Tubing Conveyed Perforating

Diunggah oleh

re_alvaroHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Tubing Conveyed Perforating

Diunggah oleh

re_alvaroHak Cipta:

Format Tersedia

Introduction to and

Benefits of Tubing-

Conveyed Perforating

Michael K. Robson, SPE, Schlumberger

Summary. Tubing-conveyed per- Benefits of TCP into the well at the end of a workstring. Af-

forating (TCP) technology has grown Operational Efficiency. TCP allows the ter the guns are fired and time is allowed

well operator to perforate long, or widely for cleanup and testing, the well is killed

dramatically during the past 5 years. with a nondamaging completion fluid and

spaced, intervals simultaneously on a sin-

This paper presents a general over- gle trip into the well rather than having to the TCP string is removed. Completion

view of state-of-the-art TCP systems make mUltiple runs on wireline. The differ- procedures-backwashing, acidizing, frac-

ence between TCP and wireline-perforating turing, or gravel packing-can then be im-

and operating techniques and dis-

rig time depends on interval length and the plemented.

cusses the TCP benefits and the number of wireline descents vs. the addi- Large Intervals or Multizone Wells.

tradeoffs involved in the use of con- tional time to position the string and to ready Large intervals or wells where several wide-

ventional wireline perforating. The the well for TCP operations. However, TCP ly spaced zones are commingled into a single

exposes the gun to the well environment production string are completed efficiently

TCP gun string, with spacers and se- on a temporary workstring. After perforat-

longer than wireline perforating, a concern

lected accessories, is run into the well in high-temperature operations. ing, the well is killed with a nondamaging

on the end of a testing or completion TCP gives the well operator an opportu- completion fluid and the gun string is re-

nity to perform a flow test immediately after moved. This system affords the benefits of

string, and the guns are positioned

perforating. Impulse-type testing techniques TCP while providing an alternative to leav-

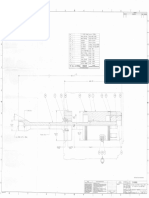

across the zones of interest (Fig. 1). can be used to identify the extent of well- ing the gun string in the well where it could

When the TCP string is positioned bore damage before large investments in interfere with future operations.

with a nuclear-type logging device, stimulation or gravel packing are made. In Gravel-Packed Wells. High-shot-density

addition to impulse testing, a variety of other TCP guns loaded with big-entry-hole

the surface well-control equipment in- testing and completion equipment can be charges shot underbalanced are used to per-

stalled, and the desired pressure un- combined with the TCP string to provide for forate a zone to be gravel packed. After

derbalance established, the guns are comprehensive reservoir evaluation immedi- cleanup, the well is killed with a nondamag-

ately after perforating. ing completion fluid and the guns are re-

fired. The result is simultaneous per-

trieved to permit the running of screens and

foration of all selected intervals with Underbalanced Perforating. An under- installation of the gravel pack.

high-performance gun systems in an balance, established between the formation Testing. A well-control valve can be used

optimal pressure environment. and wellbore pressures before the TCP guns in conjunction with TCP to provide a quick

are fired, creates an instantaneous and con- look at the near-wellbore region by impulse

trolled surge of formation fluids into the testing. A longer-duration drill stem test

well, which cleans the perforations and en- (DST) provides for a more detailed analysis

'hances the well's productivity and injec- of the commercial potential of the reservoir

tivity. through observation of the types of fluids

recovered and the flow rates.

Safety. Surface well-control equipment is The DST/TCP combination ensures opti-

installed and tested before perforating, mum perforation cleanup and provides

guaranteeing complete safety throughout all reservoir performance characteristics. The

phases of the TCP operation. system involves TCP guns run below a re-

trievable packer and a set ofDST tools. Im-

High-Performance Perforating Systems. mediately after firing, the well is tested by

Gun size is limited by the ID of the casing, alternately flowing and shutting in to devel-

pennitting use of the largest possible charges op the desired reservoir information.

(either deeply penetrating or big-entry-hole

type) and high shot densities. Guns can be Permanent TCP Completions. In a perma-

configured to provide the optimum shot den- nent TCP completion, the guns are run on

sity and pattern for the specific application. the end of the final completion string. The

wellhead and safety equipment are installed

TCP Completion Types before firing. The guns remain in the well

Temporary TCP Completions. In a tem- after the perforating operation and may be

porary TCP completion, the guns are run dropped into the rathole if desired.

In permanent completions, there is no

Copyright 1990 Society of Petroleum Engineers need to kill the well and the perforating op-

134 February 1990 • JPT

sPETechtrology

Today SERIES

- - - - Well Head / Flow Head

f------- Casing

...- - - - - - Tubing / Drill Pipe

"TCP allows the well

operator to perforate

long, or widely

- - - - DSTTools spaced, intervals

simultaneously on a

Packer single trip into the well

rather than having to

- - - - - Accessories make multiple runs

~----- Firing Heads on wirellne."

>------ TCP Guns

Fig. 1-TCP gun string positioned downhole.

eration is performed with the wellhead and pressure, high temperature, or sour gas pre- 2. Type of perforation desired (big hole

all safety equipment in place. vails. A permanent TCP completion pro- for sand control or deep penetration for a

Short Intervals. In development wells vides for maximum safety under these natural or stimulated completion).

where gross intervals to be perforated are conditions. 3. Desired shot density and shot phasing.

short (no more than 200 ft [61 m)), suffi- 4. Clearance requirements in view of

Dual Completion. Two production zones

cient rathole can be provided to drop the fishing.

can be perforated selectively with TCP guns

guns, leaving the perforated interval unre- 5. Environmental conditions (guns are

stricted with the production string in place. with a dual string in a permanent com- available for service to 425°P and 20,000

Subsequent through-tubing work, such as pletion. psi [218°C and 138 MPa] with exposure

production logging, wireline reperforating, times up to 200 hours).

and fluid isolation with a through-tubing TCP Hardware Considerable flexibility in equipment

bridge plug, can be readily performed. selection provides for optimum completion

Guns. The selection of a gun system for a

Gravel Pack. New techniques permit in- of any particular well. A wide choice of per-

specific perforating job depends on the fol-

stallation of the gravel pack on the same trip forating charges, shot densities, and shot

as the TCP operation, providing for a per- lowing: phases in a given gun size is available.

manent completion. I. Completion hardware dimensions, such Large, extra-deep-penetrating charges

Hostile-Environment Wells. Well safety as casing ID (or packer ID for "sting- loaded at a reduced shot density provide ef-

is particularly critical on jobs where high through" TCP operations). fective perforating in natural completions.

JPT • February 1990 135

Author Higher shot densities with optimum shot Firing system redundancy reduces the

phasing provide enhanced productivity for possibility of a misfire, a major considera-

Michael K. Robson wells completed in laminated or shaly sands. tion in light of the time required to retrieve

is general manager Big-entry-hole charges fired at high shot and rerun a TCP string. All modern TCP

at the Schlumber· densities provide for effective perforations firing heads can be combined to provide

ger Perforating & for gravel-packed completions. Guns that

Testing Center in redundancy.

perforate only one side of the casing can be

Rosharon, TX. Rob·

son oversees the

provided for the completion of deviated Accessories. A wide variety of accessories

engineering and wells in which sand production is antic- enhances TCP operations. Circulating subs

manufacturing of ipated. permit the TCP string to be isolated during

equipment used in tripping and completion procedures. Debris

evaluating and Firing Systems. Firing heads are located at

the top of the gun string, allowing guns to can be circulated out and fluid circulated in

completing wells. He holds a BS degree

In geological engineering from Queens be assembled safely before the head is in- before firing to provide a controlled under-

U., Kingston, Onto stalled. The choice of firing systems hinges balanced condition.

on safety, reliability, redundancy, flexibil- Valves are available to allow tubing to be

ity, and cost considerations. pressure tested or opened before firing.

Firing heads may be fired electrically or These valves afford excellent control of

actuated by tubing or annulus pressure, me- surge conditions and are effective in multi-

chanical stuffing or jarring on slickline, or zone and workover applications.

a drop bar. Safety is ensured with pressure- Other accessories include a variety of gun-

fired or mechanical systems by the require- release subs for permanent completions,

ment that a minimum hydrostatic pressure shock absorbers, swivels, and dual-comple-

exist before the system can be actuated. A tion hardware.

predetermined time delay can be provided

with the pressure-fired systems to afford Conclusions

time to establish the desired pressure under-

balance. New-generation firing systems af- The primary purpose of TCP is to establish

ford increased safety and reliability by the best possible communication between the

permitting the gun string to be run into the reservoir and the wellbore. Many factors in-

hole without the firing head being attached. fluence the TCP system choice and highlight

Once the gun is positioned, the firing head the need for communication between the

is run into the well on wireline or slickline various engineering groups.

and attached to the gun. Cable is removed

or left in place, and then the guns are fired. Provenance

Electrically fired systems use a female wet This paper is SPE 19109. Technology To-

connector conveyed by wireline that mates day Series articles provide useful summary

with a male connector run in with the guns. information on both classic and emerging

This system has the benefits of direct feed- concepts in petroleum engineering. Pur-

back of wireline perforating and capability pose: To provide the general reader with a

for real-time pressure, temperature, and basic understanding of a significant concept,

flow measurements. Interpretation of these technique, or development within a specif-

measurements provides well performance

ic area of technology.

information immediately after the guns are

fired. JPT

136 February 1990 • JPT

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- How To Read A Daily Drilling: A Beginner's GuideDokumen12 halamanHow To Read A Daily Drilling: A Beginner's GuideJosué Emmanuel Blásquez Contreras100% (1)

- Compress IbilityDokumen2 halamanCompress Ibilityre_alvaroBelum ada peringkat

- Spe 179603 PaDokumen10 halamanSpe 179603 Pare_alvaroBelum ada peringkat

- EcopetrolDokumen30 halamanEcopetrolre_alvaroBelum ada peringkat

- Spe 174541 PaDokumen11 halamanSpe 174541 Pare_alvaroBelum ada peringkat

- Spe 35385 PaDokumen9 halamanSpe 35385 Pare_alvaroBelum ada peringkat

- Spe 12565 PaDokumen2 halamanSpe 12565 Pare_alvaroBelum ada peringkat

- OTC-28468-MS Optimizing Well Test Design Using Integrated Rate and Pressure Transient Analysis in Fracture Basement ReservoirsDokumen8 halamanOTC-28468-MS Optimizing Well Test Design Using Integrated Rate and Pressure Transient Analysis in Fracture Basement Reservoirsre_alvaroBelum ada peringkat

- SPE 120897 Predicting Water Influx From Common Shared AquifersDokumen20 halamanSPE 120897 Predicting Water Influx From Common Shared Aquifersre_alvaroBelum ada peringkat

- Decline Curve Analysis For Composite Reservoirs M. Issaka A. AmbasthaDokumen11 halamanDecline Curve Analysis For Composite Reservoirs M. Issaka A. Ambasthare_alvaroBelum ada peringkat

- Petsoc 2005 113 Mattar DMBDokumen10 halamanPetsoc 2005 113 Mattar DMBre_alvaroBelum ada peringkat

- Annex-A: Additional Cash Flow InformationDokumen1 halamanAnnex-A: Additional Cash Flow Informationre_alvaroBelum ada peringkat

- Annex-B: Additional Information About Production System IntegrationDokumen3 halamanAnnex-B: Additional Information About Production System Integrationre_alvaroBelum ada peringkat

- Date:: Petroleum Engineering 324 - Well Performance Daily Summary Sheet Spring 2009 - Blasingame/IlkDokumen12 halamanDate:: Petroleum Engineering 324 - Well Performance Daily Summary Sheet Spring 2009 - Blasingame/Ilkre_alvaroBelum ada peringkat

- Date:: Petroleum Engineering 324 - Well Performance Daily Summary Sheet Spring 2009 - Blasingame/IlkDokumen21 halamanDate:: Petroleum Engineering 324 - Well Performance Daily Summary Sheet Spring 2009 - Blasingame/Ilkre_alvaroBelum ada peringkat

- Petrel - LAS LoadingDokumen11 halamanPetrel - LAS Loadingre_alvaroBelum ada peringkat

- Petrel - Contacts at Differents DepthsDokumen4 halamanPetrel - Contacts at Differents Depthsre_alvaroBelum ada peringkat

- Egyptian Mud Engineering & Chemicals Company: Page 1 of 1Dokumen1 halamanEgyptian Mud Engineering & Chemicals Company: Page 1 of 1GPCBelum ada peringkat

- Wellhead Operations and Maintenance CourseDokumen65 halamanWellhead Operations and Maintenance CourseAbdelkhak KhallaBelum ada peringkat

- Rc-Monthly Cost SheetDokumen2 halamanRc-Monthly Cost SheetAsif KhanzadaBelum ada peringkat

- Bybee 2002Dokumen2 halamanBybee 2002ARIF SETIAWANBelum ada peringkat

- MWD - Annular Pressure BasicsDokumen4 halamanMWD - Annular Pressure BasicskhalidmkarajagiBelum ada peringkat

- Surface Data Logging CoreDokumen249 halamanSurface Data Logging CoreMohamed ElshoraBelum ada peringkat

- F-S Divertor PDFDokumen174 halamanF-S Divertor PDFJohn NorrieBelum ada peringkat

- Iadc Bullhead Field 012214Dokumen3 halamanIadc Bullhead Field 012214Muhammad Afrizal KautsarBelum ada peringkat

- Spe - Iadc 79850 Kazakhstan PMCD Case StudyDokumen21 halamanSpe - Iadc 79850 Kazakhstan PMCD Case StudyThiban Chandra KeshavanBelum ada peringkat

- Well Control Equipment Course (Wcec) For Floating RigsDokumen3 halamanWell Control Equipment Course (Wcec) For Floating RigsrickyngsBelum ada peringkat

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageDokumen20 halamanFaculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageOmer IkhlasBelum ada peringkat

- Completions DesignDokumen22 halamanCompletions DesignAbiodun AkalaBelum ada peringkat

- Latihan HitunganDokumen9 halamanLatihan HitunganMuhamad FadilahBelum ada peringkat

- Supervisor Questions & Answer IWCFDokumen127 halamanSupervisor Questions & Answer IWCFhamid nobakht100% (1)

- Evaluation of Technical Drilling OperationDokumen56 halamanEvaluation of Technical Drilling OperationAkuffo TheophilusBelum ada peringkat

- P & P AnswerDokumen143 halamanP & P AnswerOmerBelum ada peringkat

- APAC Report Issue 231 Mid-May 2023 PDFDokumen22 halamanAPAC Report Issue 231 Mid-May 2023 PDFMohammad AnnasBelum ada peringkat

- Use of Hydro Cyclone in Drilling Rig As Mud CleanerDokumen24 halamanUse of Hydro Cyclone in Drilling Rig As Mud Cleanerhador76100% (1)

- Título: Chapter 4: Drilling: PUC Minas Virtual - 1Dokumen2 halamanTítulo: Chapter 4: Drilling: PUC Minas Virtual - 1giselechavesBelum ada peringkat

- Technical Data For Workover RigsDokumen1 halamanTechnical Data For Workover Rigsloveneshjain100% (1)

- Casing ExerciseDokumen9 halamanCasing ExerciseYesar Bin Mustafa AlmalekiBelum ada peringkat

- Reference Standards Edition Effective/Reaffirme D Date API Product NumberDokumen26 halamanReference Standards Edition Effective/Reaffirme D Date API Product NumberGiang Nguyen Ninh100% (1)

- Lampiran 2 Dillers Method Kill Sheet IADCDokumen3 halamanLampiran 2 Dillers Method Kill Sheet IADCNirwan Purwa LahardiBelum ada peringkat

- Offshore Drilling Overview: Challenges and Solutions (Shell)Dokumen27 halamanOffshore Drilling Overview: Challenges and Solutions (Shell)National Commission on the BP Deepwater Horizon Oil Spill and Offshore Drilling100% (2)

- 20 - IWCF Practice Exam Booklet - 05mar13 PDFDokumen127 halaman20 - IWCF Practice Exam Booklet - 05mar13 PDFAdolfo AnguloBelum ada peringkat

- Logging InnovationDokumen8 halamanLogging InnovationAnkit ChourasiaBelum ada peringkat

- C12-Surface BOPSDokumen119 halamanC12-Surface BOPSmissaoui100% (1)

- 2well Control - ExerciseDokumen140 halaman2well Control - ExercisemmmmjjBelum ada peringkat

- MFF Oilfield Stock in JKTDokumen1 halamanMFF Oilfield Stock in JKTjokoBelum ada peringkat