Application of Composites For Centrifugal Pumps

Diunggah oleh

ravide76Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Application of Composites For Centrifugal Pumps

Diunggah oleh

ravide76Hak Cipta:

Format Tersedia

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 4 - September 2015

A Review on Application of Composite Materials to Increase

the Efficiency of the Centrifugal Pumps

Neha Sharad Kotak

Final year, Mechanical Engineering, SIES GST Navi Mumbai

Maharashtra, India

ABSTRACT- During long operating cycles, the properties, and do not cause galling or seizing. This

metallic, mating parts of your pump can sustain permits a dramatic reduction in clearances between

damage, resulting in costly repairs and delays. As the rotating and stationary wear parts which lead to a

abrasive surfaces brush past one another, critical multitude of performance advantages. This paper

components experience fatigue and even product expounds the effects of replacing conventional wear

failure due to wear, galling, and seizing of pump rings between a centrifugal pump casing inlet and the

equipment. The demand for pump reliability and rotatable impeller having a plurality of

performance is ever increasing. Today the primary circumferentially spaced blades. A substitute wear

characteristics sought by pump users are higher ring is formed of a thermoplastic polymer, POLY-

reliability, lower vibration levels and better efficiency ETHER-ETHER-KETONE (PEEK) which is

across a wide range of operating conditions. This thermally stable and self-lubricating over a range of

paper explains the methods to improve the efficiency temperatures of from zero to 600° F. Because the

of centrifugal pumps by using new composite thermal coefficient of expansion of PEEK is

materials with better performance. Up to 20 per cent substantially different from the pump casing metal

of a pump’s energy consumption is saved with the use and the impelled metal, the use of the PEEK allows

of composite impellers, especially where the pump is the efficiency of the pump to be increased by

required to work with a corrosive or erosive correctly selecting the diameters for construction of

medium. The introduction of new composite the wear ring for operation over a selected range of

materials that have the ability to cover applications temperatures of the pumped fluid. This application

that traditional composites were not suitable for, are reduces the clearance between the surfaces of the

now possible with the inclusion of PEEK (Poly-Ether elements to substantially improve pump efficiency

Ether-Ketone) based composites in the American while at the same time vibration and wear are

Petroleum Institute (API). Polymer-based composite reduced substantially

materials have excellent strength and wear

desired, PEEK additionally increases the life

efficiency and reliability by plugging impeller

KEYWORDS- American petroleum institute (API),

balance holes. This not only reduces recirculation,

Centrifugal pump, Composite materials, PEEK (poly- but also increases seal chamber pressure to prolong

seal life. The method is believed to cover a higher

EtherEther-ketone).

percentage of all centrifugal pumping applications.

I. INTRODUCTION

Centrifugal Pump efficiency varies with Speed,

Impeller diameter, design of the impeller fitted and

different materials when offered to different

specifications. In order to increase the

efficiency ,a method for modifying wear rings and

bushings in centrifugal pumps operating at

temperatures ranging from zero to 600° F in

centrifugal pumps is possible by retrofitting the

pumps with wear rings and bushings made of

thermoplastic Poly-Ether-Ether-Ketone, "PEEK".

Because of its thermal stability over such

temperatures and its self-lubricating nature, PEEK

makes it possible to run much closer clearances

between the impeller intake and the pump casing,

improving hydraulic performance and reducing

energy-wasting recirculation. The method also Fig1.Centrifugal pump

substantially reduces internal damage from mishaps

in the pump. If

ISSN: 2231-5381 http://www.ijettjournal.org Page 186

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 4 - September 2015

II. IMPELLER MODIFICATIONS BASED produces very positive results with regard to the

ON THESAME IMPELLER SHAPE TO ability to reach and treat even very narrow areas such

INCREASE THE EFFICIENCY as impeller vanes in multistage pumps which cannot

be reached for polishing.

A. Change of impeller design

III. WEAR COMPONENTS OF PUMP AND

The possibility of installing in the original pump

Casing, an impeller with a new design selected from THEIR USE PARAMETERS

a wide range of available pumps can help in The wear components are designed to support and

increasing the efficiency. stabilize the pump rotor and offer protection to the

shaft, impeller and pump casing because they absorb

B. De-staging or Re-staging wear and abuse from regular use and upset

Removing (or adding to a previously de-staged conditions. In addition to these roles, wear rings act

pump) one or more impellers from a multistage as internal seals. They help to restrict the flow of

pump allows the performance curve to be moved media moving from the discharge side of the impeller

upward or downward, achieving roughly through the wear ring clearances back into the

thesame effects as modification of the diameter. suction eye of the impeller which is a cause of loss of

efficiency .The smaller the clearance between wear

C. Volute / Diffuser modifications ring interfaces, the better the pump efficiency.

Traditionally, bushings and wear rings have been

The geometry of the static channels has a dramatic made from metallic materials, but there has been a

impact on the performance of a centrifugal revolutionary change and composite materials are

pump. Thus modifying parameters such as the volute being used as a replacement for these metal wear

cross sectional area, the position of the volute parts. Using reinforced polymer-based composite

cutwater, and the shape and distance of the cutwater materials can lead to some dramatic advantages

to the impeller provides significant flexibility in the including minimized running clearances, lower

shape of the performance. vibration levels, extended wear life and lower repair

cost. Minimized running clearances are possible due

to the non-galling and non-seizing nature of

reinforced polymer composites. Since galling and

seizing are not an issue, clearances can be designed

to approximately half of that recommended for metal-

to-metal configurations.

These slimmer running clearances restrict internal

leakage which results in greater pump efficiency. In

addition to gains in efficiency as a result of

reductions in running clearances, vibration levels are

often favorably impacted. Close clearance bushings

and wear rings are better able to generate a thin liquid

film on which the rotor can glide. Basically, wear

rings and bushings are transformed into hydrostatic

radial bearings. This is more difficult to achieve

when there is a larger space between the rotating and

stationary interfaces.

IV. COMPOSITE MATERIALS

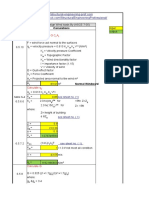

Fig 2. Centrifugal Pump Efficiency Performance

curve A composite consists of two or more distinct

D. Volute cleaning and coating of the casing with materials that, when combined, create a material that,

is stronger, tougher and/or more durable than the

ceramic paint individual materials would be standing alone.

Saving energy is a key issue The API 610 9th edition, recognizes and lists

in plant operations today. In centrifugal pumps, polymer-based composites as an acceptableoption for

the efficiency is directly affected by the replacing metal wear parts to improve pump

friction encountered by the process fluid as it passes performance in appropriate applications. It is

through the pump. This demands optimum important to point out that there are almost

surface finish in order to reduce friction. Further as many different types of composite materials

reduction can be achieved by applying specialized as there are applications for their use. This is because

ceramic coatings along all the channels. A the make up of a composite can and should be

recent introduction in the pump industry, this process

ISSN: 2231-5381 http://www.ijettjournal.org Page 187

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 4 - September 2015

tailored to have physical properties and properties, extended dry run performance, broad

characteristics that match the demands of the chemical resistance, PEEK can reduce wear

application. Polymer-based composite materials are clearances up to 50%,in many cases without the risk

typically made up of a thermoplastic (often referred of damaging many parts. PEEK polymers are

to as the matrix) and a reinforcing fiber material obtained by step-growth polymerization

(often referred to as the filler). These classes of bythe dialkylation of bisphenolatesalts. Since this is a

polymer-based composites contain the same two base PEEK dominant compound, it’s Coefficient of Linear

materials, Poly-EtherEther-Ketone (PEEK) Thermal Expansion (CLTE) it is twice that of Carbon

thermoplastic and carbon fiber. The molding of the Steel .Due to the difference in expansion rates, it is

blended resin allows the thermoplastic (PEEK) to best suited for and typically used for stationary,

flow around and encapsulate the filler (carbon fiber) pressed-in parts such as bushings or case wear rings

creating a quite homogeneous material. The ratio in applications above ambient temperatures. It is

between the polymer matrix and the filler is highly resistant to thermal degradation as well as

manipulated to yield materials with a desired range of attack by both organic and aqueous environments.

properties and characteristics that match the Also, this material will contract at a higher rate

requirements of the intended application. The type of than mostmetals and will be more suited for press-on

filler, percentage of filler, and shape, size and applications n sub-

orientation of the filler, all play an important part in ambient temperature environments.

determining the physical properties and different

thermal characteristics of the composite.

A.Composite impellers

Composite impellers are only 15 per cent of the

weight of traditional metallic materials. They can

offer energy savings because of their light weight and

also because they are not affected by corrosion, and

they are suitable for upgrades. Energy savings from

the composite pump impellers are produced by two

sources. Firstly, the composite material being light

weight, requires less energy to move the mass of the Fig 4.PEEK material.

impeller. Secondly,it comes from the fact that they

do not corrode so as a consequence does not change

the design characteristics of the pump’s impeller. A. Characteristics Of PEEK Material

When the metallic pump parts begin to wear from PEEK is a high performance thermoplastic that has

corrosion, efficiency drops drastically. This drop in both high strength and high temperature limits, e.g.

efficiency not only has a significant impact on energy up to 600° F.PEEK expands at a much greater rate

consumption but also increases the cost of than metals. This means that as operating

maintenance. The life of the pump can be reduced to temperatures increase, the interference fit between

months instead of years as originally intended. the impeller and the wear rings loosens. To account

Machining enables the composite impeller to be for the greater expansion of the PEEK wear ring, a

optimized for the service in which the pump is heavy initial "cold" (ambient temperature)

designed. Since these impellers are corrosion interference fit can be used, and the upper

resistant to most liquids, they do not become temperature limits for the pumped fluid must be

imbalanced even after years of service and this specified. PEEK has excellent chemical resistance

reduction in vibration also translate into higher and may be used for pumping numerous

efficiency and a reduction in energy consumption. hydrocarbons from crude oil to propane. It is also

The lower weight not only reduces startup load but suitable for condensates, boiler feed water, sour water

also reduces shaft deflection. This allows the rotating and a wide variety of other dirty water services.

element to run with tighter clearances between the Other services include ammonia, caustic, DEA and

rings and the impeller giving the increases in carbonate. It has been used as the premier material

efficiency and the reduction energy consumption. for sealing elements in compressor valves and has

been widely applied in pumps, as well as other

V. POLY-ETHERETHER-KETONE (PEEK) compressor application. However, PEEK wear rings

are not suitable in pumping sulfuric acid, nitric acid,

POLY-ETHERETHER-KETONE is a matrix (PEEK HF acid, or chlorine. For hostile environments,

thermoplastic) dominated composite consisting of a PEEK is a high strength alternative to

compression-molded material of approximately 70% fluoropolymers. PEEK carries a Variable

PEEK and reinforcing fibers with a random flammability rating and exhibits very low smoke and

orientation.Offering outstanding wear and friction toxic gas emission when exposed to flame.

ISSN: 2231-5381 http://www.ijettjournal.org Page 188

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 4 - September 2015

an extremely low coefficient of friction but they are

much softer than metals and are intended to be the

B. Types ofPeek Materials

sacrificial component should severe upset conditions

1 .Ketron PEEK (H101) develop. Composites can withstand hard contact with

little or no damage and can handle intermittent dry

This general purpose grade is unreinforced and offers

run episodes. In cases where dry run is quite

the highest elongation and toughness of all PEEK

extensive, the composite will suffer surface melt but

grades.

will not damage expensive metal parts such as

2. 30% Glass-reinforced Ketron PEEK (H301)

impellers, shafts or pump casings.

The addition of glass fibers significantly reduces the

expansion rate and increases the flexural modulus of

VI. CONCLUSION

PEEK. This grade is ideal for structural applications

that require improved strength, stiffness or stability, To conclude with ,this paper exemplify that

especially at temperatures above 300°F (150°C). thermoplastic composite materials have been and can

be applied to either the rotating or stationary wear

3. 30% Carbon fiber-reinforced Ketron PEEK (H201) parts in a broad range of centrifugal pumps. On the

application of PEEK material, the reduced clearance

The addition of carbon fibers enhances the

obtained minimizes the recirculation to maximize the

comprehensive strength and stiffness of PEEK, and

rotor stability and overall efficiency. These materials

dramatically lowers its expansion rate. It offers

also provide greater hardness deferential between

designers optimum wear resistance and load carrying

wear part, the composite material serving as wear

capability in a PEEK-based product. This grade

component and minimizes the shaft run out. Polymer

provides 3.5 times higher thermal conductivity than

based composite materials have many qualities and

unreinforced PEEK - dissipating heat from the

characteristics that can lead to improved pump

bearing surface faster.

performance and longer mean time between pump

repairs. Composites are also sacrificial in nature and

4.Virgin PEEK

they will not damage expensive metal parts .In cases

Its high mechanical properties at elevated of severe upset conditions and pump failure

temperatures, combined with excellent chemical and composite materials help to protect metal parts,

hydrolysis resistance, make it the most popular mitigating damage and lowering the overall cost of

advanced thermoplastic material available today. repair .They also reduce the deflection and the

vibration for dramatically reduced energy

consumption and repair costs. Pump users need to

5. Glass filled PEEK

understand these differences and it is important that

It exhibits higher modulus than VRPK(neat composite parts be designed to compensate for the

PEEK),thus offering more resistance to deformation thermal expansion differentials.

under load at elevated temperatures. This material is

an ideal candidate for many structural component REFERENCES

applications carrying high static loads. [1].Jinbao Lin, YanjuanJin, Zhu Zhang, and Xiaochao Cui

“Strength Analysis of the Carbon-Fiber Reinforced Polymer

Impeller Based on Fluid Solid Coupling Method”.

C.Peek as Wear Material [2]. Author Federic W. Buse “Tutorial on composite pumps”.

[3].Composite wear materials for rotating equipment.

Polymer composites contain thermoplastics as PEEK. [4].Pumps and pumping systems.

This is a ductile material which absorbs shocks and [5].Composite impellers produce significant lifecycle savings.

vibrations, dampening the effects of resonating metal

components. PEEK wear components are always

mated against metal wear surfaces. They possess high

strength properties, excellent impact resistance and

ISSN: 2231-5381 http://www.ijettjournal.org Page 189

Anda mungkin juga menyukai

- The Power of Wear RingsDokumen18 halamanThe Power of Wear RingsVinh Do ThanhBelum ada peringkat

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDari EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazinePenilaian: 5 dari 5 bintang5/5 (1)

- Improving Reliability and Efficiency of Centrifugal PumpsDokumen4 halamanImproving Reliability and Efficiency of Centrifugal PumpsHatem ShawkiBelum ada peringkat

- Meeting the Pump Users Needs: The Proceedings of the 12th International Pump Technical ConferenceDari EverandMeeting the Pump Users Needs: The Proceedings of the 12th International Pump Technical ConferenceBelum ada peringkat

- Hydraulic Efficiencies of Impeller and PumpDokumen9 halamanHydraulic Efficiencies of Impeller and PumpJohn Archie MendozaBelum ada peringkat

- Design and Analysis of TPA Purdue PDFDokumen24 halamanDesign and Analysis of TPA Purdue PDFJohn DoeBelum ada peringkat

- Hydraulic Pumps Lec NotesDokumen30 halamanHydraulic Pumps Lec NotesDarsh MenonBelum ada peringkat

- Eccentric Reducers and Straight Runs of Pipe at Pump Suction - Hydrocarbon Processing - September 2010Dokumen4 halamanEccentric Reducers and Straight Runs of Pipe at Pump Suction - Hydrocarbon Processing - September 2010kronafBelum ada peringkat

- Pump BrochureDokumen10 halamanPump Brochuresen_subhasis_58100% (1)

- Advance Design of PumpsDokumen20 halamanAdvance Design of Pumpsfugga100% (1)

- Ms Megachem A2740 8e 3Dokumen23 halamanMs Megachem A2740 8e 3nata siagianBelum ada peringkat

- Slurry PumpsDokumen69 halamanSlurry PumpsJhonny AlvarezBelum ada peringkat

- Presentation of PumpDokumen46 halamanPresentation of PumpArindam SamantaBelum ada peringkat

- Preliminary Design of Turbopumps and Related Machinery - NASA PDFDokumen406 halamanPreliminary Design of Turbopumps and Related Machinery - NASA PDFStacy WilsonBelum ada peringkat

- b3311 722-2Dokumen7 halamanb3311 722-2Arnaldo BenitezBelum ada peringkat

- Pistonless PumpDokumen21 halamanPistonless PumpDeepuDevarajanBelum ada peringkat

- Centrifugal Pump OverloadingDokumen2 halamanCentrifugal Pump OverloadingAbdul AlimBelum ada peringkat

- Detailed Performance of A Radial-Bladed Centrifugal Pump Impeller in WaterDokumen56 halamanDetailed Performance of A Radial-Bladed Centrifugal Pump Impeller in Waterzakibrant23Belum ada peringkat

- 5.7 Centrifugal PumpsDokumen8 halaman5.7 Centrifugal PumpsSaleem Chohan100% (1)

- T II P Training Program On Basic Process Engineering PracticesDokumen26 halamanT II P Training Program On Basic Process Engineering PracticesAsmita AndaniBelum ada peringkat

- SM 3026 PDFDokumen8 halamanSM 3026 PDFMiguel CasasBelum ada peringkat

- Boiler Feed Pump - KSBDokumen1 halamanBoiler Feed Pump - KSBgulmal husainBelum ada peringkat

- Sección Bombas Centrífugas - Kent ArnoldDokumen21 halamanSección Bombas Centrífugas - Kent Arnoldmonjardin68Belum ada peringkat

- Bomba CPKDokumen20 halamanBomba CPKPatricio Andres Silva SanzanaBelum ada peringkat

- Multistage Pump - Kirloskar PDFDokumen63 halamanMultistage Pump - Kirloskar PDFpsuvarnasBelum ada peringkat

- PDF IIHR402Dokumen61 halamanPDF IIHR402Sanjib MazumderBelum ada peringkat

- Cavitation and Pump NPSHRDokumen39 halamanCavitation and Pump NPSHRRicardo BarrosBelum ada peringkat

- Hydraulic Resevoir Design Criteria PDFDokumen10 halamanHydraulic Resevoir Design Criteria PDF2345421Belum ada peringkat

- Training - Flowserve Apm Pump CW Pump Part3-2Dokumen4 halamanTraining - Flowserve Apm Pump CW Pump Part3-2hasan099Belum ada peringkat

- Centrifugal PumpDokumen360 halamanCentrifugal PumpArnel V. EsllerBelum ada peringkat

- CraneEngineering - Centrifugal Pumps HandbookDokumen24 halamanCraneEngineering - Centrifugal Pumps Handbookjosegabrielrosas100% (1)

- Report On Axial Flow Pump-0510087Dokumen10 halamanReport On Axial Flow Pump-0510087Soud FarhanBelum ada peringkat

- Centrifugal PumpDokumen9 halamanCentrifugal Pumpasfand12345100% (1)

- 10 Things You Need To Know About NPSHDokumen4 halaman10 Things You Need To Know About NPSHB rgBelum ada peringkat

- Impeller - KSBDokumen6 halamanImpeller - KSBEd0% (1)

- Pumping Control Methods and Their Impact On System EfficiencyDokumen16 halamanPumping Control Methods and Their Impact On System EfficiencyWahidHamedBelum ada peringkat

- Impeller DesignDokumen6 halamanImpeller Design19MECH052 SYED YOUNUS100% (1)

- Centrifugal Pumps PresentationDokumen28 halamanCentrifugal Pumps Presentationprasoon_eilBelum ada peringkat

- Review of Parameters Influencing Hydraulic Forces On Centrifugal ImpellersDokumen12 halamanReview of Parameters Influencing Hydraulic Forces On Centrifugal ImpellersHosseinBelum ada peringkat

- Pumps and Compressors: Week 7Dokumen20 halamanPumps and Compressors: Week 7ednsmnBelum ada peringkat

- Study of The Centrifugal Pump Efficiency at Throttling and Speed ControlDokumen4 halamanStudy of The Centrifugal Pump Efficiency at Throttling and Speed ControlHassan SouleymanBelum ada peringkat

- Radial Pump Impeller Design ExampleDokumen16 halamanRadial Pump Impeller Design ExampleDon Poul JoseBelum ada peringkat

- Blackmer Positive Displacement Pump For Liquefied Gas ApplicationsDokumen20 halamanBlackmer Positive Displacement Pump For Liquefied Gas ApplicationsDaniel Leal Pintor100% (1)

- Pump Notes PDFDokumen25 halamanPump Notes PDFUsman KhalidBelum ada peringkat

- Cent-Pump Performance Curves and Similarity LawsDokumen9 halamanCent-Pump Performance Curves and Similarity LawsMachineryengBelum ada peringkat

- Centrifugal Pump2Dokumen15 halamanCentrifugal Pump2limakupang_matBelum ada peringkat

- The Effect of Sand-Clay Slurries On The Performance of Centrifugal PumpsDokumen6 halamanThe Effect of Sand-Clay Slurries On The Performance of Centrifugal PumpsOlga ĆalasanBelum ada peringkat

- Compressors: Me7313 Industrial Automation and ControlDokumen13 halamanCompressors: Me7313 Industrial Automation and ControlNuwan DinushaBelum ada peringkat

- Pump Clinic 43Dokumen3 halamanPump Clinic 43fnahas_bhBelum ada peringkat

- The Axial Flow Compressor CompromiseDokumen8 halamanThe Axial Flow Compressor Compromisekincandia100% (4)

- Canned Motor Pumps in Refinery PDFDokumen2 halamanCanned Motor Pumps in Refinery PDFthawdarBelum ada peringkat

- Hydraulic Pump ContDokumen15 halamanHydraulic Pump ContbmdbmdbmdBelum ada peringkat

- Slurry PumpDokumen97 halamanSlurry Pumpsmendoza100% (1)

- Canned Motoer PumpDokumen5 halamanCanned Motoer PumpSteve WanBelum ada peringkat

- Pump Motor TripDokumen4 halamanPump Motor TripKamal UddinBelum ada peringkat

- Pumps & Systems - August 2015Dokumen116 halamanPumps & Systems - August 2015Dragan Belcovski100% (1)

- Tswennfi68 - Performance of Centrifugal PumpsDokumen8 halamanTswennfi68 - Performance of Centrifugal PumpsCristian RABelum ada peringkat

- Ku Reprint Ps April2007Dokumen2 halamanKu Reprint Ps April2007keyur1109Belum ada peringkat

- Mep All QuestionsDokumen79 halamanMep All QuestionsbabaBelum ada peringkat

- OneSteel Data Charts - FinalDokumen20 halamanOneSteel Data Charts - FinalDaniel CheesmanBelum ada peringkat

- MEMS Sensor For AftershockDokumen10 halamanMEMS Sensor For Aftershockravide76Belum ada peringkat

- TheCourse Python V2.2Dokumen63 halamanTheCourse Python V2.2September RainBelum ada peringkat

- Numerical Investigation of Working Fluid Effect On Stirling Engine PDFDokumen6 halamanNumerical Investigation of Working Fluid Effect On Stirling Engine PDFravide76Belum ada peringkat

- SOTWFungi 2018 Full Report PDFDokumen92 halamanSOTWFungi 2018 Full Report PDFjamiro52Belum ada peringkat

- Linear - Generator - For - A - Free - Piston - Stirling - Engine 2014 PDFDokumen6 halamanLinear - Generator - For - A - Free - Piston - Stirling - Engine 2014 PDFravide76Belum ada peringkat

- Linear Generator For A Free Piston Stirling Engine 2014Dokumen6 halamanLinear Generator For A Free Piston Stirling Engine 2014ravide76Belum ada peringkat

- Linear - Generator - For - A - Free - Piston - Stirling - Engine 2014 PDFDokumen6 halamanLinear - Generator - For - A - Free - Piston - Stirling - Engine 2014 PDFravide76Belum ada peringkat

- A Four Power-Piston Low-Temperature Differential Stirling PDFDokumen8 halamanA Four Power-Piston Low-Temperature Differential Stirling PDFravide76Belum ada peringkat

- SNS Well P&ADokumen15 halamanSNS Well P&Aravide76Belum ada peringkat

- A Four Power-Piston Low-Temperature Differential StirlingDokumen16 halamanA Four Power-Piston Low-Temperature Differential Stirlingravide76Belum ada peringkat

- Review of Probabilistic Inspection Analysis MethodsDokumen42 halamanReview of Probabilistic Inspection Analysis Methodsravide76Belum ada peringkat

- Review of Probabilistic Inspection Analysis MethodsDokumen42 halamanReview of Probabilistic Inspection Analysis Methodsravide76Belum ada peringkat

- A Review of Beam Pumping Energy-Saving TechnologiesDokumen13 halamanA Review of Beam Pumping Energy-Saving Technologiesravide76Belum ada peringkat

- Eddy Probe SystemsDokumen44 halamanEddy Probe Systemsravide76Belum ada peringkat

- Wind Loads Calculations by ASCE7 05 For Any BuildingDokumen12 halamanWind Loads Calculations by ASCE7 05 For Any BuildingshubhamdereBelum ada peringkat

- Iso 3036 PDFDokumen3 halamanIso 3036 PDFPalani.MBelum ada peringkat

- 188 Lamborghini Gallardo 101 EngDokumen4 halaman188 Lamborghini Gallardo 101 EngVIET VehicleBelum ada peringkat

- Module 3 PDFDokumen18 halamanModule 3 PDFVladimirBelum ada peringkat

- Aeromodelling DesignDokumen70 halamanAeromodelling DesignMayank AgrawalBelum ada peringkat

- Entropy of Mixing PDFDokumen16 halamanEntropy of Mixing PDFrupaliroyBelum ada peringkat

- Fundamentals of Fluid Mechanics Chapter 12 TurbinesDokumen44 halamanFundamentals of Fluid Mechanics Chapter 12 Turbinesalisnowkiss6570Belum ada peringkat

- Service Manual H2SM 912H03R2 SM071225Dokumen50 halamanService Manual H2SM 912H03R2 SM071225Courtney PettyBelum ada peringkat

- Aerodynamic DragDokumen486 halamanAerodynamic Draggswicke gmailBelum ada peringkat

- MAE3241 Ch01 IntroductionDokumen20 halamanMAE3241 Ch01 Introductionmblaskovich2010Belum ada peringkat

- 01 Operator Manual - StirLIN-2 - J0847 - ENDokumen54 halaman01 Operator Manual - StirLIN-2 - J0847 - ENA TurkiBelum ada peringkat

- 530 - Dryers ManualDokumen4 halaman530 - Dryers ManualmecambBelum ada peringkat

- Questionnaires 1Dokumen5 halamanQuestionnaires 1Neo GarceraBelum ada peringkat

- 2012 CatalogDokumen352 halaman2012 Catalogartie1969100% (1)

- Mfe24pi1505 Design of Production Toolingdrill BushingsDokumen14 halamanMfe24pi1505 Design of Production Toolingdrill BushingsSubrat pandaBelum ada peringkat

- 59 Why Nuts and Bolts Come Loose V1Dokumen2 halaman59 Why Nuts and Bolts Come Loose V1jillianixBelum ada peringkat

- Tutorial Vapor and Combined Power CyclesDokumen3 halamanTutorial Vapor and Combined Power CyclesShariff Mohamad Fairuz0% (1)

- I-Beam Girder ComputionsDokumen10 halamanI-Beam Girder ComputionsMark Christopher Del RosarioBelum ada peringkat

- Honeywell Electro-Hydraulic Servo Valves EHSVDokumen2 halamanHoneywell Electro-Hydraulic Servo Valves EHSVAhua HuangBelum ada peringkat

- Lecture 1 Ultimate Bearing CapacityDokumen22 halamanLecture 1 Ultimate Bearing CapacityErica Jane TatelBelum ada peringkat

- 1 SMDokumen18 halaman1 SMYogi Kawar Ganga NathBelum ada peringkat

- NATCO TurbulatorDokumen2 halamanNATCO TurbulatorshansalBelum ada peringkat

- Flow Divertor Ball Valve DN20 - DN32 - DN50: DescriptionDokumen3 halamanFlow Divertor Ball Valve DN20 - DN32 - DN50: Description윤병택Belum ada peringkat

- R320LC 7Dokumen673 halamanR320LC 7Ricardo VilcaBelum ada peringkat

- Auto Chassis NotesDokumen70 halamanAuto Chassis NotesSrinivas NadellaBelum ada peringkat

- MCL 311 Lab 4 PDFDokumen29 halamanMCL 311 Lab 4 PDFAditya SheoranBelum ada peringkat

- Geared Coupling Manual PDFDokumen5 halamanGeared Coupling Manual PDFSatBelum ada peringkat

- Twin Screw Compressor Performance and Its Relationship With RotorDokumen7 halamanTwin Screw Compressor Performance and Its Relationship With RotorSaeedAkbarzadehBelum ada peringkat

- Developer Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseDokumen18 halamanDeveloper Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseGokul SelvarajBelum ada peringkat