Concrete PDF

Diunggah oleh

Ritesh PaliwalJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Concrete PDF

Diunggah oleh

Ritesh PaliwalHak Cipta:

Format Tersedia

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Unit - 1

CONCRETE

CONCRETE -

A Mixture is contain (water + Cement + Sand Agg. + ad mixture)

Water - Property mixing (Toimpouove the quality of concrete)

+

Cement - Binding material

+

Sand - Filler material

+

Agg. - Inert material

+

Admixture - Specially use for increasing workability & strength

CEMENT

Historical development of OPC -

colour match

Manfactur Process of Oridinary Portland Cement : -

(i) Dry Process

(ii) Wet Process

(i) Dry Process - Raw material weight

Mix et process of the weight of Raw-meterial Mix

(ii) Wet process: Wet process raw materials weight 35-

50% mix

Note: -

Wet Process method

raw material Slurry Form Convert

Stage Matrial Add

Manufacturing Of OPC by Wet Process

OPC Raw-matrials Calcureous matrial (lime stone chalk), Argillaceous

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 1 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

material (shale, Clay)

Raw matrial - (Calcureous + Agrillaceous)

Raw matrials Calcareous materials Jaw Crushers Size reduce (about

- 150 mm) size

Argillaceous Calcureous material Fine Grinding

Ball Mill Tube Mill

OPC Raw material Chemical Composition

S.NO. OXIDE PERCENTAGE FOR GOOD

CEMENT

1 Lime/calcium oxide 6067% 63%

2 Silica (SiO 2) 1725% 22%

3 Iron oxide (Fe 2O 3) 0.56%

4 Alumina(Al 2O3 ) 38%

5 Magnesia(MgO) 0.14%

6. Sulphur Trioxide (SO 3) 1.33%

7. Alkalies (K2O, Na2 O) 0.41.3%

According dessending Order Cao > Sio2 > Al2O3 > Fe2O3>SO3>Mgo > So3 > Alkalies

- For a good OPC Cement - the composition is lime - 63% + silica 22% + 15% other gradient

- Maximum Quantity in OPC - Lime (CaO)

- Minimum Percentage in OPC - Alkalies

Ball Mill Tube mill Raw material Mix Raw

Materials Slurry Form Convert

Cement rotary Kiln dia 2.5

length 90-120 mtr 1 in 300 Angle inclined

Slurry Form Convert Raw materials Rotary Kiln Higher ENP

Raw materials Gravity Temperature

1400 -15000c Slurry (Nodules)

clinkers

Finer grinding Ball mill Tube mill

Weight Gypsum (CaSo4.2H2O) Calcium

Sulphate (CaSo4) Cement Gypsum

Flash setting Cement Initial Setting time

Gypsum Retarder

Raw matrials Oxcide

Bogoues Bogoues Compound

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 2 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Bogus Compound

S.No. Compund Approximate Qty

1. Tricalcium Aluminate C3 A 3CaOAl2 O3 10.80%

2. Tricalcium Silicates C3 S 3CaOSiO2 54.10%

3. Dicalcium Silicates C2 S 2CaOSiO2 16.60%

4. Tetra Calcium C4 AF 4CaOAl2 O3Fe 2O 3 9.10%

Aluminate Ferriate

Le - Chetelia or Thornebohm Clincker Observation properties

bogoues Compound Bogoues compound

C3S - Alite C3A - Celite

C2S - Belite C 4Af - Felite

C3A :- (Tricalcium Aluminate) :

(i) Add C3A Reaction

(ii) C3S Set

Flash setting

Setting time increase C3A Counter Attack

Gypsum (CaSo4.H2O) or Calcium Sulphate (CaSo4) mix

(iii) Cement initial or Final Setting time C3A

(iv) cement C3A Sulphate resistance capacity

Sulphate resistance C3A

(v) Stage Heat of Hydration C3A

S.No. Compound Heat of Hydration(Cal/gram)

3 days 28 days 13 years

1. C3A 212 311 324

2. C3S 58 104 122

3. C4AF 69 98 102

4. C2S 12 42 59

Heat of Hydration Stage C3A

Heat of Hydration C2S

(vi) Undesirable properties C3A responisble

Heat of Hydration :- (Heat

lebration) Heat of Hydration

C4AF (Tetra Calcium Alminate Ferrite) (4Cao.Fe2O3.Al2O3) :-

This is Also Known as 'Felite'

Rate of Hydration C4AF

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 3 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Rate of Hydration C4AF Rate of Hydration C2S

Note: C3A, C4AF C3A strength C4AF

Strength contribution

C3S (Tricalcium Silicate) (3Cao.Sio2) :-

This is Also known as 'Alite'

OPC C3S

28 Days Strength Charecterstic Early Strength

C3S

C2S (Di-Calcium Silicate) :-

(i) This Also Known as 'Belite'

(ii) Ultimete Strength C2S C2S (Slowly)

Strength

(iii) Heat of Hydration Reduce C2S Comparetively

(iv) Cemical Attacks Against (More resistance against

Chemicals Attack) C2S

Strength C3S Strength C4AF

Bogus Compound composition In Cement

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 4 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Compound Qty. in Percentage

C3S 54.10

C2S 16.60

C3A 10.9

C4AF 9.10

C3S

C4AF

2 Main Component C3S or C2S

Oxide Row Meterial Lime High Setting time or strength

Increse Oxide Silica Strength or

Setting Increase

Strength setting time of cement lime content

silica content

Cement oxide Unburnt lime (free lime) or Magnesia

Unsoundness (expansion in cement after initial setting time)

oxide Iron colour (greenish Gray) oxide

burning process Help

Factory production Dry process cement 1 tonne cement 100 kg Coal

Wet Process 1 Tonne cement 350 kg coal

10000c Temperature Heated Loss of Weight due to igniation

5% of the weight of cement Loss of weight, moisture

content, Co2, Free lime of magnesia (evaporation)

Insoluble or Residual Matter in cement :-

insolube matter weight of cement

Magnesia Weight of cement

Particals Original Volume Expand

Aggregrates or Sand Partical Thin Layer (Gel)

cement Heat Libration Heat of hydration

Note :- Lime Original Volume 2.3 time expand

Slagging of lime

Water Requirement for Hydration of cement compound :-

Water requirement for Hydration of C2S - 24% of the weight of cement

Water required for Hydration of C2S - 21% of the weight of cement

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 5 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

For combined requirement to start the intially heat of Hydration - 23% of the weight of cement.

This is also known as Bound water.

Water required for gel process - 15% of the weight of cement

Total water required for complete Heat of Hydration - 38% of the weight of cement

Types of Cement :-

1. 33 grade - IS-269

Ordinary Portland Cement (O.P.C.) 43 grade - IS-8112

53 grade - IS-12269

Types of OPC Compressive Strength at

different age of cement

2 days 7 days 28 days

33 Grade 16 mpa 22 mpa 33 mpa

43 Grade 23 mpa 33 mpa 43 mpa

53 Grade 27 mpa 37 mpa 53 mpa

Grade Fineness or 28 days Stength represent

fineness represent

Fineness :-

53 grade > 43 Grade > 33 Grade

1 beg weight 50 kg 1 beg volume 0.0347 m3 (34.7 liter)

Initial setting time of O.P.C. Cement should not less than 30 minute.

Finial setting time of O.P.C. cement shound not more than 10 hours. (600 minute)

Normal relation between initial & final setting time T=90+1.20 t,

Where T= Final Setting time, t=Initial setting time

2. Repid Harding & Rapid strength cement :-

Compare to OPC Higher portion of C3S and Lower portion of C2S and finer grinding cement.

Repid Harding cement OPC Compare C3S increase C2S

decrease OPC Compare Finer (Finer grinding)

Repid Harding cement (R.H.C.) Stage Strength OPC compare (Higher)

R.H.C Strength O.P.C. Strength

1 days = 3days

3 days = 7 days

Initial setting time of Rapid Hardning cement - Greater than 30 minutes

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 6 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Final Setting time of Rapid Hardning cement - Less than 10 Hours

Repid Hardning cement Ultimate strength O.P.C. equal concrete

mass concrete work (Retaining wall, Dam, Bridge) R.H.C. cement OPC

compared initial strength slow

Use of R.H.C. - R.H.C.

1. Road Repair Work or New Road work

2. Use in cold Area's

3. If form Work removing early then rapid hardning cement is prefered.

4. Use in pre-stress (Pre fabricated concrete)

3. Quick setting cement :-

OPC Clinkers (at the time of grinding) Gypsum

(CaSo4.2H2O) Reduce Quick Setting cement

Initial setting time for quick setting cement - Not less than 5 minutes

Final setting time of Quick setting cement - Not More than 30 Minutes

Use of Quick setting cement :

1. Use under water construction (where pumping involve)

2. Use for grounting opration (Grouting)

4. Low Heat Cement :-

OPC Compare C3A or C3S

C2S (Increase)

[Compare to OPC Lower percentage of C3A & C3S or Higher Percentage of C2S]

Low Heat Cement (L.H.C.) Final ultimate Streangth OPC equal Ultimate

Strength OPC Compare Higher

L.H.C. Strength OPC Strength

3 days 1 days

7 days 3 days

Initial setting time of L.H. Cement - More than 60 Minutes

Final setting time of L.H. Cement - Less than 10 Hours (600 minutes)

Use of Low Heat Cement :

1. Use in Mass concrete work (Dam. Retaining wall, Bridge etc.)

5. Sulphate Resisting Cement :-

Slulphate resisting cement OPC C3A or C4AF Reduce

C3S or C2S OPC Compare Increase

Sulphate Resisting Cement C3A 2XC3A + C4AF

Sulphate resisting Cement Conditions

1. Use for marine condition

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 7 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

2. If Concrete use in Foundation, Basement and all Structure with contact soil.

3. If concrete use in construction of sevrage treatment units.

6. Super Suphate Resesting Cement :- Slage + 10-15%

Gypsum + OPC Mix

Coloured Cement :- Coloured Pigment

White Cement :- White Cement Pure lime Stone or Chalk

Iron oxide Reduce White Cement Iron

oxide Clinkers OPC Compare Finer

Ex - Birla white, J.K. white Putty.

Note :- To measeure the coloured of cemnt Hunter Scale is used (White ness measured)

Whiteness should not less 70% when measured ISI scals.

9. Hydrophobic Cement :-

Longer Storage

OPC Clinkers clinker Weight 0.1%

to 4%, Oleic, Streac, Boric acid mix Particals Water

replant thin film (layer) Particals water Contact

Hydrophobic cement cost ordinary portland cement

10. Portland Slag Cement :-

OPC Slag Mix

Properties

1. Low heat of Hydration

2. Better Resistance to Chloride

3. Better Resistance of Marine effects

4. Reduce the permability of cement concrete

5. Increase the chemical resistance capacity

11. Extra Rapid Hardening Cement -

Rapid hardening Compare Strength Condition Extra

Rapid Hardening Cement Preferred Rapid Hardening

cement 2% weight of cement Calieiuim chloride (CaCl2) content mix

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 8 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Cold Area

Extra Rapid Hardening cement Strength rapid hardining Compare

Extra Rapid hardening cement 7 days Strength rapid Hardening compare

12. High Alumina Cement :-

Lime Stone (Chalk) and Bauxite Finer Gryinding

Mix High Alumina cement

High Alumina cement intial setting time 4 Hours Final setting time 5 hours

Note :- High Alumina cement Initial setting time OPC, RHC, LHC Final

setting time

High Alumina Cement is used in following conditious -

1. Better resistance capacity against chemical Attack.

2. Better resistance against marine effect.

13. Portland Pozzolona Cement (PPC) :-

OPC Pozzolanic matarial 15-35% (Now

days) or (10-25%) (earlier) mix

Pozzolanic material binding porperty

Mix binding porpaerty develop Pozzolanic material silica

or Alumina Main Content

A Pozzolonic material - High siliceous & High Alumineous

PPC Cement Strength 33 grade OPC equal

Example of Pozzolonic Material -

(i) SURKHI (ii) FLY-ASH

SURKHI - Pozzolonic Material (Pilla bricks)

FLY-ASH - Pozzolonic material, Thermal Power Stations Wastage

Propertics of PPC :-

1. Low Heat of Hydration

2. Use ful in Marine condition

3. Use for Hydraulic structure other than mass concrete construction.

4. Longer currying period required compare to OPC

5. It is Cheaper compare to OPC

6. Reduce the permability of concrete

7. More Volume Covered by 50 kg bag.

Note :- Rapid Hardening cement OPC compare 10% More costly.

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 9 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Testing of Cement :-

It is classify in two types-

1. Field Test

2. Laboratry Test

1. Field Test - Following test are conduction to determine the properties of cement-

(a) Cement should be free from lump.

(b) Colour of cement should be greenish grey.

(c) Thrust your hand into beg and it must give cool feeling.

(d) Take a pinch of cement and feel between the fingure. It should give a smooth feeling.

(e) Take a sample of cement and throw it on bucket of full with water, the particles of cement should be

float for sometime before they sink.

2. Laboratry Test -Following test are done in laboratry

(a) Constancy Test :-

Test Condition - Humidity maintain - 90%

Room Temprature - 27 20c

Test Appratus -Vicate Appratus are used

self weight - 300 gram

Plunger size - dia -10mm

height - 50 mm

Sample mould size -

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 10 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

vicats apparatus mm dia 50 mm hight plunger

apparatus weight mould penetrate

plunger mould top r mm penetrate bottom mm

consistancy of cement

Standard consistance obtained - 30% water of the weight of cement.

(b) Setting Time Test - Setting time Clasified

(i) Initial setting time (ii) Final setting Time

inital or final setting time vicket apparatus use

initial or Final setting time 0.85 P Mix

Test Condition - Temperature - 270c 2ºC

Test condition same as a consistency test

Initail setting time - Paste apparatus penetration 1 mm square size

Needle cement paste penetration Needle top 33-35

mm penetrate Bottom 5-7 mm Initial setting time of cement

Final setting time - vicate apparatus Final setting

time vicate appratus 5 mm dia colar

concrete Final setting time of cement

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 11 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Intial & final setting time of different types of cement :-

S.No. Types of Cement Initial Setting Final Setting

1. Quick Setting Cement More than 5 minutes Not more than 30 min

2. Low heat cement More than 60 minutes Not more than 10 hrs.

3. High Alumina Cement More than 4 hrs. Not more than 5 hrs

4. OPC, PPC, Slag, More than 30 minutes Not more than 10 hrs

Sulphate, Hydrophobic (600 minuts)

RHC, Super Sulphate

(c) Soundness Test -

Soundness test cement initial setting time expansion

Soundness test 0.78 P mix P standard

consistancy soudness Test

(i) Le-chetelia Method (ii) Autoclave

Le chetelia Appartus Free lime soundness

AutoclaveAppartus Free lime or magnesia Soundness

Magnesia Soundness Condition

Le-Chetelia Appartus:-

The unsoundness or expansion of cement (edge distance of Le-Chetelia Appartus) should not more

than 10mm in case of OPC, R.H.C., L.H.C., P.P.C.

(d) Strength Test - Cement Tensile or compressive strength 1:3 (cement : Sand)

Mix

Test

(i) Tensile strength Test (ii) Compressive strength Test

(i) Tensile Strength Test - Test condition - Temprature - 27 20c

Humidity - 90% (moisture content in atomosphere)

P

Water Requirement - 2.5%

5

'P' Standard consitency

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 12 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

OPC Cement Tensile strength 3 days 2 N/mm2

OPC Cement 7 days Tensile strength 2.5 N/mm2

Cement Tensile strength, compressive strength 10-15%

1 Briqutte Crossectional Area 6.45 cm 2

Cement Tensile Strength 6 Nos. Briqutte Average

Strength Tensile Strength of cement

(ii) Compressive Strength Test -

Test condition : Temperature - 270C+2ºC

Humidity - 90%

P

Water Requirement - 3%

4

Cement Compressive Strength Cube (7.06 7.06 7.06 cm) or

70.6 mm Cube Crossection Area (7.06 7.06 = 49.84 cm2 50

cm or 5000 mm2)

2

PPC and OPC Cement 3 days or 7 days Compressive Strength 16 N/mm2 or 22 N/mm2

Cement Strength test 185 gram cement ( 200 gram) or 555 gram sand ( 600

gram)

Cement Strength test Cement, Sand or Water Minimum Mixing Period 3 Minute

(e) Fineness Test -Cement Fineness Area/Mass Ratio

Cement Fineness Method

(i) Sieve Analysis Method

(ii) Air Permeability Method (Nurse & Blain Permeability Method)

(iii) Sedimentaion Method or Wagner's turbidity meter Method

(i) Sieve Analysis Method - Cement Fineness test, sieve Analysis method

Sieve No. is 9 (90 ) (0.09 mm) sieve mechinal derive

(Shaking) Sieve

S.No. Types of Cement % of

Residue

1. OPC 10%

2. PPC 5%

3. RHC 5%

(ii) Air Permeability method - Method Fineness Blain Appratus

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 13 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Different types of cement Specific surface area

S.NO. Types of Cement Specific Surface Area Should Not

Less than

1. High Alumina Cement 2250 cm2 /gram

OR OPC

2

2. PPC 3000 cm /gram

3. RHC and LHC 3250 cm2 /gram

4. Super Sulphate Cement 4000 cm2 /gram

(iii) Specific Gravity Test - Cement Specific Gravity test Le-Chetelia Flask

OPC cement Specific gravity 3.15

Uint -II

WORK ABILITY

Concrete mix easily transport easily place

easily compaction Finishing "Workable concrete" Concrete

"Workability"

Consistancy - It is the related mobility and also the one dimensional measurment of workability. It

is the property of concrete which provided penetration resistance in concrete paste.

Following test are use to find out the workability of concrete :-

(i) Slump test

(ii) Compaction Factory test

(iii) Vee-Bee test

(iv) Flow test

(v) Kelly ball test

(i) Slump Test -

- Slump test laboratry or fiels Method

very wet or very dry (very High workable or very low workable)

concerete suitable

- Slump test Cement concrete workability or consistancy

- Slump test Concrete maximum size of Aggregate 40 mm 38

mm

- Slump test Mould or tapering rod Size

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 14 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Slump Mould

Concrete fill in mould for slump test - 4 layers

Thickness of each layer - 7.5 cm of each layer

No. of blows on each layer - 25 blows

SLUMP :- It is classified in three types -

(i) True slimp (ii) shear slump (iii) Collapse slump

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 15 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

(Non-Cohesive slump-represent segrightation of conc.)

If concrete slump evenly then it is called true slump.

If one half of the cone slide down than it is called shear slump and also known as cohessive concrete

concrete very high workable collapsable slump denote

- Concrete Slump value Classify

S.N. Slump Value Workab ility Degree of Plasticity

1 2575 mm Low workable conc. Stiff plastic conc.

2. 50100 mm Medium workable conc. Plastic Conc.

3. 100150 mm High workable conc. Flowing Conc.

Note :- Slump test are more useful plastic mix.

Recomanded value of slump for different types of work -

S.N. Types of work Slump

Value

1. Conc. in Road Construction 2040 mm

2. Mass Conc. Work (dam, bridge) 2550 mm

3. Conc. in Beam and Slab 50100 mm

4. Conc. in Column or thin walls 80150 mm

normal R.C.C. works

(ii) Compating Factor Test - test laboratry method Low workable concrete

Test concrete compaction factor

instrument Compaction factor

Wight of partially compaction Con.

Compacting Factor= Weight of Fully Compacted Con.

Hopper-A

Bottom Internal Dia=12.7 cm

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 16 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Top internal dia=25.4 cm

Internal height of hopper =27.9 cm

Distance between hopper A and Hopper B 20.30 cm

Hopper-B

Bottom internal dia- 12.7 cm

Top internal dia -22.9 cm

Internal Hieght of Hopper =22.9 cm

Distance between hopper B and Mould =20.3 cm

Mould

Internal Dia=15.2 cm

Internal Height=30.5 cm

Compacting Factor Concrete Workablity Classify

S.No. Compacting Factor Workability Plasticity

1. 0.750.80(.78.80) Very Low Stiff

2. 0.800.85 Low workable Stiff

Plastic

3. 0.850.92 Medium work Plastic

4. G reater than 0.92 High workable Flowing

(>0.92)

(iii) Vee-Bee test - Test very low workable concrete Test Vibration

instrument concrete mould

mould Concrete Vibration Concrete

Flat Concrete Workability Vee-Bee

Value

Concrete Workability Vee-Bee value Classified

S.No. VeeBee Value W orkability P lasticity

1. Less than 2 sec High workable Flowing

2. 25 sec Medium Platic

3. 510 sec Low Stiff Plastic

4. 1020 sec Very low Stiff

(iv) Flow Test - Laboratry test Catagory Test cement concrete

consistancy, cohessiveness and seggrigation properites concrete

Test Flow Plate 700 700 mm table weight 16 kg 1kg

concrete mould size

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 17 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Tempring Rod

Mould Plate up and down up

and down Height 12.5 mm up and down time 2 sec

5 sec Plate 15 time up and down

Spread Concrete 6 directions nearest 5 mm measure

Avg. spread diameter in cm 25

Flow percent = 100

25

Note :- Concrete Flow value 0 to 150% vary test very high workable

concrete

(v) Kelly-Ball Test - Method Field category Method Result, slump test

compare more accurate method slump test compare (Quicker result)

Test cement consistancy

concrete workability high concrete strength

concrete permeability & poronsness high

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 18 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

concrete workability low concrete strenght high con-

crete permeability & porousness low

Factor Affection The Workability of Concrete

Following Factor are affected workability of concrete -

Water content :- Workability of concrete Water content

Note : Concrete workability cement water ratio inversly proportional

1

workability

cement

water

Mix Proportion :- Mix of concrete broadly classified as 2 typed

a) Lean mix b) Rich Mix

a) Lean Mix : If aggregate to cement ratio is high is called lean mix.

lean mix workability is low as compared to rich mix. (Lean mix low workable)

b) Rich Mix : if the aggregate to cement ratio is low is called Rich mix

Workability of rich mix are more compare to lean mix.

Size of aggregate :- Courser partical Workability Finner courser compare

Courser agg. - Less surface area - More workable - Low stregnth

Finner agg. - More surface area - Less workable - High Strength

Shape of Aggregate : According to Shape of Aggregate it is classified in 4 types -

a) Rounded Aggregate

b) Angular Aggregate (Cubical Angular Agg.)

c) Flakiness aggregate

d) Elonginated Aggregate

Note :- In Concrete Best Workability Concrete High Workable Rounded

Shape Aggregate are used.

- Concrete High Strength Angular Shape (Cubical shape) Aggregte are used.

- In Concrete work Flakiness or eloginated shpaes aggregate are not used.

5. Surface Texture of Aggregate :- According to surface texture the aggregate is classified in two

types-

A) Rough Surface Texture B) Smooth surface Texture

- High workable conrete Smooth surface texture aggregate

Surface area rough agg. Compare

- High strength concrete Rough surface texture aggregate

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 19 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

surface Area Smooth Agg. compare

Smooth Surface : Higher workability - lower strength

Rough surface- Low workablility - Higher strength

SUMMARY

1

- Surface Area

Size of agg.

- Surface Area Surface Roughness

1

- Workability

SurfaceArea

- Strength of Concrete Surface Area

Grading of Aggregate :- Well graded aggregates Workability High poorly graded agg.

Workability

Workability of concrete Grading of Aggregate

Strength of Concrete & Grading of Aggregate

Poprosity of Aggregate :- Concrete High Porosity Aggregates

concrete Workability Reduce Low Porosity Aggregates

Concerete Workability increase

Time :- Concrete Placing (Mixing) Time Concrete

Workability reduce

Temperature :- Concrete Workability Temperature increase

Decrease

Admixture :- Concrete Workability increase Concrete Admixtures Provide

Concrete High workability

water

1. Workablity Ratio

Cement

1

if Cement is more than Workablity

Cement/water

cement

2. Lean mix. Workablity

Agg.

1

if Agg. is more Workablity

Agg./Cement

3. Workability Size of Agg.

4. Workability Smoothness

5. Workability Gradeing of Agg.

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 20 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

1

6. workability

Porosity

1

7. workability

Time

1

8. workability

Temperature

workability Admixture

Note :- Conrete Workability or Strength Water, Cement Ratio, Cement Agg.

Ratio, Size of Agg., Smoothness, Gradeing Admixture

Degree of Plasticity Slump Value in Compacting VeeBee

Workability (mm) Factor Value Value (see)

Very low Stiff .75 0.80 1020 (sec)

Low Stiff 2575 mm 0.800.85 510 Sec

Plastic

Medium Plastic 50100 mm 0.850.92 25 sec

High Flow 100150 mm Greter than 0.92 Less than 2 sec

Very High Flow

Most suitable Most Suitable low Most suitable very

medium and high workable low workable

SEGGREGATION

Seggregation :- Concrete Mix Placing larger particals Smaller

particals Sepration Seggregation

Concrete Seggregation

1. Not Proper Perportion of concrete content.

2. Not proper handeling of concrete at the time of transportation, placing.

3. At the time of placing Free fall Height are exceed 1.5 m.

4. Not proper cohessive force between concrete contains.

Preventation of seggregation in concrete :-

1. Proper Perportion of concrete content.

2. Proper handeling of conrete at the time of transportation placing.

3. At the time of placing free fall height are not exceed 1.5 m

4. Proper adhesion force between concrete content

5. Use of Pozzolonic material.

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 21 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

6. Use of Air entering agent in concrete

BLEEDING :- Conceret Finish Water Concerete Sepretion

Concrete Top surface Conceret defect Bleeding

Preventation of Bleeding in concrete :-

1. Use of Pozzolonic Material

2. Use of Airentering Agent

3. Use of Richer mixer (because lean mix have more bleeding)

4. Uniform and compete mixing of concrete

5. Proper porportion of concrete content

Process of manufacturing of concrete :-

Following steps are follows to manufacture concrete

1. Batching

2. Mixing

3. Transportation

4. Placing

5. Compaction

6. Finishing

7. Curing

1. Batching - Concrete Step Baching Concrete

Materials Mode Measured Concrete batching

a) Volume Batching - Niminal Mix (M-5 to M-25)

b) Weight Batching - Design Mix

Weight Baching is more Accurate Compare to volume Bactching.

2. Mixing of Concrete - Concrete Mix

a) Hand Mixing

b) Machine Mixing

Concrete Mix hand mixing Machine mixing compare Proper mix

hand mix process machine mix compare 10% cement Extra mix

Transportion : Concrete Mix transportation

placing free fall hight 1.5 m

4. Compaction - Concrete Placing Higher Compaction efforts (proper compac-

tion) high Strength Concrete Compaction Concrete

Air Voids remove Concrete Stength concrete

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 22 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Airvoids concrete Strength Reduce

% of voids in concrete Reduce of Strength of concrete

1% 5%

2% 10%

5% 30%

10% 50%

5. Curing of concrete - Concrete Finishing Wet Process

curing of concrete Concrete Wet Curing period

Method of curing - Concrete Curing

1. Water curing

2. Membrance Curing

3. Application of heat & steam curing

4. Miscellaneous Process

Note :- In Normal Condition OPC Minimum Curing Period 7 days RHS have smaller curing period.

Low heat cement have most longer curing period.

Unit - III

AGGEREGATES

Classification of Aggregates according to source - Aggregates

Artifical Aggregate Bricks

Source of Aggregates

1. Naturally - Obtained from Rocks

2. Artificially - Obtained From Brick slag

Natural Agregated

1. Igneous Rock

Ex.- Granite, Basalt, Trap, Dolerite

2. Sedimentary Rocks

Ex.- Lime Stone, Sand Stone, Chalk, Gypsum, Kankar

3. Metamorphick Rocks

ex- Quratzite, slate, marble

Note :- Conceret Aggregates Igneous Rock Best Quality

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 23 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Classification of a aggregates According to size-

Acc. Size Aggregates are Classified in 2 types-

1. Courser Aggregates

2. Finer Aggregates

1. Coarser Aggregates - Aggregated 75mm sieve 4.75 mm Sieve

Coarser Aggregates

[A Aggregate which is passing from 75mm sieve and retend on 4.75mm sieve is called coarser

Aggregates]

2. Finer Aggregates - Aggregate 4.75mm Sieve 0.150mm sieve

Finer Aggregates

Classification of a Aggregates According to surface texture -

According to surface Texture Aggregates are Classified as follow -

1. Smooth surface

ex- Slate, marble, chert

2. Rough surface (Angular)

ex- sand stone, oilites

3. Glassy

Ex- Black flinsh

4. Honey Combed surface

Ex- Scoria, Pumile

5. Crystal Surface

Ex- Basalt, Dolerlite, Granite, Glassic

Note :- Stone Aggregate "Glassy Surface"

Influence The strength of concrete by the texture -

Percent of Partical Water cement

Smooth Rough Ratio

100% 0% 0.54

50% 50% 0.57

0% 100% 0.60

Strength of Aggregate

Flexural strength Compressive Strength

4.30 N/mm2 34.8 N/m2

4.60 N/mm2 32.1 N/m2

4.80 N/mm2 29.5 N/m2

Note :- Higher Compressive strength Smooth Aggregate are Used.

higher Flexural Strength (High bond strength under tension) in

that condition "Rough surface Agg." are used.

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 24 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Classification of Aggregates According to Shape :-

According to shape Aggregates are classified as below -

1. Rounded particals

2. Angular or cubical particals

3. Elonginated particals

4. Flakiner particals

1. Rounded Particals - Concrete Better Workability concrete Rounded

Particals

2. Anfular or cubical particals - Concrete higher strength Condition

Angular or cubical Aggregate preffered

Note :-

1. Concrete elonginated Flakiness Agg. Rounded or Angular

agg. mix flakiness elonginated index 15%

elonginated or flakiness index 6.3mm Particals Valied

2. Rounded particals Void ratio 33% Angular particals void ratio 44%

Rounded particals compare Angular partical higher strength concretes

Angular partical bond Strength rounded particals Compare High

9

3. Elonginated Aggregate - Aggregate length Mean Dimension of Aggregate

5

elonginated Aggregate

Lenght are exceed : 1.8 x mean dimension of Agg.

Min. Dimension - Avg. of passing and retand sieve

Q. What is the lenght of elonginated agg. If passing on 45 mm sieve and retend on 20 mm

sieve.

45 20

1.8 58.50mm

2

9

Elonginated Agg= mean dim ension

5

45 20

Mean Dimension = 32.5

2

9

= 32.5 58.50mm

5

4. Flakiness Aggregate : Aggregate thickness 3/5 x mean dimension

Flakines Agg.

[If thickness of agg are less than 0.60x mean dimesion]

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 25 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Q. Agg. sieve sieve retend

Agg. flakiness thickness

20 10 20 10

0.60 9.0mm 9mm Flakiness Agg. = 15

2 2

3

Flakiness Agg.= mean dim ension

5

3

15 9mm

5

Classification accroding to zone:

According to zone aggregate are classified in 4 zone:

Agg. Zone ZoneI ZoneII ZoneIII ZoneIV

Type of Aggregate Coarse Agg Medium Agg. Find Agg. Very Fine Agg

Aggregate zone Agg. finness Agg. Size

Reduce

Fineness Modules:

Fineness Modules Sand Aggregate Classfied

Types of Sand Finess Modules

Fine Sand 2.2-2.6

Medium Sand 2.6-2.9

Coarser Sand 2.9-3.2

Types of Aggregates Fineness Modules

Find Sand 2.0-3.5

Medium Sand 5.0-7.0

Coarser Sand 6.5-8.5

Note: Sand Fineness modules 3.2

Fineness modules : Sand or Agg. fineness modules sand Agg. particals size

Idea Fineness calculate standard sieve

sieve percentage 100 divide fineness modules calculate

Calculate the fintness modules of a given sample if passing quantity is of sample are given at differ-

ent -different sieve.

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 26 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Stan dard Passing R eta ine d % o f R eta nie d

Sie ve Q ty Q ty Agg/ Sa nd

40m m 50 Ni l 0%

kg=100%

20m m 45kg=9 0% 5Kg 5/50x100=1 0%

10m m 38 Kg=76% 7Kg 10% +7/5x100=24% 12/ 50= 24%

4.75mm 32Kg=64% 6 Kg 24% +6/50x100= 36% 18/ 50= 36%

2.36 mm 24Kg=48% 8Kg 36% +8/50x100= 52 % 26/ 50= 52%

1.18 mm 17Kg=34% 7Kg 52% +7/50x100= 66% 33/ 50= 66%

600? 10Kg=20% 7Kg 66% +7/50x100= 80 % 40/ 50= 80%

350? ? 8Kg=1 6% 2Kg 80% +2/50x100= 84% 42/ 50= 84%

150? ? 0Kg=0 % 8Kg 84% +8/50x100= 100 5 0/ 50=100%

452

Fineness moudles = 4.52

100

Bulking of sand or Aggregates:

dry sand or Agg. Moisture content sand

or Agg. partical surface tension create particals

sand or Agg. volume 5% moisture content sand or

Agg. or bulking maximum continuesly moisture maximum

continuesly Moisture content sand or Agg

20% moisture content sand or Agg

Note :

1. Bulking of Sand of Agg. 5% moisture Maximum

2. Buling of sand Finner Particles Coarser Particales

3. Dry sand or Agg. Moisture content Agg.

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 27 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Amount 5% maximum moisture

reduce

4. moisture content directly proportional

TEST On Aggregate's:

Calculate the prporties of Aggergatics following test are conducted:

Properties of Aggregate Test

Crushing Strength Crushing Test

Hardness Derry Abrasioin testing

Rate of Wear Attriation test

Toughness Impect test

Durability Soundness test

Shape factor Shape test

Abraison value Loss Angleste

Aggregate crusing value (A.C.V.):

Sample -Agg. crushing value sample 12.5 mm sieve

mm sieve retained

Aggregate crushing value Agg. mould Size

normally 25 mm dia or 25 mm height

Aggregate mould pluner total 40 ton load (4 ton per minutes)

Aggregate mm sieve pass

W2

A.C.V.= 100

W1

Where,

W1=Total weight of sample

W2=Weight of sample passing through 2.36 mm sieve

Result: Agg Road Pavement or Bitumen povement top surface(Bearing surface)

A.C.V. Value 30%

Agg. bearing surface other then bearing surface Road Base

coarse or concrete ACV Value 45%

Aggregate Impact Value Test:

Test Aggregate Impact Resistanmce Compacity Impact resistance

Mould Size 10.2 cm Mould Aggregate

14 Hammer 38 cm height Sample

2.36 mm Sieve pass hammer

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 28 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Nos of blow = 15

W2

AIV Value = 100

W1

Where W1=Total weight of sample

W2=Weight of sample passing through 2.36 mm sieve.

1. Agg Road Pavement Bearing surface (Top surface of pavement)

Agg. Impact value 30%

Agg. bearing surface Base coarser or road, concerete

Agg. Impact Value 45%

Aggregates Abraisa Value (A.A.V.)

Agg. Abraisa Value lose angles machine

Agg. RPM Sample 1.70

mm Sieve pass

W2

A.A.V.= 100

W1

Where W1=Total weight of sample

W2=Weight of sample passing through 1.70 mm sieve.

Result:

Agg. beaing surface top surface of road pavement

Agg. Abraisa Value 30%

Agg. Wearing surface Base

coarser or concrete Agg. Abraisa value 50%

ACV AIV AAV

Agg. Are use for Notmore Not more Not more

wearing surface than 30% than 30% than 30

Agg. Are used for other Not more Not more Not more

than wearing surface than 45% than 45% than 50%

like as Base coarser &

concrete work

Deval Attriation testing Machine:

testing machine cylinder 20 cm dia or 34 cm long horizontal 30º 30º

inclination test Agg. rate of wear

Dorry Abrasion Testing Machine:

Testing machine Hardness of Agg.

Loss of Wt. in Gram

Hardness= 20-

3

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 29 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Note: Road or concrete Agg Hardness cofficent 17

Angularity No.67%-% of value of solid particals in a Agg. Sample

Q. If all particle are rounded:

% of solid particals = 67%

% of voids =33%

Angularity No. =67-67=0

Note: Aggregate's angularity No. lies between 0-11

Specific Gravity : Concrete Agg specific gravity 2.6-2.8

Water absorption or Mositure content:

Agg. concrete water absorption capacity Agg. 10%

Agg. Bitumen Pavement water absorption capacity 0.5-1%

Akalies Aggregate Reaction :

Agg. Silica content late reaction

concrete damage posibility concrete

reaction cement alkalies 0.6%

Strength of Concrete

The strength concrete are classified in two types:

1. Compressive strength of concrete

2. Tensile strength of concrete

1. Compressive strength of concrete: To calculate the compressive strength of concrete cubetesting

or coretesting are used.

Compressive strenght of concrete

Cube test Core test

Standard size of cube Standrad size of cylinder

(15cm x 15cm x 15 cm) (15 cm x 30 cm)

Note : Cement concrete compressive strenght core result, cube resutl 85%

Cube strength cube strength

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 30 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Age factor's for permissible compressive strength in case of OPC are use

Age of 3 days 7 days 28 2 3 6 1 year

Concrete days month month month

Compressive 0.50 0.600.70 1.0 1.10 1.16 1.20 1.24

Strength

Wise Com. 50% 6670% 100% 110% 116% 120% 124%

Str. Factor

Note : Concrete 28 days strength characterstic strength of concrere

Tensile strenght of Concrete: Concrete tensile strength compressive strength

approximate 10%

Two methods are used to calculate tensile strength of concrete

1. Direct method 2. Indirect Method

1. Direct Tensile Method: Tensile Strength effective

method result accurate

Indirect tensile method : Indirect method tensile strength test

1. Flexural strenght of concrete or Modulas of Rupture

2. Spliting strength of concrete

1. Flexural strength of concrete : modulus of rupture of concrete

standard size of mould 70 cm x 15 cm x 15 cm

cube size 50cm x 10 cm x 10 cm

Concrete flexural tensile strength 3rd Point loading

IS concrete flexural strength

Flexural Strength of Concrete Fcr= 0.70 ck or 0.70 fck

Note: Direct tensile strength flexural tensile

Ratio:

Direct Tensile

0.50

Flexural Tensile Strength

Flexural Tensile Strength

2.0

Direct Tensile

Spilit Strength of concrete test esa concrete speciman CTM Machine

method large scale concrere tensile stregnth

result accurate spilit tensile strength test

direct tensile strength compare 5-12% High result

Flexural tensile strength > Spilit tensile strength > Direct Tensile Strength

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 31 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Fcr> Fcs>Fct

Note: Resultant tensile strength direction force perpendicular

Bond Strength :Concrere bond strenght steel or concrete friction or adhession

or

concrete hight flexural tensile strength or high impact stregnth smaller size

crush aggregate

Unit

Admixtures

Concretre properties improve admixtures

classify

1. Plasticizers 2. Super Plasticizers 3. Retarder

4. Accleators 4. Air Entering Admixtures

1. Plasticizwers -Concrete concrete work ability improve

concrete use 5-15% reduce

concrete strength increase

Concrete plasticizer cement weight to 0.4% mix

example-Modifed ligno sulpohate (MLS), Sul;phonated nepthaline Formal dehyded (SNF)

2. Supper plasticizer : Advance plasticizer

concrete working improve concrete Use

15-30% reduce

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 32 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Eg:- Modified lignosulphonate, sulphonated nepthalene, formaldehydrade (SNF)

3. Retarder:- Concrete setting time extend Prolonging of setting time

admixtures retarder concrete admixtures retarder

(i) Calicum sulphate (CaSO4) (ii) Gypsum (CaSO4.2H2O)

(iii) Starches (iv) Cellulose

(v) Acid and Salts (vi) Sugar

- sugar effective retarder concrete

concrete ultimate strength setting

time extend sugar

concrete ultimate strength setting time extend

Accleators : Concrete setting time decrease admixture

accleators concrete calcium chloride (CaCl2) Admixture

cement concrete weight of cement

Air entering Agnets: Concrete arientering agents concrete workability increasing

concrete air entering agents concrete freezing and thawing

against safe concrete concrete strength redue

Function of Air Entering Agent:

1. Better Workability

2. Better resistance against freesing and thawing

3. Reduce the strength of concrete at all stages

4. Reduce segrigation of concrete

5. Reduce Bleeding of concrete

6. Reduce the unit weight of concrete

7. Reduce the permability of concrete

8. Reduce the Alkalies Aggregate recation

Unit

Pre-Stress Concrete

- concrete stress develop pre-stress concrete

Pre-stress concrete heavy load or larger span

Tendon : Pre-stress concrete carry steel bar or wire group

system tendon

Cable:Pre-stress concrete tendon cable

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 33 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

- Pre-stress concrete High grade of steel or high grade of concrete

- Pre-stress concrete High grade of steel use shrinkage or creep reduce

Pre-stress concrete steel ultimate stress 1500 N/mm2 (Yield stress =0.6x1500=900-

1000 N/mm2) steel

Method or system of Pre-stress

Concrete pre-stress develop system

1. Pre-tension Method

2. Post-Tension Method

1. Pre-Tension Method: Pre stressing method concreting steel bars

tension develop pre tension method

method pre stressing min grade of concrete M-40

Minimum Nominal concrete cover 20 mm

Pre-tension method concrete Pre-stress develop

1. Unit Mould Method 2. Long line Method

1. Unit mould method member pre-stress develop

Long line method member pre-stress develop

factory production Long line method preffered

2. Post-tension Method: Pre-stressing method concreting

reinforcement stress develop post tension method

Post-tension method pre-stressing Min.Grade of concrete M-30

minimum nominal concrete cover 30mm

Post Tension method: Pre-stress develop

(i) Fressinet Method

(ii) Megnal Balton Method

(iii) Lee-McCall Method

pre-tension method pre-stressing member strength or durability

larger span Method uneconomical larger span case post-

tension method

Losses In Pre-Stress Concrete:

Concrete Pre-stress loss in pre-stress concrete

Pre-stress concrete Losses mainly Classify

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 34 Contact No.: 9610446964

Little Birds School, Sanjay Nagar, Front of Railway Station, Alwar

Losses In Pre-Stress Concrete

Immidiate Losses Time depended losses

Elastic shorting Friction Ancharge Loss due Loss due to Loss due to

of concrete losses slip losses to creep shrinkage steel relaxation

- Loss due to elastic shorting of conc. pre tension method develop

- Loss due to friction post-tension method develop

- Pre tension method total losses 20%

- Post tension method total losses 15%

- Pre-tension method post-tension method compare 5% Loss

- Pre-stress concrete steel relexation 2-8% losses

- Shrinkage strain in Pre-tension method =0.0003

2 10 4

- Shrinkage strain in Post-tension method =

log10 t 2

- Where t=represent age of concrete

Study Material & Online Exams Facility available on web App.

Website:-WWW.civilianinstitutealwar.in 35 Contact No.: 9610446964

Anda mungkin juga menyukai

- Surface Engineering NotesDokumen17 halamanSurface Engineering NotesRajesh Shah0% (1)

- Agreement For Security ServicesDokumen13 halamanAgreement For Security Serviceskishor pratap singhBelum ada peringkat

- DurabilityDokumen34 halamanDurabilitySrikanth KonikiBelum ada peringkat

- OPC Vs PPC - Difference Between OPC and PPC Cement - Civil LeadDokumen12 halamanOPC Vs PPC - Difference Between OPC and PPC Cement - Civil Leaddhan singhBelum ada peringkat

- Difference Between Silica Fume and Fly AshDokumen14 halamanDifference Between Silica Fume and Fly AshSohail Anwar100% (1)

- Cement Raw MaterialDokumen14 halamanCement Raw MaterialCold KillerBelum ada peringkat

- Design of Shotcrete ConcreteDokumen8 halamanDesign of Shotcrete ConcreteDevinder SokhiBelum ada peringkat

- Ree Buddha College of Engineering, Pattoor: ConcreteDokumen9 halamanRee Buddha College of Engineering, Pattoor: ConcreteBala GopalBelum ada peringkat

- Cement Manufacturing ProcessDokumen81 halamanCement Manufacturing ProcessAryabhatt ThakurBelum ada peringkat

- Types of CementDokumen7 halamanTypes of Cementmohamed ahmedBelum ada peringkat

- Morth 1700 Structural ConcreteDokumen23 halamanMorth 1700 Structural ConcreteRamesh88% (40)

- Handbook CPWD NoPWDokumen498 halamanHandbook CPWD NoPWAijaz Zende100% (6)

- Rammed Earth - Module3Dokumen24 halamanRammed Earth - Module3Aditi Sharma100% (1)

- GGBS PropertiesDokumen12 halamanGGBS PropertiesAshwin BalasubramanianBelum ada peringkat

- Sla Agreement HousekeepingDokumen20 halamanSla Agreement HousekeepingRitesh PaliwalBelum ada peringkat

- Structural Materials Lab Report FinalDokumen14 halamanStructural Materials Lab Report FinalSara Keranakis100% (1)

- New Procedure To Investigate External Sulphate Attack On Cementitious MaterialsDokumen8 halamanNew Procedure To Investigate External Sulphate Attack On Cementitious MaterialsCarlos Augusto Sánchez RondónBelum ada peringkat

- CY6251: Engineering Chemistry IIDokumen26 halamanCY6251: Engineering Chemistry IIAnkur GuptaBelum ada peringkat

- Cement and Concrete Presentation LafargeDokumen131 halamanCement and Concrete Presentation LafargeJohnnie Strydom100% (1)

- Advance Cement Concrete M Tech LabDokumen36 halamanAdvance Cement Concrete M Tech LabDr Sanjay GuptaBelum ada peringkat

- Effect of Ultra Fine Flyash and Ultra Fine Ggbs On The Workability and Compressive Strength of ConcreteDokumen6 halamanEffect of Ultra Fine Flyash and Ultra Fine Ggbs On The Workability and Compressive Strength of ConcreteManishMokalBelum ada peringkat

- Mix BM & SDBCDokumen3 halamanMix BM & SDBChafsal90% (10)

- Marshall Method of Asphalt-Concrete Mix DesignDokumen16 halamanMarshall Method of Asphalt-Concrete Mix DesignfitrianiBelum ada peringkat

- A Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionDokumen11 halamanA Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionIJRASETPublications100% (1)

- Report in Technical Analysis CEMENTDokumen26 halamanReport in Technical Analysis CEMENTNatrium KirchhoffBelum ada peringkat

- Engineering Materials: CementDokumen26 halamanEngineering Materials: CementSathvika KodimyalaBelum ada peringkat

- Metakaolin-Pozzolanic Material For Cement in High Strength ConcreteDokumen4 halamanMetakaolin-Pozzolanic Material For Cement in High Strength ConcreteElango PaulchamyBelum ada peringkat

- Cement Manufacturing ProcessDokumen2 halamanCement Manufacturing ProcessTeja Mandapati100% (2)

- Testing of Cement: Free Powerpoint Templates Free Powerpoint TemplatesDokumen23 halamanTesting of Cement: Free Powerpoint Templates Free Powerpoint TemplatesVivekChaudharyBelum ada peringkat

- 08 - Chapter 2 (Literature Review)Dokumen26 halaman08 - Chapter 2 (Literature Review)Nancy PrevinBelum ada peringkat

- The Design of Fly-Ash Concretes (I. A. Smith)Dokumen22 halamanThe Design of Fly-Ash Concretes (I. A. Smith)Dinakar PraneethBelum ada peringkat

- Blended CementsDokumen75 halamanBlended CementsRam VenkatachalamBelum ada peringkat

- Optimizing The Use of Fly Ash in ConcreteDokumen24 halamanOptimizing The Use of Fly Ash in ConcretePratik RaoBelum ada peringkat

- HR - Meehanite MetalDokumen3 halamanHR - Meehanite MetalzamporpsBelum ada peringkat

- Cement Classification BDPDokumen26 halamanCement Classification BDPkonstantasBelum ada peringkat

- AfriSam Technical Ref Guide Update 2018 PDFDokumen162 halamanAfriSam Technical Ref Guide Update 2018 PDFvillanuevamarkdBelum ada peringkat

- ConcreteDokumen31 halamanConcreteShashank Patole100% (1)

- Portland Cement ConcreteDokumen47 halamanPortland Cement ConcreteAbbasabbasiBelum ada peringkat

- Design of Pavement by Using Geo PolymerDokumen33 halamanDesign of Pavement by Using Geo PolymermohammedaliarBelum ada peringkat

- Erez Allouche Latech Geopolymer ConcreteDokumen9 halamanErez Allouche Latech Geopolymer ConcreteRudra KushalBelum ada peringkat

- PPTDokumen28 halamanPPTRama Arul SakthiBelum ada peringkat

- Bogue's Compounds - DR VSR SOEDokumen6 halamanBogue's Compounds - DR VSR SOEvempadareddy100% (1)

- Failure TheoriesDokumen21 halamanFailure TheoriesMadhan Krishnamurthy100% (1)

- Module 2 CementDokumen20 halamanModule 2 CementKamil ShairBelum ada peringkat

- Mechanical Properties of High Volume Fly Ash Concrete Subjected To Elevated TemperaturesDokumen29 halamanMechanical Properties of High Volume Fly Ash Concrete Subjected To Elevated TemperaturesUmer FarooqBelum ada peringkat

- Experimental Study On High Strength and Low Shrinkage ConcreteDokumen3 halamanExperimental Study On High Strength and Low Shrinkage ConcreteijaertBelum ada peringkat

- Literature Survey On Geopolymer Concretes and A Research Plan in Indian ContextDokumen13 halamanLiterature Survey On Geopolymer Concretes and A Research Plan in Indian ContextVikas BiradarBelum ada peringkat

- CHRYSO-additive For Cement PDFDokumen20 halamanCHRYSO-additive For Cement PDFidefix45100% (1)

- By Christopher DzuwaDokumen10 halamanBy Christopher DzuwaChrisBelum ada peringkat

- Water Cement Ratio (W/C) : VC +VW Vah + VHP + VCPDokumen12 halamanWater Cement Ratio (W/C) : VC +VW Vah + VHP + VCPVijay BhanBelum ada peringkat

- Slump LossDokumen4 halamanSlump LossAman SahadeoBelum ada peringkat

- Advanced Technologies in ConcreteDokumen24 halamanAdvanced Technologies in ConcreteNaga Ashok GandiBelum ada peringkat

- En 197Dokumen1 halamanEn 197ulaska1Belum ada peringkat

- 2-Theories of Failure (MOS-2)Dokumen28 halaman2-Theories of Failure (MOS-2)Sohaib Zaib KhanBelum ada peringkat

- Project Sand Repacement and Cement Replacement With Crusher DustDokumen47 halamanProject Sand Repacement and Cement Replacement With Crusher DustAdusumalli Surendra BabuBelum ada peringkat

- Presentation of Calcium AluminateDokumen18 halamanPresentation of Calcium AluminateASHRAFUL KABIRBelum ada peringkat

- Role of Water Cement Ratio On The Cement MortarDokumen7 halamanRole of Water Cement Ratio On The Cement MortarPankaj Munjal100% (1)

- European Asphalt Standards - PresentationDokumen17 halamanEuropean Asphalt Standards - PresentationCharles LangatBelum ada peringkat

- Fly Ash For Cement ConcreteDokumen48 halamanFly Ash For Cement Concreterashm006ranjanBelum ada peringkat

- Concrete PropertiesDokumen32 halamanConcrete PropertiesEldho CaBelum ada peringkat

- Case Study COFFERDAM ARCHITECTUREDokumen2 halamanCase Study COFFERDAM ARCHITECTUREAniketĺ Deshmukh100% (1)

- Experiment:8 Aim: Find Out Moisture, Volatile Matter and Ash Content in FuelDokumen3 halamanExperiment:8 Aim: Find Out Moisture, Volatile Matter and Ash Content in FuelDhruv RanaBelum ada peringkat

- Cement Manufacturing ProcessDokumen11 halamanCement Manufacturing Processashish.khangar9358100% (2)

- Sand Cement Brick Containing Recycled PDFDokumen7 halamanSand Cement Brick Containing Recycled PDFsyakirohBelum ada peringkat

- Fibrous Materials Reinforced Composites PDFDokumen25 halamanFibrous Materials Reinforced Composites PDFyigitilgazBelum ada peringkat

- Important Note On Concrete TechnologyDokumen25 halamanImportant Note On Concrete TechnologyPrantik Adhar SamantaBelum ada peringkat

- Polymer Impregnated Concrete - Uses, Properties of Polymers in ConcreteDokumen4 halamanPolymer Impregnated Concrete - Uses, Properties of Polymers in ConcretesahilkaushikBelum ada peringkat

- Green Concrete Partially Comprised of Farming Waste Residues A RiviewDokumen35 halamanGreen Concrete Partially Comprised of Farming Waste Residues A RiviewfiqBelum ada peringkat

- Buyers GuideDokumen32 halamanBuyers GuideFord cellBelum ada peringkat

- The Iron Blast Furnace: Theory and PracticeDari EverandThe Iron Blast Furnace: Theory and PracticePenilaian: 3 dari 5 bintang3/5 (2)

- Final Year Project Presentation ON: Portland CementDokumen17 halamanFinal Year Project Presentation ON: Portland CementfarhanBelum ada peringkat

- Laboratory Compaction Characteristics and Moisture-Density Relationship of Subgrade, Embankment Soils, and Backfill MaterialDokumen13 halamanLaboratory Compaction Characteristics and Moisture-Density Relationship of Subgrade, Embankment Soils, and Backfill MaterialRitesh PaliwalBelum ada peringkat

- Query in TenderDokumen1 halamanQuery in TenderRitesh PaliwalBelum ada peringkat

- Fraud Notice Careers PDFDokumen1 halamanFraud Notice Careers PDFRitesh PaliwalBelum ada peringkat

- Resume SampleDokumen4 halamanResume SampleRitesh PaliwalBelum ada peringkat

- Detailed PDFDokumen8 halamanDetailed PDFRitesh PaliwalBelum ada peringkat

- Section 3300Dokumen2 halamanSection 3300amintaka1025Belum ada peringkat

- SubcontractorAgreement8 15 08Dokumen7 halamanSubcontractorAgreement8 15 08Ritesh PaliwalBelum ada peringkat

- Ushas Marketi NG: Wishing U Happy DeepawaliDokumen1 halamanUshas Marketi NG: Wishing U Happy DeepawaliRitesh PaliwalBelum ada peringkat

- National Institute of Technology Calicut: Walk-In-InterviewDokumen1 halamanNational Institute of Technology Calicut: Walk-In-InterviewRitesh PaliwalBelum ada peringkat

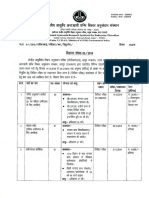

- Notification GAIL India LTD SR Engineer Officer PostsDokumen19 halamanNotification GAIL India LTD SR Engineer Officer PostsRitesh PaliwalBelum ada peringkat

- Name of The Department Post & No. of Vacancy Reservation Roster PointDokumen4 halamanName of The Department Post & No. of Vacancy Reservation Roster PointRitesh PaliwalBelum ada peringkat

- Walk-In Interview: Dec 2018 at Delhi For Delhi Team and On 22 Dec 2018 at Chennai For Chennai Team. For Details of TheDokumen8 halamanWalk-In Interview: Dec 2018 at Delhi For Delhi Team and On 22 Dec 2018 at Chennai For Chennai Team. For Details of TheRitesh PaliwalBelum ada peringkat

- Icmr-National Institute of VirologyDokumen5 halamanIcmr-National Institute of VirologyRitesh PaliwalBelum ada peringkat

- FSTFT, F F FFTM /#FTV Hi FF : FTM M) GFFL $ FCHJDokumen2 halamanFSTFT, F F FFTM /#FTV Hi FF : FTM M) GFFL $ FCHJRitesh PaliwalBelum ada peringkat

- IIT Dharwad Advt No. 012 V5 FinalDokumen8 halamanIIT Dharwad Advt No. 012 V5 FinalRitesh PaliwalBelum ada peringkat

- Notification English School Education Dept Karnataka KARTET 2018Dokumen11 halamanNotification English School Education Dept Karnataka KARTET 2018Ritesh PaliwalBelum ada peringkat

- FT " FT FT: FTR.R:R 1Lgl "Fifctgt . R R G :E / 1Rff, 3R'FlfuDokumen6 halamanFT " FT FT: FTR.R:R 1Lgl "Fifctgt . R R G :E / 1Rff, 3R'FlfuRitesh PaliwalBelum ada peringkat

- Ipgtra Advt 2 2018 Teaching PostDokumen5 halamanIpgtra Advt 2 2018 Teaching PostRitesh PaliwalBelum ada peringkat

- Khandwavigyaptiphase 9Dokumen10 halamanKhandwavigyaptiphase 9Ritesh PaliwalBelum ada peringkat

- Detailed 05goaDokumen11 halamanDetailed 05goaRitesh PaliwalBelum ada peringkat

- Ipgtra Advt 2 2018 Teaching PostDokumen4 halamanIpgtra Advt 2 2018 Teaching PostKirankumar MutnaliBelum ada peringkat

- Notification BECIL Patient Care Manager Patient Care Coordinator PostsDokumen3 halamanNotification BECIL Patient Care Manager Patient Care Coordinator PostsRitesh PaliwalBelum ada peringkat

- Notification TRB Tripura STGT PostsDokumen5 halamanNotification TRB Tripura STGT PostsRitesh PaliwalBelum ada peringkat

- Advt 232018Dokumen7 halamanAdvt 232018Ritesh PaliwalBelum ada peringkat

- Advt ScientistDokumen3 halamanAdvt ScientistRitesh PaliwalBelum ada peringkat

- Bunnings CatalogDokumen21 halamanBunnings CatalogStratos Tsiavis100% (1)

- Tolerancije Limova I CeviDokumen4 halamanTolerancije Limova I CeviZoran Tanja JarakovićBelum ada peringkat

- Basic Material Science Lecture - 1Dokumen22 halamanBasic Material Science Lecture - 1Mustafa Enes KırmacıBelum ada peringkat

- Bill of Materials Mekanika CNC Router 1200x800Dokumen4 halamanBill of Materials Mekanika CNC Router 1200x800Javier JhamalBelum ada peringkat

- On BondsDokumen18 halamanOn BondsMahesh Ramteke100% (1)

- Specification.: Steel ScrapDokumen24 halamanSpecification.: Steel ScrapKalpeshBelum ada peringkat

- HS Transition JointDokumen2 halamanHS Transition Jointvivek jayswalBelum ada peringkat

- 8m Octagonal Pole DrawingDokumen1 halaman8m Octagonal Pole DrawingSameer KmBelum ada peringkat

- P2-Footing Beam Shiv 29 - 11 - 23Dokumen1 halamanP2-Footing Beam Shiv 29 - 11 - 23rahulBelum ada peringkat

- A193B7 MaxTemp AllwbleStress - Portland BoltDokumen5 halamanA193B7 MaxTemp AllwbleStress - Portland BoltAnonymous nw5AXJqjdBelum ada peringkat

- Data Sheet - Joint Unions, DIN11851, ImperialDokumen2 halamanData Sheet - Joint Unions, DIN11851, ImperialfedorBelum ada peringkat

- Commercial Catalog - Kymik Zincalume TanksDokumen6 halamanCommercial Catalog - Kymik Zincalume TanksSaptarshi RoyBelum ada peringkat

- ALUMERO - Alloys EN AW 6060 AlMgSi0 - WebDokumen1 halamanALUMERO - Alloys EN AW 6060 AlMgSi0 - WebemilasanovskiBelum ada peringkat

- PPR Pipe SizingDokumen1 halamanPPR Pipe SizingTAREQBelum ada peringkat

- Tablas ACAR 2Dokumen2 halamanTablas ACAR 2Carlos OrtizBelum ada peringkat

- Stenflex - GR Sae1 2H21Dokumen2 halamanStenflex - GR Sae1 2H21françois MBelum ada peringkat

- MaterialData - 56973 2Dokumen2 halamanMaterialData - 56973 2red_beastBelum ada peringkat

- D.Price List Fatima EnterprisesDokumen3 halamanD.Price List Fatima EnterprisesGhalla Food TradersBelum ada peringkat

- Plasticbrick 190603072205Dokumen24 halamanPlasticbrick 190603072205NUR SYAFIQAH BINTI FISAL MET211031Belum ada peringkat

- Sanwa Export 02 Gate ValveDokumen1 halamanSanwa Export 02 Gate ValveTou SvnkBelum ada peringkat

- Main Villa GF Arc Window Schedule 02Dokumen1 halamanMain Villa GF Arc Window Schedule 02MiteshSuneriyaBelum ada peringkat

- Dow Corning 983Dokumen3 halamanDow Corning 983antoineBelum ada peringkat

- VEDAFEU Fire Barrier SystemsDokumen32 halamanVEDAFEU Fire Barrier SystemsShyam AwalBelum ada peringkat

- Casing Patch PresentationrevDokumen23 halamanCasing Patch PresentationrevJesus BolivarBelum ada peringkat