Lewisten BlowerManual

Diunggah oleh

tayyabemeHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Lewisten BlowerManual

Diunggah oleh

tayyabemeHak Cipta:

Format Tersedia

TABLE OF CONTENTS

Page

Customer Letter/ Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Gas conveyed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Working conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2.1 Speed of rotation

2.2.2 Pressure

2.2.3 Temperature

2.3 Capacity adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2.1 Bearing storage

3.2.2 Preservation of the compression chamber

4.1 On-site positions of blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.2 Changing the inlet/outlet arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.3 Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

4.3.1 Direct coupling

4.3.2 Belt drive coupling

4.4 Direction of rotation – air flow direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.5 System piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.5.1 Inlet pipe

4.5.2 Outlet pipe

4.6 Check valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.7 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.8 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.1 Preliminary controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.2.1 First start-up

5.2.2 Normal start-ups

5.3 Operating checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.3.1 Daily checks

5.3.2 Check after first 50 hours

5.3.3 Check every 500 hours

5.4 Stopping the blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.1 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1.1 Oil change

7.0 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

8.1 Blower Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9.1 Blower in operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9.2 Before any blower service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9.3 During blower service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

10.1 Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

10.2 Oil viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

10.3 Recommended oils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

10.4 Minimum working temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Sectional drawings & parts descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Blower Engineering Instructional Manual 2

Dear Customer,

Thank you for purchasing a Blower Engineering product.

You are strongly recommended to take the following preliminary actions:

1. The instructions given in this manual must be strictly followed prior to positioning

and operating the machine.

2. The maintenance operations are to be carried out exactly as described in this manual.

3. Safety regulations are to be complied with completely.

4. The operators and the personnel in charge must be well acquainted with these

instructions, which must be available to them whenever required.

5. The use of the machine must be only as described in the operating manual.

The model number of the blower and pertinent serial number are to be quoted any time additional

information is requested. The serial number is applied on the nameplate fixed to the machine.

Warranty

We warrant that this product will be free from defects in material and workmanship for a period of one (1) year

from date of start up, or eighteen (18) months from date of shipment, whichever comes first. Within the warranty

period, we shall repair or replace, F.O.B. our plant, such products that are determined by us to be defective.

This warranty will not apply to any product that has been subjected to misuse, negligence or accident or

misapplied or improperly installed. This warranty will not apply to any product which has been disassembled,

repaired or otherwise altered by any persons not authorized by our Service Department.

Errors and omissions excepted.

Information to change on a moments notice.

Blower Engineering Instructional Manual 3

1.1 Scope

This manual applies to Rotary Blowers of the TL Series from size 10 to size 2300, both in

horizontal (H) and vertical (V) versions.

1.2 Operating principle

TL Series Blowers are positive displacement blowers comprising two conjugate shaped Tri-Lobe

rotors which rotate inside a “figure 8” shaped body. The incoming gas is trapped in the space

that forms between the body (figure 1a, 1b) and discharged via the outlet (figure 1c, 1d). The

operating pressure is generated by the resistance met by the gas exiting the unit. The capacity is

proportional to the speed of rotation and is almost constant when the operating pressure varies.

1a 1b 1c 1d

Fig. 1

1.3 Construction

The TL Series Blower is engineered for the smoothest possible flow of air, resulting in lower

pressure, pulsation and noise.

The body is closed at both ends by end plates in which the housings for the seals and bearings

are located. The rotors are synchronized by a pair of timing gears having helical, hardened and

ground teeth. The shafts have labyrinth seals; gas leaks are collected in special air spaces in the

covers and are discharged into the atmosphere. Two sumps are mounted on the covers which act

as oil sumps for splash lubrication of the bearings and the synchronizing gears. The gears are

secured on the shafts through conical coupling under oil pressure (TL10-81). The TL90-2300 use

adjustable hub and gear rings keyed to the shaft.

Number Description

1 Body

2 Rotor

3 Rotor

4 End Plates

5 Gears

2 1 3 5 6 4 4 6 6 Labyrinth Seals

Fig. 2

Blower Engineering Instructional Manual 4

2.1 Gas conveyed

The blower can be used to convey inert gases such as air nitrogen or other gases which are

compatible with the lubricating oil and with the materials used in the construction of the blower.

WARNING: The blower cannot be used to convey gases which are explosive, toxic

or in any way dangerous.

NOTE: To convey special gases consult Blower Engineering.

2.2 Working conditions

2.2.1 Speed of rotation – The maximum speed of rotation is shown in Table I. The

minimum speed of rotation depends on the maximum allowed differential temperature.

2.2.2 Pressure – The inlet pressure ranges from 3 psig (20.7 kPa) to 15 psig (103.4 kPa).

The maximum differential pressure is shown in Table I, and depends on the size of the

blower. The maximum compression ratio for all sizes of blowers is 2.

2.2.3 Temperature – The inlet temperature of the gas ranges from -13ºF (-25ºC) to 122ºF (50ºC).

The maximum differential temperature allowed is shown in Table I, and depends on the size of

the blower. The maximum temperature of the gas allowed at the discharge is 266ºF (130ºC).

Table I: Operation Limits

TL Arrangement ∆t TL Arrangement ∆t

Size Vertical Horiz. psig “Hg ºF ºC Size Vertical Horiz. psig “Hg ºF ºC

10 4600 4600 13 13 200 110 105 2200 n/a 15 15 200 110

20 4600 4600 15 15 200 110 110 2200 1600 15 15 200 110

30 4700 4700 15 15 200 110 120 2200 1600 12 13 180 100

40 4700 4700 15 15 200 110 121 2200 1600 10 12 150 83

41 4700 4700 10 12 150 83 500 1800 n/a 15 15 200 110

50 4100 2900 15 15 200 110 700 1800 n/a 13 13 200 110

60 4100 2900 15 15 200 110 900 1800 n/a 12 13 180 100

61 4100 2900 10 12 150 83 1100 1800 n/a 9 12 135 75

70 3700 2600 15 15 200 110 1200 1300 n/a 15 15 200 110

80 3700 2600 15 15 200 110 1250 1300 n/a 12.5 13 180 100

81 3700 2600 10 12 150 83 1300 1000 n/a 15 15 200 110

90 2700 1900 15 15 200 110 1600 1000 n/a 12 13 180 90

100 2700 1900 12 13 180 100 2000 1000 n/a 9 12 135 75

101 2700 1900 10 12 150 83 2300 600 n/a 12 13 180 100

Blower Engineering Instructional Manual 5

2.3 Capacity adjustment

Capacity can only be adjusted in one of the two following ways:

• Varying the speed of rotation. This can be achieved via belt drives or by varying the electric

motor supply voltage frequency or with a double polarity motor.

• Bleeding off of excess capacity via a regulating valve on the outlet

Do not use the safety valve for this purpose because it will suffer excessive wear.

Do not re-circulate the excess gas into the blower inlet with cooling because it could cause

excessive heating.

WARNING: Do not adjust the gas capacity by using throttle valves placed on the

Inlet or outlet piping.

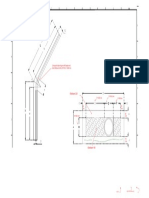

3.1 Handling

To hoist the blower, use a

cable as shown in fig. 3

WARNING:

Do not use the holes in the

flanges to lift the blower. Horizontal: /H Vertical: /V

Fig. 3

3.2 Storage

Keep the blower in a dry cool closed environment. Do not remove the protective coverings

placed over the blower openings. Renew the preservation every 6 months, or more frequently

if the climate is damp.

3.2.1 Bearing storage – Half fill the sumps with anti-rust oil. Manually rotate the blower

shaft. Dispose of the used oil in accordance with local regulations.

3.2.2 Preservation of the compression chamber – Remove the protective coverings

from the blower openings. Apply a thin film of anti-rust oil to the internal surfaces of the body

to the covers and to the rotor surfaces.

WARNING: Use anti-rust and foam inhibiting oil with fire point over 392ºF

(200ºC) only.

Table II: Anti-rust oil

Shiny External Parts Rust Ban 343 EXXON

Compression Chamber Rust Ban 343 EXXON

Blower Engineering Instructional Manual 6

4.1 On-site positioning of blower

The blower has to be set horizontally on a level surface and attached using bolts which secure

the feet or the outlet flange.

4.2 Changing the inlet/outlet arrangement

(from size 10 to 121 only)

To move from the arrangement with inlet and outlet on a vertical axis to that with inlet and

outlet on a horizontal axis and vice versa, exchange the oil levels by changing the position of

the plugs in accordance with fig. 4.

Vertical Arrangement: /V Horizontal Arrangement: /H

Left-hand shaft only Bottom shaft only

E E E E

A D B A D B

Fig. 4

Letter Description

A Left Foot

B Right Foot

C Oil fill plug

D Oil drain plug

E Oil level sight glass

4.3 Coupling

4.3.1 Direct coupling – Slide the half couplings onto the shaft of the blower and of the motor

using suitable tools.

WARNING: Do not use a hammer to slide on the half couplings.

Secure the half couplings with security dowels which will push on the keys.

• Place the blower at the distance from the motor indicated by coupling manufacturer.

• Align the shafts of the blower and of the motor and, where necessary insert shims under the

feet of the motor and/or blower.

• Check the alignment by using calipers or gauges as per coupling manufacturer’s specifications.

Blower Engineering Instructional Manual 7

4.3.2 Belt drive coupling – Use suitable equipment to mount the sheaves onto the blower and

motor shafts. The minimum blower sheave diameters are shown in Table IV.

WARNING: Do not use a hammer to mount the sheaves.

Mount the drive belts. Belt tension is produced by using the motor thrust screws in

accordance with the values shown in Table V. During this phase, the alignment of the sheaves

must be checked using a scale resting against the sheaves as shown in figure 5.

WARNING: Excessive belt tension could damage the blower and the motor.

Secure the feet of the motor

Table IV: Minimum sheave diameter [inches / mm]

Differential Pressure [psig / kPa]

TL 3 20.7 5 34.5 6 41.4 7 48.3 8 55.2 10 68.9 12 82.7 13 89.6 15 103.4

10 4 100 4 100 4 100 4 100 4 100 5 125 5 125 6 150

20 4 100 4 100 4 100 4 100 4 100 5 125 5 125 6 150 6 150

30 4 100 4 100 4 100 4 100 4 100 5 125 6 150 6 150 6 150

40 4 100 4 100 4 100 5 125 5 125 6 125 6 150

41 4 100 4 100 4 100 5 125 5 125

50 5 125 5 125 5 125 6 150 6 150 7 175 8 200 8 200 8 200

60 5 125 6 150 6 150 7 175 7 175 8 200

61 6 150 7 175 7 175 8 200 8 200

70 6 150 6 150 6 150 7 175 7 175 8 200 9 225 9 225 9 225

80 6 150 7 175 7 175 8 200 8 200 9 225

81 7 175 8 200 8 200 9 225

90 8 200 8 200 8 200 9 225 9 225 10 250 11 275 11 275 11 275

100 8 200 9 225 9 225 10 250 10 250 11 275

101 9 225 10 250 10 250 11 275

105 10 250 10 250 10 250 11 275 11 275 12 300 14 350 14 350 14 350

110 10 250 10 250 10 250 11 275 11 275 12 300 14 350 14 350 14 350

120 10 250 11 275 11 275 12 300 12 300 14 350

121 11 275 12 300 12 300 14 350 14 350

500 11 280 12 300 12 300 12 300 12 300 14 350 14 350 16 400 16 400

700 12 300 12 300 12 300 14 350 14 350 16 400 16 400 16 400

900 12 300 12 300 12 300 14 350 14 350 16 400 16 400

1100 13 330 13 330 14 350 14 350 16 400

1200 13 330 13 330 14 350 14 350 16 400 18 450 18 450 20 500 20 500

1250 13 330 13 330 14 350 14 350 16 400 18 450 18 450

1300 13 330 13 330 14 350 16 400 16 400 18 450 18 450 20 500 20 500

1600 16 400 16 400 16 400 18 450 18 450 18 450 20 500 20 500 20 500

2000 18 450 18 450 18 450 20 500 22 560

2300 18 450 18 450 20 500 20 500 22 560 22 560 25 640 25 640

Check pressure rating for all blowers

Blower Engineering Instructional Manual 8

Table V: Recommended Deflection Force per Belt

V-Belt Small Sheave Diameter Range Recommended Deflection Force

Cross Small Sheave Speed Ratio Minimum Maximum

Section RPM Range Range

inches mm lbs kg lbs kg

2.20 56 1200 - 3600 2.8 1.27 4.1 1.86

2.35 - 2.50 60 - 64 1200 - 3600 3.2 1.45 4.7 2.13

2.65 - 2.80 67 - 71 1200 - 3600 2.00 3.5 1.59 5.1 2.31

3VX 3.00 - 3.15 76 - 81 1200 - 3600 to 3.8 1.72 5.5 2.49

3.35 - 3.65 85 - 93 1200 - 3600 4.00 4.1 1.86 6.0 2.72

4.12 - 5.00 105 - 127 900 - 3600 4.8 2.18 7.1 3.22

5.30 - 6.90 135 - 175 900 - 3600 5.8 2.63 8.6 3.90

4.40 - 4.65 112 - 118 1200 - 3600 9.0 4.08 13 5.90

4.90 - 5.50 124 - 140 1200 - 3600 10 4.54 15 6.80

5.90 - 6.70 150 - 170 1200 - 3600 2.00 11 4.99 17 7.71

5VX

7.10 - 8.00 180 - 203 600 - 1800 to 13 5.90 19 8.62

8.50 - 10.90 216 - 277 600 - 1800 4.00 14 6.35 20 9.07

11.80 - 16.00 300 - 406 400 - 1200 15 6.80 23 10.43

7.10 - 8.00 180 - 203 600 - 1800 2.00 11 4.99 16 7.26

5V 8.50 - 10.90 216 - 277 600 - 1800 to 13 5.90 18 8.16

11.80 - 16.00 300 - 406 400 - 1200 4.00 14 6.35 21 9.53

12.50 - 17.00 318 - 432 600 - 1200 2.00 28 12.70 41 18.60

8V to

18.00 - 24.00 457 - 610 400 - 900 4.00 32 14.51 48 21.77

* If replacing 3V or 5V belts with the same belt length and same number of belts in 3VX or 5VX

cross section, belt tension does not need to be increased.

NOTE: New drives designed with 3VX or 5VX belts should be tensioned at the respective deflection

force value shown in above table.

Simplified V-Belt Tensioning Method

Step 1– Determine the force required

to deflect one belt 1/64"

Tension Measured By Deflection per inch (1/64th cm per

centimeter) of span length.

Deflection

1/64" per Step 2– Measure the span length of

inch of span your drive. Compare this

Span

Length

,t deflection force with the

range given in Table V.

If it is less than the

minimum recommended

force, the belts should be

re-tensioned.

Force

If it is more than the

maximum recommended

force, the drive is tighter

than it needs to be.

Blower Engineering Instructional Manual 9

4.4 Direction of rotation – air flow direction

GAS

GAS

Fig. 7

WARNING: Do not use the blower with a direction of rotation or a flow direction which

differs from that shown in figure 7.

4.5 System piping

The diameters of the system piping must never be smaller than the diameters of the blower

openings. If the diameters are different, use a taper connector. The system piping should be

properly aligned and supported to prevent placing stress on the blower. Provide flexible joints.

The pipes must be thoroughly cleaned before connection. The gaskets must not interfere with

the gas system.

WARNING: Remove the protective covers from the blower openings before connecting the pipes.

4.5.1 Inlet pipe 4.5.2 Outlet pipe

• Connect a silencer directly to the inlet of • Connect a silencer directly to the

the blower. outlet of the blower.

• Thoroughly clean. • Support the piping at the point

• If necessary install a dirt filter for nearest to the flexible coupling.

the first 100 working hours. • Insulate the pipes so as to avoid

• Install a pressure gauge to check the dirt filter. heating the environment and as a

• Support the pipe. precaution to accidental contact.

4.6 Check valve

To stop the counter-rotation of the blower when it stops while loaded, install a check valve on

the discharge, when acting under pressure, or on the inlet when acting under vacuum conditions.

4.7 Safety valve

To limit the maximum operating pressure of the blower use a safety valve on the discharge,

when acting under pressure, or on the inlet when acting under vacuum conditions.

WARNING: Install the safety valves as close as possible to the inlet/outlet at the blower,

without placing shut-off valves in-between.

Blower Engineering Instructional Manual 10

4.8 Electrical connection

Use only authorized specialists to set up the electrical system, working in compliance with

regulations applying to the place of installation and in accordance with the requirements of

the local body supplying electrical energy. Check on the motor plate:

• Voltage • Frequency

• Number of phases • Absorbed current

Connect the cables as shown in the diagram accompanying the terminal box of the motor. If the

diagram has not been supplied, request it from the motor manufacturer. Use electrical cables of

suitable size, depending on the nominal current of the electrical motor. Keep the electric cables

away from heat sources and/or pointed edges. The motor must be protected by means of an

automatic switch set at the value of the rated current shown on the plate. For the safety of personnel,

the system must be protected by a suitable grounding device.

WARNING: Blower service must be carried out only after disconnecting the electric supply.

5.1 Preliminary controls

If the blower has been in storage for more than 6 months, check its state of preservation.

• Check the coupling or the sheave alignment

• Check the belt tension.

• Check that the blower shaft rotates freely manually.

• Check that the safety protection devices have been correctly installed and secured.

• Fill the blower with oil as described in paragraph 6.1.1.

5.2 Start up

5.2.1 First start-up

WARNING: During this operation personnel are in direct contact with the blower, and

for this reason noise protection must be worn.

Open the shut-off valve.

• Check that the safety valve has been set at the operating value.

• Check the rotation by ‘jogging’ the motor.

WARNING: Do not rotate the blower in the wrong direction for more than a few revolutions.

Start the blower

• Increase the operating pressure gradually until the rated value is reached.

• After about 10 to 20 minutes check that there are no oil leakages and strange noises or

vibrations. If such problems are found, stop the blower immediately.

5.2.2 Normal start-ups – Start the blower: with direct start-up the motor starts even with the

maximum discharge counter-pressure. With star-delta start-up, on the other hand, or with the

starter; the counter-pressure must be zero.

Blower Engineering Instructional Manual 11

5.3 Operating checks

5.3.1 Daily checks – With the blower running, check:

Outlet temperatures.

• Discharge pressure (when functioning under pressure).

• Suction pressure (when functioning in vacuum conditions).

• Absorbed power.

5.3.2 Check after first 50 hours – With the blower shut down, check:

The oil level.

• Oil leaks.

• Auxiliary circuit leaks.

• Belt tension.

5.3.3 Check every 500 hours – With the blower shut down, check:

The oil level.

• Oil viscosity and condition.

• Belt wear.

• Flexible coupling inserts.

• Auxiliary circuits.

5.4 Stopping the blower

If possible, remove the counter-pressure.

• Stop electric supply.

The blower can also be stopped in the presence of the counter-pressure but, because of the high

current absorption of the electric motor; problems with the electric circuit could result.

WARNING: Check that the deceleration of the blower is even and without vibrations.

Blower Engineering Instructional Manual 12

6.1 Preventive maintenance

6.1.1 Oil change

The first oil change should be performed after 100 working hours. Further oil changes are per-

formed every 2000 working hours. Oil should be checked regularly and oil changes made more

frequently if lubricant becomes contaminated due to adverse conditions.

The type of oil is shown in paragraph 10.

WARNING: Dispose of the used oil in accordance with the local regulations.

WARNING: Regardless, stick to the half way mark on the oil level sight glass.

Oil quantity: /V (qts / L) Oil quantity: /H (qts / L)

Blower Size 1 2 Total 1 2 Total

10 - 20

0.79 0.75 0.48 0.45 1.27 1.20 0.48 0.45 0.32 0.30 0.80 0.75

30 - 40

50-60-61 1.27 1.20 0.85 0.80 2.12 2.00 0.63 0.60 0.42 0.40 1.05 1.00

70-80-81 2.11 2.00 1.37 1.30 3.48 3.30 0.95 0.90 0.63 0.60 1.58 1.50

90-100-101 3.70 3.50 2.11 2.00 5.81 5.50 1.59 1.50 1.06 1.00 2.65 2.50

105 7.40 7.00 3.70 3.50 11.10 10.50 N/A N/A N/A N/A N/A N/A

110-120-121 5.07 4.80 3.17 3.00 8.24 7.80 3.28 3.10 2.01 1.90 5.29 5.00

500-1100 10.55 10.00 5.28 5.00 15.83 15.00 N/A N/A N/A N/A N/A N/A

1200-1250 N/A N/A N/A N/A N/A N/A

1300-2000 N/A N/A N/A N/A N/A N/A

2300 N/A N/A N/A N/A N/A N/A

Oil Level : with blower shut down

OIL FILL PLUG

OIL FILL PLUG

OIL LEVEL SIGHT GLASS

OIL LEVEL SIGHT GLASS

OIL DRAIN PLUG

OIL DRAIN PLUG

VENTS

VERTICAL

Blower Engineering Instructional Manual 13

7.0 Troubleshooting

Cause Remedies

7.1 Inlet pressure different from the design value

Inlet piping is clogged Check piping and remove obstruction

Rotation speed is not the same as design RPM Check rotation speed and reset to design RPM

7.2 Outlet pressure different from the rated value

Outlet piping is clogged Check piping and remove obstruction

Rotation speed is not the design RPM Check rotation speed and reset to design RPM

7.3 Outlet temperature different from the rated value (stop the blower immediately)

Inlet temperature different from design value Check inlet temperature and reset to rated value

Compression ratio is not the same as the Check inlet and outlet pressures and reset to

design conditions rated values

Rotors are worn Measure clearances of rotors (see paragraph 6.2.3)

7.4 Power absorbed different from the rated value

Differential pressure different from rated value Check the inlet and outlet pressure and reset to

rated value

Speed of rotation is not the same as rated value Check the speed of rotation and reset to

rated value

Incorrect electrical connection Check electrical system

Rotors making contact Stop blower immediately (see paragraph 7.3)

7.5 Loss of oil

Drive shaft seal is worn Replace the drive shaft seal

Oil drain and level plugs gaskets are worn Replace the gaskets

Oil level plugs are broken Refill sump to proper oil level

7.6 High oil temperature

Oil level too high Reset correct oil level (see paragraph 6.1.1)

Oil too viscous Use less viscous oil

High differential pressure See paragraph 7.2

Oil produces foam Change the type of oil

7.7 Unusual noises and/or vibrations (stop the blower immediately)

Differential pressure exceeds rated value Check inlet and outlet pressures and reset to

rated values

Discharge temperature exceeds rated value see paragraph 7.3

Rotors making contact Stop blower immediately, measure gear and

rotor clearances

Scale on internal parts Thoroughly clean the rotors and compression

chamber

Bearings are worn Measure bearing clearances and, if necessary,

replace them

Intake of foreign particles Remove foreign particles, clean the inside of

the blower

Blower Engineering Instructional Manual 14

8.1 Blower disassembly

Disassembly of the blower within the guarantee period results in the cancellation of the guarantee.

Disassembly repair work and reassembly of the blower must be carried out only by skilled

personnel and with the aid of suitable equipment and the relevant manual. This manual contains

only the instructions for preventative maintenance. For any references to components see

attached sections.

NOTE: The guarantee does not cover damages caused by operations carried out incorrectly

during disassembly and/or reassembly of the blower.

WARNING: Before starting disassembly of the blower, make sure that the power has been

disconnected. Follow the instructions in paragraph 9.2.

Disassemble the drive components (sheave or coupling), following the manufacturer's instructions

if there are locking devices or by means of an extractor if attached directly onto the shaft.

WARNING: Do not hammer the shaft, coupling or sheave.

Personnel who may come into contact with the blower must observe the most elementary safety

rules in order to minimize the possibility of suffering physical injury With this in mind, all

personnel who work in or pass through the area where the blower is functioning must be

instructed in the safety rules to follow and must be warned through the use of danger notices.

9.1 Blower in operation

Do not touch the external surfaces of the blower because they could reach temperatures higher

than 285ºF (141ºC) and therefore cause burns.

• Donot hold objects or insert limbs into the blower openings because the moving rotors

could cause serious physical injury.

• Provide suitable protection devices for the coupling and/or drive belts.

• Ifthe blower is operating disconnected from system piping, place a screen in front of the

inlet and keep away from the blower outlet flow.

• Do not open the oil plugs.

• Do not turn off the safety systems which are provided.

• Do not stand too close to the safety valve discharge.

• Avoidprolonged exposure to the noise produced by the blower; if suitable protection is not

worn. The sound pressure near the blower could be greater than 85 dB (A).

9.2 Before any blower service

Stop the blower by disconnecting the electrical supply.

• Disconnect the electrical supply cables.

• Bring the unit to atmospheric pressure.

WARNING: The gas contained in the blower may be hot, toxic and irritant.

Blower Engineering Instructional Manual 15

9.3 During blower service

Check that all operations described in Paragraph 9.2 have been completed.

• Use adequate equipment and procedures to disconnect and handle the system piping.

• Use adequate equipment to disassemble the blower components.

• Use adequate equipment and procedures to hoist the blower and its main parts.

The weight could exceed 66 lbs (30 kg).

10.1 Oil type

Oil Type ISO Class Acc. To

Mineral oil for general use C, CL, CLP DIN 51517

Mineral oil for hydrostatic and hydrodynamic circuits H, HL DIN 51524

Mineral oil for internal combustion engines HD

Synthetic oil

10.2 Oil viscosity

ISO Class USE

ISO - VG 150 oil temperature up to 176ºF (80ºC) compression ratio up to 1.7 gas

discharge temperature up to 230ºF (110ºC) ambient temperature up

to 95ºF (35ºC)

ISO - VG 220 oil temperature up to 230ºF (110ºC) compression ratio higher than 1.7

gas discharge temperature up to 230ºF (110ºC) ambient temperature

higher than 95ºF (35ºC) installation in soundproof enclosure

10.3 Recommended oils

Pour point Pour point

Make Type ISO VG - 150 ISO VG - 220

°F °C °F °C

Exxon Nuto 150 0 -18 220 0 -18

Mobil D.T.E. Extra Heavy 16 -9 BB 20 -7

Pennzoil Pennzbell R + O 150 15 -9 R + O 220 15 -9

Shell Tellus C 150 0 -18 C 220 5 -15

Texaco Regal R + O 150 12 -11 R + O 220 12 -11

10.4 Minimum working temperature

Check that the pour point of the oil is less than the minimum temperature that can be reached

in the ambient If this is not the case, select an oil with a lower viscosity (a g.: ISO VG-100), or

use an oil specially made for low temperatures according to recommendations of oil producers.

Blower Engineering Instructional Manual 16

16 13 14 42 30 19 9 1 4 52 17 19 9 37

55 70

61

53

41

29

58

62 10

11

27

5

51

49

22 26

47

57

12 15 19 45 46 vent 2 3 58 64 18 20 28 43 8 48

TL10 NBS & TL20 NBS (New Bearing Style)

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

1 1 casing 1 29 special plain washer

2 2 foot 2 30 circlip

1 3 drive rotor 16 37 stud-bolt

1 4 driven rotor 1 41 bearing

1 5 seal plate 2 42 bearing

4 7 oil level sight glass 1 43 bearing

1 8 oil slinger, drive 16 45 piston sealing ring

2 9 end plate 4 46 o-ring

1 10 drive sump 1 47 rotary shaft lipseal

1 11 gear sump 1 48 key

1 12 drive gear 1 49 key

1 13 driven gear 1 51 roll pin

2 14 bearing cover 4 52 centering pin

2 15 gear spacer 2 53 centering pin

2 16 gear nut spacer 4 55 bolt

4 17 ringholder 2 56 bolt

4 18 sealing chamber 4 57 bolt

3 19 oil splash disc 5 58 bolt

1 20 oil splash disc drive 16 61 nut

2 22 oil slinger, gear 2 62 gear locking nut

1 26 shaft sleeve 4 64 plain washer

1 27 bearing locking nut 2 65 tab washer

1 28 circlip 16 70 plain washer

Blower Engineering Instructional Manual 17

17 13 15 39 21 41 8 1 4 49 11 20 36

54 58

66

50

38

67

55

59 10

9 56

65

48 25

46

23 24

47

26

14 16 29 21 42 43 vent 2 3 55 60 19 18 44 32 40 7 45

TL30 NBS & TL40 NBS (New Bearing Style)

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

1 1 casing 1 32 oil thrower

2 2 foot 20 36 stud-bolt

1 3 drive rotor 1 38 bearing

1 4 driven rotor 2 39 bearing

1 7 oil slinger, drive 1 40 bearing

1 8 gear end plate 2 41 circlip

1 9 gear sump 16 42 piston sealing ring

1 10 drive sump 4 43 o-ring

1 11 drive end plate 1 44 circlip

1 13 driven gear 1 45 key

1 14 drive gear 1 46 key

2 15 bearing cover 1 47 rotary shaft lipseal

2 16 gear spacer 1 48 roll pin

2 17 gear nut spacer 4 49 centering pin

4 18 ringholder 2 50 centering pin

4 19 sealing chamber 4 54 bolt

1 20 oil splash disc 5 55 bolt

2 21 oil splash disc 4 56 bolt

1 23 oil slinger, gear 20 58 nut

1 24 shaft sleeve 2 59 gear locking nut

1 25 bearing locking nut 4 60 plain washer

1 26 seal plate 4 65 spring washer

2 29 clearance ring 20 66 plain washer

4 30 oil level sight glass 1 67 plain washer

Blower Engineering Instructional Manual 18

15 12 13 47 73 41 5 4 10 39 6 72 46 52

61 57

66

40

25

54

8

58

7

62

65

38

18

37

22 19

44

26

11 14 29 73 33 43 vent 9 27 55 56 17 16 30 71 48 21 36

TL50 NBS, TL60 NBS & TL61 NBS (New Bearing Style)

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

4 1 oil level sight glass 1 36 key

1 4 casing 1 37 key

1 5 gear endplate 1 38 roll pin

1 6 drive endplate 4 39 centering pin

1 7 gear sump 2 40 centering pin

1 8 drive sump 2 41 circlip

1 9 drive rotor 4 43 o-ring

1 10 driven rotor 1 44 rotary shaft lipseal

1 11 drive gear 1 46 bearing

1 12 driven gear 2 47 bearing

2 13 bearing cover 1 48 bearing

2 14 gear spacer 28 52 stud-bolt

2 15 gear nut spacer 1 54 bolt

4 16 ringholder 4 55 bolt

4 17 sealing chamber 4 56 plain washer

1 18 bearing locking nut 28 57 nut

1 19 shaft sleeve 2 58 gear locking nut

1 21 oil slinger, drive 4 61 bolt

1 22 oil slinger, gear 4 62 bolt

1 25 plain washer 4 65 spring washer

1 26 seal plate 28 66 plain washer

2 27 foot 2 67 tab washer

2 29 clearance ring 1 71 oil splash disc

1 30 retaining ring 1 72 oil splash disc

16 33 piston sealing ring 2 73 oil splash disc

Blower Engineering Instructional Manual 19

16 13 14 42 30 9 1 4 52 9 37

55 70

61

53

41

29

58

62 10

11 56

69

51

49

22 26

47

43

12 15 19 45 46 vent 2 3 58 64 18 17 21 23 8 48

TL20

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

1 1 casing 2 30 circlip

2 2 foot 16 37 stud-bolt

1 3 drive rotor 1 41 bearing

1 4 driven rotor 2 42 bearing

4 7 oil level sight glass 1 43 bearing

1 8 oil slinger, drive 16 45 piston sealing ring

2 9 end plate 4 46 o-ring

1 10 drive sump 1 47 rotary shaft lipseal

1 11 gear sump 1 48 key

1 12 drive gear 1 49 key

1 13 driven gear 1 51 roll pin

2 14 bearing cover 4 52 centering pin

2 15 gear spacer 2 53 centering pin

2 16 gear nut spacer 4 55 bolt

4 17 ringholder 1 56 bolt

4 18 sealing chamber 5 58 bolt

4 19 oil splash disc 16 61 nut

1 21 spacer 2 62 gear locking nut

2 22 oil slinger, gear 4 64 plain washer

2 23 spring washer 1 69 tab washer

1 26 shaft sleeve 16 70 plain washer

1 29 special plain washer

Blower Engineering Instructional Manual 20

15 12 13 47 41 5 4 10 39 5 18 25

54 58

66

40

46

34

55

59 8

7 53

67

38

37

22 33

44

48

11 14 45 19 35 vent 27 9 55 57 17 16 20 23 21 36

TL30, TL40, TL50 & TL60

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

4 1 oil level sight glass 1 33 shaft sleeve

1 4 casing 1 34 plain washer

2 5 end plate 16 35 piston sealing ring

1 7 gear sump 1 36 key

1 8 drive sump 37 key

1 9 drive rotor 1 38 roll pin

1 10 driven rotor 4 39 centering pin

1 11 drive gear 2 40 centering pin

1 12 driven gear 2 41 circlip

2 13 bearing cover 1 44 rotary shaft lipseal

2 14 gear spacer 2 45 clearance ring

2 15 gear nut spacer 1 46 bearing

4 16 ringholder 2 47 bearing

4 17 sealing chamber 1 48 bearing

2 18 oil splash disc 1 53 bolt

2 19 oil splash disc 4 54 bolt

1 20 spacer 5 55 bolt

1 21 oil slinger, drive 4 57 plain washer

1 22 oil slinger, gear 20 58 nut

1 23 spring washer 2 59 gear locking nut

20 25 stud-bolt 20 66 plain washer

2 27 foot 1 67 tab washer

Blower Engineering Instructional Manual 21

61 22 6 5 2 56 6 13 25 3 7 11

27

63

69

14

8 60

68

23

59

69

50

17

66

47

36

15 38 28 1 69 64 62 46 21 37 10 40

TL70, TL80 & TL81

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

1 1 drive rotor 1 28 retaining ring

1 2 driven rotor 3 30 oil level sight glass

1 3 splashguard 1 36 bearing

1 5 casing 2 37 bearing

2 6 end plate 2 38 bearing

1 7 gear sump 2 40 gear lock nut

1 8 driven sump 12 46 piston sealing ring

1 10 drive gear 1 47 rotary shaft lipseal

1 11 driven gear 1 50 key

4 13 sealing chamber 6 56 centering pin

4 14 ringholder 1 59 bolt

1 15 bearing cover 4 60 bolt

1 17 shaft sleeve 8 61 bolt

2 18 foot 4 62 bolt

2 19 foot 1 63 bolt

2 21 oil splash disc 20 64 bolt

2 22 oil splash disc 1 66 set screw

1 23 oil slinger A 4 68 plain washer

2 25 gear spacer 26 69 plain washer

1 27 oil slinger B

Blower Engineering Instructional Manual 22

62 60 15 38 19 21 48 6 55 2 5 55 6 48 22 55 20 37 7

83 82

24

8 59

40 23

28 40

47

13

9 17

10 71

40

27

25

16 26

61

80

85 15 38 19 22 48 14 1 83 75 69 63 48 14 21 20 37 29

TL90, TL100 & TL101

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

1 1 drive rotor 1 27 key

1 2 driven rotor 1 28 key

1 5 casing 1 29 key

2 6 end plate 4 30 oil level sight glass

1 7 drive sump 2 37 bearing

1 8 gear sump 2 38 bearing

1 9 driven gear 2 40 gear locking nut

1 10 drive gear 1 47 rotary shaft lipseal

2 11 foot 12 48 piston sealing ring

2 12 foot 6 55 centering pin

1 13 gear hub 1 59 bolt

4 14 ringholder 6 60 bolt

2 15 bearing cover 6 61 bolt

1 16 oil slinger, gear 20 62 bolt

1 17 shaft sleeve 24 63 bolt

2 19 clearance ring 8 69 stud-bolt

2 20 retaining ring 3 71 headless set screw

2 21 oil splash disc 8 75 nut

2 22 oil splash disc 6 80 plain washer

1 23 oil slinger, drive 6 82 plain washer

1 24 plain washer 52 83 plain washer

1 25 gear spacer 6 85 spring washer

1 26 key

Blower Engineering Instructional Manual 23

8 60 15 38 22 48 14 6 55 2 5 83 75 63 68 6 14 48 21 18 37 7

83

62 40

84

40

23

13 40

27 47

10 17

71

9

26

40

28

25

29

16

61

80

85 15 38 22 48 14 1 48 14 21 18 37

TL110, TL120 & TL121

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

1 1 drive rotor 1 27 key

1 2 driven rotor 1 28 key

1 5 casing 1 29 key

2 6 cover 4 30 oil level sight glass

1 7 drive sump 2 37 bearing

1 8 gear sump 2 38 bearing

1 9 drive gear 4 40 gear locking nut

1 10 driven gear 1 47 rotary shaft lipseal

2 11 foot 12 48 piston sealing ring

2 12 foot 6 55 centering pin

1 13 gear hub 6 60 bolt

4 14 ringholder 6 61 bolt

2 15 bearing cover 12 62 bolt

1 16 oil slinger, gear 24 63 bolt

1 17 shaft sleeve 8 68 stud-bolt

2 18 retaining ring 3 71 headless set screw

2 21 oil splash disc 8 75 nut

2 22 oil splash disc 6 80 plain washer

1 23 oil slinger, drive 38 83 plain washer

1 25 gear spacer 12 84 plain washer

1 26 key 6 85 spring washer

Blower Engineering Instructional Manual 24

11 60 68 77 82 22 26 60 68 77 82 55 2 60 68 77 82 55 6 21 60 68 77 82 55 37 10 12 65

76

8 7

15 51

64 24

77 66

66 75

75 62

79

24 63

23

17

56

71

66

75

20

38 50

47

19

16 61

60 68 77 82 14 60 68 77 82 55 1 5 13 21 37 25 80 84 52 9 3 40 36

TL500, TL700, TL900 & TL1100

Qty Per Part Part Qty Per Part Part

Blower Number Description Blower Number Description

1 1 drive rotor 4 30 oil level sight glass

1 2 driven rotor 1 36 bearing

1 3 splashguard 2 37 bearing

1 5 casing 2 38 bearing

2 6 end plate 1 40 gear locking nut

1 7 gear sump 1 47 rotary shaft lipseal

1 8 driven sump 1 50 key

1 9 drive gear 1 51 key

1 10 driven gear 1 52 key

2 11 bearing carrier 14 54 rivet pin

1 12 gear hub 6 55 centering pin

2 13 ring holder, drive 2 56 roll pin

2 14 ring holder, driven 68 60 bolt

2 15 bearing cover 6 61 bolt

1 16 oil slinger, drive 4 62 bolt

1 17 shaft sleeve 6 63 bolt

1 19 seal plate 16 64 bolt

1 20 plain washer 1 12 65 bolt

2 21 oil splash disc 3 66 bolt

2 22 oil splash disc 12 68 stud-bolt

1 23 oil slinger, driven 3 71 headless set screw

2 24 plain washer 12 75 plain washer

1 25 gear spacer 3 76 plain washer

12 26 piston sealing ring 96 77 plain washer

Blower Engineering Instructional Manual 25

NOTES

Diagrams:

Blower Engineering Instructional Manual 26

NOTES

Diagrams:

Blower Engineering Instructional Manual 27

Design Features

• Bearings: Spherical/cylindrical roller and ball bearing • Heavy-Duty and ribbed cast iron housing and

combinations; minimum 100,000 hour design life. end covers: Reduce noise levels and increase heat

• Tri-Lobe Rotors: Involute contoured impeller profiles dissipation.

for maximum efficiency. • Versatile Mounting: Horizontal or vertical airflow is

• Impeller/Shaft Rigidity: Reduces mechanical deflection easily achieved by relocating the removable mounting

and vibration. feet incorporated in models TL10 through TL500.

• Oil Seals: Simple non-wearing • Splash Oil Lubrication: Assures improved bearing life

slinger type oil seals, provide and operational simplicity.

positive sealing in both oil • Gas or air is delivered in an uncontaminated, oil free

sumps. Unaffected by high state.

temperatures. No shaft wear. • The unit may be coupled directly or driven by

• Air Seals: Piston ring air seals V-belts.

provide dependable non-wearing • Rotation of the impellers is synchro-

operation to minimize air nized by a pair of timing gears having

leakage past the shafts. helical, hardened and ground teeth.

Packaged Systems

from

Blower Engineering

Lewiston, New York

Telephone: 1-800-388-1339

Facsimile: 1-800-523-8808

Website: www.blowerengineering.com

Anda mungkin juga menyukai

- Final Bore PathDokumen4 halamanFinal Bore PathtayyabemeBelum ada peringkat

- Valve Material EquivalentsDokumen3 halamanValve Material EquivalentsAndre Villegas Romero100% (1)

- Ethafoam 220: Change The Bend Angle To 90 Degree and Bend Radius To 20D (20 6 25.4 3048 MM)Dokumen1 halamanEthafoam 220: Change The Bend Angle To 90 Degree and Bend Radius To 20D (20 6 25.4 3048 MM)tayyabemeBelum ada peringkat

- EnhancedPipeline Layout PDFDokumen21 halamanEnhancedPipeline Layout PDFCRACKMAN_HPBelum ada peringkat

- Comp220 ProjectSpreadsheetDokumen7 halamanComp220 ProjectSpreadsheettayyabemeBelum ada peringkat

- Active FacilityDokumen716 halamanActive FacilitytayyabemeBelum ada peringkat

- Image2020 10 21 000750Dokumen2 halamanImage2020 10 21 000750tayyabemeBelum ada peringkat

- AGADokumen28 halamanAGAAgam HanasichulaBelum ada peringkat

- AB 066aApplicationforPowerEngineersExaminationDeclarationforOwnerEngineersExperienceDokumen1 halamanAB 066aApplicationforPowerEngineersExaminationDeclarationforOwnerEngineersExperiencetayyabemeBelum ada peringkat

- Student Request For Leave or Extended Absences Form - 000827961 PDFDokumen1 halamanStudent Request For Leave or Extended Absences Form - 000827961 PDFtayyabemeBelum ada peringkat

- AB-066 Appl Engineer-Oper ExamDokumen1 halamanAB-066 Appl Engineer-Oper ExamtayyabemeBelum ada peringkat

- Student Request For Leave or Extended Absences Form - 000827961 PDFDokumen1 halamanStudent Request For Leave or Extended Absences Form - 000827961 PDFtayyabemeBelum ada peringkat

- Competency Standards JuneDokumen11 halamanCompetency Standards JuneAdrianBelum ada peringkat

- Personal and Peer Evaluation FormDokumen2 halamanPersonal and Peer Evaluation FormtayyabemeBelum ada peringkat

- Hibon Tri Lobe Blower Manual PDFDokumen55 halamanHibon Tri Lobe Blower Manual PDFtayyabeme100% (1)

- MSA Booklet - March 2018Dokumen50 halamanMSA Booklet - March 2018Agnel StanleyBelum ada peringkat

- Lewisten BlowerManualDokumen28 halamanLewisten BlowerManualtayyabeme100% (1)

- 2020IPEIA PosterSessionsDokumen2 halaman2020IPEIA PosterSessionstayyabemeBelum ada peringkat

- Appeal NewsDokumen24 halamanAppeal NewstayyabemeBelum ada peringkat

- 1418.1-2002 Amdt 1-2004 Cranes Hoists and Winches - General RequirementsDokumen3 halaman1418.1-2002 Amdt 1-2004 Cranes Hoists and Winches - General RequirementstayyabemeBelum ada peringkat

- PakistanDokumen27 halamanPakistantayyabemeBelum ada peringkat

- PIP Vecta001 Tank Selection GuideDokumen28 halamanPIP Vecta001 Tank Selection Guidetayyabeme100% (1)

- جو چلے تو جاں سے گُذر گئےDokumen61 halamanجو چلے تو جاں سے گُذر گئےapi-19994826Belum ada peringkat

- Plotting With MATLABDokumen58 halamanPlotting With MATLABtayyabemeBelum ada peringkat

- (Ebook - English) How To Improve Your MemoryDokumen2 halaman(Ebook - English) How To Improve Your MemorytayyabemeBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Nissan Serena c24 Repair Manual IndexDokumen18 halamanNissan Serena c24 Repair Manual IndexAditya Pratama0% (2)

- Th1200 - Self Propelled Combination Topper Hedger Specification SheetDokumen2 halamanTh1200 - Self Propelled Combination Topper Hedger Specification SheetLuis Eduardo Antonio AguirreBelum ada peringkat

- The Ultra Quiet High Pressure Fan Coil: CRSL Crsl-EcmDokumen72 halamanThe Ultra Quiet High Pressure Fan Coil: CRSL Crsl-EcmJustin ReyesBelum ada peringkat

- Solar Dryer With Auto TrackingDokumen4 halamanSolar Dryer With Auto TrackingNirmala selvarajBelum ada peringkat

- Cooling Tower in Unit OperationDokumen10 halamanCooling Tower in Unit Operationseraj ibramemBelum ada peringkat

- Elecon ET Catalogue PDFDokumen42 halamanElecon ET Catalogue PDFVisnu Sankar86% (7)

- Canon IR7095 Error CodesDokumen21 halamanCanon IR7095 Error CodesnafeesBelum ada peringkat

- Air Curtains Catalogue 2021Dokumen74 halamanAir Curtains Catalogue 2021Thomas TanBelum ada peringkat

- Air Conditioner Not CoolingDokumen13 halamanAir Conditioner Not CoolingrayBelum ada peringkat

- Carrier Poluprom FMCC SM 2014 PDFDokumen136 halamanCarrier Poluprom FMCC SM 2014 PDFzawsaBelum ada peringkat

- Huntair Coplanar Silencer 1107Dokumen2 halamanHuntair Coplanar Silencer 1107Tu Burin DtBelum ada peringkat

- Heat RecoveryDokumen59 halamanHeat RecoveryWilson FigueiraBelum ada peringkat

- A6d800 Ae05 03 EngDokumen6 halamanA6d800 Ae05 03 EngAdemar FukeBelum ada peringkat

- VAV Design GuideDokumen326 halamanVAV Design GuideHESuarez100% (3)

- Curriculum Vitae New 2017 MD Sajid AlamDokumen6 halamanCurriculum Vitae New 2017 MD Sajid AlamAlam MD SazidBelum ada peringkat

- Heat Exchanger Fan Selection - Part 1 of 2 - Application Note - Lytron IncDokumen3 halamanHeat Exchanger Fan Selection - Part 1 of 2 - Application Note - Lytron Incvinicius schwabBelum ada peringkat

- Technical Specification - ACMV 221222Dokumen82 halamanTechnical Specification - ACMV 221222yuzzaen.execproBelum ada peringkat

- LSCB - LRC Catalog - 106-EDokumen28 halamanLSCB - LRC Catalog - 106-ELhexter Bryan PasaguiBelum ada peringkat

- OK-ELC 0-7: Air Cooler IndustryDokumen10 halamanOK-ELC 0-7: Air Cooler IndustrySteven VargasBelum ada peringkat

- JT3D (TF33) S2P4Dokumen128 halamanJT3D (TF33) S2P4junmech-1Belum ada peringkat

- McQuay All ProductDokumen46 halamanMcQuay All ProductSetiawan Indrajaya Soeradji100% (1)

- HK 5830 PDFDokumen21 halamanHK 5830 PDFSantos EderaldoBelum ada peringkat

- Air SeparationDokumen53 halamanAir SeparationFran Jimenez100% (2)

- Tdp-612 Fans Features and AnalysisDokumen43 halamanTdp-612 Fans Features and AnalysisMaher OthmanBelum ada peringkat

- ACUSDokumen36 halamanACUSOsama.ShawkyBelum ada peringkat

- 2020 Goodman HVAC SpecsDokumen36 halaman2020 Goodman HVAC SpecsSamBelum ada peringkat

- Final Na Finalna Final AlbosDokumen16 halamanFinal Na Finalna Final AlbosEarl John FiestaBelum ada peringkat

- A320 Ata-21Dokumen62 halamanA320 Ata-21ROHIT KUMAR SINGHBelum ada peringkat

- 2014 Therma V All Ok JavDokumen18 halaman2014 Therma V All Ok JavDaniel AchovskiBelum ada peringkat

- Educational Information For High Expansion Foam Fire Extinguishing SystemDokumen3 halamanEducational Information For High Expansion Foam Fire Extinguishing SystemAjay W DhimanBelum ada peringkat