01 SpanSet Indo HSE Catalogue 2011

Diunggah oleh

Raza AidanHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

01 SpanSet Indo HSE Catalogue 2011

Diunggah oleh

Raza AidanHak Cipta:

Format Tersedia

Technical Data Sheet

LOCTITE® 770™

December-2008

PRODUCT DESCRIPTION Effect on Cured Properties of Cyanoacrylate Adhesives

LOCTITE® 770™ provides the following product Products 406, 496 and 460 are based on ethyl, methyl and

characteristics: ß-Methoxyethyl esters respectively. Other LOCTITE® liquid

Technology Primer - Cyanoacrylate products based on these esters will behave in a similar fashion

Chemical Type Aliphatic amine to these examples. LOCTITE® 770™ is not recommended for

Solvent n-Heptane use with gel products.

Active Ingredient 0.07 to 0.13LMS

Concentration, % TYPICAL PERFORMANCE OF CURED MATERIAL

Appearance Transparent to slightly hazy liquidLMS Performance Data

Fluorescence Positive under UV lightLMS Substrates treated with LOCTITE® 770™

Viscosity Very low After 24 hours @ 22 °C / 55% RH:

Cure Not applicable Lap Shear Strength, ISO 4587:

Application CA surface primer Polypropylene and LOCTITE® N/mm² 3 to 10

406™ (psi) (440 to 1,450)

® N/mm² 2 to 7

Polypropylene and LOCTITE

LOCTITE® 770™ is used to make polyolefin and other low 496™ (psi) (290 to 1,015)

energy surfaces suitable for bonding with Loctite cyanoacrylate Polypropylene and LOCTITE ® N/mm² 1 to 4

adhesives. On such treated surfaces the cured performance of 460™ (psi) (145 to 580)

LOCTITE® cyanoacrylate adhesives is generally similar to that Thermoplastic Rubber and N/mm² 2 to 6

described in the TDS for the relevant adhesive. It is only LOCTITE® 406™ (psi) (290 to 870)

recommended for difficult to bond substrates which include Polytetrafluorethylene (PTFE) N/mm² 1 to 6

and LOCTITE® 406™ (psi) (145 to 870)

polyethylene, polypropylene, polytetrafluoroethylene (PTFE)

and thermoplastic rubber materials. LOCTITE® 770™ HDPE treated with LOCTITE® 770™ to:

Polyolefin Primer is not recommended in assemblies where Mild steel (grit blasted) without N/mm² 4 to 10

primer and LOCTITE® 406™ (psi) (580 to 1,450)

high peel strength is required.

Polypropylene treated with N/mm² 5 to 15

primer and LOCTITE® 496™ (psi) (725 to 2,175)

TYPICAL PROPERTIES

Specific Gravity @ 25 °C 0.68 TYPICAL ENVIRONMENTAL RESISTANCE

Viscosity @ 20 °C, mPa·s (cP) 1.25

Environmental Resistance of Cyanoacrylate bonds on

Drying Time @ 20 °C, seconds ≤30

substrates treated with LOCTITE® 770™

On Part Life, hours ≤8

Cured for 24 hours:

Flash Point - See MSDS

Lap Shear Strength, ISO 4587

Hot Strength

TYPICAL PERFORMANCE Polypropylene to Polypropylene

Shear strength measured at elevated temperature, N/mm²

Fixture time and cure speed achieved as a result of using

Shear Strength Adhesive 406

10

LOCTITE® 770™ depend on the adhesive used and the

substrate bonded.

Effect on Cure Speed of Cyanoacrylate Adhesives

LOCTITE® 770™ also behaves as an activator and

5

accelerates the cure speed of cyanoacrylate adhesives.

Fixturing time on most primed substrates is less than 5

seconds but 24 hours at room temperature (22 °C) should be

allowed for adhesive to develop maximum bond strength.

0

0 20 40 60 80 100 120

Temperature, °C

TDS LOCTITE® 770™, December-2008

Grit Blasted Mild Steel to Polypropylene Handling precautions

Shear strength measured at elevated temperature, N/mm² Primer must be handled in a manner applicable to highly

flammable materials and in compliance with relevant local

Shear Strength Adhesive 496

10

regulations. The solvent can affect certain plastics or coatings.

It is recommended to check all surfaces for compatibility before

use.

5 Loctite Material SpecificationLMS

LMS dated November-6, 2000. Test reports for each batch are

available for the indicated properties. LMS test reports include

selected QC test parameters considered appropriate to

specifications for customer use. Additionally, comprehensive

controls are in place to assure product quality and

0 consistency. Special customer specification requirements may

0 20 40 60 80 100 120 be coordinated through Henkel Quality.

Temperature, °C

Heat Aging

Storage

Polypropylene treated with LOCTITE® 770™ Store product in the unopened container in a dry location.

100 Storage information may be indicated on the product container

% Tensile strength retained

labeling.

80 Optimal Storage: 8 °C to 21 °C. Storage below 8 °C or

greater than 28 °C can adversely affect product properties.

60 °C Material removed from containers may be contaminated during

60

use. Do not return product to the original container. Henkel

80 °C Corporation cannot assume responsibility for product which

40 has been contaminated or stored under conditions other than

those previously indicated. If additional information is required,

20 please contact your local Technical Service Center or

Customer Service Representative.

0

0 200 400 600 800 1000

Time, hours Conversions

(°C x 1.8) + 32 = °F

Chemical/Solvent Resistance kV/mm x 25.4 = V/mil

On Isopropyl Alcohol wiped Polypropylene, treated with mm / 25.4 = inches

LOCTITE® 770™. (For effect of other solvents see TDS for µm / 25.4 = mil

N x 0.225 = lb

relevant adhesive)

N/mm x 5.71 = lb/in

N/mm² x 145 = psi

% of initial strength MPa x 145 = psi

Environment °C 100 h 500 h 1000 h N·m x 8.851 = lb·in

95% RH 40 100 100 100 N·m x 0.738 = lb·ft

N·mm x 0.142 = oz·in

GENERAL INFORMATION mPa·s = cP

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected

with a sealant for chlorine or other strong oxidizing

materials.

Directions for use:

Primer may be applied by spraying, brushing or dipping at

ambient temperature. Excess primer should be avoided.

Presence of primer may be detected by means of a UV

inspection lamp (365 nm). If polyolefin and more active or

easier to bond materials are involved, apply the primer to the

polyolefin only.

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE® 770™, December-2008

Note

The data contained herein are furnished for information only

and are believed to be reliable. We cannot assume

responsibility for the results obtained by others over whose

methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons

against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Henkel Corporation

specifically disclaims all warranties expressed or implied,

including warranties of merchantability or fitness for a

particular purpose, arising from sale or use of Henkel

Corporation’s products. Henkel Corporation specifically

disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion

herein of various processes or compositions is not to be

interpreted as representation that they are free from

domination of patents owned by others or as a license under

any Henkel Corporation patents that may cover such

processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered

by one or more United States or foreign patents or patent

applications.

Trademark usage

Except as otherwise noted, all trademarks in this document

are trademarks of Henkel Corporation in the U.S. and

elsewhere. ® denotes a trademark registered in the U.S.

Patent and Trademark Office.

Reference 1.2

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Anda mungkin juga menyukai

- Cummins B Series Repair ManualDokumen588 halamanCummins B Series Repair Manualbvhdareldalmasso100% (17)

- Data Industri JabodetabekDokumen669 halamanData Industri JabodetabekBudy Nugraha88% (24)

- Pad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesDokumen3 halamanPad LEEA-048 Guidance On The Design Testing and Inspection of Fabricated Pad EyesAnirudh S. Goel83% (6)

- H1 SteeringDokumen225 halamanH1 SteeringVinay Kumar NeelamBelum ada peringkat

- Dyneon PTFE BrochureDokumen0 halamanDyneon PTFE BrochureXray UandBelum ada peringkat

- Loctite SF 770: Product DescriptionDokumen3 halamanLoctite SF 770: Product DescriptionNishant SenapatiBelum ada peringkat

- Loctite 401Dokumen3 halamanLoctite 401Asrizal Tri WinaryoBelum ada peringkat

- LOCTITE SI 5927 RED en - GLDokumen2 halamanLOCTITE SI 5927 RED en - GLOmer IkhlasBelum ada peringkat

- Loctite 401™: Technical Data SheetDokumen4 halamanLoctite 401™: Technical Data SheetAngga PramudyaBelum ada peringkat

- Polipol 750 Ta H15 TDS enDokumen3 halamanPolipol 750 Ta H15 TDS enjohana5c.5alvaBelum ada peringkat

- Loctite 454™: Technical Data SheetDokumen4 halamanLoctite 454™: Technical Data Sheetle ducBelum ada peringkat

- Loctite 403Dokumen4 halamanLoctite 403AunKrubBelum ada peringkat

- HMC Loctite 444Dokumen2 halamanHMC Loctite 444sengottBelum ada peringkat

- Loctite SI 5060™: Product DescriptionDokumen3 halamanLoctite SI 5060™: Product DescriptionSanthosh Kumar RavichandranBelum ada peringkat

- Loctite 460™: Technical Data SheetDokumen3 halamanLoctite 460™: Technical Data Sheetdantewow1Belum ada peringkat

- 406-2012 New-EnDokumen3 halaman406-2012 New-EnNishant SenapatiBelum ada peringkat

- Henk Loctite Superflex Red TdsDokumen2 halamanHenk Loctite Superflex Red TdsMariano DomenechBelum ada peringkat

- Loctite 577 en UsDokumen4 halamanLoctite 577 en Uschittaranjan routBelum ada peringkat

- 587 enDokumen2 halaman587 enabhayundaleBelum ada peringkat

- 5660 enDokumen3 halaman5660 enסטניסלב טלשבסקיBelum ada peringkat

- LOctite SI 5900Dokumen3 halamanLOctite SI 5900Giovanni HernandezBelum ada peringkat

- Technical Data Sheet - Loctite 596Dokumen2 halamanTechnical Data Sheet - Loctite 596VIVEK UPADHYAYBelum ada peringkat

- LOCTITE SI 5331 en - GLDokumen2 halamanLOCTITE SI 5331 en - GLkaplanuygarBelum ada peringkat

- Loctite EA 9466™: Product Description Typical Curing Performance Fixture TimeDokumen4 halamanLoctite EA 9466™: Product Description Typical Curing Performance Fixture TimeVesna NikolicBelum ada peringkat

- LOCTITEDokumen2 halamanLOCTITEHrBelum ada peringkat

- Si 5699-EnDokumen3 halamanSi 5699-EnWahyu Riz AmblakadarrBelum ada peringkat

- 5570 WhiteDokumen2 halaman5570 WhitesasidharkanthetiBelum ada peringkat

- Loctite 5699 - enDokumen3 halamanLoctite 5699 - enRider OaklandBelum ada peringkat

- Loctite Stycast 2762: Technical Data SheetDokumen3 halamanLoctite Stycast 2762: Technical Data SheetankitaBelum ada peringkat

- Loctite 577™: Technical Data SheetDokumen4 halamanLoctite 577™: Technical Data SheetCristian SerbovBelum ada peringkat

- Loctite 495 (OLD) : Technical Data SheetDokumen3 halamanLoctite 495 (OLD) : Technical Data SheetRahul GargBelum ada peringkat

- Ceilcote 660HV Corocrete - Topcoat FlooringDokumen2 halamanCeilcote 660HV Corocrete - Topcoat FlooringEspie SualogBelum ada peringkat

- Loctite 403Dokumen3 halamanLoctite 403Layeeq Ahmed PallikondaBelum ada peringkat

- Loctite SI 5900: Technical Data SheetDokumen3 halamanLoctite SI 5900: Technical Data SheetSanthosh Kumar RavichandranBelum ada peringkat

- Loctite 2432: Technical Data SheetDokumen2 halamanLoctite 2432: Technical Data SheetFabio ParceroBelum ada peringkat

- Loctite 435Dokumen3 halamanLoctite 435AunKrubBelum ada peringkat

- Loctite 416™: Technical Data SheetDokumen3 halamanLoctite 416™: Technical Data SheetJuanManuelPerillaBelum ada peringkat

- Loctite 415™: Technical Data SheetDokumen3 halamanLoctite 415™: Technical Data SheettheoBelum ada peringkat

- Loctite EA 9464: Product DescriptionDokumen3 halamanLoctite EA 9464: Product DescriptionehsanBelum ada peringkat

- Henkel Loctite 401 406 454 and 495 ReformulationDokumen14 halamanHenkel Loctite 401 406 454 and 495 Reformulationmishka123Belum ada peringkat

- Desmodur N 75 BADokumen4 halamanDesmodur N 75 BASergiu Tarala100% (1)

- Polywithe® - 8000 CLDokumen1 halamanPolywithe® - 8000 CLsébastien cardinaleBelum ada peringkat

- Loctite Liofol BC 1580-EnDokumen3 halamanLoctite Liofol BC 1580-EnCharly DtBelum ada peringkat

- Sikaflex-403-Tanksilo - Joint Sealing CompoundDokumen5 halamanSikaflex-403-Tanksilo - Joint Sealing CompoundtinashemambarizaBelum ada peringkat

- LOCTITE SF 7387 en - GLDokumen2 halamanLOCTITE SF 7387 en - GLGregBelum ada peringkat

- Lite 3060 - TdsDokumen2 halamanLite 3060 - TdsJuan Sebastián Fernández RamírezBelum ada peringkat

- Loctite Fixmaster Metal Magic Steel™: Technical Data SheetDokumen3 halamanLoctite Fixmaster Metal Magic Steel™: Technical Data SheetHamzaNoumanBelum ada peringkat

- Si 596 Red-EnDokumen3 halamanSi 596 Red-EnkabiriscBelum ada peringkat

- TDS 1365882 1405419 1461229 US Loctite Super Glue Professional Carded Bottle 20 G 2018 04 06pdfDokumen3 halamanTDS 1365882 1405419 1461229 US Loctite Super Glue Professional Carded Bottle 20 G 2018 04 06pdfwand.surveyBelum ada peringkat

- Thioplast G4: Liquid Polysulfide Polymer With Thiol End Groups (MW 1800)Dokumen3 halamanThioplast G4: Liquid Polysulfide Polymer With Thiol End Groups (MW 1800)kebenshanBelum ada peringkat

- DION IMPACT 9102 SeriesDokumen5 halamanDION IMPACT 9102 SeriesLENEEVERSONBelum ada peringkat

- Polylite 441 800 eDokumen3 halamanPolylite 441 800 echetanBelum ada peringkat

- Loctite Ea 9430-EnDokumen2 halamanLoctite Ea 9430-EnDan AyalaBelum ada peringkat

- Loctite 496-En PDFDokumen3 halamanLoctite 496-En PDFjaymuscatBelum ada peringkat

- TDS PC 7218-EnDokumen3 halamanTDS PC 7218-Enangga alvianBelum ada peringkat

- Loctite 435™: Technical Data SheetDokumen3 halamanLoctite 435™: Technical Data SheettejassidhpuraBelum ada peringkat

- TDS Loctite LOCTITE PC 9626 Fixmaster Deep Pour GroutDokumen2 halamanTDS Loctite LOCTITE PC 9626 Fixmaster Deep Pour Groutfadlywirawan7Belum ada peringkat

- The World Quality Leader in Cashew Liquid Technology: Coating Products PortfolioDokumen8 halamanThe World Quality Leader in Cashew Liquid Technology: Coating Products Portfolioمحمد عزتBelum ada peringkat

- Corocrete Eng A4 20090807Dokumen3 halamanCorocrete Eng A4 20090807andriBelum ada peringkat

- Acronal S400Dokumen3 halamanAcronal S400Anonymous ZzwxObIlLe100% (1)

- Desmodur N 75 MPA - en - 00832197 00009989 00054371Dokumen4 halamanDesmodur N 75 MPA - en - 00832197 00009989 00054371VeliYunusKavalciBelum ada peringkat

- 670.bull.2022 (22.0)Dokumen3 halaman670.bull.2022 (22.0)Francisco RodríguezBelum ada peringkat

- Desmodur N 3390 BA: Characterization Form SuppliedDokumen4 halamanDesmodur N 3390 BA: Characterization Form Suppliedbuzas94Belum ada peringkat

- Araldite 2011 Structural Adhesive: Advanced MaterialsDokumen6 halamanAraldite 2011 Structural Adhesive: Advanced MaterialsrezaeibehrouzBelum ada peringkat

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADokumen1 halaman2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanBelum ada peringkat

- Contoh Crane LatticeDokumen112 halamanContoh Crane LatticeRaza AidanBelum ada peringkat

- 100% Made in Italy: MIN MAX MIN MAX MIN MAX MIN MAX MIN MAX MIN MAXDokumen1 halaman100% Made in Italy: MIN MAX MIN MAX MIN MAX MIN MAX MIN MAX MIN MAXRaza AidanBelum ada peringkat

- Bridon Crane and IndustrialDokumen93 halamanBridon Crane and Industrialadh3ckBelum ada peringkat

- CMAA No.70 (2000)Dokumen90 halamanCMAA No.70 (2000)jsyun0831100% (10)

- KATO ALL TERRAIN CRANE AND CARRIER SPECIFICATIONSDokumen16 halamanKATO ALL TERRAIN CRANE AND CARRIER SPECIFICATIONShungdqBelum ada peringkat

- Water Jet Pump - Equipment List 2022Dokumen1 halamanWater Jet Pump - Equipment List 2022Raza AidanBelum ada peringkat

- Crane Chart - Tadano AR-2000MDokumen16 halamanCrane Chart - Tadano AR-2000Mdamnaged100% (2)

- FL150-8401 MRDokumen2 halamanFL150-8401 MRRaza AidanBelum ada peringkat

- Thern Portable Floor Crane Manual JECDokumen15 halamanThern Portable Floor Crane Manual JECRaza AidanBelum ada peringkat

- Calculating The Load of Basket Hitches and BridlesDokumen2 halamanCalculating The Load of Basket Hitches and Bridlesbilo1984Belum ada peringkat

- Sac3500 All-Terrain Crane 350 Tons Lifting Capacity: Quality Changes The WorldDokumen27 halamanSac3500 All-Terrain Crane 350 Tons Lifting Capacity: Quality Changes The WorldRaza AidanBelum ada peringkat

- Floor Cranes Mini Floor CraneDokumen1 halamanFloor Cranes Mini Floor CraneRaza AidanBelum ada peringkat

- FD 30Dokumen546 halamanFD 30Raza AidanBelum ada peringkat

- FD 30Dokumen546 halamanFD 30Raza AidanBelum ada peringkat

- Design of Monorail SystemsDokumen20 halamanDesign of Monorail SystemsAshfaq Anwer50% (2)

- Winch Operation Lift PLan v0Dokumen14 halamanWinch Operation Lift PLan v0Raza Aidan100% (1)

- Rigging: GuideDokumen244 halamanRigging: Guideyusry72100% (11)

- d5 d8 Brochure enDokumen14 halamand5 d8 Brochure enRaza AidanBelum ada peringkat

- Welding Inspection: Defects/Repairs Course Reference WIS 5Dokumen54 halamanWelding Inspection: Defects/Repairs Course Reference WIS 5Raza AidanBelum ada peringkat

- SA CERTEX Fake Crosby ShacklesDokumen1 halamanSA CERTEX Fake Crosby ShacklesRaza AidanBelum ada peringkat

- Block Inspection Report Form: CommentsDokumen1 halamanBlock Inspection Report Form: CommentsRaza AidanBelum ada peringkat

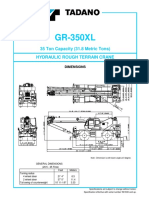

- Alt GR 350XL-Tier-4Dokumen12 halamanAlt GR 350XL-Tier-4Raza AidanBelum ada peringkat

- Pad Eye Design AnalysisDokumen10 halamanPad Eye Design AnalysisRaza AidanBelum ada peringkat

- Beam CantileverDokumen16 halamanBeam CantileverAdam SlametBelum ada peringkat

- BS 21-Pipe Thread PDFDokumen22 halamanBS 21-Pipe Thread PDFRaza AidanBelum ada peringkat

- 1.1 Simple Span Beams: CHAPTER 1: Analysis of BeamsDokumen11 halaman1.1 Simple Span Beams: CHAPTER 1: Analysis of BeamsRaza AidanBelum ada peringkat

- BS 21-Pipe Thread PDFDokumen22 halamanBS 21-Pipe Thread PDFRaza AidanBelum ada peringkat

- Study Eco-Efficiency of Recovery Scenarios of Plastic Packaging - 2001Dokumen266 halamanStudy Eco-Efficiency of Recovery Scenarios of Plastic Packaging - 2001ademaj08Belum ada peringkat

- A4-P 1.0 enDokumen21 halamanA4-P 1.0 enmkpqBelum ada peringkat

- Mba Pom Exam 122019Dokumen6 halamanMba Pom Exam 122019Ped SalvadorBelum ada peringkat

- Secondary Physics Temp NotesDokumen3 halamanSecondary Physics Temp NotesHarish PrabhuBelum ada peringkat

- D20Dtf Engine InformationDokumen16 halamanD20Dtf Engine InformationFrancisco Alejandro TelloBelum ada peringkat

- Underground Cables - 010954Dokumen23 halamanUnderground Cables - 010954lawrence momanyiBelum ada peringkat

- Effectivity of Cellophanes As Alternative of Commercialized FloorwaxDokumen14 halamanEffectivity of Cellophanes As Alternative of Commercialized FloorwaxFranzes Mar Eria100% (1)

- Filter Maintenance IndicatorDokumen14 halamanFilter Maintenance Indicatormuatafa1948pBelum ada peringkat

- AsphaltDokumen182 halamanAsphaltEnd EndBelum ada peringkat

- FTIR Spectrometer AnalysisDokumen16 halamanFTIR Spectrometer AnalysisßraiñlĕsšȜĭnšteĭñBelum ada peringkat

- Quiet Fan Heater FHW for Water Connection Offers Heating and VentilationDokumen20 halamanQuiet Fan Heater FHW for Water Connection Offers Heating and VentilationCrisTimBelum ada peringkat

- Solutions of Solids in LiquidsDokumen16 halamanSolutions of Solids in LiquidsNoorhalieza AliBelum ada peringkat

- Exploration GeologyDokumen36 halamanExploration Geologyفردوس سليمانBelum ada peringkat

- Rate Analysis-KalikaDokumen35 halamanRate Analysis-KalikaPujan Amit Gurung100% (1)

- Blanco Ku 0099M 13094 DATA 1 PDFDokumen96 halamanBlanco Ku 0099M 13094 DATA 1 PDFCm EtcmBelum ada peringkat

- Jotamastic 70Dokumen9 halamanJotamastic 70Muhammad HanafiBelum ada peringkat

- Utilisation of Foundry Sand in Concrete ProductionDokumen9 halamanUtilisation of Foundry Sand in Concrete ProductionDhiraj YelmateBelum ada peringkat

- Report of Landfill in MichiganDokumen67 halamanReport of Landfill in MichiganAndre SuitoBelum ada peringkat

- Numerical optimization of a transcritical CO2/propylene cascaded refrigeration-heat pump systemDokumen18 halamanNumerical optimization of a transcritical CO2/propylene cascaded refrigeration-heat pump systemzhyhhBelum ada peringkat

- Wärtsilä EGC Alarm ListDokumen11 halamanWärtsilä EGC Alarm ListTomislav BanićBelum ada peringkat

- CrackingDokumen20 halamanCrackingNiaz Ali KhanBelum ada peringkat

- The WPS Writers GuideDokumen129 halamanThe WPS Writers GuideGEORGEVPAUL_14565666Belum ada peringkat

- Toyota Turbo Applications ListDokumen33 halamanToyota Turbo Applications ListAdan Flores Correa100% (5)

- 6063 Aluminium Alloy - WikipediaDokumen3 halaman6063 Aluminium Alloy - WikipediaNinad PawarBelum ada peringkat

- Technical Data Sheet Baltoflake EcolifeDokumen5 halamanTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadBelum ada peringkat

- UPoles - Paper - Durability of Poles in NESC Grade C Construction by HJ Dagher - 04-23-2001.ashxDokumen22 halamanUPoles - Paper - Durability of Poles in NESC Grade C Construction by HJ Dagher - 04-23-2001.ashxVictor JimenezBelum ada peringkat