1260709146e - Hydraulics PDF

Diunggah oleh

Abdul Hameed OmarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1260709146e - Hydraulics PDF

Diunggah oleh

Abdul Hameed OmarHak Cipta:

Format Tersedia

E – HYDRAULICS

Clickable list

(Use the hierarchical list under "Bookmarks" to access individual tables and/or sub-topics)

Nomenclature E-1

Pump outputs E-2

Optimum bit hydraulics E-3

Nozzle sizes & flow areas E-4

Hole cleaning E-5

Slip velocities E-6

Miscellaneous equations (1) E-7

Miscellaneous equations (2) E-8

SIEP: Well Engineers Notebook, Edition 4, May 2003 E–i

NOMENCLATURE

The following are the symbols and units used in this Section, except where otherwise

noted : Units

Field SI

An = total area of bit nozzles inches2 mm2

C = coefficient of QN in equation for ∆Ps - -

Dh = diameter of hole inches mm

Dp = diameter of drillpipe inches mm

D1 = small diameter inches mm

D2 = large diameter inches mm

D = inside diameter (conduit or pump liner) inches mm

dc = chip diameter or greatest dimension inches mm

HHPt = total hydraulic horsepower hp kW

HHPs = hydraulic horsepower expended in system hp kW

HHPb = hydraulic horsepower expended at bit hp kW

IF = jet impact force lbs N

J = nozzle size (e.g. 12, 14 etc.) J/ " mm

32

L = length of conduit ft m

or length of pump stroke inches mm

N = exponent of Q in equation giving ∆Ps - -

P1 = surface pressure losses psi kPa

∆P = pressure drop psi kPa

∆Pt = total pressure drop psi kPa

(or pump discharge pressure)

∆Ps = pressure drop in system psi kPa

∆Pb = pressure drop across bit nozzles psi kPa

PV = plastic viscosity cp cp

Q = flow rate galls/min dm3/min

Rn = Reynold's number - -

Va = annular velocity ft/min m/min

Vp = velocity of fluid inside circular pipe ft/min m/min

Vs = slip velocity ft/min m/min

Vc = critical velocity ft/min m/min

Vn = jet velocity ft/sec m/sec

YP = yield point lbs/100ft2 lbs/100ft2

µ = effective viscosity cp cp

ρdf = pressure gradient of drilling fluid psi/ft kPa/m

ρc = pressure gradient of cuttings psi/ft kPa/m

(usually sg = 2.51)

Note: nozzle sizes are given as numbers (e.g. 12,14, etc.) meaning

in fact 12/32", 14/32", x/32", etc.

SIEP: Well Engineers Notebook, Edition 4, May 2003 E–1

PUMP OUTPUTS

Double Acting Duplex Pump

gal/min = 0.00679 x

bbl/min = 0.000162 x

L x (2D2 - d2) x SPM x fractional volumetric efficiency

ft3/min = 0.000909 x

L/min = 0.0257 x

Single Acting Triplex Pump

gal/min = 0.01020 x

bbl/min = 0.000243 x

L x D2 x SPM x fractional volumetric efficiency

ft3/min = 0.001364 x

L/min = 0.0386 x

All of the above equations are valid when the pump sizes are specified in inches, as is

normally the case even on rigs where SI units are standard.

When dimensions are quoted in millimetres the applicable equations to obtain the

output in SI units are :

Double Acting Duplex Pump

L/min = 1.568 x 10-6 x L x (2D2 - d2) x SPM x fractional volumetric efficiency

Single Acting Triplex Pump

L/min = 2.355 x 10-6 x L x D2 x SPM x fractional volumetric efficiency

Note :

In pump calculations a “stroke” actually means one rotation of the pump crank. Thus a

triplex pump for example will deliver three piston pumping actions per stroke.

E–2 SIEP: Well Engineers Notebook, Edition 4, May 2003

OPTIMUM BIT HYDRAULICS

Two approaches can be used - either to optimise the bit hydraulic horsepower, which

will occur when ∆Pb is approximately equal to 2/3 ∆Pt , or to optimise the jet impact

force, which will occur when ∆Pb is approximately equal to 1/2 ∆Pt. Nozzles can then be

chosen to achieve the required result.

Note that the relationships quoted above are approximate and are presented to give a

feeling for the order of magnitude of the values required. For a more accurate estimate

of the required Pb the properties of the drilling fluid need to be taken into account - in

this case the parameters C and N in the equation ∆Ps = C.QN. The procedure below

shows how to determine these, and how to apply them to calculate the optimum nozzle

sizes corresponding to each approach.

Note also, however, that the optimisation of bit hydraulics is often compromised by

other hydraulic requirements such as hole cleaning requirements and the pressure

drops / flowrate restrictions associated with certain pieces of downhole equipment.

In the approximations given above N has been taken as 2 for simplicity; however until a

better value has been determined, as follows, it is recommended to use 1.82 in

calculations.

Prior to pulling out of hole to change bit, determine the following:

1. Total Pressure Drop (∆Pt)

Observe ∆Pt for two or three different pump outputs (Q), preferably close to the rate

used when drilling.

2. N & C values

a) Find the bit pressure drop (∆Pb) for different values of Q

Field units SI units

ρdf x Q2 15.7 x ρdf x Q2

∆Pb = ∆Pb =

564 x An2 An2

b) Find the system pressure drop (∆Ps) for different values of Q

∆Ps = ∆Pt - ∆Pb

∆Ps1

Log

∆Ps2 ∆Ps1 ∆Ps2

N= and C = =

Q Q1N Q2N

Log 1

Q2

∆Ps = C.QN

3. Nozzle area (An) for optimum use of available power

a) Pt (max) should be known

b) Find system pressure drop (∆Ps)

SIEP: Well Engineers Notebook, Edition 4, May 2003 E–3

Pt

To optimise Bit Hydraulic Horsepower - ∆Ps =

N+1

2Pt

To optimise Jet Impact Force - ∆Ps =

N+2

(∆P

1/N

c) Find pump output to give ∆Ps

C )

- Qopt = s

d) Find available bit pressure drop - ∆Pb = Pt - ∆Ps

so,

Field units SI units

Qopt ρdf ρdf

An = An = 3.962.Qopt

23.75 ∆Pb ∆Pb

Nozzle sizes and flow areas

Nozzle Nozzle Flow area Flow area Flow area

size number of 1 nozzle of 2 nozzles of 3 nozzles

In mm Inch2 mm2 inch2 mm2 inch2 mm2

7/32 5.5 7 0.0376 24.3 0.0752 48.5 0.1127 72.7

1/4 6.4 8 0.0491 31.7 0.0982 63.4 0.1473 95.0

9/32 7.1 9 0.0621 40.1 0.1242 80.1 0.1864 120.2

5/16 7.9 10 0.0767 49.5 0.1534 99.0 0.2301 148.4

11/32 8.7 11 0.0928 59.9 0.1856 119.7 0.2784 179.6

3/8 9.5 12 0.1104 71.2 0.2209 142.5 0.3313 213.7

13/32 10.2 13 0.1296 83.6 0.2592 167.2 0.3889 250.9

7/16 11.1 14 0.1503 97.0 0.3007 194.0 0.4510 291.0

15/32 11.9 15 0.1726 111.4 0.3451 222.6 0.5177 334.0

1/2 12.7 16 0.1963 126.6 0.3927 253.4 0.5890 380.0

9/16 14.3 18 0.2485 160.3 0.4970 320.6 0.7455 481.0

5/8 15.9 20 0.3068 197.9 0.6136 395.9 0.9204 593.8

11/16 17.5 22 0.3712 239.5 0.7424 479.0 1.1137 718.5

3/4 19.0 24 0.4418 285.0 0.8836 570.1 1.3254 855.2

7/8 22.3 28 0.6013 287.9 1.2026 775.9 1.8040 1163.9

E–4 SIEP: Well Engineers Notebook, Edition 4, May 2003

HOLE CLEANING

Insufficient hole cleaning is a common cause of stuck pipe especially in deviated wells.

Good hole cleaning depends on the properties of the drilling fluid, the flow rate of the

drilling fluid and the procedures used. The ABC of Stuck Pipe, Supplement 2, Hole

Cleaning (EP94-1908) is a useful reference on this subject.

Remember ;

• Holes between 30 and 60 degrees inclination are the hardest to clean due to the

formation of unstable solids beds on the low side of the hole. These unstable beds

can “avalanche” down the hole.

• At greater than 60 degrees inclination stable beds form which are very difficult to

remove without some mechanical action. Pipe rotation is ideal for this even when

only slow rotation is possible.

• If no other guide to the minimum annular velocity is available, then a rule of thumb

is to try to maintain a minimum of 45 m/minute. The best guide to hole cleaning is

what you see on the weight indicator and shakers.

• Balanced combination pills are very effective for sweeping the hole. A low viscosity

low density pill is followed by a high viscosity high density (ca 2 kPa/m over the

existing fluid gradient) pill. Pumping must be continuous while the pills are in the

hole. Make sure the low density pill does not underbalance the well at any stage

(eg when opposite the BHA).

• If possible rotate and reciprocate the string while circulating clean. The reciproca-

tion stroke should be greater than the length of a single to avoid building ridges on

the low side of the hole.

• Solids beds move up the hole far slower than the fluid velocity in the middle of the

largest part of the annular space, perhaps 3 to 5 times slower. This means that

extra circulating time is needed when cleaning the hole.

• Initial overpull when tripping should be limited to 10 to 15 kdaN (no rotation or circu-

lation) if a hole cleaning problem is suspected. If this limit is reached more hole

cleaning should be considered prior to pullingout of hole.

• Good drag charts are essential for spotting problems early.

A set of equations are presented on the next page that can be used to estimate the slip

velocity of cuttings under different circumstances. It is recommended that slip velocity

should be less than half the annular velocity (averaged across the cross-section).

SIEP: Well Engineers Notebook, Edition 4, May 2003 E–5

SLIP VELOCITIES

Turbulent flow - spherical chips

dc(ρc - ρdf) Where K = 9.41 for SI units and 156 for field units

Vs = K

ρdf

Turbulent flow - flat chips

dc(ρc - ρdf) Where K = 3.66 for SI units and 60.6 for field units

Vs = K

ρdf

Laminar flow - spherical chips

Kdc2(ρc - ρdf) Where K = 75.0 for SI units and 160,000 for field units

Vs =

µ (see below for the value of µ)

Laminar flow - flat chips

Kdc2(ρc - ρdf) Where K = 29.1 for SI units and 62,100 for field units

Vs =

µ (see below for the value of µ)

The value of µ in the laminar flow equations is given by :

K.YP(Dh - Dp) Where K = 4.79 for SI units and 399 for field units

µ = PV +

Va

E–6 SIEP: Well Engineers Notebook, Edition 4, May 2003

MISCELLANEOUS EQUATIONS (1)

Pump output to give annular velocity

(D 2 - Dp2) Where K = 1,270 for SI units and 24.5 for field units

Q = Va h

K

Fluid velocity inside pipe

Where K = 1,270 for SI units and 24.5 for field units

Vp = KQ

D2

Fluid velocity in annulus

KQ Where K = 1,270 for SI units and 24.5 for field units

Va =

(D22 - D12)

Critical velocity inside pipe (RN = 2,000)

K1(PV + PV2 + (K2 x D2 x YP x ρdf))

Vc =

ρdf x D

Where K1 = 588 for SI units and 3.36 for field units

and K2 = 0.0163 for SI units and 238 for field units

Critical velocity in annulus (RN = 2,000)

K1(PV + PV2 + (K2 x (D2 - D1)2 x YP x ρdf))

Vc =

ρdf x (D2 - D1)

Where K1 = 588 for SI units and 3.36 for field units

and K2 = 0.0122 for SI units and 179 for field units

Compare Vc with Va or Vp for each section of the annulus, drill string and surface

equipment, thus determining whether flow is laminar or turbulent.

Pressure losses in system (Equations are those used for Hydraulic Slide Rules)

Turbulent flow in a circular pipe :

K x Q1.82 x ρdf0.82 x PV0.18 x L

∆P =

D4.82

Where K = 794 for SI units and 8.65 x 10-4 for field units

Turbulent flow in an annulus :

K x Q1.82 x ρdf0.82 x PV0.18 x L

∆P =

(D2 - D1)3 x (D2 + D1)1.82

Where K = 794 for SI units and 8.65 x 10-4 for field units

Laminar flow in a circular pipe :

L.YP L.PV.Vp Where K1 = 0.392 for SI units and 225 for field units

∆P = +

K1.D K2.D2 and K2 = 1.88 for SI units and 90,000 for field units

Laminar flow in an annulus :

L.YP + L.PV.Va Where K1 & K2 are as for the previous

∆P =

K1(D2 - D1) K2(D2 - D1)2 equation

Repeat for all sections of annulus, drill string and surface equipment

SIEP: Well Engineers Notebook, Edition 4, May 2003 E–7

MISCELLANEOUS EQUATIONS (2)

Bit pressure drop available

∆Pb = ∆Pt - ∆Ps or HHPb = HHPt - HHPs

where HHPt is the input horsepower x the mechanical efficiency of the pump

HHP = ∆P x Q Where K = 60,000 for SI units and 1,714 for field units

K Note: ∆Pt could be limited (2,000-2,500 kPa/3,000-3,500 psi)

Nozzle area to produce ∆Pb

ρdf Where K = 3.96 for SI units and 0.0421 for field units

An = K.Q

∆Pb

K2.Q2.ρdf

therefore : ∆Pb =

An2

Jet velocity

Where K = 16.7 for SI units and 0.32 for field units

Vn = K.Q

An

Jet impact force

K.Q2.ρdf Where K = 0.0283 for SI units and 0.0032 for field units

IF =

An

Surface connection losses (P1)

P1 = Eρ0.8Q1.8(PV)0.2

where E is a constant depending on the type of surface equipment and units used

Surface Value of E

equipment

type Field units SI units

1 2.7 x 10-3 1.4 x 10-4

2 1.0 x 10-3 5.3 x 10-5

3 5.6 x 10-4 2.9 x 10-5

4 4.5 x 10-4 2.3 x 10-5

Surface Standpipe Rotary hose Swivel Kelly

equipment Length ID Length ID Length ID Length ID

type ft m ins mm ft m ins mm ft m ins mm ft m ins mm

1 40 12.19 3.0 76.2 45 13.72 2.0 50.8 4 1.22 2.0 50.8 40 12.19 2.25 57.2

2 40 12.19 3.5 88.9 55 16.76 2.5 63.5 5 1.52 2.5 63.5 40 12.19 3.25 82.6

3 45 13.72 4.0 101.6 55 16.76 3.0 76.2 5 1.52 2.5 63.5 40 12.19 3.25 82.6

4 45 13.72 4.0 101.6 55 16.76 3.0 76.2 6 1.83 3.0 76.2 40 12.19 4.00 101.6

E–8 SIEP: Well Engineers Notebook, Edition 4, May 2003

Anda mungkin juga menyukai

- CH 4 Drilling HydraulicsDokumen71 halamanCH 4 Drilling HydraulicsSaravin Selhvadurai100% (1)

- Clickable List: E - HydraulicsDokumen9 halamanClickable List: E - Hydraulicssaeed65Belum ada peringkat

- Part 1Dokumen13 halamanPart 1Ahmed HassanBelum ada peringkat

- Calculations - Guidlines For Control Valve Sizing - SelectionDokumen40 halamanCalculations - Guidlines For Control Valve Sizing - SelectionShubham KeniBelum ada peringkat

- Line SizingDokumen20 halamanLine SizingAhmed HassanBelum ada peringkat

- Drilling Hydraulics ADokumen63 halamanDrilling Hydraulics Asryn89100% (3)

- Air Comperssor Test Rig ReciprocatingDokumen4 halamanAir Comperssor Test Rig ReciprocatingShashank pBelum ada peringkat

- Ejectors and Jet Pumps - Design and Perfo 2Dokumen101 halamanEjectors and Jet Pumps - Design and Perfo 2rezarossBelum ada peringkat

- Section 5B Rheology & HydraulicsDokumen10 halamanSection 5B Rheology & HydraulicsLazharBelum ada peringkat

- GPSA Engineering Data Book 14th Edition compressor calculationsDokumen40 halamanGPSA Engineering Data Book 14th Edition compressor calculationsEstuardo Javier Gan RodríguezBelum ada peringkat

- Formula SheetDokumen4 halamanFormula SheetAlbertoBila100% (1)

- Directional Drilling CalcuationsDokumen43 halamanDirectional Drilling CalcuationsNourden Al100% (1)

- Taking Up A Characteristic of A Centrifugal Compressor With An Adjustable Inlet Guide GridDokumen21 halamanTaking Up A Characteristic of A Centrifugal Compressor With An Adjustable Inlet Guide GridJIGAR SURA100% (3)

- Actuators: Version 2 EE IIT, Kharagpur 1Dokumen30 halamanActuators: Version 2 EE IIT, Kharagpur 1Khaled MahranBelum ada peringkat

- Actuators: Version 2 EE IIT, Kharagpur 1Dokumen30 halamanActuators: Version 2 EE IIT, Kharagpur 1Khaled MahranBelum ada peringkat

- Air Compressor Test Rig Foot Mounted MotorDokumen5 halamanAir Compressor Test Rig Foot Mounted MotorTinku SharmaBelum ada peringkat

- Variable Parameters and Design of Fluid MachinesDokumen27 halamanVariable Parameters and Design of Fluid MachinesJay PatelBelum ada peringkat

- Drilling Bits: and HydraulicsotimizationDokumen52 halamanDrilling Bits: and HydraulicsotimizationMustafa FoudaBelum ada peringkat

- Line sizing calculations made easyDokumen28 halamanLine sizing calculations made easyAhmed HassanBelum ada peringkat

- Compressed Air Pipe Lines - Online Pressure Drop CalculatorDokumen3 halamanCompressed Air Pipe Lines - Online Pressure Drop CalculatorJesús MontañoBelum ada peringkat

- Determine Heat LoadDokumen3 halamanDetermine Heat LoadBhawani Pratap Singh PanwarBelum ada peringkat

- Department of Mechanical, Energy and Industrial Engineering MECE 521: Design of Thermal SystemsDokumen11 halamanDepartment of Mechanical, Energy and Industrial Engineering MECE 521: Design of Thermal SystemsThebe Tshepiso MaitshokoBelum ada peringkat

- Cement Fluid Flow GuideDokumen10 halamanCement Fluid Flow GuideHasnaoui SamirBelum ada peringkat

- L2. Sewer Hydraulics: The Islamic University of Gaza-Civil Engineering Department Sanitary Engineering - ECIV 4325Dokumen13 halamanL2. Sewer Hydraulics: The Islamic University of Gaza-Civil Engineering Department Sanitary Engineering - ECIV 4325ThierryBelum ada peringkat

- Lecture 2. Sewer Hydraulics1 PDFDokumen13 halamanLecture 2. Sewer Hydraulics1 PDFkumarsathishsBelum ada peringkat

- Smacna Duct Designfundamentals PDFDokumen151 halamanSmacna Duct Designfundamentals PDFandi nainggolan100% (1)

- Hd-54 Single Stage Air CompressorDokumen8 halamanHd-54 Single Stage Air CompressorErGiteshAroraBelum ada peringkat

- CE202 2020 HM Part III SlidesDokumen50 halamanCE202 2020 HM Part III SlidesVisal PiscelBelum ada peringkat

- Pressure Drop CalculationsDokumen28 halamanPressure Drop Calculationshicham100% (2)

- Control valve sizing handbookDokumen21 halamanControl valve sizing handbooktiwarishailendra2198Belum ada peringkat

- Jet Bit Nozzle Size SelectionDokumen46 halamanJet Bit Nozzle Size SelectionBharat BhattaraiBelum ada peringkat

- BV Calculation Sheet - RADokumen6 halamanBV Calculation Sheet - RAKrishnamoorthyBelum ada peringkat

- NPSH and Head Calculation SamplesDokumen40 halamanNPSH and Head Calculation SamplesArjonaJoséBelum ada peringkat

- 14 Jet Bit Nozzle Size SelectionDokumen46 halaman14 Jet Bit Nozzle Size Selectiontotos20100% (2)

- CB Design OptimisationDokumen12 halamanCB Design OptimisationmBelum ada peringkat

- 1 - Fluid Mechanics Takehome Project AssignmentDokumen4 halaman1 - Fluid Mechanics Takehome Project Assignmentazeem sheikhBelum ada peringkat

- Gas Compression IDokumen18 halamanGas Compression IwahyuBelum ada peringkat

- Flow MeasurementDokumen81 halamanFlow MeasurementmohamedBelum ada peringkat

- A Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFDokumen12 halamanA Spreadsheet Program For The Calculation of Piping Systems and The Selection of Pumps PDFtebo8teboBelum ada peringkat

- 02 Drill Bit Hydraulics CalculationsDokumen61 halaman02 Drill Bit Hydraulics CalculationsArkhatTompakovBelum ada peringkat

- Flujo de FluidosDokumen72 halamanFlujo de Fluidosmolimoli1981Belum ada peringkat

- 02-Gas Compression Fundamentals-1Dokumen47 halaman02-Gas Compression Fundamentals-1Muhammad Asad100% (1)

- AGA-3 Orifice - DocDokumen4 halamanAGA-3 Orifice - Docsuci wulandariBelum ada peringkat

- Rotary Screw Compressor Discussion and Calculations: NotesDokumen9 halamanRotary Screw Compressor Discussion and Calculations: Notesfarshad100% (2)

- WT&D (Optimization of WDS) PDFDokumen89 halamanWT&D (Optimization of WDS) PDFAbirham TilahunBelum ada peringkat

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Handbook of Heating, Ventilating and Air ConditioningDari EverandHandbook of Heating, Ventilating and Air ConditioningPenilaian: 4 dari 5 bintang4/5 (6)

- Southern Marine Engineering Desk Reference: Second Edition Volume IDari EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IBelum ada peringkat

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDari EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsBelum ada peringkat

- Combinatorial Algorithms: For Computers and CalculatorsDari EverandCombinatorial Algorithms: For Computers and CalculatorsPenilaian: 4 dari 5 bintang4/5 (2)

- 10 - Simple Mud Engineerv1.22Dokumen2 halaman10 - Simple Mud Engineerv1.22Abdul Hameed OmarBelum ada peringkat

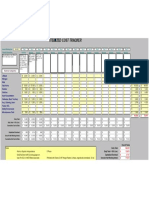

- Itemized Cost Tracker for Offshore Well WorkDokumen1 halamanItemized Cost Tracker for Offshore Well WorkAbdul Hameed OmarBelum ada peringkat

- Data Input Sheet: A Worksheet From Well Control TOOLKIT - .Dokumen4 halamanData Input Sheet: A Worksheet From Well Control TOOLKIT - .Abdul Hameed OmarBelum ada peringkat

- 1260709465flow Back Test RecordDokumen2 halaman1260709465flow Back Test RecordAbdul Hameed OmarBelum ada peringkat

- 08 - BASIC MUD REPORTv1.5Dokumen21 halaman08 - BASIC MUD REPORTv1.5Abdul Hameed OmarBelum ada peringkat

- 16dti (EDocFind - Com)Dokumen2 halaman16dti (EDocFind - Com)Abdul Hameed OmarBelum ada peringkat

- Hydraulic Calculations MudpumpDokumen1 halamanHydraulic Calculations MudpumpSudish BhatBelum ada peringkat

- 39 - Buckling & Wellhead Load After CementingDokumen2 halaman39 - Buckling & Wellhead Load After CementingAbdul Hameed OmarBelum ada peringkat

- WBM Report RECAP wbmDokumen22 halamanWBM Report RECAP wbmAbdul Hameed OmarBelum ada peringkat

- Assortment of Mini ApplicationsDokumen1 halamanAssortment of Mini ApplicationsAbdul Hameed OmarBelum ada peringkat

- Well Control Kill Sheet (Low Angle Wells) : Drillstring Volume Annular Volume (BBLS) (BBLS)Dokumen2 halamanWell Control Kill Sheet (Low Angle Wells) : Drillstring Volume Annular Volume (BBLS) (BBLS)khaledBelum ada peringkat

- Well lubricate and bleed procedure documentDokumen1 halamanWell lubricate and bleed procedure documentAbdul Hameed OmarBelum ada peringkat

- BOP stack and accumulator volumesDokumen4 halamanBOP stack and accumulator volumesAbdul Hameed OmarBelum ada peringkat

- 29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodDokumen2 halaman29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodAbdul Hameed OmarBelum ada peringkat

- 21 Volumetric MethodDokumen1 halaman21 Volumetric MethodAbdul Hameed OmarBelum ada peringkat

- Maximum Casing Pressure and Pit GainDokumen1 halamanMaximum Casing Pressure and Pit GainstevebeardsleyBelum ada peringkat

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Dokumen1 halamanDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarBelum ada peringkat

- Ideal Kick Removal: Drill Hole DataDokumen2 halamanIdeal Kick Removal: Drill Hole DataAbdul Hameed OmarBelum ada peringkat

- Well lubricate and bleed procedure documentDokumen1 halamanWell lubricate and bleed procedure documentAbdul Hameed OmarBelum ada peringkat

- Mud-Gas Separator Sizing Worksheet: Prerecorded InformationDokumen3 halamanMud-Gas Separator Sizing Worksheet: Prerecorded InformationAbdul Hameed OmarBelum ada peringkat

- 2009 Separator CalcsDokumen18 halaman2009 Separator CalcsneelBelum ada peringkat

- Mud-Gas Separator Sizing Worksheet: Prerecorded InformationDokumen3 halamanMud-Gas Separator Sizing Worksheet: Prerecorded InformationAbdul Hameed OmarBelum ada peringkat

- New TDS 11 CourseDokumen171 halamanNew TDS 11 CourseAbdul Hameed Omar100% (3)

- 1260707780BOP Equipment Failure ReportDokumen1 halaman1260707780BOP Equipment Failure ReportAbdul Hameed OmarBelum ada peringkat

- Formation TemperatureDokumen2 halamanFormation TemperatureAbdul Hameed OmarBelum ada peringkat

- TDS-11SA Lubrication and Maintenance GuidelinesDokumen1 halamanTDS-11SA Lubrication and Maintenance GuidelinesEduardo Vilela RomeroBelum ada peringkat

- 1260707829bop Test FormDokumen4 halaman1260707829bop Test FormAbdul Hameed Omar100% (1)

- Over PullDokumen1 halamanOver PullAbdul Hameed OmarBelum ada peringkat

- TDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTDokumen1 halamanTDS-11SA With 2 AC X 400 HP Motors Current Drill Pipe Torque Amps LBS-FTAbdul Hameed OmarBelum ada peringkat

- GestioIP 3.0 Installation GuideDokumen17 halamanGestioIP 3.0 Installation GuidepiterasBelum ada peringkat

- BSC Prospectus 2019-20Dokumen37 halamanBSC Prospectus 2019-20Gaurav VamjaBelum ada peringkat

- Chapter-Iv: Profile of The Hindu News PaperDokumen5 halamanChapter-Iv: Profile of The Hindu News PaperMurugan SaravananBelum ada peringkat

- Design Rules CMOS Transistor LayoutDokumen7 halamanDesign Rules CMOS Transistor LayoututpalwxyzBelum ada peringkat

- UntitledDokumen47 halamanUntitledAndy SánchezBelum ada peringkat

- Volume 1 Drafting Design and Presentation StandardsDokumen328 halamanVolume 1 Drafting Design and Presentation StandardsAntonio Herrera PérezBelum ada peringkat

- Brief Summary of The Original COCOMO ModelDokumen5 halamanBrief Summary of The Original COCOMO ModelTirthajit SinhaBelum ada peringkat

- Engine Service Tool ReferenceDokumen4 halamanEngine Service Tool ReferenceandrzejBelum ada peringkat

- Man Power PlanningDokumen5 halamanMan Power PlanningKarthik AchinBelum ada peringkat

- Over View On 5 S TechnicDokumen14 halamanOver View On 5 S TechnicSachleen Singh BajwaBelum ada peringkat

- POSSIBILITIES OF LOW VOLTAGE DC SYSTEMSDokumen10 halamanPOSSIBILITIES OF LOW VOLTAGE DC SYSTEMSTTaanBelum ada peringkat

- SPP 40 Series Sponsored BE MTech Projects CollegewiseDokumen145 halamanSPP 40 Series Sponsored BE MTech Projects CollegewiseVinay KumarBelum ada peringkat

- Volvo 850 GLT Owners Manual 1993Dokumen176 halamanVolvo 850 GLT Owners Manual 1993jpaulorosado2186Belum ada peringkat

- Tutorial Ip 2 Win EnglishDokumen25 halamanTutorial Ip 2 Win EnglishGarry Zein0% (1)

- MGS3750 28FDokumen4 halamanMGS3750 28FAndi Z Pasuloi PatongaiBelum ada peringkat

- Paint Color Comparison ChartDokumen132 halamanPaint Color Comparison ChartCarlos Rubiños AlonsoBelum ada peringkat

- Nazneen Wahab CVDokumen5 halamanNazneen Wahab CVRavi MittalBelum ada peringkat

- Surging & Blow Out of Loop Seals in A CFBC BoilerDokumen9 halamanSurging & Blow Out of Loop Seals in A CFBC Boilermohamed faragBelum ada peringkat

- Msds Thinner 21-06Dokumen8 halamanMsds Thinner 21-06ridhowibiiBelum ada peringkat

- Detector of FM SignalDokumen4 halamanDetector of FM SignalR. JaNNaH100% (1)

- JEDI Slides Intro1 Chapter 02 Introduction To JavaDokumen17 halamanJEDI Slides Intro1 Chapter 02 Introduction To JavaredbutterflyBelum ada peringkat

- PERFAPPRAISAL Research proposal on performance appraisal practices at National Bank of Pakistan and United Bank LimitedDokumen4 halamanPERFAPPRAISAL Research proposal on performance appraisal practices at National Bank of Pakistan and United Bank LimitedNadia KhanBelum ada peringkat

- Aluminium GMAW GuideDokumen32 halamanAluminium GMAW GuideDaniel Salinas100% (2)

- Introduction To Windows PDFDokumen24 halamanIntroduction To Windows PDFRaymoon Twopass DaysBelum ada peringkat

- Grade 6 Science PuzzleDokumen4 halamanGrade 6 Science Puzzlemargie riveraBelum ada peringkat

- Active Control of Flow Separation Over An Airfoil Using Synthetic JetsDokumen9 halamanActive Control of Flow Separation Over An Airfoil Using Synthetic JetsDrSrujana ReddyBelum ada peringkat

- CH Sravan KumarDokumen5 halamanCH Sravan KumarJohnBelum ada peringkat

- Skybox Security Sales&Tech OverviewDokumen46 halamanSkybox Security Sales&Tech Overviewerdem100% (1)

- Budget EstimatesDokumen251 halamanBudget EstimatesMUHAMMAD QASIM RAJPARBelum ada peringkat

- A Polypropylene Film With Excellent Clarity Combined With Avery Dennison Clearcut™ Adhesive Technology and With A Glassine LinerDokumen4 halamanA Polypropylene Film With Excellent Clarity Combined With Avery Dennison Clearcut™ Adhesive Technology and With A Glassine LinerAhmad HaririBelum ada peringkat