Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic Hydrocarbons

Diunggah oleh

Christian SanhuezaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic Hydrocarbons

Diunggah oleh

Christian SanhuezaHak Cipta:

Format Tersedia

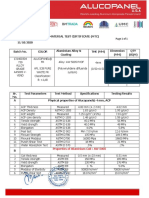

Garlock 5500

MATERIAL PROPERTIES*

Color: Gray

Composition: Inorganic fibers with a nitrile binder

Fluid Services1: 3

Saturated steam , most refrigerants, water, oils, gasoline and aliphatic

hydrocarbons

Temperature2, °F (°C)

Minimum: -100 (-73)

Continuous Max: +550 (+288)

Maximum: +800 (+427)

Pressure2, Maximum, psig (bar): 1200 (83)

P x T (max.)2, psig x °F (bar x °C)

1/32 and 1/16": 400,000 (14,000)

1/8": 275,000 (9,600)

Meets Specification: ABS (American Bureau of Shipping) and Fire Safe

PHYSICAL PROPERTIES*

ASTM F36 Compressibility, range, %: 7-17

ASTM F36 Recovery, %: 50

ASTM F38 Creep Relaxation, %: 15

ASTM F152 Tensile, Across Grain, psi (N/mm2): 1500 (10)

ASTM F1315 Density, lbs./ft.3 (grams/cm3): 110 (1.76)

ASTM F433 Thermal Conductivity (K), W/m°K (Btu.·in./hr.·ft.2·°F): 0.43-0.53 (3.00-3.65)

ASTM D149 Dielectric Properties, range, volts/mil.

Sample conditioning 1/16" 1/8"

3 hours at 250°F: 284 245

96 hours at 100% Relative Humidity: - -

ASTM F586 Design Factors 1/16" & Under 1/8"

"m" factor: 6.6 6.6

"y" factor, psi (N/mm2): 2600 (17.9) 3300 (22.8)

ROTT Gasket Constants, 1/16": Gb=1,247 a=0.249 Gs=11.0

ASTM F104 Line Call Out: F712103A9B4E23K7L501M4(4)

SEALING CHARACTERISTICS*

ASTM F37B ASTM F37B DIN 3535- 4

Fuel A Nitrogen Gas Permeability

Gasket Load, psi (N/mm2): 500 (3.5) 3000 (20.7) 4640 (32)

Internal Pressure, psig (bar): 9.8 (0.7) 30 (2) 580 (40)

Leakage 0.2 ml/hr. 1.0 ml/hr. 0.05 cc/min

IMMERSION PROPERTIES*- ASTM F146 Fluid Resistance after Five Hours

ASTM #1 Oil ASTM IRM #903 ASTM Fuel A ASTM Fuel B

300°F (150°C) 300°F (150°C) 70-85°F (20-30°C) 70-85°F (20-30°C)

Thickness Increase, (%) 0-10 0-15 0-10 0-15

Weight Increase, (%) <15 - <10 <15

Tensile Loss, (%) - <40 - -

Notes:

This is a general guide and should not be the sole means of selecting or rejecting this material. ASTM test results in accordance with ASTM F-104;

properties based on 1/32" (0.8mm) sheet thickness unless otherwise mentioned.

* Values do not constitute specification Limits

1

See Garlock chemical resistance guide.

2

Based on ANSI RF flanges at our preferred torque. When approaching maximum pressure, continuous operating temperature, minimum

temperature or 50% of maximum PxT, consult Garlock Applications Engineering. Minimum temperature rating is conservative.

3

Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000-10,000psi. Gasket thickness of 1/16" strongly preferred.

Retorque the bolts/studs prior to pressurizing the assembly. For saturated steam above 150psig or superheated steam, consult Garlock Engineering.

4

A9: Leakage in Fuel A (Isooctane), Gasket Load = 500psi (3.5N/mm2), Pressure = 9.8psig (0.7bar): Typical = 0.2ml/hr, Max = 1.0ml/hr. A9:

Leakage in Nitrogen, Gasket Load = 3,000psi (20.7N/mm2), Pressure = 30psig (2bar): Typical = 0.5ml/hr, Max = 1.5ml/hr.

Anda mungkin juga menyukai

- Garlock 9900 Data Sheet PDFDokumen1 halamanGarlock 9900 Data Sheet PDFMartin Andrew TugadeBelum ada peringkat

- Gas Sweetening and Processing Field ManualDari EverandGas Sweetening and Processing Field ManualPenilaian: 4 dari 5 bintang4/5 (7)

- Garlock Style 5500 Spec Sheet - (NA) 2016-11 ENDokumen1 halamanGarlock Style 5500 Spec Sheet - (NA) 2016-11 ENALONSO GOMEZBelum ada peringkat

- Garlock 700Dokumen1 halamanGarlock 700Jairo ArroyoBelum ada peringkat

- 3504 Blue Gylon Data Sheet PDFDokumen1 halaman3504 Blue Gylon Data Sheet PDFYnuzneBelum ada peringkat

- Garlock Style 3000 Spec Sheet - (NA) 2016-11 enDokumen1 halamanGarlock Style 3000 Spec Sheet - (NA) 2016-11 enalan2003_1_29040Belum ada peringkat

- Garlock Style 9900 Spec Sheet - (NA) 2021-09 ENDokumen1 halamanGarlock Style 9900 Spec Sheet - (NA) 2021-09 ENDrojanle MezbraBelum ada peringkat

- Garlock GYLON 3500Dokumen1 halamanGarlock GYLON 3500echavarriBelum ada peringkat

- Garlock Style 700 Spec Sheet - (NA) 2016-11 enDokumen1 halamanGarlock Style 700 Spec Sheet - (NA) 2016-11 enMarín HernándezBelum ada peringkat

- Garlock Graph Lock 3125ssDokumen1 halamanGarlock Graph Lock 3125ssJhon AlarconBelum ada peringkat

- Garlock Hi TempDokumen4 halamanGarlock Hi Temprock starBelum ada peringkat

- Garlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENDokumen1 halamanGarlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENSu Kil SungBelum ada peringkat

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDokumen1 halamanGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040Belum ada peringkat

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDokumen1 halamanGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040Belum ada peringkat

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enDokumen1 halamanGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enAndres Rodriguez HerreraBelum ada peringkat

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDokumen1 halamanGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsRicardo Perez VerdugoBelum ada peringkat

- Style 2900 Data SheetDokumen1 halamanStyle 2900 Data SheetRicardo OrdoñezBelum ada peringkat

- Garlock Blue Gard 3000 Data SheetDokumen1 halamanGarlock Blue Gard 3000 Data SheetMatheus TorresBelum ada peringkat

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDokumen1 halamanGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaBelum ada peringkat

- Ifg 5500Dokumen1 halamanIfg 5500Amir100% (1)

- 8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationDokumen2 halaman8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationIrving Alan Uc FernandezBelum ada peringkat

- Garlock Style 706 Data SheetDokumen1 halamanGarlock Style 706 Data SheetArturo Gasperin BarrigaBelum ada peringkat

- 3510 Off White Gylon Data SheetDokumen1 halaman3510 Off White Gylon Data SheetJose CarlosBelum ada peringkat

- Garlock 22 Red SBR Rubber Sheet Data SheetDokumen1 halamanGarlock 22 Red SBR Rubber Sheet Data SheetkasebBelum ada peringkat

- Garlock 3504 Blue Gylon Data SheetDokumen1 halamanGarlock 3504 Blue Gylon Data SheetdanielbustBelum ada peringkat

- Elix ABS M220: Technical InformationDokumen3 halamanElix ABS M220: Technical InformationDiegoTierradentroBelum ada peringkat

- 1.9.1.2-80T - 18 8 Stainless SteelDokumen4 halaman1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaBelum ada peringkat

- LEXAN FST3403tDokumen3 halamanLEXAN FST3403tJose Ramon Florez OrdizBelum ada peringkat

- SABIC Cycolac MG47FDokumen3 halamanSABIC Cycolac MG47FChu ChuBelum ada peringkat

- PG-GL Data SheetDokumen1 halamanPG-GL Data Sheetazeem bilalBelum ada peringkat

- Elix ABS E401: Technical InformationDokumen3 halamanElix ABS E401: Technical InformationDiegoTierradentroBelum ada peringkat

- 5000W ABS Taita TaiwanDokumen1 halaman5000W ABS Taita TaiwanPhạm Thanh TùngBelum ada peringkat

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Dokumen3 halamanStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoBelum ada peringkat

- Atriot: Technical Data SheetDokumen1 halamanAtriot: Technical Data Sheetazeem bilalBelum ada peringkat

- 1.9.1.2-85T - 316 Stainless SteelDokumen4 halaman1.9.1.2-85T - 316 Stainless SteelfendynovapamelaBelum ada peringkat

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterDokumen4 halamanSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterMohammad HosseinBelum ada peringkat

- Dupont Kalrez 4079: Product DescriptionDokumen2 halamanDupont Kalrez 4079: Product DescriptionAfzal ImamBelum ada peringkat

- ExxonMobil LLP846029 Rotational Molding ResinDokumen2 halamanExxonMobil LLP846029 Rotational Molding ResinLuis Hernandez GarciaBelum ada peringkat

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Dokumen4 halamanMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- 6210GCFNC1 英文物性表 20161122Dokumen1 halaman6210GCFNC1 英文物性表 20161122Sơn Nguyễn ĐắcBelum ada peringkat

- Elix ABS P2M-AT: Technical InformationDokumen3 halamanElix ABS P2M-AT: Technical InformationDiegoTierradentroBelum ada peringkat

- Lexan™ Copolymer 943X: Region AmericasDokumen3 halamanLexan™ Copolymer 943X: Region AmericasAdirSchoierBelum ada peringkat

- Klinger C4401 PDFDokumen2 halamanKlinger C4401 PDFArtur MkrtchyanBelum ada peringkat

- SAN - KUMHO - 350-HW - TDS FDokumen4 halamanSAN - KUMHO - 350-HW - TDS FakshayBelum ada peringkat

- Elix Pc-Abs 5130Dokumen4 halamanElix Pc-Abs 5130DiegoTierradentroBelum ada peringkat

- DRISCOPLEX 6500 Tubería y AccesoriosDokumen7 halamanDRISCOPLEX 6500 Tubería y AccesoriosBrayan CJBelum ada peringkat

- Rotolene: Meet The Unbeatable The Resin That Has It AllDokumen2 halamanRotolene: Meet The Unbeatable The Resin That Has It Allrosy_hernandez_8Belum ada peringkat

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDokumen2 halamanCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseBelum ada peringkat

- Iig - ENERWRAP - MA - 960DataSheetDokumen1 halamanIig - ENERWRAP - MA - 960DataSheettmp_rootsBelum ada peringkat

- Hopelex Af 3100Dokumen2 halamanHopelex Af 3100FarizBelum ada peringkat

- MA8110 TDS Rev11Dokumen2 halamanMA8110 TDS Rev11Rushikesh DeshpandeBelum ada peringkat

- Rescocast 17ECDokumen1 halamanRescocast 17ECJavier Hinojosa Garrido LeccaBelum ada peringkat

- Inexhaust Gasket SpecificationsDokumen1 halamanInexhaust Gasket Specificationsmuhammad0umar-4Belum ada peringkat

- ABS Cycolac MG47Dokumen3 halamanABS Cycolac MG47countzeroaslBelum ada peringkat

- NORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFDokumen3 halamanNORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFbhushansalunkeBelum ada peringkat

- Hyvolt IibrochureDokumen1 halamanHyvolt Iibrochuresamuel cruz menddozaBelum ada peringkat

- BS7531 Grade X. MASTERDokumen1 halamanBS7531 Grade X. MASTERKishor JadhavBelum ada peringkat

- Ficha Tecnica Teadit 1082Dokumen2 halamanFicha Tecnica Teadit 1082damianBelum ada peringkat

- San 310CTRDokumen2 halamanSan 310CTRNguyễn Hồng NamBelum ada peringkat

- Banjara EmbroideryDokumen34 halamanBanjara EmbroideryKriti Rama ManiBelum ada peringkat

- Electricity 10thDokumen45 halamanElectricity 10thSuryank sharmaBelum ada peringkat

- Asphalt Plant Technical SpecificationsDokumen5 halamanAsphalt Plant Technical SpecificationsEljoy AgsamosamBelum ada peringkat

- EnerconDokumen7 halamanEnerconAlex MarquezBelum ada peringkat

- 1SXP210003C0201Dokumen122 halaman1SXP210003C0201Ferenc SzabóBelum ada peringkat

- Ajp Project (1) MergedDokumen22 halamanAjp Project (1) MergedRohit GhoshtekarBelum ada peringkat

- Aisladores 34.5 KV Marca Gamma PDFDokumen8 halamanAisladores 34.5 KV Marca Gamma PDFRicardo MotiñoBelum ada peringkat

- Expense Tracking - How Do I Spend My MoneyDokumen2 halamanExpense Tracking - How Do I Spend My MoneyRenata SánchezBelum ada peringkat

- Polytropic Process1Dokumen4 halamanPolytropic Process1Manash SinghaBelum ada peringkat

- ATPDraw 5 User Manual UpdatesDokumen51 halamanATPDraw 5 User Manual UpdatesdoniluzBelum ada peringkat

- 6 V 6 PlexiDokumen8 halaman6 V 6 PlexiFlyinGaitBelum ada peringkat

- CSEC Jan 2011 Paper 1Dokumen8 halamanCSEC Jan 2011 Paper 1R.D. KhanBelum ada peringkat

- Audit On ERP Implementation UN PWCDokumen28 halamanAudit On ERP Implementation UN PWCSamina InkandellaBelum ada peringkat

- Environmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsDokumen8 halamanEnvironmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsAhmad Zubair Hj YahayaBelum ada peringkat

- What Caused The Slave Trade Ruth LingardDokumen17 halamanWhat Caused The Slave Trade Ruth LingardmahaBelum ada peringkat

- CDKR Web v0.2rcDokumen3 halamanCDKR Web v0.2rcAGUSTIN SEVERINOBelum ada peringkat

- 2016 066 RC - LuelcoDokumen11 halaman2016 066 RC - LuelcoJoshua GatumbatoBelum ada peringkat

- Introduction To Motor DrivesDokumen24 halamanIntroduction To Motor Drivessukhbat sodnomdorjBelum ada peringkat

- 90FF1DC58987 PDFDokumen9 halaman90FF1DC58987 PDFfanta tasfayeBelum ada peringkat

- Weekly Learning PlanDokumen2 halamanWeekly Learning PlanJunrick DalaguitBelum ada peringkat

- Online Learning Interactions During The Level I Covid-19 Pandemic Community Activity Restriction: What Are The Important Determinants and Complaints?Dokumen16 halamanOnline Learning Interactions During The Level I Covid-19 Pandemic Community Activity Restriction: What Are The Important Determinants and Complaints?Maulana Adhi Setyo NugrohoBelum ada peringkat

- ICSI-Admit-Card (1) - 230531 - 163936Dokumen17 halamanICSI-Admit-Card (1) - 230531 - 163936SanjayBelum ada peringkat

- Hip NormDokumen35 halamanHip NormAiman ArifinBelum ada peringkat

- P 1 0000 06 (2000) - EngDokumen34 halamanP 1 0000 06 (2000) - EngTomas CruzBelum ada peringkat

- My CoursesDokumen108 halamanMy Coursesgyaniprasad49Belum ada peringkat

- The Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and CountriesDokumen13 halamanThe Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and Countriesluisbmwm6Belum ada peringkat

- Food and Beverage Department Job DescriptionDokumen21 halamanFood and Beverage Department Job DescriptionShergie Rivera71% (7)

- Perkins 20 Kva (404D-22G)Dokumen2 halamanPerkins 20 Kva (404D-22G)RavaelBelum ada peringkat

- Week 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student HandoutDokumen3 halamanWeek 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student Handoutdwkwhdq dwdBelum ada peringkat

- Embedded Systems DesignDokumen576 halamanEmbedded Systems Designnad_chadi8816100% (4)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactDari EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactPenilaian: 5 dari 5 bintang5/5 (5)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDari EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincPenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeDari EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifePenilaian: 4 dari 5 bintang4/5 (1)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeDari EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimePenilaian: 5 dari 5 bintang5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingDari EverandIt's Elemental: The Hidden Chemistry in EverythingPenilaian: 4 dari 5 bintang4/5 (10)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDari EverandChemistry for Breakfast: The Amazing Science of Everyday LifePenilaian: 4.5 dari 5 bintang4.5/5 (90)

- Taste: Surprising Stories and Science About Why Food Tastes GoodDari EverandTaste: Surprising Stories and Science About Why Food Tastes GoodPenilaian: 3 dari 5 bintang3/5 (20)

- Oxygen: The molecule that made the worldDari EverandOxygen: The molecule that made the worldPenilaian: 4.5 dari 5 bintang4.5/5 (108)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDari EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifePenilaian: 5 dari 5 bintang5/5 (4)

- Guidelines for Defining Process Safety Competency RequirementsDari EverandGuidelines for Defining Process Safety Competency RequirementsPenilaian: 3 dari 5 bintang3/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDari EverandChemistry for Breakfast: The Amazing Science of Everyday LifePenilaian: 4.5 dari 5 bintang4.5/5 (14)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsDari EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsBelum ada peringkat

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDari EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolBelum ada peringkat

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideDari EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideBelum ada peringkat

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDari EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsPenilaian: 5 dari 5 bintang5/5 (3)

- The Periodic Table: A Very Short IntroductionDari EverandThe Periodic Table: A Very Short IntroductionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Tribology: Friction and Wear of Engineering MaterialsDari EverandTribology: Friction and Wear of Engineering MaterialsPenilaian: 5 dari 5 bintang5/5 (1)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsDari EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsPenilaian: 4 dari 5 bintang4/5 (146)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeDari EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeBelum ada peringkat

- The Billion-Dollar Molecule: The Quest for the Perfect DrugDari EverandThe Billion-Dollar Molecule: The Quest for the Perfect DrugPenilaian: 5 dari 5 bintang5/5 (2)

- Fundamentals of Chemistry: A Modern IntroductionDari EverandFundamentals of Chemistry: A Modern IntroductionPenilaian: 5 dari 5 bintang5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactDari EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactPenilaian: 5 dari 5 bintang5/5 (1)

- Guidelines for Integrating Process Safety into Engineering ProjectsDari EverandGuidelines for Integrating Process Safety into Engineering ProjectsBelum ada peringkat