GP 10 - Fwa - Setup - dc970 April 21

Diunggah oleh

XcopyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GP 10 - Fwa - Setup - dc970 April 21

Diunggah oleh

XcopyHak Cipta:

Format Tersedia

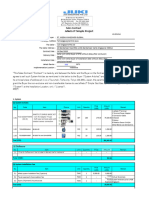

GP10 FWA Standard Setup (dC 970) NOTE: NVM locations [988-121] [988-122] [988-123] [988-126] [988-127] [988-128]

E: NVM locations [988-121] [988-122] [988-123] [988-126] [988-127] [988-128] [988-

129] and [988-130] [988-400] require input values.

Purpose

The purpose of this procedure is to ensure that the Full Width Array is adjusted correctly and

performing accurate calibrations. The procedure is to be performed from start to finish and

establishes the following parameters:

• LED Intensity - This routine uses the Yellow tile on the WR Roll to record the scanner

response to the lamp at FWA installation or Lamp replacement.

• Gain/Offset - This routine calibrates scanner response to Lamp intensity.

• Shading Profile - This routine sets correction values in the Scanner to compensate for

variations in the Scanner CCD light response.

• Parameters - This routine calibrates the read position, focal point and depth of field for the

Scanner.

• Check Paper Measurement GP 7 - This procedure establishes accurate paper measure-

ment points for the FWA in order to enable accurate performance by FWA applications.

Several other separate routines are embedded in dC 970 and they are performed for the fol-

lowing purpose:

• Calibrate Color Sensor - This routine uses the Yellow tile on the WR Roll to calibrate color

response of the FWA.

• Adjust Replaced Lamp - Performed when the Lamp Assembly is replaced.

• Adjust Replaced Color Calibration Plate - Performed when the WR Roll assembly is

replaced.

Prerequisites

Before performing this routine at installation, ensure that the WR Roll tiles (PL20.1) and both

sides of the Lamp Window (GP9) are clean. Figure 1 WR Bar Code Values

Ensure that there are no IQ defects with the system and that the xerographic subsystem is 3. Check that the values on the Lamp Assembly match the values in NVM. In the example in

operating properly. Figure 2, the value in [988-137] should be 0004 (a zero is added to make four digits).

Procedure

Perform each of the following in order.

NVM / Label Check

1. Enter CE Diagnostics (Entering and Exiting CE mode)

2. Check that the values on the WR Roll Assembly match the values in NVM. In the example

in Figure 1, the value in [988-126] should be 0143; the value in [988-127] should be 0527,

etc.

6 General Procedures and Information October 2013 Initial Issue

GP10 6-12 Xerox XXXX Color Press

2. Press Start to adjust LED 1 (Figure 4)

Figure 4 Adjust LED Intensity Step 1

3. Press Next and then press Start to adjust LED 2 (Figure 5).

Figure 2 Lamp Bar Code Value

Adjust Lamp Intensity

1. Enter dC 970 and press the Adjust LED Intensity button (Figure 3).

Figure 5 Adjust LED Intensity Step 2

4. Press Next and then press Start to adjust LED 1/2 (Figure 6).

Figure 3 dC 970 Main Screen

Initial Issue October 2013 6 General Procedures and Information

Xerox XXXX Color Press 6-13 GP10

Table 1

Error Code

Error and Stored in [988-

description Component Action 006]

RGB unbalanced LED 2 Replace the Illumi- 53

LED 1/2 nation Module

RGB unbalanced LED 1&2 Replace the Illumi- 56

LED 1/2 nation Module

Adjust Gain / Offset

1. Enter dC 970 and press the Adjust Gain / Offset button (Figure 7).

Figure 6 Adjust LED Intensity Step 3

5. If there are no NGs, press Save to save the adjustment values. If NGs appear, values are

displayed with a red bar. Refer to Table 1 to troubleshoot the error code stored in [988-

006].

Table 1

Error Code

Error and Stored in [988-

description Component Action 006]

LED intensity too LED 1 Increase Gain 51

low NVM [988-143]

and readjust Figure 7 dC 970 Main Screen

LED intensity too LED 2 Replace the Illumi- 54

low nation Module 2. Press Start to perform the Adjustment with Gain selected in the pulldown menu (Figure

LED intensity too LED 1&2 Increase Gain 57 8).

low NVM [988-143]

and readjust

LED intensity too LED 1 Decrease Gain 52

high NVM [988-143]

and readjust

LED intensity too LED 2 Replace the Illumi- 55

high nation Module

LED intensity too LED 1&2 Decrease Gain 58

high NVM [988-143]

and readjust

RGB unbalanced LED 1 Replace the Illumi- 50

LED 1/2 nation Module

6 General Procedures and Information October 2013 Initial Issue

GP10 6-14 Xerox XXXX Color Press

5. Select Offset from the pulldown menu and ensue that Current Values fall between the

Minimum and Maximum values (Figure 10).

NOTE: NGs will be displayed in Red.

Figure 8 Gain / Offset Adjustment

3. Select Gain from the pulldown menu and ensue that Current Values fall between the

Minimum and Maximum values (Figure 9).

Figure 10 Offset Values After Adjustment

NOTE: NGs will be displayed in Red.

6. If the values are OK, press Save to save the values and proceed to Update Shading

Profile. If the values are NG, continue with this procedure.

7. Remove the Lamp Window and clean both sides of the glass with Lens and Mirror

Cleaner and a lint free cloth GP9.

8. Access the dC330 and ensure that the Lamps light [045-002]. Troubleshoot electrical con-

nections or replace the Assembly (BSD 6.11).

9. Repeat the Gain / Offset adjustment.

Update Shading Profile

1. Enter dC 970 and press the Update Shading Profile button (Figure 11).

Figure 9 Gain Values After Adjustment

4. If the values are OK, proceed to step 5. If the values are NG, continue with step 7.

Initial Issue October 2013 6 General Procedures and Information

Xerox XXXX Color Press 6-15 GP10

NOTE: Shading failures will result in NVM [988-006] having a value of 29.

5. If there are values greater than 1, perform GP15 (WR Roll Evaluation) and GP6 Window

Cleaning and repeat the adjustment. If the adjustment fails again, replace the WR Roll

Assembly (REP 6.5).

Adjust Parameters

1. Enter dC 970 and select Adjust Parameters (Figure 13)

Figure 11 dC 970 Main Screen

2. Press Start to begin the adjustment.

3. Check for values greater than 1 in both the Window Stain and Shading Stripe pulldown

menus. (Figure 12)

Figure 13 dC 970 Main Screen

2. Press Start to begin the adjustment.

3. Ensure that there are no NGs displayed in the Gain values (Figure 14). If NGs are dis-

played, go to steps 7and 8 to resolve.

Figure 12 Shading Profile Adjustment

4. If there are no NGs, press Save to save the adjustment values and proceed to Adjust

Parameters.

6 General Procedures and Information October 2013 Initial Issue

GP10 6-16 Xerox XXXX Color Press

Figure 14 Gain Parameters Figure 16 Scan Position Detection Surface Values

4. Ensure that there are no NGs displayed in the Illumination Depth Detection Surface val- 6. Ensure that there are no NGs displayed in the Focus Detection Surface values are (Fig-

ues (Figure 15). If NGs are displayed, go to steps 7and 8 to resolve. ure 17). If NGs are displayed, go to steps 7and 8 to resolve.

Figure 15 Illumination Depth Detection Surface Values Figure 17 Focus Detection Surface Values

5. Ensure that there are no NGs displayed in the Scan Position Detection Surface values 7. If the any of the adjustments fail after the first attempt perform the following:

(Figure 16). If NGs are displayed, go to steps 7and 8 to resolve. • Clean FWA window per GP9

• Clean the WR Roll

Initial Issue October 2013 6 General Procedures and Information

Xerox XXXX Color Press 6-17 GP10

• Check/Rerun “Adjust Gain / Offset” adj again GP11 Transfer Drawer Service Position

8. If the adjustment fails again, perform the following:

Purpose

• Check the WR Roll position per GP15

This procedure will place the Transfer Drawer to the fully extended service position.

• Ensure that the WR NVM / Barcode values are correct (Steps 3 and 4).

• Check operation of the LED Light assembly WARNING

• Replace the LED Lamp assy (REP 6.6)

Do not perform repair activities with the power on or electrical power supplied to the

• Replace Top FWA assembly (REP 6.7) machine. Some machine components contain dangerous electrical voltages that can

9. Perform GP 7 to ensure accurate position FWA readings when creating “Alignment Pro- result in electrical shock and possible serious injury.

files”. DANGER: Ne pas effectuer de dépannnage avec le contact principal activé ou avec l'ali-

mentation électrique appliquée à la machine. Certains éléments de la machine compor-

tent des tensions électriques dangereuses qui peuvent causer un choc électrique et de

graves blessures.

AVVERTENZA: Non effettuare alcuna riparazione con l'alimentazione elettrica inserita.

Alcuni componenti contengono corrente ad alta tensione che può provocare forti

scosse e gravi ferite.

VORSICHT: Es dürfen erst Reparaturarbeiten durchgeführt werden, wenn das Gerät aus-

geschaltet ist oder der Netzstecker nicht mehr mit der Stromquelle verbunden ist. Ein-

ige Komponenten des Gerätes sind stromführend und können daher zu ernsthaften

Verletzungen oder Stromschlägen führen.

AVISO: No realice reparaciones con la máquina encendida o conectada a la corriente.

Algunos componentes de la máquina contienen voltajes eléctricos peligrosos que

pueden producir una descarga eléctrica y causar daños graves.

CAUTION

Do not pull out the Transfer Drawer with power supplied to the machine. This could result in

electrical damage to the machine.,

Procedure

1. Power off the machine by performing the following:

a. Press the ON/OFF button on the right side of the Control Panel.

b. When the light near the ON/OFF button stops blinking, open the Left Front Door and

the Center Front Door, and switch off the circuit breaker.

2. Turn the locking handle clockwise and pull out the Transfer Drawer.

3. Extend the drawer to the service position:

1. Press the release latch on each side with a screwdriver blade and pull the drawer

outward until it stops (Figure 1).

6 General Procedures and Information October 2013 Initial Issue

GP10 , GP11 6-18 Xerox XXXX Color Press

Anda mungkin juga menyukai

- XC2005 Position Controller: (Rigour II Ver 4.0)Dokumen16 halamanXC2005 Position Controller: (Rigour II Ver 4.0)alguifarro85% (20)

- Broken Needle PolicyDokumen9 halamanBroken Needle Policyelisav89% (9)

- Auto Refractometer Repair ManualDokumen54 halamanAuto Refractometer Repair Manualjuliogarrido100% (8)

- PS-In202SS Operators Manual EnglishSpanishDokumen32 halamanPS-In202SS Operators Manual EnglishSpanishOdali100% (1)

- TM-42 Manual (ENG) 20050707-97Dokumen8 halamanTM-42 Manual (ENG) 20050707-97Michael Karantzias83% (6)

- Prime Scales Ps-In 202Dokumen16 halamanPrime Scales Ps-In 202José Manuel Mejía100% (1)

- Digi Ds-425p ManualDokumen19 halamanDigi Ds-425p ManualSuphon UasmithBelum ada peringkat

- Philips - Gravador DVD DVDR615 - Manual de Serviço - 14123101 PDFDokumen126 halamanPhilips - Gravador DVD DVDR615 - Manual de Serviço - 14123101 PDFLuiz Alberto MagriBelum ada peringkat

- Testing and Commissioning (ACMV)Dokumen5 halamanTesting and Commissioning (ACMV)Alex Choong100% (1)

- AC40 1060 Service ManualDokumen68 halamanAC40 1060 Service ManualmacrufoBelum ada peringkat

- Samsung 940bw PlusDokumen78 halamanSamsung 940bw PlusFariasBelum ada peringkat

- E21 Operation Manual: (Version: V1.04)Dokumen27 halamanE21 Operation Manual: (Version: V1.04)Тимур АлиевBelum ada peringkat

- Service Bulletin: R: SB-07-100 (F03-006) P: D: V: S: MDokumen13 halamanService Bulletin: R: SB-07-100 (F03-006) P: D: V: S: MmoviteknikaBelum ada peringkat

- (Data Type) Two-Word (Unit of Data) Six-Digit Number RRGGBB (RR: Red Component Value, GG: Green ComponentDokumen81 halaman(Data Type) Two-Word (Unit of Data) Six-Digit Number RRGGBB (RR: Red Component Value, GG: Green ComponentMahir DžafićBelum ada peringkat

- Ag2022-02 20220211Dokumen10 halamanAg2022-02 20220211Edwin QuisilemaBelum ada peringkat

- Service Manual: Model: DS-425Dokumen15 halamanService Manual: Model: DS-425Tian TianBelum ada peringkat

- GstDef2.1 Defining Tool Issue2.18Dokumen28 halamanGstDef2.1 Defining Tool Issue2.18Mohamed Abou El hassanBelum ada peringkat

- Instruction Manual For BLT Armeg Group Control System: SERIAL NO. GNCG0002Dokumen33 halamanInstruction Manual For BLT Armeg Group Control System: SERIAL NO. GNCG0002Cristian de LeonBelum ada peringkat

- Projection Television: 56HM195 62HM195 72HM195Dokumen45 halamanProjection Television: 56HM195 62HM195 72HM195alberthayesBelum ada peringkat

- FP92E C501 Service Manual 9J.L2V72.000 9J.L2V72.000-C501-001 9J.L2V72.001 NA Q9C5Dokumen49 halamanFP92E C501 Service Manual 9J.L2V72.000 9J.L2V72.000-C501-001 9J.L2V72.001 NA Q9C5Iliescu CristianBelum ada peringkat

- Toshiba 52-62hmx94svm Service ManualDokumen39 halamanToshiba 52-62hmx94svm Service ManualKenwood TrioBelum ada peringkat

- A100K10675 VSP-12-Way UserguideDokumen4 halamanA100K10675 VSP-12-Way UserguideВладимир ЗагородинBelum ada peringkat

- Experiment 7Dokumen9 halamanExperiment 7abstudio0049Belum ada peringkat

- GST P-9910B Handheld ProgrammerDokumen15 halamanGST P-9910B Handheld ProgrammeretchegarayfBelum ada peringkat

- DS II Tutorial 2-SecB, E, FDokumen6 halamanDS II Tutorial 2-SecB, E, FAbhijit PaikarayBelum ada peringkat

- Kisssoft Tutorial 12 Sizing of A Planetary Gear SetDokumen18 halamanKisssoft Tutorial 12 Sizing of A Planetary Gear SetNguyễnVănLăngBelum ada peringkat

- HD67 Service Manual (DDP2431) V1.0Dokumen37 halamanHD67 Service Manual (DDP2431) V1.0Bartolo PelaezBelum ada peringkat

- Axe Microprocess 5 Digital Panel Meter: Key Introduce Operation ManualDokumen3 halamanAxe Microprocess 5 Digital Panel Meter: Key Introduce Operation ManualMOREEBelum ada peringkat

- Service Manual: Trinitron Color TVDokumen17 halamanService Manual: Trinitron Color TVohukBelum ada peringkat

- XC-2001 Position Control Series (Single-Dual Electric ... - Linh MauDokumen7 halamanXC-2001 Position Control Series (Single-Dual Electric ... - Linh MauSasha Naumchenko100% (3)

- Practical Work 5Dokumen7 halamanPractical Work 5Muhammad ZakiyBelum ada peringkat

- AED Detector CalibrationDokumen8 halamanAED Detector Calibrationyonas abebeBelum ada peringkat

- JWI-3000 Service ManualDokumen23 halamanJWI-3000 Service ManualGabriel Spinato100% (1)

- GST852RP LCD Repeater Panel Issue 2.07.2Dokumen14 halamanGST852RP LCD Repeater Panel Issue 2.07.2Seagull MarineBelum ada peringkat

- 8050 Service BulletinsDokumen132 halaman8050 Service BulletinsTomislav BareticBelum ada peringkat

- Tp5000siplusrf Easy User GuideDokumen2 halamanTp5000siplusrf Easy User Guidedforsythe639Belum ada peringkat

- XC2006 V620 English2Dokumen16 halamanXC2006 V620 English2ramzibtrBelum ada peringkat

- Di-620 Manual PDFDokumen30 halamanDi-620 Manual PDFTrường ThạchBelum ada peringkat

- 2.12 Blue Defocus Adjustment: Sticking Out of BlueDokumen1 halaman2.12 Blue Defocus Adjustment: Sticking Out of Blueapi-3797948Belum ada peringkat

- Alignment and AdjustmentsDokumen30 halamanAlignment and AdjustmentsHarpreet DhimanBelum ada peringkat

- Anti-Collision Micro Controller Based: Speed-O-Controls Pvt. LTDDokumen1 halamanAnti-Collision Micro Controller Based: Speed-O-Controls Pvt. LTDAndes PutraBelum ada peringkat

- MGuide1200 User en de FR EsDokumen184 halamanMGuide1200 User en de FR EsAngelo DomingoBelum ada peringkat

- AGC 100 Operator's Manual 4189340753 UKDokumen17 halamanAGC 100 Operator's Manual 4189340753 UKRicardo JúniorBelum ada peringkat

- Conversor de SeñalDokumen7 halamanConversor de SeñalGustavo OviedoBelum ada peringkat

- Interfacing of 16x2 LCD With 8051 MicrocontrollerDokumen7 halamanInterfacing of 16x2 LCD With 8051 MicrocontrollerVinothkumar Uruman100% (1)

- 62HM95 SM Rev3Dokumen45 halaman62HM95 SM Rev3Franklin GoodrichBelum ada peringkat

- Taukeypad-Electric Gate ManualDokumen5 halamanTaukeypad-Electric Gate ManualChris GavevaBelum ada peringkat

- Jud408553-B8000 Serv Man-Test ProcDokumen10 halamanJud408553-B8000 Serv Man-Test ProcalexFillBelum ada peringkat

- MM9000 Setup ProcedureDokumen5 halamanMM9000 Setup ProcedurecesarcaterpillarBelum ada peringkat

- Datakom-Dkm0224 Nfpa110Dokumen11 halamanDatakom-Dkm0224 Nfpa110Minn Thet NaingBelum ada peringkat

- DP E08canDokumen8 halamanDP E08canhowet32126Belum ada peringkat

- Aoc - Monitor - Lm520iDokumen40 halamanAoc - Monitor - Lm520imarialixd4472Belum ada peringkat

- Interfacing 16×2 LCD With 8051Dokumen39 halamanInterfacing 16×2 LCD With 8051gunda manasaBelum ada peringkat

- Sales Contract For Janets JT Simple - 288sest (PT - Medika Maesindo Global)Dokumen3 halamanSales Contract For Janets JT Simple - 288sest (PT - Medika Maesindo Global)pecorepp.maesindoBelum ada peringkat

- NovaLCT-Mars Points of AttentionDokumen7 halamanNovaLCT-Mars Points of AttentionJavier LasobrasBelum ada peringkat

- SM DU User Manual - V1.1 - 20070522Dokumen22 halamanSM DU User Manual - V1.1 - 20070522Talha NasrBelum ada peringkat

- Manual Uwe W10Dokumen27 halamanManual Uwe W10michigato100% (1)

- Infineon-LED7SEG - User - Module-Software Module Datasheets-V01 - 02-ENDokumen13 halamanInfineon-LED7SEG - User - Module-Software Module Datasheets-V01 - 02-ENAsrulBelum ada peringkat

- Colorlight S4 User ManualDokumen22 halamanColorlight S4 User ManualAbdel AdimBelum ada peringkat

- Joint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardDari EverandJoint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardBelum ada peringkat

- Virtual Boy Architecture: Architecture of Consoles: A Practical Analysis, #17Dari EverandVirtual Boy Architecture: Architecture of Consoles: A Practical Analysis, #17Belum ada peringkat

- Versant 80 - 180 - 280 ACA and HFSI v7Dokumen2 halamanVersant 80 - 180 - 280 ACA and HFSI v7XcopyBelum ada peringkat

- Windows 10 Availability For Ricoh Fiery Servers: Why Upgrade To Windows 10?Dokumen3 halamanWindows 10 Availability For Ricoh Fiery Servers: Why Upgrade To Windows 10?XcopyBelum ada peringkat

- Instructions & Info - ACA, HFSI, Script & RML (011020)Dokumen3 halamanInstructions & Info - ACA, HFSI, Script & RML (011020)Xcopy100% (1)

- C35 Style - Drum Cartridge Rebuild Instructions (For Xerox WorkCentre 5632 - 5687, 5735 - 5790, 5845-5890Dokumen5 halamanC35 Style - Drum Cartridge Rebuild Instructions (For Xerox WorkCentre 5632 - 5687, 5735 - 5790, 5845-5890XcopyBelum ada peringkat

- 1-16XA4D RelnoteDokumen14 halaman1-16XA4D RelnoteXcopyBelum ada peringkat

- X60SS 041 PDFDokumen2 halamanX60SS 041 PDFXcopyBelum ada peringkat

- Firmware Instructions Release Notes Versant 80 32 83Dokumen9 halamanFirmware Instructions Release Notes Versant 80 32 83XcopyBelum ada peringkat

- Fiery Reference Manual v1.1Dokumen90 halamanFiery Reference Manual v1.1XcopyBelum ada peringkat

- Windows 10 Availability For Xerox Fiery Servers: Why Upgrade To Windows 10?Dokumen2 halamanWindows 10 Availability For Xerox Fiery Servers: Why Upgrade To Windows 10?XcopyBelum ada peringkat

- Specifications For Xerox Color 1000i Press: Image Resolution TechnologyDokumen1 halamanSpecifications For Xerox Color 1000i Press: Image Resolution TechnologyXcopyBelum ada peringkat

- 9.1.3.2 Installation of Bypass Tray OnlyDokumen4 halaman9.1.3.2 Installation of Bypass Tray OnlyXcopyBelum ada peringkat

- 700-700i DCP v3.7 MN SW Release Notes 20111028Dokumen28 halaman700-700i DCP v3.7 MN SW Release Notes 20111028XcopyBelum ada peringkat

- Tray 5 Registration AdjustmentsDokumen1 halamanTray 5 Registration AdjustmentsXcopy50% (2)

- 700DCP Customer Alignment Training Procedure Final1Dokumen7 halaman700DCP Customer Alignment Training Procedure Final1XcopyBelum ada peringkat

- 4110F Inverter and Duplex Solenoid AdjutmentDokumen3 halaman4110F Inverter and Duplex Solenoid AdjutmentXcopyBelum ada peringkat

- Create Custom Profile PDFDokumen3 halamanCreate Custom Profile PDFXcopyBelum ada peringkat

- Xerox Finishers PDFDokumen3 halamanXerox Finishers PDFXcopyBelum ada peringkat

- 700-700i DCP V3 7 MN System SW Download Procedure 20111028Dokumen14 halaman700-700i DCP V3 7 MN System SW Download Procedure 20111028XcopyBelum ada peringkat

- Registration Base Line Procedure PDFDokumen5 halamanRegistration Base Line Procedure PDFXcopyBelum ada peringkat

- 4110 V4 0 System SW Download Procedure-Revised 7-13-07Dokumen12 halaman4110 V4 0 System SW Download Procedure-Revised 7-13-07XcopyBelum ada peringkat

- Sample IOM-SchlumbergerDokumen10 halamanSample IOM-Schlumbergerbmanojkumar16Belum ada peringkat

- CEMS Guidelines Volume I Full VersionDokumen28 halamanCEMS Guidelines Volume I Full Versionbabis1980100% (1)

- Chunky Meatbots Produces A Wide Variety of Unorthodox Bread SaucesDokumen3 halamanChunky Meatbots Produces A Wide Variety of Unorthodox Bread SaucesElliot RichardBelum ada peringkat

- Manual Positector6000 DahecDokumen69 halamanManual Positector6000 Dahecjose raulBelum ada peringkat

- Calculation of Liquid Petroleum QuantitiesDokumen10 halamanCalculation of Liquid Petroleum QuantitiesHenry MaedaBelum ada peringkat

- GN RESOUND Smart FitDokumen18 halamanGN RESOUND Smart FitPraveenaslp EddulaBelum ada peringkat

- Cert Ultramat23 GB Metrol Sira Mcerts Mc040033 08Dokumen9 halamanCert Ultramat23 GB Metrol Sira Mcerts Mc040033 08Nicolae VisanBelum ada peringkat

- ISA-RP52.1-1975 - Recommended Enviroments For Standards LaboratoriesDokumen32 halamanISA-RP52.1-1975 - Recommended Enviroments For Standards LaboratoriesJorge Cota AcostaBelum ada peringkat

- ADT681Dokumen3 halamanADT681kamendrix kamendrixBelum ada peringkat

- Manuals Pqa Analizador Redes MI 2192 MetrelDokumen88 halamanManuals Pqa Analizador Redes MI 2192 MetrelDavid Cusi VenturaBelum ada peringkat

- App Note 002 Measuring The Conductivity of Pure Water Using USP 645Dokumen8 halamanApp Note 002 Measuring The Conductivity of Pure Water Using USP 645fonsynickBelum ada peringkat

- HSB Human Humalyzer Calibration Toolset 001 PDFDokumen2 halamanHSB Human Humalyzer Calibration Toolset 001 PDFluisoft88Belum ada peringkat

- Digital Weighing Indicator: MI-800 Series User ManualDokumen45 halamanDigital Weighing Indicator: MI-800 Series User ManualAbdelghani LayebBelum ada peringkat

- Tuttnauer EHS-Series Autoclave - Service ManualDokumen130 halamanTuttnauer EHS-Series Autoclave - Service ManualKittiwat Wongsuwan100% (1)

- TSI, DustTrak - DRX Model 8533, 8534, 8535Dokumen84 halamanTSI, DustTrak - DRX Model 8533, 8534, 8535johnsmithBelum ada peringkat

- Calibration Procedure FOR Multimeters: Technical ManualDokumen280 halamanCalibration Procedure FOR Multimeters: Technical ManualXptoleo LeoBelum ada peringkat

- INST240 Sec1Dokumen90 halamanINST240 Sec1mohammed el erianBelum ada peringkat

- Reagent Set Up AU400Dokumen47 halamanReagent Set Up AU400quankddBelum ada peringkat

- Textile Testing MachinesDokumen14 halamanTextile Testing MachinesNenadCirkovicBelum ada peringkat

- Hitec - Katalog Mikroskopy QZW CNC 2018 ENDokumen24 halamanHitec - Katalog Mikroskopy QZW CNC 2018 END.T.Belum ada peringkat

- Control SystemsDokumen16 halamanControl SystemsCarlos Andres Porras NinoBelum ada peringkat

- CPM For DLT-5500: Communication PlatformDokumen54 halamanCPM For DLT-5500: Communication PlatformMauricio Contreras R.Belum ada peringkat

- Validation of Nuclear Gauge Density-Meter Readings Against Sand Replacement MethodDokumen6 halamanValidation of Nuclear Gauge Density-Meter Readings Against Sand Replacement MethodGerald MaregesiBelum ada peringkat

- Flow Meter NivusDokumen71 halamanFlow Meter NivusCatalin EneBelum ada peringkat

- FA410 S6 DataSheetDokumen1 halamanFA410 S6 DataSheetKelvin NgBelum ada peringkat

- The Real "Total Cost of Ownership" of Your Test Equipment: Keysight TechnologiesDokumen8 halamanThe Real "Total Cost of Ownership" of Your Test Equipment: Keysight TechnologiesAshwin BhatBelum ada peringkat

- The Bulk Modulus of Hydraulic Fluids at Elevated TemperaturesDokumen62 halamanThe Bulk Modulus of Hydraulic Fluids at Elevated TemperaturesEvgeny ShavelzonBelum ada peringkat