Research 18-23 PDF

Diunggah oleh

Editor IjprtJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Research 18-23 PDF

Diunggah oleh

Editor IjprtHak Cipta:

Format Tersedia

International Journal of Pharmacy Research and Technology

2012, Volume 2, Issue 3, 18-23

ISSN 2250 – 0944 (Online)

ISSN 2250 – 1150 (Print)

Research Article

Formulation Development and Evaluation of Metformin Hydrochloride Extended Release Tablets

Nishit Gohel1*, D. M. Patel2, Komal Patel3, Rushik Ghodasara1

1

School of Pharmacy, RK University, Rajkot and Parul Institute of Pharmacy and Research, Vadodara, Gujarat, India

2

Shri Sarvajanik Pharmacy College, Mehsana, Gujarat, India

3

Dharmaj degree pharmacy college, Dharmaj, Gujarat, India

*Correspondence Author: Email: nishitgohel@gmail.com

Received: 20/7/2012, Revised: 27/08/2012 Accepted: 2/09/2012

ABSTRACT

Extended release tablets of Metformin HCl were developed due to lower half-life, high solubility and less bioavailability.

The tablets were prepared by hydrophilic matrix technique and combination of hydrophilic matrix with hydrophobic coating

as reservoir. Hypromellose was used as matrixing agent and ethyl cellulose as hydrophobic coating material. In vitro

dissolution studies of optimized, F3a (3% coated) formulation showed satisfactory results for f2 and f1 values i.e 80.29 and

2.87 respectively. And the dissolution profile was almost similar with that of reference product. The results of the dissolution

study were examined according to Zero, First and Higuchi model as shown for reference product. The regression coefficient

(R2) value obtained from the log %ARR (Amount Remaining to Release) versus time was 0.9396 which is nearer to 1,

indicating first order release for formulation F3a.

Results of stability study carried out on formulation F3a for three months indicated that, there was no any significant change

in drug release of the tablet as well as % assay results were found within specifications. Hence, the optimized formulation

was stable.

Keywords: Type II diabetes, Hypromellose, Extended release, Metformin HCl, Matrix tablets

INTRODUCTION get the required release and their effect on release pattern.

Diabetes mellitus is a major and growing public health [5-9]

problem throughout the world. Recent estimates project that

the number of patients diagnosed with type II diabetes will MATERIALS AND METHODS

more than double to 300 million before 2025. Metformin HCl was obtained from Alembic limited as

[1]Maintaining normal plasma glucose levels is a key factor a gift sample. Reference product Glumet XR (Cipla Ltd.)

in reducing the risk of developing diabetes complications. was purchased from local chemist. Methocel® K100M CR

[2,3] Metformin is a biguanide antihyperglycemic agent (HPMC) was collected as a gift sample from Colorcon Asia

used in the treatment of non-insulin dependent diabetes Pvt. Ltd. Avicel PH 101 (microcrystalline cellulose) was

mellitus (NIDDM). collected as a gift sample from FMC Biopolymer.

In spite of its favorable clinical response and lack of Magnesium stearate was purchased from Signet. Potassium

significant draw backs, chronic therapy with metformin dihydrogan ortho phosphate and sodium hydroxide were

hydrochloride suffers from certain problems. The marketed obtained as gift samples from Merck Ltd. All other

immediate release products need to be administered 2-3 chemicals and reagents used were of analytical grades.

times daily. The current metformin therapy is associated

with high incident of GI side effects seen in about 30% of Preparation of hydrophilic matrix tablets

patients. [4] Moreover inherent compressibility, very high Extended release tablets were formulated by wet

solubility (i.e. >300 mg/ml at 25° C), initial burst effect of granulation matrix tablet technology using hydrophilic

drug from immediate release tablets and less bioavailability polymer, Hypromellose (Methocel® K100M CR). Trials

(60%) due to saturable absorption process can lead to were taken with different concentrations of Hypromellose

difficulty in providing an optimum therapeutic effect from a and tablet weight as shown in table 1. Accurately weighed

formulation. quantities of Metformin Hydrochloride, Hypromellose,

So, the attempts were made to formulate an extended Lactose monohydrate, Povidone K-30 and Microcrystalline

release drug delivery system that has a longer transit time in cellulose were dispensed as per formulation table 1 in clean

the stomach and acts as an in vivo reservoir that releases dispensing booth and sifted through 40# sieve. The sifted

drug at a controlled rate continuously over a prolonged time material was mixed uniformly in polybag for 10 minutes

for absorption in the stomach and the intestine. Various and granulated with the hydroalcoholic binder solution

studies and literatures reported the use of HPMC matrices (PVP K 30) by adding drop wise with continuous mixing to

and ethyl cellulose to control the release of variety of drug get optimum granulation. The wet mass was dried in tray

from matrices. drier, sifted through 20# sieve and weighed. The blend was

As extended release tablets offers several advantages lubricated with magnesium stearate dispensed according to

over conventional therapy, it is proposed in the present % yield and sifted through 60# sieve. The blend was

study to develop a competitive extended release tablets of properly mixed in polybag and compressed on 8-station

Metformin Hydrochloride by using the hydrophobic (EC) compression machine using specified punches according to

and hydrophilic polymer (HPMC) alone/ in combination table 1for 500mg strength of tablets.

have been used as coating and matrix material in order to

18 | IJPRT | July – September

Gohel et al / International Journal of Pharmacy Research & Technology 2012 2(3) 18-23

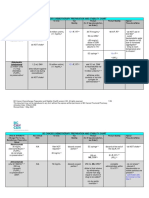

Table 1 Composition of Metformin HCl extended release tablets

Ingredients F1 F2 F3 F4 F5

Metformin HCl 500 500 500 500 500

Lactose monohydrate 120 80 40 100 25

Hypromellose 80 120 160 250 375

Microcrystalline cellulose NA NA NA 100 50

Povidone K30 50 50 50 30 30

Water:IPA(1:1) q.s q.s q.s q.s q.s

Mg. Stearate 10 10 10 20 20

Tablet Weight (mg) 760 760 760 1000 1000

Punch size 17.15×7.15 mm* 17.15×7.15 mm* 17.15×7.15 mm 19×8 mm# 19×8 mm#

* Oval Shaped, # capsule shaped

Functional coating using hydrophobic polymer of solution was taken from each sample and diluted up to

Functional coating of formulation F3 was done with 25ml in 25ml volumetric flask. From this solution 1 ml of

hydrophobic polymer Ethyl cellulose (Ethocel® 7CPS) and solution was withdrawn and diluted up to 10ml in 10ml

PEG 4000-F as plasticizer (60:40 %w/w) to meet the target volumetric flask. Absorbance of the solution was measured

profile of reference product as shown in table 2. Coating at 232 nm. The concentration of Metformin Hydrochloride

solution was prepared using Isopropyl alcohol: was calculated using slope of calibration curve and % assay

Dichloromethane: Water (30:65:5). Coating was done in was calculated using the following equation:

conventional coating pan till weight gained up to 3%, 5% Conc. µg/ml Media Vol. 100

and 7% for F3a, F3b and F3c batches respectively. % Assay

1000 Dilution Factor Label claim

Table 2 Coating composition for Formulation F3 In-vitro drug release study

Coating F3a F3b F3c In-vitro drug release studies of extended release tablets

Ingredients (3%) (5%) (7%) were performed in automatic USP dissolution apparatus 1,

Ethyl cellulose basket type (Electrolab, Mumbai, India) at the speed of 100

60 60 60 rpm. Dissolution tester USP (Elactrolab TDT-08L) was

(Ethocel® 7cpS)*

PEG 4000F *

40 40 40 connected with Electrolab peristaltic pump, for automatic

IPA:DCM:Water 35:65:5 35:65:5 35:65:5 sample withdrawal and replacement of media, and

*

Composition of each ingredient is given in percentage Elactrolab fractional collector, for collection of sample.

Phosphate buffer pH 6.8 was used as a dissolution media.

Evaluationof blends The bowls of the dissolution tester was filled with 1000ml

The formulated powder blends were evaluated for of phosphate buffer pH 6.8 and allows to attaining a

angle of repose, bulk density, tapped density, percentage temperature of 37±0.5ºc. The reservoir for the replacement

compressibility index and % loss on drying. [10-12] of the media was also filled with phosphate buffer.

Apparatus was started when temperature achieved to

Evaluation of Tablets 37±0.5ºc and the tablet was placed to the bottom of the

The compressed tablets (formulations F1 to F5) and basket. The protocol of the dissolution apparatus was set for

reference standard were tested for hardness, thickness, automatic 10ml sample withdrawal and replacement of

percentage friability and weight variation test. Hardness of fresh media at predetermined time interval i.e. 1hr, 2hr,

tablets was tested using Dr. Schleuniger hardness tester 4hr, 6hr, 8hr, 10hr, 12 hr, 16hr, 20hr and 24hr. Thesamples

(8M). The thickness of the tablets was measured by digital withdrawn were filtered through a 0.45 µ membrane

vernier caliper (Digimatic). Friability of the tablets was filter(Nunc, New Delhi, India) and the drug content in each

determined in a Roche friabilator (Electrolab). Weight sample wasanalyzed by UV spectrophotometer after

variation test was performed according to the official suitable dilution(Shimadzu UV-1700) at 232 nm.[13] Drug

method (Indian Pharmacopoeia, 1996). dissolved at specifiedtime periods was plotted as percentage

cumulative release versis time (hours) curve.

Table 3 Evaluation of blends F1 to F5

Parameter F1 F2 F3 F4 F5 Kinetics of Drug Release

In order to investigate the mechanism of drug release

Bulk Density 0.45 0.54 0.49 0.43 0.45

from extended release tablets of Metformin HCl, the release

Tapped Density 0.52 0.63 0.59 0.55 0.55

rate obtained from dissolution studies were fitted to various

Compressibility

13.46 14.28 16.95 21.81 22.22 kinetic equationsas shown for reference product[14-16].The

index

kinetics models used were a,

Hausner's ratio 1.15 1.16 1.2 1.29 1.22

Zero order equation(Qt= Q0 – K0t), First order equation (ln

Loss on drying

2.68 2.37 2.36 2.12 2.67 Qt= lnQ0 - Kt), Higuchi’s equation(Qt= K h t1/2)

(%w/w)

The regression coefficient (R2) value obtained from the log

Angle of repose

33.69 29.74 32.41 33.69 36.52 %ARR (Amount Remaining to bereleased) versis time was

(θ)

examined to find out the release mechanism.

Assay of tablet Swelling index

Three tablets were taken from each batch. Every tablet Tablet of each trial was weighed initially and kept on

was crushed individually, dissolved in 1000 ml of cover slip in the petri-plate filled with 6.8 pH phosphate

phosphate buffer pH 6.8 and sonicated for 15 minutes. 5ml buffer. After specific time intervals weight gained by

IJPRT | July – September | 19

Gohel et al / International

I J

Journal of Pharrmacy Researcch & Technologgy 2012 2(3) 18-23

1

tabletwas measured

m up to 24

2 hours till thee weight remainss ICH guideelines [17]: 25⁰C C ± 2⁰C (60% ± 5% RH), 30⁰C C±

constant. Thhe % weight gainn by the tablet was

w calculated byy 2⁰C (65% ± 5% RH) and 40⁰C ± 2⁰C (755% ± 5% RH). Six S

the formula,, tablets weere individually packed in Aluu-Alu bag, sealled

properly and

a put at abovee specified conddition in incubattor

for 3 monnths. Tablets plaaced for stress testing i.e, 40⁰C

C±

Where, S..I. = Swelling index 2⁰C (75% % ± 5% RH) w were evaluated for in-vitro druug

Wt = Weight of taablet at time t

W release, annd content deterrmination after one,

o two and thrree

W = Weight of tablet

Wo t at differentt time interval. month. Taablets placed for long term testinng i.e, 25⁰C ± 2⁰⁰C

(60% ± 5% % RH) and inteermediate testingg i.e, 30⁰C ± 2⁰⁰C

Stability stu

udy (65% ± 5% % RH) were evaluated for same parameters aft fter

Stabilitty study was carried out forr the optimizedd three montths.

formulation for following condition

c and tim

me period as perr

Table 4 Evaaluation of tabllets of formulatiions F1 to F5, F F3a, F3b and F33c

Weight

W Hardness Thicknness Friiability

Batch No.

N * % Assay**

(

(mg) (Kp)* (mm))* ((%)*

F1 749.888 (±2.55) 13.50 (±0.82) 6.73 (±0..019) 0

0.210 997.85 (±0.37)

F2 750.008 (±1.36) 13.48 (±0.36) 6.76 (±00.03) 0

0.263 9

98.22 (±0.34)

F3 750.224 (±2.09) 11.78 (±0.52) 6.71 (±0..009) 0

0.268 9

99.22 (±0.46)

F4 1003.2 24 (±2.84) 15.36 (±0.46) 6.79 (±0..054) 0

0.324 9

98.81 (±0.41)

F5 1002.2 24 (±2.47) 15.04 (±0.70) 6.79 (±0..038) 0

0.369 9

98.85 (±0.33)

F3a (3%%) 774.888 (±1.12) 15.3 (±0.87) 6.71 (±00.13) 0

0.056 9

99.32 (±0.34)

F3b (5%%) 789.993 (±1.58) 19.7 (±0.65) 6.83 (±00.20) 0

0.047 9

99.12 (±0.46)

F3c (7%%) 804.998 (±1.86) 21.9 (±0.54) 6.97 (±00.17) 0

0.035 9

98.83 (±0.41)

*

Each readinng is an average of five determinnations. (Avg.± S.D)

**

Each readiing is an averagee of three determ

minations. (Avg.±

± S.D)

RESULTS AND DISCUSS SION the polymmer combinationn. The graph of o swelling inddex

Powder blends were evaluated for angle a of reposee, verses tim wn in Figure 2. Swelling index of

me (Hr.) is show

bulk densitty, tapped denssity, percentage compressibilityy the formullation F1 was deecreased after 20

0 Hr. due to low

wer

index and % loss on dryingg. The results aree shown in tablee polymer concentration.

c Hydration rate an nd water uptake of

3.Bulk dennsity was foundd in the range of 0.450-0.5400 the formuulation F2, F3, F4 and F5 waas almost simillar

gm/cm3 annd the tapped density betweeen 0.520-0.6300 indicates there

t was no maajor effect on swwelling index aft

fter

gm/cm3. Alll powder blendds except formulation F4 withh 10.66% poolymer concentration.

Hausner’s ratio

r (<1.25) inndicated better flow propertiess.

The compreessibility index for formulationss F1, F2 and F33

was found between

b 13.46 and

a 16.95, whichh indicated goodd

flowability. While formulaations F4 and F5 F showed poorr

flowability due to compresssibility indexes 21.81 and 22.222

respectivelyy. For all formulaations angle of repose was foundd

in the range of 29.74-36.552 (<40º), indicaating good flow w

properties.

In ordeer to optimise thhe formulation extended

e releasee

tablets of Metformin

M HCl were

w prepared by y two strategies:

Matrix tableet using hydropphilic polymer, Combination of

matrix and reservoir by hydrophilic pollymer core andd

hydrophobicc coating.

Figure 2 Swelling index verses

v Time (Hrr.) of formulatioons

Prepared taablets were ev valuated for weight

w variationn,

F1 to F5

thickness annd hardness andd % assay whicch are shown inn

table 4. Du ue to good flow wability of bleends, formulatedd

tablets weree of uniform weight,

w with accceptable weighht

variations as

a per pharmacoopoeial specificaations. Thicknesss

of formulatiions F1, F2 and F3 was found between

b 6.71mm m

to 6.76 mm m. The average thickness of theese formulationss

was found tot be 6.72 mm withw deviation ±00.019mm. Whilee

average thicckness of formulations F4 and F5 F was 6.79 mm m

with deviaation ±0.046 mm. The haardness of thee

formulations F1, F2, and F33 was found to be b 11.78 to 13.500

Kp, and forr the formulationns F4 and F5 it was found to bee

15.36Kp to 15.04Kp. All fo ormulations show wed less than1% %

(w/w) friabiility which was within

w the prescrribed limits. [18]]

The results of the sweelling index whiich are shown inn

Figure 2, reeveals that the hydration

h rate and

a water uptakee Figure 3 Comparative dissolution profilees of formulatioons

of the formuulation increase with increasing concentration of F1 to F5 with

w Glumet XR

20 | IJPRT | July – Septem

mber

Gohel et al / International Journal of Pharmacy Research & Technology 2012 2(3) 18-23

Formulation F1 Formulation F2

Formulation F3 Formulation F4

Formulation F5 Formulation F3a

Formulation F3b Formulation F3c

Figure 1 Tablets before and after water uptake (F1 to F5, F3a, F3b and F3c)

In-vitro drug release depends on several factors, such Hence, the two trials were taken at 1000 mg tablet weight

as the manufacturing process, the type of excipients and using 250 and 375 mg hypromellose, and by adding water

theamount of drug. The results of In-vitro dissolution insoluble excipient, i.e. microcrystalline cellulose. The

studies of formulations F1 to F5 are shown in Figure 3. dissolution profile of these two formulations was also faster

Dissolution profiles for Cumulative percentage drug release than the reference product.Cumulative percentage drug

verses time (Hr.) are shown in Figure 3. release, which was obtained from in-vitro dissolution study

Swelling Index

of the formulations F1 and F2, was not satisfactory. And

the values of f2 and f1, as indicated in individual

4

dissolution profiles was also not obtained upto the desired

3.5

3

extent. Initial bursting effect and fast dissolution profile

was observed in formulations F1 and F2 due to lower

Swelling index

2.5

2 concentration of polymer.

1.5

1

While, the formulation F3 showed satisfactory results

0.5 of cumulative percentage drug release. The values of f2 =

0 59.64; f1 = 8.40 revealed that, the curves of reference

0 2 4 6 8 10 12 14 16 18 20 22 24 26

Time (Hr.)

product and formulation F3 can be considered similar. But

Sw elling Index F3a Sw elling Index F3b Sw elling Index F3c the initial burst effect was still observed, which was less as

compared to formulations F1 and F2.

Figure 4 Swelling index of batches F3a, F3b, F3c Cumulative percentage drug release and values of f2

and f1 for the formulations F4 and F5 was not found to be

The cumulative % drug release of reference product satisfactory. They showed faster release profile and both

(Glumet XR) and formulations were compared by similarity formulations were not considered due to higher weight of

factor (f2) and difference factor (f1) values.From the tablet as compared to F3.

results, it was revealed that In-vitro drug release of F1, F2 So, the attempt was taken for functional coating

and F3 formulations;containing increasing amount of rate (Hydrophobic coating) on formulation F3 for the prevention

controlling polymer, i.e. hypromellose, (80, 120 and of initial burst effect and to prolong the drug release for

160mg) per tablet were faster than the reference product. extended period of time.Functional coating (modified

IJPRT | July – September | 21

Gohel et al / International Journal of Pharmacy Research & Technology 2012 2(3) 18-23

release film coating) was applied on the formulation F3 In the present research work extended release tablets

using Ethyl cellulose (as hydrophobic film former) and of Metformin Hydrochloride were prepared by different

PEG 4000-F (as plasticizer). 3% (F3a), 5% (F3b) and 7% strategies: Matrix tablet using hydrophilic polymer,

(F3c) coating was applied by calculating target weight Combination of matrix and reservoir by hydrophilic

based on average weight of core tablet. The tablets were polymer core and hydrophobic coating

withdrawn at different interval as 3%, 5% and 7% coating So, the attempt was taken for functional coating of

was achieved. formulation F3 using hydrophobic polymer i.e. Ethyl

Dissolution Profile of Metformin Hydrochloride

cellulose (Ethocel® 7cpS) and 3%, 5% and 7% coating was

applied for the batches F3a, F3b and F3c respectively. The

120

results of these trials revealed that, the F3a (3% coated)

100 batch showed satisfactory results for f2 and f1 values. And

the dissolution profile was almost similar with that of

Cumulative % Release

80

reference product. Other trials F3b and F3c did not shown

60

satisfactory results. The formulation F3a was kept for

40

stability study where, results of % assay and in vitro

20 dissolution study of stability batch F3a were found to be

0

satisfactory.

0 2 4 6 8 10 12 14 16 18 20 22 24 26

Hence, from above results obtained, it can be

Time (Hr.)

concluded that the formulation F3a (3% coated) showed

better extended release profile of the drug, as compared

Target Profile F3a F3b F3c

Figure 5 Comparative dissolution profiles of batches F3a, with reference product and was also stable after stability

F3b, F3c with Glumet XR study.

Thickness of tablets F3a, F3b and F3c was found REFERENCES

between 6.71 mm to 6.97 mm. The average thickness of 1. A N Nagappa, “Novel strategies for the therapeutic

these formulations was found to be 6.84 mm with deviation management of type-II diabetes,”Health administrator,

±0.017mm.The hardness of the formulations F3a, F3b, and 20, 58-68 (2008).

F3c was found to be 15.3, 19.7 and 21.9 respectively as 2. U.K Prospective Diabetes study group, “Intensive

shown in table 4. Here also, all formulations showed less blood-glucose control with sulphonylurea or insulin

than1% (w/w) friability which was within the prescribed compared with type-II diabetes”, UKPDS 33, Lancet

limits. [18] 352, 837-859 (1998).

The results of the swelling index as shown in Figure 4 3. U.K Prospective Diabetes study group, “Intensive

reveal that the hydration rate and water uptake of the F3a blood-glucose control with Metformin on complications

formulation decrease as compared to core tablets (F3). in over weight patients with type-II diabetes”, UKPDS

Swelling index of the F3b and F3c formulation was 34, Lancet 352, 854-865 (1998).

decreased more as compared to core tablets, which is 4. Bristol Myers Squibb, “Package inserts”,

shown in Figure 4. Hydration rate and water uptake of the Glucophage/Glucophage XR, June (2001).

F3b and F3c formulations was almost similar indicates that, 5. Raghuram Reddy K, Srinivas Mutalik and Srinivas

there was no major effect of coating on swelling index, Reddy,“Once daily sustained Release matrix tablets of

after 3% coating. Nicorandril: Formulation and Invitro Evaluation”,AAPS

Cumulative percentage drug release, which was Pharm Sci Tech, 4(4), 1-9 (2003).

obtained from in-vitro dissolution study of the F3a 6. S Savavanan, KS Nataraj, K Verampalayam and S

formulation showed satisfactory results, and the values of Ganesh,“Hydroxy propyl methyl cellulose based

f2 = 80.29; f1 = 2.87 indicated that, the curves of reference cephalexin extended release tablet: influence of tablet

product and formulation F3a can be considered almost formulation: Hardness and storage on Invitro release

similar, which is shown in Figure5. And the initial burst kinetics”, Chem Pharm Bull, 51(8), 978-983 (2003).

effect was also been suppressed. The drug release data from 7. KEV Nagoji, S Srinivas Rao and ME Bhanoji Rao,

the batches F3a, F3b and F3c are shown in Figure 5. “Release studies of nimesulide from ethyl cellulose and

Cumulative % drug release profile for the formulations F3b hydroxyl propyl methyl cellulose matrices”,Indian J

and F3c was suppressed to higher extent and were similar Pharm Sci, 62(5), 482 – 484 (2000).

with each other. And they did not showed satisfactory 8. KR Rao, P Senapti and MK Das,“Formulation and

results of the curve values, f2 and f1 with reference invivo evaluation of ethyl cellulose microspheres

product. containing Zidovudine”,J Micro encapsule, 22(8), 863-

The regression coefficient (R2) values obtained from 876 (2005).

the log %ARR (Amount Remaining to Release) verses time 9. S Ray, PK Ghosh, B Das, LK Gosh and Gupta

were0.6295, 0.9396 and 0.8673 for zero order, first order BK,“Statistical optimization supported product

and Higuchi model respectively. The value nearer to one development of antiasthamatic multiparticulate drug

indicates first order release for formulation F3a. Results of delivery system”,Ind J Pharm Sci, 62(3), 175-180

stability study carried out on formulation F3a for three (2000).

months indicated that, there was no any significant change 10. United States Pharmacopoeia XXIV NF 19, United

in drug release of the tablet. And % assay results were States Pharmacopoeial Convention, Rockville, 1913-

found within specifications. Hence, the optimized 1914, 2235-2236 (2000).

formulation was stable. 11. L Lachman, HA Liberman andLJ Kanig,Theory and

Practice of Industrial Pharmacy, 67-69, 296-302, 316-

CONCLUSION 318 (1991).

22 | IJPRT | July – September

Gohel et al / International Journal of Pharmacy Research & Technology 2012 2(3) 18-23

12. J Staniforth, ME Aulton, “Powder Flow”, administration” AAPS PharmSciTech, 8(1), E1-E9

Pharmaceutics -The science of dosage form design, (2007).

Churchill livingstone, 198-210 (2002). 16. A Halder, “Preparation and In-vitro evaluation of

13. SC Basak, J Rahman and M Ramlingam,“Design and polystyrene- coated diltiazem-resin complex by oil-in-

In-vitro testing of a floatable gastroretentive tablet of water emulsion solvent evaporation method”,AAPS

metformin hydrochloride”, Pharmazie, 62, 145-148 PharmSciTech 7(2), E1-E8 (2006).

(2007). 17. ICH Topic Q 1 A (R2), Stability Testing of new Drug

14. M Guyot, F Fawaz,“Nifedipine loaded- polymeric Substances and Products, Note for guidance on

microspheres: preparation and physical characteristics”, stability testing: stability testing of new drug substances

Int J Pharm, 175, 61-74 (1998). and products, European Medicines Agency,

15. ST Mathew, SG Devi and KV Sandhya, “Formulation (CPMP/ICH/2736/99), August 2003.

and evaluation of ketorolac tromethamine- loaded 18. L Lachman, HA Liberman and LJ Kanig, Theory and

albumin microspheres for potential intramuscular Practice of Industrial Pharmacy, 67-69, 296-302, 316-

318 (1991).

IJPRT | July – September | 23

Anda mungkin juga menyukai

- Geographical Information Based Crop Yield Prediction Using Machine LearningDokumen11 halamanGeographical Information Based Crop Yield Prediction Using Machine LearningEditor IjprtBelum ada peringkat

- Research 69-73 PDFDokumen5 halamanResearch 69-73 PDFEditor IjprtBelum ada peringkat

- Research 33-36 PDFDokumen4 halamanResearch 33-36 PDFEditor IjprtBelum ada peringkat

- Research 24-27 PDFDokumen4 halamanResearch 24-27 PDFEditor IjprtBelum ada peringkat

- Research 37-41 PDFDokumen5 halamanResearch 37-41 PDFEditor IjprtBelum ada peringkat

- Research 4.2 PDFDokumen5 halamanResearch 4.2 PDFEditor IjprtBelum ada peringkat

- Research 74-81 PDFDokumen8 halamanResearch 74-81 PDFEditor IjprtBelum ada peringkat

- Research 28-32 PDFDokumen5 halamanResearch 28-32 PDFEditor IjprtBelum ada peringkat

- Research 65-68 PDFDokumen4 halamanResearch 65-68 PDFEditor IjprtBelum ada peringkat

- Research 3 PDFDokumen3 halamanResearch 3 PDFEditor IjprtBelum ada peringkat

- Research 5 (1) 5-9 2017 PDFDokumen5 halamanResearch 5 (1) 5-9 2017 PDFEditor IjprtBelum ada peringkat

- Research 1 PDFDokumen5 halamanResearch 1 PDFEditor IjprtBelum ada peringkat

- Research 13-17 PDFDokumen5 halamanResearch 13-17 PDFEditor IjprtBelum ada peringkat

- Research 5 (1) 5-9 2017 PDFDokumen5 halamanResearch 5 (1) 5-9 2017 PDFEditor IjprtBelum ada peringkat

- Research 4.3 PDFDokumen7 halamanResearch 4.3 PDFEditor IjprtBelum ada peringkat

- Research 4.4 PDFDokumen7 halamanResearch 4.4 PDFEditor IjprtBelum ada peringkat

- Research 4.2 PDFDokumen4 halamanResearch 4.2 PDFEditor IjprtBelum ada peringkat

- Review 47-59 PDFDokumen13 halamanReview 47-59 PDFEditor IjprtBelum ada peringkat

- Research 4.5 PDFDokumen6 halamanResearch 4.5 PDFEditor IjprtBelum ada peringkat

- Research 4.3 PDFDokumen5 halamanResearch 4.3 PDFEditor IjprtBelum ada peringkat

- Research 4.1 PDFDokumen4 halamanResearch 4.1 PDFEditor IjprtBelum ada peringkat

- Research 4.1 PDFDokumen6 halamanResearch 4.1 PDFEditor IjprtBelum ada peringkat

- Research 2.5 Final PDFDokumen6 halamanResearch 2.5 Final PDFEditor IjprtBelum ada peringkat

- Research 4.6 PDFDokumen3 halamanResearch 4.6 PDFEditor IjprtBelum ada peringkat

- Research 2.2 Final PDFDokumen7 halamanResearch 2.2 Final PDFEditor IjprtBelum ada peringkat

- Research 2.3 PDFDokumen4 halamanResearch 2.3 PDFEditor IjprtBelum ada peringkat

- Research 2.4 PDFDokumen4 halamanResearch 2.4 PDFEditor IjprtBelum ada peringkat

- Ijprt 5 (1) 1-4 2017 PDFDokumen4 halamanIjprt 5 (1) 1-4 2017 PDFEditor IjprtBelum ada peringkat

- Ijprt 5 (1) 1-4 2017 PDFDokumen4 halamanIjprt 5 (1) 1-4 2017 PDFEditor IjprtBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Wellness RevolutionDokumen4 halamanWellness RevolutionWaqar GhoryBelum ada peringkat

- AnnexD.2 CertificationOfServiceDeliverySupport (Medicines)Dokumen3 halamanAnnexD.2 CertificationOfServiceDeliverySupport (Medicines)Arlyn DapulaBelum ada peringkat

- HPLC Method Development ProtocolDokumen40 halamanHPLC Method Development ProtocolDavid Torres100% (1)

- Avantor Services Overview BrochureDokumen11 halamanAvantor Services Overview BrochureXochitemiqui YoacihualtBelum ada peringkat

- Pharma Bullets NCDokumen6 halamanPharma Bullets NCTed ChrisBelum ada peringkat

- Drug StudyDokumen5 halamanDrug StudyMay Dianne Mansia Bautista100% (1)

- Capsule Filling Machine: GKF 2500 - GKF 2500 ASB - GKF 2500 ASB IPK - GKF 2500 ASB 100 % - GKF 3000Dokumen12 halamanCapsule Filling Machine: GKF 2500 - GKF 2500 ASB - GKF 2500 ASB IPK - GKF 2500 ASB 100 % - GKF 3000Mohammed S.Gouda100% (1)

- Formulation and Evaluation of Darifenacin Hydrobromide Extended Release Matrix TabletsDokumen32 halamanFormulation and Evaluation of Darifenacin Hydrobromide Extended Release Matrix TabletsSyed Abdul Haleem AkmalBelum ada peringkat

- Nerium Oleander Its Application in Basic and ApplDokumen4 halamanNerium Oleander Its Application in Basic and ApplBarc Lucel G. AlcudiaBelum ada peringkat

- Group MembersDokumen28 halamanGroup MembersBlackjack100% (1)

- PV India DCGI Presentation R3Dokumen18 halamanPV India DCGI Presentation R3Arun NairBelum ada peringkat

- Lesson 6 (New) Medication History InterviewDokumen6 halamanLesson 6 (New) Medication History InterviewVincent Joshua TriboBelum ada peringkat

- Six Sigma and Lean Concepts A Novel Approach To Pharmaceutical IndustryDokumen12 halamanSix Sigma and Lean Concepts A Novel Approach To Pharmaceutical IndustryVidyavardhini UshirBelum ada peringkat

- Oral Lichen PlanusDokumen7 halamanOral Lichen Planusdrgurpal74100% (1)

- 8279 - CV Fahmi Aditya Yulvandi New PDFDokumen1 halaman8279 - CV Fahmi Aditya Yulvandi New PDFdolibsBelum ada peringkat

- Continuous Process Technology A Tool ForDokumen8 halamanContinuous Process Technology A Tool ForAmjadRiazBelum ada peringkat

- Chemo Stability Chart - AtoKDokumen59 halamanChemo Stability Chart - AtoKAfifah Nur Diana PutriBelum ada peringkat

- Pharmaceutical Analysis I - TheoryDokumen3 halamanPharmaceutical Analysis I - TheoryHarit0% (1)

- Project Synopsis 123Dokumen3 halamanProject Synopsis 123Goutham KulkarniBelum ada peringkat

- Review Literature 3.1 CrystallizationDokumen67 halamanReview Literature 3.1 CrystallizationI. Murali KrishnaBelum ada peringkat

- Continuous Pharmaceutical Manufacturing: PharmaceuticsDokumen2 halamanContinuous Pharmaceutical Manufacturing: PharmaceuticsneproxenBelum ada peringkat

- Emergency Crash Cart ContentsDokumen15 halamanEmergency Crash Cart ContentsCLaui SagibalBelum ada peringkat

- Design and Characterization of Bilayer Tablet of Rifampicin and Isoniazid For Tuberculosis TherapyDokumen5 halamanDesign and Characterization of Bilayer Tablet of Rifampicin and Isoniazid For Tuberculosis TherapyInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- EthnopharmacognosyDokumen25 halamanEthnopharmacognosyarindam1990100% (3)

- A Study of Consumer Satisfaction Towards Service Quality and Infrastructure in Private General Hospitals of Sri Lanka With Special Reference To Colombo DistrictDokumen226 halamanA Study of Consumer Satisfaction Towards Service Quality and Infrastructure in Private General Hospitals of Sri Lanka With Special Reference To Colombo DistrictImthiyaazHassimBelum ada peringkat

- Packaging Unwrapped 2011Dokumen48 halamanPackaging Unwrapped 2011Guillaume DryBelum ada peringkat

- Indomethacin - Drug InformationDokumen16 halamanIndomethacin - Drug InformationAbraham SarabiaBelum ada peringkat

- Communication and Ethics in Pharmacy Practice: What Is To BeDokumen23 halamanCommunication and Ethics in Pharmacy Practice: What Is To BeMuhammad RezaBelum ada peringkat

- Novo's internationalization strategy through strategic JVs and acquisitionsDokumen3 halamanNovo's internationalization strategy through strategic JVs and acquisitionsAbhishek NayakBelum ada peringkat