

2. Intermediate Backfill

a. After hydrotesting and final surveying, the Contractor shall place and compact

lifts until the compacted backfill extends 12 inches (305 mm) above the top of the

pipe.

b. The maximum loose depth of the lifts shall be 8 inches (203 mm).

3. Final Backfill

The remaining volume to be filled shall be placed and compacted as follows:

Maximum Lift Maximum

Area (Loose Depth) Dry Density%

Roadway, railway, or paved areas 8 inches 95

Other areas* 8 inches 90

* Excavated material may/may not be used for final backfill.

December 2005 © Chevron Corporation 11 of 12

Construction of Underground Drainage Systems CIV-SU-4747-A

8.3 Appurtenances

9.0 TIE-IN TO EXISTING SYSTEM

Tie-ins to existing systems shall be done as shown on the construction drawing.

10.0 MISCELLANEOUS

10.1 Keep System Clean

1. The inside of the pipes and appurtenances shall be kept clean at all times.

2. Dirt, mortar, other joint material, construction tools and equipment, and other foreign material

shall be removed from the system.

10.2 Plug Openings into System

Openings into the system through pipe or appurtenances, when unattended, shall be plugged.

10.3 Embedment of Flexible Pipe

The requirement of the embedment configuration, material, compaction and installation shall be in

accordance with PIP CVS02700 Section 4.3.7.

December 2005 © Chevron Corporation 12 of 12

Anda mungkin juga menyukai

- 6 RC2 30 Civl Isd 00 002 0019Dokumen1 halaman6 RC2 30 Civl Isd 00 002 0019BhattBelum ada peringkat

- 19 Civ Du 5240Dokumen18 halaman19 Civ Du 5240Bhatt100% (1)

- 24 Civ Su 850 LDokumen17 halaman24 Civ Su 850 LBhatt100% (1)

- 25 Civ Su 985 FDokumen10 halaman25 Civ Su 985 FBhattBelum ada peringkat

- 22 Civ Su 398 oDokumen21 halaman22 Civ Su 398 oBhatt100% (1)

- Jacobs Calculations 3Dokumen2 halamanJacobs Calculations 3BhattBelum ada peringkat

- 20 DrainageDokumen102 halaman20 DrainageBhattBelum ada peringkat

- Jacobs Calculations 2Dokumen2 halamanJacobs Calculations 2BhattBelum ada peringkat

- Unlocked 246396042 ECP201 2008 Earthquake Lateral Forces Protected 09-06-2012 2Dokumen1 halamanUnlocked 246396042 ECP201 2008 Earthquake Lateral Forces Protected 09-06-2012 2BhattBelum ada peringkat

- Dj1 Dj2 Unb Unt Unl Ver 1.5Dokumen2 halamanDj1 Dj2 Unb Unt Unl Ver 1.5ajayssarode100% (1)

- Unlocked 246396042 ECP201 2008 Earthquake Lateral Forces Protected 09-06-2012 2Dokumen28 halamanUnlocked 246396042 ECP201 2008 Earthquake Lateral Forces Protected 09-06-2012 2BhattBelum ada peringkat

- Jacobs Engineering India Private Limited ProfileDokumen47 halamanJacobs Engineering India Private Limited ProfileBhattBelum ada peringkat

- 1711-F-001 002 003-Platform MassDokumen5 halaman1711-F-001 002 003-Platform MassBhattBelum ada peringkat

- Seimic Response of Liquid Storage TankDokumen4 halamanSeimic Response of Liquid Storage TanklucianduBelum ada peringkat

- Unlocked 246396042 ECP201 2008 Earthquake Lateral Forces Protected 09-06-2012 2Dokumen28 halamanUnlocked 246396042 ECP201 2008 Earthquake Lateral Forces Protected 09-06-2012 2BhattBelum ada peringkat

- Seismic Load SprectrumDokumen10 halamanSeismic Load Sprectrumvirat_daveBelum ada peringkat

- Mto CalculaionDokumen1 halamanMto CalculaionBhattBelum ada peringkat

- Seismic Load SprectrumDokumen65 halamanSeismic Load SprectrumBhattBelum ada peringkat

- Pipe Span and Weight Tables1Dokumen8 halamanPipe Span and Weight Tables1Bhatt100% (1)

- LOAD COMBINATION GENERATION MATRIXDokumen6 halamanLOAD COMBINATION GENERATION MATRIXvirat_daveBelum ada peringkat

- Apply UDLDokumen4 halamanApply UDLBhattBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Aakash-Bhora-Surja-Taara TabDokumen7 halamanAakash-Bhora-Surja-Taara TabKanai SinghaBelum ada peringkat

- Essential volleyball equipment and rulesDokumen19 halamanEssential volleyball equipment and rulesnicka castilloBelum ada peringkat

- 1101 Lab 4 - Circular MotDokumen18 halaman1101 Lab 4 - Circular MotYi Wei OngBelum ada peringkat

- Come, Holy SpiritDokumen1 halamanCome, Holy SpiritNguyễn TrinhBelum ada peringkat

- GE Nine Cell MatrixDokumen1 halamanGE Nine Cell MatrixSunil Kakkar100% (4)

- Splicing Prestressed Concrete Piles: Review and Testing of MethodsDokumen28 halamanSplicing Prestressed Concrete Piles: Review and Testing of MethodsSid KhanBelum ada peringkat

- Anaerobic Digestion of Solid Waste: Dorothee Spuhler, Seecon GMBHDokumen29 halamanAnaerobic Digestion of Solid Waste: Dorothee Spuhler, Seecon GMBHBerlian SitorusBelum ada peringkat

- Survey Questionnaire NSTPDokumen7 halamanSurvey Questionnaire NSTPedwineiou83% (6)

- The Two Raptures - Dr. Peter S. Ruckman 13 PgsDokumen13 halamanThe Two Raptures - Dr. Peter S. Ruckman 13 PgsPatBridges75% (4)

- Famous Bible CharactersDokumen161 halamanFamous Bible Charactersapi-3695841100% (1)

- 6D125-2 Engine (PC450-6) Shop Manual (SEBM006410)Dokumen366 halaman6D125-2 Engine (PC450-6) Shop Manual (SEBM006410)cuthuongtho92% (51)

- Partnership Agreement on Financing ProjectsDokumen12 halamanPartnership Agreement on Financing ProjectsASSET GMBHBelum ada peringkat

- Sample Q and ADokumen47 halamanSample Q and AHareesha N G100% (1)

- Multiple Choice Questions and Answers On Stress ManagementDokumen18 halamanMultiple Choice Questions and Answers On Stress Managementjaitripathi2686% (14)

- Donna Molinari ResumeDokumen4 halamanDonna Molinari Resumeapi-72678201Belum ada peringkat

- HYSTER H4.0UT, H4.5UT, H5.0UT PARTS MANUALconvDokumen162 halamanHYSTER H4.0UT, H4.5UT, H5.0UT PARTS MANUALconvNoufou OuedraogoBelum ada peringkat

- Appraisal Plan Template - SCAMPI B - V316Dokumen16 halamanAppraisal Plan Template - SCAMPI B - V316api-2626880150% (2)

- Criminal Justice SytemDokumen14 halamanCriminal Justice SytemMarc Lester100% (1)

- Zingerman's News Issue #223, November-December 2010Dokumen15 halamanZingerman's News Issue #223, November-December 2010Zingerman's Community of BusinessesBelum ada peringkat

- DBL PDFDokumen5 halamanDBL PDFfiatauroBelum ada peringkat

- The Setter - Edward Laverack - 1872Dokumen93 halamanThe Setter - Edward Laverack - 1872Antoan J. HlebarovBelum ada peringkat

- Assignment DataDokumen7 halamanAssignment Datashyam tomerBelum ada peringkat

- Caregiving 3Dokumen14 halamanCaregiving 3Bianca SandovalBelum ada peringkat

- Diass Answer SheetDokumen4 halamanDiass Answer SheetMa rosario JaictinBelum ada peringkat

- CL O CL: 4. Green Chemistry in Day-to-Day LifeDokumen2 halamanCL O CL: 4. Green Chemistry in Day-to-Day LifeSaurav PaulBelum ada peringkat

- IT Governance MCQDokumen3 halamanIT Governance MCQHazraphine Linso63% (8)

- Cognitive Academic Language Learning Approach: CALLA's Basic PremisesDokumen2 halamanCognitive Academic Language Learning Approach: CALLA's Basic PremisesDani SilvaBelum ada peringkat

- Youth Camp MANUAL (2012 Edition) - YFCDokumen51 halamanYouth Camp MANUAL (2012 Edition) - YFCAmiel YasonaBelum ada peringkat

- UTS Business Statistics: Skewerness, Probability and Some BinomialDokumen6 halamanUTS Business Statistics: Skewerness, Probability and Some BinomialemilyBelum ada peringkat

- 5 Deviated Nasal SeptumDokumen67 halaman5 Deviated Nasal SeptumSaiSuryaTejaBelum ada peringkat