API 1104 Acceptance Criteria

Diunggah oleh

Sunday Paul0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

508 tayangan6 halamanAPI 1104 Acceptance Criteria

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOC, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAPI 1104 Acceptance Criteria

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

508 tayangan6 halamanAPI 1104 Acceptance Criteria

Diunggah oleh

Sunday PaulAPI 1104 Acceptance Criteria

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

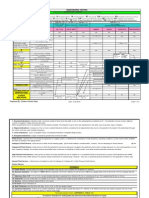

Acceptance Standards for

API 1104 Non-Destructive testing

• The length of an individual indication of IP exceeds

25 mm

• The aggregate length of indications of IP in any

continuous 300 mm length of weld exceeds 25 mm

• The aggregate length of IP exceeds 8% of the weld

length in welds less than 300 mm in length

• The length of an individual indication of IPD

exceeds 50 mm

• The aggregate length of IPD indications exceed 75

mm in a 300 mm length of weld

• The length of an individual indication of ICP

exceeds 50 mm

• The aggregate length of indications of ICP exceeds

50 mm in a length of 300 mm of weld

• The length of an individual indication of IF exceeds

25 mm

• The aggregate length of indications of IF exceeds

25 mm in a length of 300 mm of weld

• The aggregate length of IF exceeds 8% of the weld

length in welds less than 300 mm in length

• The length of an individual indication of IFD

exceeds 50 mm

• The aggregate length of indications of IFD exceeds

50 mm in a 300 mm length of weld

• The aggregate length of IFD exceeds 8% of the

weld length

•

• Any length of internal concavity is acceptable

provided the density of the radiographic image is

not greater than that of the thinnest adjacent parent

material

• For areas which exceed the density of the thinnest

adjacent parent material the criteria for burn

through will apply.

• The maximum dimension exceeds 6 mm and the

density of the BT image exceeds that of the thinnest

adjacent parent material

Burn Through • The maximum dimension exceeds the thinner of the

nominal wall thicknesses joined, and the density of

the BT image exceeds that of the thinnest adjacent

parent material

• A slag inclusion is defined as a non-metallic solid

entrapped in the weld metal or between the weld

metal and the parent material

• Elongated slag inclusions ESI

Slag Inclusions • Continuous or broken slag lines or wagon tracks-

found in fusion zones

• ISI Isolated slag inclusions are of irregular shape

and may be found anywhere in the weld

• The length of an ESI exceeds 50

mm

• The aggregate length of indications

of ESI exceeds 50 mm in a 300 mm

ESI Slag Inclusions length of weld

• The width of an ESI exceeds 1.6

mm

• The aggregate length of the ISI in

any continuous length of 300 mm of

weld exceeds 13 mm.

ISI Slag Inclusions • The width of an ISI indication

exceeds 3 mm

• More than 4 ISI indications with a

maximum width of 3 mm in a

length of 300 mm of weld

• The aggregate length of ESI and ISI

indications exceeds 8% of weld

length

• Porosity is defined as gas trapped

by solidifying weld metal before the

gas has a chance to raise to the

Porosity surface of the molten puddle and

escape.

• Porosity is generally spherical but

may be elongated or irregular shape

such as piping or worm hole

porosity

• The size of a pore is measured by

its maximum dimension

• The size of an individual pore

exceeds 3 mm

• The size of an individual pore

exceeds 25% of the nominal wall

thickness joined

• The distribution of scattered

porosity exceeds the concentration

permitted in Fig 19

• Cluster porosity CP that occurs in

any pass except the finish pass shall

Cluster Porosity comply with the criteria of the

previous slide.

• CP that occurs in the finish pass

shall be considered a defect should

any of the following conditions

exist:

• The diameter of a cluster exceeds

13 mm

• The aggregate length of CP

exceeds. 13 mm in a 300 mm

length of weld

• An individual pore within the

cluster exceeds 2 mm in size.

• HB is defned as elongated porosity

that occurs in the root pass:

• The length of an individual

Hollow Bead Porosity indication exceeds 13 mm

• The aggregate length of HB

exceeds. 50 mm in a 300 mm

length of weld

• Individual indications of HB that

exceed 6 mm

are separated by less than 50 mm

• The aggregate length of all

indications of HB exceeds 8% of

weld length

• Cracks C shall be considered a

defect:

• A crack (C) of any size or location

Cracks in a weld is NOT a shallow crater or

star crack

• A crater or star crack that exceeds 4

mm

( crater cracks are a result of weld metal

contractions during solidification)

• Undercutting is a groove melted

into the parent metal adjacent to the

weld and left unfilled by weld metal

• Undercutting adjacent to the cover

Undercutting pass EU and adjacent to the root

pass IU

• The aggregate length of EU and IU

in any combination in any

continuous 300 mm length of weld

exceeds 50 mm or 1/6th of weld

length

• Excluding incomplete penetration

due –low and undercutting (AI)

shall be considered a defect:

• The aggregate length of indications

Accumulation of imperfections in any continuous 300 mm length of

weld exceeds 50 mm

• The aggregate length of indications

exceed 8% of weld length

Anda mungkin juga menyukai

- API STD1104 acceptance criteria table radiograph discontinuitiesDokumen2 halamanAPI STD1104 acceptance criteria table radiograph discontinuitiesdownloadBelum ada peringkat

- RT Acceptance Para. 9.4Dokumen4 halamanRT Acceptance Para. 9.4Yan Ferizal100% (1)

- Saudi Aramco: Company General UseDokumen8 halamanSaudi Aramco: Company General UseMasudhBashaBelum ada peringkat

- Acceptance Criteria Asme B31 3Dokumen1 halamanAcceptance Criteria Asme B31 3Hadi Allouche100% (9)

- AWS D1.1 Acceptance StandardsDokumen2 halamanAWS D1.1 Acceptance StandardsAlper Çakıroğlu92% (12)

- NDT ACC. CriteriaDokumen6 halamanNDT ACC. CriteriaBalakumar100% (5)

- API 1104 Defects Acceptance Criteria FinalDokumen4 halamanAPI 1104 Defects Acceptance Criteria FinalHendry AriosBelum ada peringkat

- Section Defect Page Welding Imperfections StandardsDokumen4 halamanSection Defect Page Welding Imperfections Standardsjegathesmsjs86% (44)

- ASME B31.3 Acceptance Criteria - Tab 341.3.2ADokumen2 halamanASME B31.3 Acceptance Criteria - Tab 341.3.2Avsnaiduqc90% (21)

- Acceptance Craiteria of API1104, ASME B31.3 and AWS D.1.1Dokumen7 halamanAcceptance Craiteria of API1104, ASME B31.3 and AWS D.1.1MJ Magdy100% (1)

- Acceptance Criteria Radiography Test 2018 PDFDokumen7 halamanAcceptance Criteria Radiography Test 2018 PDFSigit Pratikno100% (1)

- Radiographic Acceptance Criteria: (This Table Contains Maximum Discontinuity Size Allowed)Dokumen7 halamanRadiographic Acceptance Criteria: (This Table Contains Maximum Discontinuity Size Allowed)Alzaki AbdullahBelum ada peringkat

- Asme Viii d1 Ma Appendix 4Dokumen8 halamanAsme Viii d1 Ma Appendix 4Chihiya Fitria Nurhayati100% (1)

- ASME General 100 QuestionsDokumen54 halamanASME General 100 Questionsatulpatil99100% (2)

- Pressure Vessel Exm QuestionsDokumen4 halamanPressure Vessel Exm QuestionsJithuJohn100% (1)

- Aws d1.1 Tubular Vs Non TubularDokumen1 halamanAws d1.1 Tubular Vs Non TubularrendraBelum ada peringkat

- CSWIP 3.2 Course Material For Radiographic InterpretationDokumen52 halamanCSWIP 3.2 Course Material For Radiographic InterpretationSrinivasa100% (7)

- API 1104 Sample QuestionsDokumen12 halamanAPI 1104 Sample QuestionsPatrick Dominguez80% (5)

- RT Acceptance CriteriaDokumen3 halamanRT Acceptance CriteriaAndry Rimanov89% (18)

- API 1104 Acceptance CriteriaDokumen2 halamanAPI 1104 Acceptance CriteriaEngr Arfan Ali Dhamraho79% (14)

- Acceptance Criteria for WeldsDokumen7 halamanAcceptance Criteria for WeldsAnilBelum ada peringkat

- IQI SelectionDokumen1 halamanIQI SelectionVipin PeterBelum ada peringkat

- RT Acceptance CriteriaDokumen3 halamanRT Acceptance CriteriaRanjan Kumar100% (2)

- Welding Inspector Interview QuestionDokumen14 halamanWelding Inspector Interview Questionaravindan100% (21)

- Steps To Be Prepared A PWPS and PQRDokumen9 halamanSteps To Be Prepared A PWPS and PQRAdit Nugraha100% (3)

- EQT ChecklistDokumen5 halamanEQT Checklistvijayachidu100% (1)

- Technical Inquiries To API 1104Dokumen20 halamanTechnical Inquiries To API 1104Rey Fiedacan92% (12)

- Inspection Requirements ASME VIII DIV 1 1673549276Dokumen39 halamanInspection Requirements ASME VIII DIV 1 1673549276Mat Pustjens100% (1)

- Film InterpretationDokumen21 halamanFilm InterpretationEKKACHAI PRABNAKORN100% (3)

- Index: Method Statement For Post Weld Heat TreatmentDokumen8 halamanIndex: Method Statement For Post Weld Heat TreatmentsomiqatarBelum ada peringkat

- ASME SEC V Questions and Answers V2Dokumen18 halamanASME SEC V Questions and Answers V2Ashwani Dogra100% (4)

- API 1104 - UT Acceptance StandardsDokumen5 halamanAPI 1104 - UT Acceptance StandardsABDIELBelum ada peringkat

- API 1104 Defects Acceptance Criteria FinalDokumen9 halamanAPI 1104 Defects Acceptance Criteria Finalazizieh5701Belum ada peringkat

- Acceptance Criteria For NDT (UT, RT, DPT, Visual, MPT)Dokumen5 halamanAcceptance Criteria For NDT (UT, RT, DPT, Visual, MPT)Naveen Kumar75% (4)

- ASME IX Interpretation-Part11Dokumen40 halamanASME IX Interpretation-Part11kevin herryBelum ada peringkat

- CSWIP 3.1 Welding Inspector exam detailsDokumen2 halamanCSWIP 3.1 Welding Inspector exam detailsSalahuddin Farooqui100% (1)

- Evaluation of RadiographDokumen40 halamanEvaluation of Radiographoki karyadi100% (2)

- API 1104 RT Visual Inspection CriteriaDokumen1 halamanAPI 1104 RT Visual Inspection CriteriaMekhman100% (1)

- WPS Api 1104Dokumen85 halamanWPS Api 1104Jose nuñez100% (1)

- RT Acceptance Criteria for Welding Discontinuities in ASME, API and ANSI CodesDokumen1 halamanRT Acceptance Criteria for Welding Discontinuities in ASME, API and ANSI CodesEr Md AamirBelum ada peringkat

- Duplex Ss WPSDokumen8 halamanDuplex Ss WPSVinu Raveendran100% (1)

- Temper Bead Welding WPS and PQRDokumen27 halamanTemper Bead Welding WPS and PQRSandeep Parmar100% (3)

- Class III & IV Medical Device RegulationsDokumen2 halamanClass III & IV Medical Device RegulationsBiju_PottayilBelum ada peringkat

- AWS D1.1 Acceptance CriteriaDokumen9 halamanAWS D1.1 Acceptance CriteriaNguyễn Giang Nam100% (1)

- Solved Paper On Section IxDokumen25 halamanSolved Paper On Section IxNasir Javed90% (20)

- WPS PDFDokumen1 halamanWPS PDFSarah DeanBelum ada peringkat

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- 1104 Acceptance Criteria For NDTDokumen6 halaman1104 Acceptance Criteria For NDTMd faizan AlamBelum ada peringkat

- API 1104 Welding Defect GuideDokumen48 halamanAPI 1104 Welding Defect GuidesbmmlaBelum ada peringkat

- VT Specific Level-II Question Paper AWS D1.1Dokumen44 halamanVT Specific Level-II Question Paper AWS D1.1CheeragBelum ada peringkat

- NDT AcceptanceDokumen62 halamanNDT Acceptancebommakanti srinivasBelum ada peringkat

- AWS D1.i/Di.iM:2010 Clause 6 inspection criteriaDokumen1 halamanAWS D1.i/Di.iM:2010 Clause 6 inspection criteriagigiphi75% (8)

- Din 2440-1978 EngDokumen2 halamanDin 2440-1978 EngalsonccyBelum ada peringkat

- Welded FinDokumen7 halamanWelded FinNatarajan RavisankarBelum ada peringkat

- Tech 6Dokumen8 halamanTech 6PraviBeetlesBelum ada peringkat

- Aduo - Ro 34622 34622 Metal4Dokumen28 halamanAduo - Ro 34622 34622 Metal4Calin AlexandruBelum ada peringkat

- Technical Terms About ReinforcementDokumen13 halamanTechnical Terms About ReinforcementRemo DahalBelum ada peringkat

- NDT-Acceptance Various CodesDokumen17 halamanNDT-Acceptance Various CodesShanmuga NavaneethanBelum ada peringkat

- Acceptance CriteriaDokumen19 halamanAcceptance CriteriaAnonymous 5iv0i3cZBelum ada peringkat

- HSFG Bolts RNGDokumen34 halamanHSFG Bolts RNGSANDEEP DANGDABelum ada peringkat

- Residence Time Distribution Applications: 7.1. Major TargetsDokumen66 halamanResidence Time Distribution Applications: 7.1. Major TargetsWillykateKairuBelum ada peringkat

- System Model H (T) Inlet E (T) Outlet E H (T) System Model H (T) Inlet E (T) Outlet E H (T)Dokumen19 halamanSystem Model H (T) Inlet E (T) Outlet E H (T) System Model H (T) Inlet E (T) Outlet E H (T)WillykateKairuBelum ada peringkat

- Module 3Dokumen8 halamanModule 3WillykateKairuBelum ada peringkat

- Module 4Dokumen7 halamanModule 4WillykateKairuBelum ada peringkat

- Application For NDTS MembershipDokumen3 halamanApplication For NDTS MembershipWillykateKairuBelum ada peringkat

- 256 X 256 SinoDokumen96 halaman256 X 256 SinoWillykateKairuBelum ada peringkat

- Sample B 256x256Dokumen96 halamanSample B 256x256WillykateKairuBelum ada peringkat

- Residence Time DistributionDokumen13 halamanResidence Time DistributionWillykateKairuBelum ada peringkat

- RTD Treatment and Modeling: 5.1. Calculation of MomentsDokumen15 halamanRTD Treatment and Modeling: 5.1. Calculation of MomentsWillykateKairuBelum ada peringkat

- Planning and Execution of A Radiotracer ExperimentDokumen5 halamanPlanning and Execution of A Radiotracer ExperimentWillykateKairuBelum ada peringkat

- Atte RebarConcreteDokumen17 halamanAtte RebarConcreteWillykateKairuBelum ada peringkat

- Tensile Test DataDokumen2 halamanTensile Test DataWillykateKairuBelum ada peringkat

- Module 2Dokumen15 halamanModule 2WillykateKairuBelum ada peringkat

- Radioactivity in Surface Soils Around The ProposedDokumen5 halamanRadioactivity in Surface Soils Around The ProposedWillykateKairuBelum ada peringkat

- Sino TransposeDokumen72 halamanSino TransposeWillykateKairuBelum ada peringkat

- Mechanical PropertiesDokumen72 halamanMechanical PropertiesWillykateKairuBelum ada peringkat

- Tensile Test DataDokumen2 halamanTensile Test DataWillykateKairuBelum ada peringkat

- Rebound Hammer and Ultrasonic Tests 31 ST OctoberDokumen27 halamanRebound Hammer and Ultrasonic Tests 31 ST OctoberWillykateKairuBelum ada peringkat

- Tensile Test Data (Recovered)Dokumen2 halamanTensile Test Data (Recovered)WillykateKairuBelum ada peringkat

- Introduction To NDTDokumen52 halamanIntroduction To NDTWillykateKairuBelum ada peringkat

- ME6800 Finite Element Analysis - Assignment 1: Prof. Parag Ravindran and Prof. Narasimhan Swaminathan July 31, 2017Dokumen1 halamanME6800 Finite Element Analysis - Assignment 1: Prof. Parag Ravindran and Prof. Narasimhan Swaminathan July 31, 2017WillykateKairuBelum ada peringkat

- Mechanical PropertiesDokumen72 halamanMechanical PropertiesWillykateKairuBelum ada peringkat

- Solution Question 3 PDFDokumen3 halamanSolution Question 3 PDFWillykateKairuBelum ada peringkat

- Finite Element Analysis AssignmentDokumen20 halamanFinite Element Analysis AssignmentWillykateKairuBelum ada peringkat

- Module 4Dokumen17 halamanModule 4WillykateKairuBelum ada peringkat

- Protocol for Gamma Scanning Industrial Process ColumnsDokumen16 halamanProtocol for Gamma Scanning Industrial Process ColumnsWillykateKairuBelum ada peringkat

- 20170413140749population HistoricDokumen8 halaman20170413140749population HistoricWillykateKairuBelum ada peringkat

- Residence Time DistributionDokumen13 halamanResidence Time DistributionWillykateKairuBelum ada peringkat

- 1st African Nuclear Summit-BrochureDokumen2 halaman1st African Nuclear Summit-BrochureWillykateKairuBelum ada peringkat

- DAC Curve ASME Blocks PDFDokumen1 halamanDAC Curve ASME Blocks PDFWillykateKairuBelum ada peringkat

- Fitness, Sports and Recreation Leadership: Quarter 3 - Module 1Dokumen29 halamanFitness, Sports and Recreation Leadership: Quarter 3 - Module 1Elvin Sajulla BulalongBelum ada peringkat

- Vehicles by Country ListDokumen6 halamanVehicles by Country Listkevin lassBelum ada peringkat

- PGW Customer Handbook 2017Dokumen28 halamanPGW Customer Handbook 2017Terry HaynesBelum ada peringkat

- MW3 HT vs. PowerDokumen5 halamanMW3 HT vs. Powergerencia procesos especialesBelum ada peringkat

- Week 1-12 StatisticsDokumen84 halamanWeek 1-12 StatisticsDhruvBelum ada peringkat

- Corporate Law Object ClauseDokumen34 halamanCorporate Law Object ClausedaariyakBelum ada peringkat

- Active AntennasDokumen5 halamanActive AntennasGöestaf ZarBelum ada peringkat

- List of Premier Green Building ConsultantsDokumen4 halamanList of Premier Green Building ConsultantsJahanvi ModiBelum ada peringkat

- B737-Flight Controls Systems SummaryDokumen24 halamanB737-Flight Controls Systems SummaryTrailblazer487100% (1)

- MIESDokumen4 halamanMIESSumit YadavBelum ada peringkat

- HP Color Laserjet Managed MFP E77825Dn: DatasheetDokumen4 halamanHP Color Laserjet Managed MFP E77825Dn: Datasheetmolik1Belum ada peringkat

- Caso de Estudio DukeDokumen75 halamanCaso de Estudio DukeFernando MirandaBelum ada peringkat

- Elliott Wave Guide to Pattern Recognition and Fibonacci ApplicationsDokumen55 halamanElliott Wave Guide to Pattern Recognition and Fibonacci ApplicationsAM PM100% (1)

- A300 600Dokumen2 halamanA300 600NadeemBelum ada peringkat

- 3.DOL Starter Three PhaseDokumen6 halaman3.DOL Starter Three PhaseMuhamad ReduanBelum ada peringkat

- Company ProfileDokumen12 halamanCompany ProfileDin Hua KuiBelum ada peringkat

- Overview of The Applications of Thermodynamic Databases To Steelmaking ProcessesDokumen31 halamanOverview of The Applications of Thermodynamic Databases To Steelmaking ProcessesakshukBelum ada peringkat

- Paper18b PDFDokumen47 halamanPaper18b PDFAnonymous SgD5u8R100% (1)

- Discussion Forum Unit 1Dokumen2 halamanDiscussion Forum Unit 1Samurawi Hailemariam100% (1)

- Distributor and Manufacturer of ClothDokumen8 halamanDistributor and Manufacturer of ClothKapil GajbhiyeBelum ada peringkat

- Implement Algorithms for Sorting, Graphs, Dynamic Programming & BacktrackingDokumen2 halamanImplement Algorithms for Sorting, Graphs, Dynamic Programming & BacktrackingsanjeevkunteBelum ada peringkat

- Vertical Shaft Flocculator - BrochureDokumen8 halamanVertical Shaft Flocculator - BrochureLTE002Belum ada peringkat

- 2013 Maharastra DroughtDokumen8 halaman2013 Maharastra Droughtdaniyal rasheedBelum ada peringkat

- Heating curve graph for benzeneDokumen2 halamanHeating curve graph for benzeneBluematwo TwoBelum ada peringkat

- Solved Using A Contents Search in Intelliconnect S Standard Federal Tax ReporterDokumen1 halamanSolved Using A Contents Search in Intelliconnect S Standard Federal Tax ReporterAnbu jaromiaBelum ada peringkat

- PRINCIPLE OF SUPERPOSITION - Lecture - 6 (Autosaved)Dokumen24 halamanPRINCIPLE OF SUPERPOSITION - Lecture - 6 (Autosaved)Theo AnkamahBelum ada peringkat

- Electrical Energy and Current: Additional Practice DDokumen4 halamanElectrical Energy and Current: Additional Practice DMona Mohamed SafwatBelum ada peringkat

- Holt Accounting & Tax: Poor Accounting Quality, Debt & Intangibles, and PensionsDokumen4 halamanHolt Accounting & Tax: Poor Accounting Quality, Debt & Intangibles, and PensionsWira WijayaBelum ada peringkat

- Nebosh IGC2 Part 4Dokumen54 halamanNebosh IGC2 Part 4MuhammadAkram50% (2)

- Synthesizing AspirinDokumen4 halamanSynthesizing AspirinSiddharth NagarajBelum ada peringkat