Sterilized Milk: State Standards of The People's Republic of China

Diunggah oleh

fafaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Sterilized Milk: State Standards of The People's Republic of China

Diunggah oleh

fafaHak Cipta:

Format Tersedia

.____________________________________GB 5408 – 1999 .

State Standards of the People’s Republic of China

GB

GB 5408.2 – 1999

Sterilized Milk

Promulgated on December 17, 1999 Effective on May 1, 2000

Promulgated by

State Bureau of Quality and Technology Supervision

W05061 GB 5408.2 1/6

.____________________________________GB 5408 – 1999 .

Preface

In this Standard, the “4.1.2 Food additives and food nutrition fortifiers…”, “4.3.1 Net

Contents”, “4.4 Hygiene Specification”, “4.5 The Added Quantity of Food Additives and Nutrition

Fortifiers”, and “7.1.1 The Contents of Compulsory Label’ shall be the clauses that must be done,

and the others are recommendable clauses.

The Standard was proposed by the State Bureau of Light Industry.

Matters concerning the Standard shall be delegated by the Dairy Standardization Center.

The Heilongjiang Institute of Dairy Products was in charge of drafting the Standard.

The chief drafters are Wang Yun and Wang Xin Xiang.

W05061 GB 5408.2 2/6

.____________________________________GB 5408 – 1999 .

State Standards of the People’s Republic of China

Sterilized Milk GB 5408.2 – 1999

1. Scope

The Standard stipulates the requirements of the classification, technology, test method,

labeling, packing, transportation and storage of the products of sterilized milk.

The Standard shall apply to the sterilized liquid products that are made from the main raw

material of cow (or ewe) milk or recombined milk with or without the addition of adjuncts.

2. Standards Cited

The clauses cited herein from the following Standard shall constitute the clauses of the

Standard. All those editions of the cited Standard were valid at the time of the publication of the

Standard. However, as any Standard will be revised, the users of the Standard should study the

possibility of the application of the most recent edition of the pertinent Standard.

GB 191 – 1990 Marks for Packing and Transportation

GB 2760 – 1996 Hygiene Standard for the Use of Food Additives

GB 4789.26 – 1994 Microbiological Test of Foodstuff: Commercial Sterility Test of

Bottled or Canned Foodstuff

GB/T 5009.24 – 1996 Determination Methods of Aflatoxin M 1 and B1 in Foodstuff

GN/T 5409 –1985 Methods of Milk Assay

GB/T 5413.1 – 1997 Formulated Foodstuff and Milk Powder for Babies and Infants:

Determination of Protein

GB/T 5413.30 – 1997 Milk and Milk Powder: Determination of Impurity

GB/T 5413.32 – 1997 Milk Powder: Determination of Nitrates and Nitrites

GB 7718 – 1994 General Standard of Foodstuff Label

GB 14880 – 1994 Hygiene Standard for the Use of Nutrition Fortifiers

3. Classification of Products

3.1 Sterilized Pure Cow (or Ewe) Milk: The products made from the raw materials of pure cow (or

ewe) milk or recombined milk skimmed or non-skimmed without addition of adjuncts through

ultra high temperature treatment, aseptic filling or retorting.

Approved by State Bureau of quality and Technology Supervision on Effective on May 1, 2000

December 17, 1999

W05061 GB 5408.2 3/6

.____________________________________GB 5408 – 1999 .

3.2 Sterilized Flavored Milk: The products made from the raw materials of pure cow (or ewe) milk

or recombined milk skimmed or non-skimmed with addition of adjuncts through ultrahigh

temperature treatment, aseptic filling or retorting.

4. Technical Requirements

4.1. Raw Material Requirements

4.1.1 Raw Material: The raw material shall meet the stipulations of the state standards or the

trade standards.

4.1.2 The food ingredients and nutrition fortifiers shall be selected from those allowable

substances listed in GB 2760 and GB 14880, and also shall meet the stipulations of the

state standards or the trade standards. No preservatives shall be added.

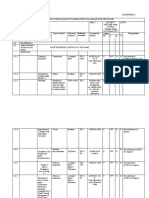

4.2. Organoleptic Properties:

The stipulations in Table 1 shall be satisfied.

Table 1

Item Sterilized Cow (or Ewe) Milk Sterilized Flavored Milk

Color Homogeneously white or pale Homogeneously white or of

yellow the color that the flavored milk

should have

Taste and Smell Intrinsic taste and smell of theThe taste and smell that the

cow milk or ewe milk without flavored milk should have

peculiar taste or smell

Texture Homogeneous liquid without flocculation or becoming viscous,

small amount of precipitation is allowable

4.3. Physicochemical Specification:

4.3.1 Net Content:

The minus deviation of the net content from the nominal quantity for a unit package shall

not be greater than that stated by the Table 2. The average net content of the products of

the same batch shall not be less than that stated by the label.

Table 2

Net Content Allowable Minus Deviation

mL

Relative Deviation, % Absolute Deviation, mL

100-200 4.5 --

200-300 -- 9

300-500 3 --

500-1,000 -- 15

1,000-10,000 1.5 --

W05061 GB 5408.2 4/6

.____________________________________GB 5408 – 1999 .

4.3.2 The protein, fat, non-fat milk solid, acidity, and impurity shall meet the stipulations in Table

3.

Table 3

Sterilized Pure Cow (or Ewe) Sterilized Flavored Milk

Item Milk

Full Fat Partially Skimmed Full Fat Partially Skimmed

Skimmed Skimmed

Fat, % 3.1 1.0-2.0 0.5 2.5 0.8-1.5 0.4

Protein, % 2.9 2.3

Non-Fat Milk Solid, 8.1 6.5

%

Acidity, T 18.0 --

Impurity, mg/kg 2

4.4. Hygiene Specification

The stipulations listed in Table 4 shall be satisfied.

Table 4 .

Item Sterilized Pure Cow (or Sterilized Flavored Milk

Ewe) Milk

Nitrates (Calculated as 11.0

NaNO3) mg/kg

Nitrites (Calculated as 0.2

NaNO2) mg/kg

Aflatoxin M1, 0.5

μg/kg

Microorganism Commercial Sterility

4.5. Added Quantity of Food ingredients and Nutrition Fortifiers

The quantity of food ingredients and nutrition fortifiers added shall meet the stipulations in

GB 2760 and GB 14880.

5. Sterilization Requirements

One of the following methods may be used for sterilization.

5.1. Ultra High Temperature Treatment: The milk is subjected to a temperature of over 135C for

several seconds in flow process, and then packed under aseptic conditions.

5.2. Retorting (Secondary Sterilization): Hermetically sealed sterilized or none-sterilized milk is

subjected to a temperature of not lower than 110C for over 10 mins.

W05061 GB 5408.2 5/6

.____________________________________GB 5408 – 1999 .

6. Experimental Method

6.1 Organoleptic Tests

6.1.1 Color and Texture: Place a certain amount of sample in a 50 mL beaker, observe the

color and texture under the natural light.

6.1.2 Taste and Smell: Open the sample package and smell the product first. Then taste it

after gargling with warm boiled water.

6.2 Physicochemical Tests

6.2.1 Net Content: Transfer the complete content of a unit package with the defined amount of

milk into a measuring cylinder, and then take the reading of its volume.

6.2.2 Protein: Determine the protein content in conformity to GB/T 5413.1 with 10 g samples.

6.2.3 Fat: Determine the fat content in conformity to GB/T 5409.

6.2.4 Non-Fat Milk Solid: Determine the non-fat milk solid content in conformity to GB/T 5409.

6.2.5 Acidity: Determine the acidity in conformity to GB/T 5409.

6.2.6 Impurity: Determine the impurity in conformity to GB/T 5413.30.

6.3 Hygienic Tests

6.3.1 Nitrates and Nitrites: Determine the nitrates and nitrites in conformity to GB/T 5413.32.

6.3.2 Aflatoxin M1: Determine the aflatoxin M1 in conformity to GB/5009.24.

6.3.3 Microorganism: Determine the microorganism in conformity to GB 4789.26.

7. Labeling, Packaging, Transportation and Storage

7.1 Labeling

7.1.1 Compulsory Label Content

7.1.1.1 The label of the product shall be made in accordance with stipulations of GB 7718.

Furthermore, the category(according to the Chapter 3 of the Standard) of the product and

the contents of protein, fat, non-fat milk solid shall be expressed explicitly.

7.1.1.2 The product made from recombined milk shall be indicated clearly “recombined milk.”

7.1.1.3 The mark for outer packing box shall meet the stipulations of GB 191.

7.1.2 Recommended Label Content

The method of sterilization may be indicated on the label (according to the Chapter 5 of the

Standard). The name of the product may be called “ xxxx milk.”

7.2 Packaging

All the packaging materials shall meet the requirements of food hygiene.

W05061 GB 5408.2 6/6

.____________________________________GB 5408 – 1999 .

7.3 Transportation

The product under transportation shall avoid being exposed to the sun shining and raining.

The product shall not be transported together with toxic, harmful or peculiarly smelling things.

7.4 Storage

The product shall be stored in a dry and well-ventilated place, and shall not be stored

together with toxic, harmful, peculiarly smelling or adversely affecting things.

___________________

W05061 GB 5408.2 7/6

Anda mungkin juga menyukai

- Design of Caustic Wash System For Light HydrocarboDokumen5 halamanDesign of Caustic Wash System For Light HydrocarboWayne MonneryBelum ada peringkat

- Commissioning and Decommissioning of Installations For Dry Chlorine Gas and LiquidDokumen18 halamanCommissioning and Decommissioning of Installations For Dry Chlorine Gas and LiquidKimberly ConleyBelum ada peringkat

- SC Wheat-Soya Blend With Sugar 1.5Kg - 3KgDokumen10 halamanSC Wheat-Soya Blend With Sugar 1.5Kg - 3Kgfaheem ulislamBelum ada peringkat

- CHEM 135 Exam 2 F15 KeyDokumen7 halamanCHEM 135 Exam 2 F15 KeyMikeBelum ada peringkat

- Chemistry Perfect Score Module Form 4 2011 No LogoDokumen96 halamanChemistry Perfect Score Module Form 4 2011 No Logohome8008100% (2)

- YoghurtDokumen7 halamanYoghurtakBelum ada peringkat

- WFP 0000020110 PDFDokumen7 halamanWFP 0000020110 PDFKalpesh RathodBelum ada peringkat

- A Review On Safety Operation Methods of A Cryogenic Air Separation UnitDokumen9 halamanA Review On Safety Operation Methods of A Cryogenic Air Separation UnitdigecaBelum ada peringkat

- Dairy 4Dokumen39 halamanDairy 4John P. BandoquilloBelum ada peringkat

- Effect of Raw Materials On Feed Pellet Quality: Ramesh Subramonian and Sotero M. Lasap IiiDokumen10 halamanEffect of Raw Materials On Feed Pellet Quality: Ramesh Subramonian and Sotero M. Lasap IiiNida yemBelum ada peringkat

- CODEX STAN 243-2003 (Iaurt)Dokumen11 halamanCODEX STAN 243-2003 (Iaurt)Dob Gabriela100% (1)

- Aerosols in AyurvedaDokumen13 halamanAerosols in AyurvedaDr ajayBelum ada peringkat

- ASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricDokumen14 halamanASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricSinan Chen100% (1)

- GB19302-2010 Tiêu chuẩn ATTP Sữa lên menDokumen6 halamanGB19302-2010 Tiêu chuẩn ATTP Sữa lên menTran My LinhBelum ada peringkat

- GB 5410 Milk Powder - Beijing - China - Peoples Republic of - 12-1-2009Dokumen7 halamanGB 5410 Milk Powder - Beijing - China - Peoples Republic of - 12-1-2009Roger QuinterosBelum ada peringkat

- CXS Evaporated MilksDokumen4 halamanCXS Evaporated MilksVallerina TariganBelum ada peringkat

- China GB 5420 2010 National Food Safety Standard CheeseDokumen4 halamanChina GB 5420 2010 National Food Safety Standard CheesePusspaBelum ada peringkat

- CXS 282eDokumen4 halamanCXS 282eZac HernándezBelum ada peringkat

- Codex Standard For Sweetened Condensed MilksDokumen3 halamanCodex Standard For Sweetened Condensed MilksHimew BraidBelum ada peringkat

- Codex Stan A-4-1971Dokumen3 halamanCodex Stan A-4-1971Raisha ZakariaBelum ada peringkat

- PNS For Fresh MilkDokumen8 halamanPNS For Fresh MilklowlowBelum ada peringkat

- Milk Powder and Cream PowderDokumen5 halamanMilk Powder and Cream PowderNat TangsuphoomBelum ada peringkat

- Cxs - 282e - Sweetened Condensed MilksDokumen4 halamanCxs - 282e - Sweetened Condensed MilksMuhammad Ikhsan 'icansensei'Belum ada peringkat

- Codex Milk Powders and AssociatesDokumen6 halamanCodex Milk Powders and AssociatesNATASHA TATENDA MANYAUBelum ada peringkat

- CXS 207eDokumen6 halamanCXS 207easasinuxpBelum ada peringkat

- Codex Stan 243-2003 STD For Fermented MilksDokumen11 halamanCodex Stan 243-2003 STD For Fermented Milksvabimhah100% (2)

- F.No. Stds/M&MP/Notification (02) /FSSAI-2016 - in The Food Safety and StandardsDokumen4 halamanF.No. Stds/M&MP/Notification (02) /FSSAI-2016 - in The Food Safety and StandardsAmrita SunilBelum ada peringkat

- Gso LabanDokumen8 halamanGso LabananeebqualitasBelum ada peringkat

- Milk CompositionDokumen4 halamanMilk CompositionNaaggaaBelum ada peringkat

- Disclosure To Promote The Right To Information: IS 1165 (2002) : Milk Powder (FAD 19: Dairy Products and Equipment)Dokumen13 halamanDisclosure To Promote The Right To Information: IS 1165 (2002) : Milk Powder (FAD 19: Dairy Products and Equipment)akBelum ada peringkat

- CODEX STAN A-11 (A) - 1975: Codex Standard For Yoghurt (Yogurt) and Sweetened Yoghurt (Sweetened Yogurt)Dokumen2 halamanCODEX STAN A-11 (A) - 1975: Codex Standard For Yoghurt (Yogurt) and Sweetened Yoghurt (Sweetened Yogurt)Ayoub OUBAHABelum ada peringkat

- Report Name:: Formulas For Special Medical Purposes Intended For Infants Draft Standard NotifiedDokumen19 halamanReport Name:: Formulas For Special Medical Purposes Intended For Infants Draft Standard NotifiedgowthamBelum ada peringkat

- Codex - ButterDokumen2 halamanCodex - ButterTantri Ayu LestariBelum ada peringkat

- EAS 22 2006 Butter SpecificationDokumen8 halamanEAS 22 2006 Butter SpecificationFelix MwandukaBelum ada peringkat

- Evaporated MilkDokumen8 halamanEvaporated MilkAnuradha MarapanaBelum ada peringkat

- FermentedDokumen8 halamanFermentedAnuradha MarapanaBelum ada peringkat

- Disclosure To Promote The Right To Information: IS 12299 (1998) : Dairy Whitener (FAD 19: Dairy Products and Equipment)Dokumen10 halamanDisclosure To Promote The Right To Information: IS 12299 (1998) : Dairy Whitener (FAD 19: Dairy Products and Equipment)Kiru Dang100% (1)

- Report NameDokumen8 halamanReport NamePhương linh TrầnBelum ada peringkat

- GCC Standardization Organization (Gso)Dokumen7 halamanGCC Standardization Organization (Gso)amir1077Belum ada peringkat

- Codex CheeseDokumen7 halamanCodex CheeseTaufiksyaefulmalikBelum ada peringkat

- Codex Codex Standard For Milk Fat Products Standard For Milkfat ProductsDokumen3 halamanCodex Codex Standard For Milk Fat Products Standard For Milkfat ProductsMuhammad SadiqBelum ada peringkat

- BIS RefList Fad16 (1761)Dokumen11 halamanBIS RefList Fad16 (1761)I. Murali KrishnaBelum ada peringkat

- Codex Standard For Wheat Protein Products Including Wheat GlutenDokumen4 halamanCodex Standard For Wheat Protein Products Including Wheat GlutenKaren SoledadBelum ada peringkat

- AFG-2014-fortified Wheat FlourDokumen14 halamanAFG-2014-fortified Wheat FlourRika Agita SariBelum ada peringkat

- Milkfat Vs Butter Oil Vs GheeDokumen32 halamanMilkfat Vs Butter Oil Vs Ghee200111019Belum ada peringkat

- PS Wheat Protein ProductsDokumen4 halamanPS Wheat Protein Productssajid waqasBelum ada peringkat

- Bwa85 en 1 1Dokumen8 halamanBwa85 en 1 1Nurul FitriaBelum ada peringkat

- CXS 280-1973 (Standard For Milkfat Products)Dokumen4 halamanCXS 280-1973 (Standard For Milkfat Products)pujiyono PTBBelum ada peringkat

- Codex Butter StandardDokumen3 halamanCodex Butter StandardChandra Nur KhalamBelum ada peringkat

- Codex Aceites y GrasasDokumen4 halamanCodex Aceites y GrasaspepitoBelum ada peringkat

- MP HT 19344yuDokumen2 halamanMP HT 19344yuVanessa Rojas LoyolaBelum ada peringkat

- Codex Standard For Wheat FlourDokumen3 halamanCodex Standard For Wheat FlourRizwan AshadBelum ada peringkat

- CXS 207eDokumen6 halamanCXS 207eMark Laurence RecioBelum ada peringkat

- CXS 2lDokumen13 halamanCXS 2lthierry gbogueBelum ada peringkat

- Roquette Pspe Y068 Viten - Vital Wheat Gluten 000000200505 enDokumen2 halamanRoquette Pspe Y068 Viten - Vital Wheat Gluten 000000200505 envirgilBelum ada peringkat

- Codex General Standard For CheeseDokumen5 halamanCodex General Standard For Cheesesunil2700Belum ada peringkat

- PS 2858-2012 For Cooking Oil Blended 2nd Rev.Dokumen10 halamanPS 2858-2012 For Cooking Oil Blended 2nd Rev.Sharked UpBelum ada peringkat

- CXS 175eDokumen3 halamanCXS 175eMinh Trường TrươngBelum ada peringkat

- Nga6 en 1 1Dokumen48 halamanNga6 en 1 1KentBelum ada peringkat

- Colun UHT Semi-Skimmed MilkDokumen3 halamanColun UHT Semi-Skimmed MilkJavier Floz VargasBelum ada peringkat

- MP HT 19343yuDokumen2 halamanMP HT 19343yuVanessa Rojas LoyolaBelum ada peringkat

- CXS 74-1981 (2019) - Standard For Processed Cereal-Based Foods For Infants and Young Children PDFDokumen8 halamanCXS 74-1981 (2019) - Standard For Processed Cereal-Based Foods For Infants and Young Children PDFHanaw MohammedBelum ada peringkat

- CXS 208eDokumen3 halamanCXS 208edrvmkamathBelum ada peringkat

- Is 4941 1994Dokumen17 halamanIs 4941 1994akBelum ada peringkat

- Handbook of Food Science and Technology 3: Food Biochemistry and TechnologyDari EverandHandbook of Food Science and Technology 3: Food Biochemistry and TechnologyBelum ada peringkat

- Cheese: The Preservation of MilkDokumen13 halamanCheese: The Preservation of MilkfafaBelum ada peringkat

- LifeprofitDokumen12 halamanLifeprofitfafaBelum ada peringkat

- LifeprofitDokumen12 halamanLifeprofitfafaBelum ada peringkat

- ANFS 404 Syllabus 2015 1Dokumen4 halamanANFS 404 Syllabus 2015 1fafaBelum ada peringkat

- LifeprofitDokumen12 halamanLifeprofitfafaBelum ada peringkat

- GRG - Spec Data-1 Rev 4-7-11Dokumen1 halamanGRG - Spec Data-1 Rev 4-7-11Chandru MohanBelum ada peringkat

- Studying The Performance of Pongamia Biodiesel by Using Nano Partical Fuel AdditivesDokumen6 halamanStudying The Performance of Pongamia Biodiesel by Using Nano Partical Fuel Additivessemi1919Belum ada peringkat

- Alfa Laval Ocm304Dokumen4 halamanAlfa Laval Ocm304The ProfessionalBelum ada peringkat

- The EURO Currency Coins: Research atDokumen37 halamanThe EURO Currency Coins: Research atSherif EltoukhiBelum ada peringkat

- GenePrint Fluorescent STR Systems ProtocolDokumen50 halamanGenePrint Fluorescent STR Systems ProtocolNaveen NkBelum ada peringkat

- Experiment 3 - Thermal ConductivityDokumen9 halamanExperiment 3 - Thermal ConductivitySaniha Aysha AjithBelum ada peringkat

- VSTEP-Reading Test 1Dokumen13 halamanVSTEP-Reading Test 1Ph DiBelum ada peringkat

- Q DT /DX:) ) Rsub (X) ( (W) Over ( (M) (2) )Dokumen8 halamanQ DT /DX:) ) Rsub (X) ( (W) Over ( (M) (2) )Aiza AlbuferaBelum ada peringkat

- Multiphase Modelling of Hydrocyclones - Prediction of Cut-SizeDokumen12 halamanMultiphase Modelling of Hydrocyclones - Prediction of Cut-Sizeenivaldo.sb3897Belum ada peringkat

- 2-Excellent Chemistry Assignment The Solid StatesDokumen5 halaman2-Excellent Chemistry Assignment The Solid StatesSachin B SBelum ada peringkat

- Chapter 4 Major Reaction WDokumen102 halamanChapter 4 Major Reaction Wsinte beyuBelum ada peringkat

- Pages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignDokumen191 halamanPages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignAhmed HassanBelum ada peringkat

- Model QAP For Plates1Dokumen3 halamanModel QAP For Plates1tarun kaushalBelum ada peringkat

- Ft-Peramin Conpac 149s - 112011 - v1 (GB)Dokumen2 halamanFt-Peramin Conpac 149s - 112011 - v1 (GB)RajuNSanaboinaBelum ada peringkat

- HSSC-II PHYSICS HALF SYLLABUS (16-To-20) April 2021Dokumen4 halamanHSSC-II PHYSICS HALF SYLLABUS (16-To-20) April 2021Heaven ColoursBelum ada peringkat

- The Top 10 Reasons Why You Shall Pick Tupperware Nano Water Filtration SystemDokumen12 halamanThe Top 10 Reasons Why You Shall Pick Tupperware Nano Water Filtration Systemsyahmi1337Belum ada peringkat

- 5.0 Fabrication-6 PDFDokumen1 halaman5.0 Fabrication-6 PDFRohit KambleBelum ada peringkat

- Electronegativity (Allen Scale)Dokumen2 halamanElectronegativity (Allen Scale)YourMotherBelum ada peringkat

- Midland Gear Pumps Phase 1Dokumen5 halamanMidland Gear Pumps Phase 1Рома БлошенкоBelum ada peringkat

- Absorption of Magnesium CompoundsDokumen8 halamanAbsorption of Magnesium CompoundsJo KBelum ada peringkat

- Costick SodaDokumen16 halamanCostick SodaJalindar BansodeBelum ada peringkat

- Physics II Problems PDFDokumen1 halamanPhysics II Problems PDFBOSS BOSSBelum ada peringkat

- Quantum Defect Theory I PDFDokumen14 halamanQuantum Defect Theory I PDFana1novi1Belum ada peringkat