Estimates For Epcc/ Epcm Skids

Diunggah oleh

shrieersJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Estimates For Epcc/ Epcm Skids

Diunggah oleh

shrieersHak Cipta:

Format Tersedia

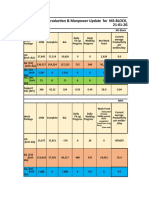

ESTIMATES FOR EPCC/ EPCM SKIDS

UNIT PRICE IN TOTAL PRICE IN

EPCC / EPCM SERVICES DESCRIPTION MAN HOURS REMARKS

USD/SAR USD/SAR

A MATERIAL COST

a.1 Structural

a.2 Mechanical

a.3 Piping

a.4 Electrical

a.5 Instrumentation

B DESIGN & DETAIL ENGINEERING

b.1 Please refer ANEWA's Techno Commercial proposal , SOW & Exclusions

All drawings & documents to comply with SAES-J-004 and SAES-J-005

C.1 FABRICATION

c.1 General Removal of all items subject to damage during flushing, cleaning and pressure testing

c.2 Piping Piping fabrication for skid unit

c.3 Piping installation on skid unit

c.4 Pre testing of all pipe on skid

c.5 Painting, Insulating, Blasting & Cleaning of pipework

c.6

c.7 Structural Fabrication of steel frame/ skid

c.8 Assembly and painting of steel frame

c.9

c.10 Electrical LV Switch rack installation

c.11 Battery Charger System installation

c.12 Cable, Cable Tray , Conduit laying & termination

c.13 Instrumentation Field Instrument installation

c.14 Panel installation / RTU & JB

c.15 Cable, Cable Tray , Conduit laying & termination

D PACKING & TRANSPORTATION

d.1

E INSPECTION & TESTING

Modular Skid to comply SAES-J-003

Piping

e.1 Pneumatic and hydraulic tubing

e.2 Flushing of pipelines

e.3 Chemical cleaning and testing of pipework

e.4 Drying of tested pipework

e.5 Test ISO's and P&ID's showing the extent of each pressure test

e.6 Hydro test

e.7 Testing of process lines and all relevant tapping’s

e.8 Testing of all tie in and utilities

e.9 Non Destructive Examination - NDE

e.10 Insulation

e.11 Flow coding

e.12 Final inspection of pipework

e.13 Pipe Welding procedures and Tests as per ASME b 31.3 and SAES-W-011

e.14 Structural Strucutral Welding conform to AWS D1.1

e.15 Bolt tensioning if any

e.16 Pipe supports , Equipments , Panels & cable tray supports

e.17 Electrical LV Switch rack Energising

e.18 Battery Charger System Functional check

e.19 Cabling and testing

e.20 Instrument Instrument Mounting and Hookups

e.21 Instrument tube Leak and Pressure Leak Tests

e.22 Control panels / JB installation and testing

e.23 Instrument calibration

e.24 Cabling and testing

e.25 COATING & PAINTING Coating & Painting will conform with SAES-H-101V & APCS-26 (external surfaces)

e.26 Coating & Painting will conform with SAES-H-102 & APCS-102B (internalsurfaces)

e.27 Paint for supports will conform with SAES-H-101V & APCS-4 & APCS-6

e.28 Technicians

e.29 Engineers

e.30 Sr. Engineers

E IFAT - INTEGRATED FACTORY ACCEPTANCE TESTS

e.1 Pressure and vacuum testing of the final skid

e.2 Checking the working of pumps and instrumentation

e.3 Cabling and its testing

e.4 Control loops and control program software RTU AND PLC functions

e.5 Pump and its operation dry and load conditions

e.6 Gas Skid with assesecories

e.7 Emergency Shutdown System (ESD)

e.8 Well / Fire Shutdown Panel

e.9 Test Separator/ Multi Phase Flow Meter

e.10 Instrumentation functional tests including PLC and RTU

e.11 Electrical functional tests

e.12 Cable and Conduit Installation as per SAES-P-104

e.13 Grounding of Electrical Equipments as per SAES-P-111

e.14 Adequate spares as per Standards

e.15 Positive Material Identification PMI as per SAES-A-206

e.16 Check Nameplate with all details

F ISAT - INTEGRATED SITE ACCEPTANCE TESTS

f.1 Overall Inspection of Skids

f.2 Overall Inspection of Skid Accessories

f.3 Installation Inspection of Skids with respect to Packing notes

f.4 Installation Inspection of Tie Ins

G PRE COMMISSIONING

Performance of all remaining works

other than commissioning and

Performance Tests.

g.1 Reinstatement of all items after testing.

g.2 The completion and testing of the SKID equipment & systems

g.3 Testing of all parts and systems of the Works including the communications systems (if required).

g.4 Provision of initial fill of packing, chemicals, inhibitors, lubricants, glycol, water and other stocks have been made.

g.5 Checking, site modifications.

g.6 Flushing/cleaning of Tanks & Piping

g.7 Calibration of PSVs

g.8 Calibration of all the instruments

g.9 Loop checking

g.10 Complete checking of the safety system

g.11 Checks on electrical system and other vendor packages including PLC/ESD etc.

g.12 Commissioning spares

H COMMISSIONING

h.1 Tie Ins including Process & Utilities

h.2 Power Up

h.3 Loop checking

h.4 Cabling and termination

h.5 Lighting

I AS BUILT

Anda mungkin juga menyukai

- CS Pipes Installation CostDokumen12 halamanCS Pipes Installation Costrajkamal_e100% (2)

- InchDia Cal. For SqPadDokumen2 halamanInchDia Cal. For SqPadparthBelum ada peringkat

- Conversion of MT To Inch DiaDokumen4 halamanConversion of MT To Inch DianikunjBelum ada peringkat

- Manhour StandardsDokumen6 halamanManhour StandardsErick EnriquezBelum ada peringkat

- Pipes PoolsDokumen3 halamanPipes PoolsjorgemachigueBelum ada peringkat

- Weight Factor Plan: Project Work Package Contractor Revision DateDokumen4 halamanWeight Factor Plan: Project Work Package Contractor Revision DatescottigiancarloBelum ada peringkat

- Pipeline Unit Cost Estimator May-08 PDFDokumen1 halamanPipeline Unit Cost Estimator May-08 PDFGeorge DeriBelum ada peringkat

- Cost and Estimate Pressure TankDokumen8 halamanCost and Estimate Pressure TankLester MuscaBelum ada peringkat

- FlangeDokumen13 halamanFlangehuangjlBelum ada peringkat

- Shutdown ScheduleDokumen31 halamanShutdown Schedulewaqas khanBelum ada peringkat

- Price List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevDokumen67 halamanPrice List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevRenny DevassyBelum ada peringkat

- Overall CCTRDokumen182 halamanOverall CCTRInaam Ullah Mughal100% (2)

- Option-2-Piping Support Structural BOQDokumen12 halamanOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenBelum ada peringkat

- DESCON Engineering Limited: Cost Centers List Civil WorksDokumen11 halamanDESCON Engineering Limited: Cost Centers List Civil Worksasif iqbalBelum ada peringkat

- Piping Cost BreakdownDokumen2 halamanPiping Cost BreakdownMarie100% (1)

- Fabrication and Erection Piping Manhour Work SheetDokumen2 halamanFabrication and Erection Piping Manhour Work SheetRuelBelum ada peringkat

- Reporting Format Total Piping 11Dokumen2 halamanReporting Format Total Piping 11Lakshmanan VenkateswaranBelum ada peringkat

- 08-Mainline Pipeline Estimate Detail (Canada)Dokumen11 halaman08-Mainline Pipeline Estimate Detail (Canada)Satria Pinandita100% (2)

- 2b Piping Estimate & Summary FormDokumen14 halaman2b Piping Estimate & Summary FormEK63100% (1)

- ABH Pipeline ScheduleDokumen13 halamanABH Pipeline ScheduleGovind Jha100% (1)

- 16 Project Cost EstimateDokumen6 halaman16 Project Cost EstimateBhuneshwar Chelak100% (2)

- Seth Cost Estimate Rev 2 Opt 1 & 2Dokumen40 halamanSeth Cost Estimate Rev 2 Opt 1 & 2LantBelum ada peringkat

- Dia Inch PipingDokumen77 halamanDia Inch PipingmyDJAPA myDJAPABelum ada peringkat

- USS - Clairton Battery CDokumen10 halamanUSS - Clairton Battery CRay KelleyBelum ada peringkat

- Piping Stress Man Hour EstimationDokumen2 halamanPiping Stress Man Hour EstimationMubarik AliBelum ada peringkat

- Labor Cost For PipingDokumen148 halamanLabor Cost For PipingHenry San PedroBelum ada peringkat

- Total Bid Amount P 13,747,562.21Dokumen2 halamanTotal Bid Amount P 13,747,562.21Alvin Dela CruzBelum ada peringkat

- Man Power Planing For LPG Tank FoundationDokumen2 halamanMan Power Planing For LPG Tank FoundationArie UdienBelum ada peringkat

- Manhours REV 1 - 15-02-2015Dokumen6 halamanManhours REV 1 - 15-02-2015Pavan Kumar100% (1)

- 2a Piping Estimate & Summary ExampleDokumen29 halaman2a Piping Estimate & Summary ExampleTutu RohanaBelum ada peringkat

- D.M.Plant OperatorsDokumen5 halamanD.M.Plant OperatorsTiu TonBelum ada peringkat

- Piping Manhours (Weight)Dokumen25 halamanPiping Manhours (Weight)Nejat AbabayBelum ada peringkat

- Daily Progress UpdateDokumen20 halamanDaily Progress UpdateMathias OnosemuodeBelum ada peringkat

- SL No Process Flow Total PDF Total Tiff Man HoursDokumen2 halamanSL No Process Flow Total PDF Total Tiff Man Hoursash1968100% (2)

- EstimationDokumen7 halamanEstimationLatifa Traya50% (2)

- Piping BOQ (13 Jul)Dokumen25 halamanPiping BOQ (13 Jul)Mubashir100% (2)

- 2 A Piping Estimate Summary ExampleDokumen23 halaman2 A Piping Estimate Summary Exampleans99Belum ada peringkat

- Progress Update For Pre Fabrication WorksDokumen4 halamanProgress Update For Pre Fabrication WorksAlagu ThirunavirkarasuBelum ada peringkat

- Capital Cost EstimatorDokumen14 halamanCapital Cost Estimatoramirho3einBelum ada peringkat

- Code Ref.Dokumen155 halamanCode Ref.Selvakpm06Belum ada peringkat

- 2a Piping Estimate & Summary ExampleDokumen15 halaman2a Piping Estimate & Summary ExampleRaymond MetselaarBelum ada peringkat

- Estimate of PipingDokumen1 halamanEstimate of Pipingsaranyavishnukanth100% (1)

- SL No DRG No DescriptionDokumen13 halamanSL No DRG No DescriptionRajesh BhadraBelum ada peringkat

- Structural Steel Works Man-HoursDokumen2 halamanStructural Steel Works Man-HoursRenny Devassy100% (1)

- Global SCANDokumen187 halamanGlobal SCANLuis GonzalezBelum ada peringkat

- Electrode CalculationDokumen2 halamanElectrode CalculationTejas PatelBelum ada peringkat

- 12 5 2 Schedule of Fab EreDokumen1 halaman12 5 2 Schedule of Fab EreGlobaltoyoBelum ada peringkat

- Productivity Rate (Piping Works)Dokumen21 halamanProductivity Rate (Piping Works)Ahmed Essam TimonBelum ada peringkat

- Weld Map of Well 32 FLDokumen13 halamanWeld Map of Well 32 FLArfanAliBelum ada peringkat

- Progress SummaryDokumen1 halamanProgress SummaryIrwan KurniawanBelum ada peringkat

- Piping Progress Measurement - Meter-Inch and Dia-InchDokumen1 halamanPiping Progress Measurement - Meter-Inch and Dia-InchdasubhaiBelum ada peringkat

- Fabrication Cost Estimation Including ManpowerDokumen33 halamanFabrication Cost Estimation Including ManpowerVinayak PujariBelum ada peringkat

- U00034-PL-MTO-0001 - MTO For Export PipelinesDokumen7 halamanU00034-PL-MTO-0001 - MTO For Export PipelinesThiên KhánhBelum ada peringkat

- PipeClass NG 11.08.09 PDFDokumen138 halamanPipeClass NG 11.08.09 PDFbadelitamariusBelum ada peringkat

- GeioseisDokumen4 halamanGeioseisPANAGIOTIS GKOUROSBelum ada peringkat

- Execution of Hydro Power Plant - PLANNING AND OPERATIONDokumen49 halamanExecution of Hydro Power Plant - PLANNING AND OPERATIONkapolaBelum ada peringkat

- E14-B LV Switchboard and MCCDokumen3 halamanE14-B LV Switchboard and MCCAmyBelum ada peringkat

- Chapter - E15: Site Testing and CommissioningDokumen2 halamanChapter - E15: Site Testing and CommissioningvenkateshbitraBelum ada peringkat

- Section C.3 FAT For DCSDokumen11 halamanSection C.3 FAT For DCSChava TejaBelum ada peringkat

- ITR-A E Submarine CableDokumen1 halamanITR-A E Submarine CableMomo ItachiBelum ada peringkat

- EPRSubmittal Guide 2019 FinalDokumen18 halamanEPRSubmittal Guide 2019 FinalshrieersBelum ada peringkat

- Cable Short Circuit CapDokumen2 halamanCable Short Circuit CapshrieersBelum ada peringkat

- Lead Acid Battery Sizing Example For Check in ETAP Using EtaDokumen7 halamanLead Acid Battery Sizing Example For Check in ETAP Using EtashrieersBelum ada peringkat

- Jetty AreaDokumen6 halamanJetty AreashrieersBelum ada peringkat

- Employees Job Assignment & Tracking Sheet: Employee Name Project Involved Tasks Assigned DateDokumen12 halamanEmployees Job Assignment & Tracking Sheet: Employee Name Project Involved Tasks Assigned DateshrieersBelum ada peringkat

- Cable SizingDokumen11 halamanCable Sizingshrieers100% (1)

- Short CircuitDokumen6 halamanShort CircuitshrieersBelum ada peringkat

- Submission Status-ElectricalDokumen1 halamanSubmission Status-ElectricalshrieersBelum ada peringkat

- Tag No. KW Rating in HP As Per L&T Catalog Rated Current As Per L&T CatalogDokumen2 halamanTag No. KW Rating in HP As Per L&T Catalog Rated Current As Per L&T CatalogshrieersBelum ada peringkat

- We Are AwdDokumen3 halamanWe Are AwdshrieersBelum ada peringkat

- Ei BQ NewDokumen10 halamanEi BQ NewshrieersBelum ada peringkat

- IEEE Red Book Cover IEEE Red BookDokumen1 halamanIEEE Red Book Cover IEEE Red BookshrieersBelum ada peringkat

- 501 453racDokumen1 halaman501 453racshrieersBelum ada peringkat

- SC CalculationsDokumen97 halamanSC CalculationsshrieersBelum ada peringkat

- Electrical Applicable Standards-LatestDokumen22 halamanElectrical Applicable Standards-Latestshrieers100% (2)

- Tekla Structure Analysis & Design Link With Analysis SoftwareDokumen6 halamanTekla Structure Analysis & Design Link With Analysis SoftwareYoung JekalBelum ada peringkat

- Analysis of Methodologies For The Evaluation of Power Outage Costs PDFDokumen5 halamanAnalysis of Methodologies For The Evaluation of Power Outage Costs PDFHachimenum AmadiBelum ada peringkat

- Project Sem1 - 2019 2020Dokumen4 halamanProject Sem1 - 2019 2020Hariss LuqmanBelum ada peringkat

- Hydro Culv 21Dokumen10 halamanHydro Culv 21rungekutasaBelum ada peringkat

- Syllabus 73185352Dokumen147 halamanSyllabus 73185352Gaurav MishraBelum ada peringkat

- Road BOQDokumen129 halamanRoad BOQSunil Kumar GeraBelum ada peringkat

- Masonry Box Behavior (Marques, R. 2015)Dokumen181 halamanMasonry Box Behavior (Marques, R. 2015)Jose ManuelBelum ada peringkat

- PLM - Indishtech PVT Ltd-Corporate ProfileDokumen16 halamanPLM - Indishtech PVT Ltd-Corporate ProfileMounesh7Belum ada peringkat

- Fiac Air Compressors CI - 1Dokumen8 halamanFiac Air Compressors CI - 1JuanPabloAlvarez100% (1)

- Attachment 01-Project Standards & Specifications-PearlDokumen8 halamanAttachment 01-Project Standards & Specifications-Pearlum erBelum ada peringkat

- GeoformerDokumen2 halamanGeoformerDao Ba ThanhBelum ada peringkat

- Azipod XO PresentationDokumen19 halamanAzipod XO PresentationButrosGali88Belum ada peringkat

- Final Internship Report of ComsatsDokumen49 halamanFinal Internship Report of ComsatsMuhammad Umair100% (1)

- Multi Choice Tech 1 AnswerDokumen20 halamanMulti Choice Tech 1 AnswerquyennqBelum ada peringkat

- Building Planning and DrawingDokumen35 halamanBuilding Planning and DrawingArun Bhuyan100% (2)

- Pages From KERPEN CableDokumen2 halamanPages From KERPEN CablerelaxjackBelum ada peringkat

- en - O.1 - 8131 38Dokumen61 halamanen - O.1 - 8131 38yones83% (72)

- Engineering Documents in EPCDokumen9 halamanEngineering Documents in EPCEditan IwedBelum ada peringkat

- Mohd Razswan Bin Rus: Contact InfoDokumen4 halamanMohd Razswan Bin Rus: Contact InfoPelajar NIK MUHAMAD NOR SYAZANIS BIN NIK SYARMANBelum ada peringkat

- CVEN214 - Lecture 4 Axial Loads - Dr. Wael AlnahhalDokumen33 halamanCVEN214 - Lecture 4 Axial Loads - Dr. Wael AlnahhalNadeenMohamedBelum ada peringkat

- Aircraft Structures 1 - 15AE54Dokumen161 halamanAircraft Structures 1 - 15AE54Jason Jeevan86% (7)

- Pricelist Reilee Group of Services Rizal Bookhouse 1Dokumen8 halamanPricelist Reilee Group of Services Rizal Bookhouse 1HarveyBelum ada peringkat

- DSR Rates For Additional Cost Calculation: Page Code No Description Unit Rate Rate (61% Above DSR)Dokumen2 halamanDSR Rates For Additional Cost Calculation: Page Code No Description Unit Rate Rate (61% Above DSR)vijayakapoorBelum ada peringkat

- PIP STE05121 Anchor Bolt Design Guide PDFDokumen56 halamanPIP STE05121 Anchor Bolt Design Guide PDFjamilBelum ada peringkat

- Impact FactorDokumen13 halamanImpact FactorNindy SabrinaBelum ada peringkat

- Slab With ReportsDokumen36 halamanSlab With ReportsER Manish MakhijaBelum ada peringkat

- Analysis and Design of A Multi Storied Residential Building of (Ung-2+G+10) by Using Most Economical Column MethodDokumen8 halamanAnalysis and Design of A Multi Storied Residential Building of (Ung-2+G+10) by Using Most Economical Column MethoddhanashekarVBelum ada peringkat

- Structural Engineering For SolarDokumen9 halamanStructural Engineering For SolarO'Donnell & NaccaratoBelum ada peringkat

- Iso 2857-1973 A2-1986Dokumen2 halamanIso 2857-1973 A2-1986azitaggBelum ada peringkat

- Es 200 Easy - Pintu Geser OtomatisDokumen8 halamanEs 200 Easy - Pintu Geser OtomatisLivian TeddyBelum ada peringkat