Lightfastness Testing Explained

Diunggah oleh

Serhan Ünver0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

36 tayangan3 halamanblue wool parameters

Judul Asli

blue wool article

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniblue wool parameters

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

36 tayangan3 halamanLightfastness Testing Explained

Diunggah oleh

Serhan Ünverblue wool parameters

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

Lightfastness of Printing Inks

The lightfast properties of printing inks can

be defined as the amount of resistance to

fade or color change of a printed surface

when exposed to daylight (or an artificial light

source) over a set period of time.

LIGHTFASTNESS, WEATHERABILITY OR

CHEMICAL ATTACK?

Prolonged exposure to daylight is only one of

many reasons for color fade. A lightfastness

rating is given as an ink property that can be

quantified under a narrow set of parameters in SUNLIGHT SPECTRUM 250nm-2500

the lab. However, if the same printed sample

were exposed to outside conditions, the resulting At the lower end of the daylight band is the

color fade results would vary considerably from Ultraviolet content; these wavelengths extend

the original lightfastness rating based on the beyond 380nm to approximately 100nm. Located

weather ability parameters of the exposed just outside the daylight band, these wavelengths

sample. The same printed surface could also are more energetic and are largely responsible

react to Chemical Attack from solvents that for color fading.

come into contact with the print from overprint

lacquers, varnishes, lamination adhesives or The UV wavelengths are characterized at three

even leaching of chemicals from the materials different levels: UV-A, UV-B, & UV-C. It is only

stored in the package. UV-A & B that penetrate our atmosphere and it is

these we are concerned with. Of these, the UV-B;

The scope of this paper is on lightfastness. As the shortest wavelength, has the most potential

the term suggests, it refers to the resistance of a to fade colors (as well as cause burns of the skin

color to fading in the presence of daylight. and other conditions).

Daylight, as we know it, forms part of the

electromagnetic spectrum. This can be described The energy radiated via the electromagnetic

as a broad band of energy, radiated from the sun spectrum is not uniformly distributed throughout

in the form of waves. The part of the the world. Also, the energy output varies

electromagnetic spectrum seen below that considerably depending on the seasons of the

daylight occupies is measured in nanometers – year. Latitude, altitude, location and time of the

from 380 – 760nm. year have an enormous effect on the levels of

color fading. Discounting the effects of chemicals

Corporate Headquarters – Zeller+Gmelin Corporation

4725 Jefferson Davis Highway – Richmond, Virginia 23234

Phone 800 84UV INK – 804 275 8486 – Fax 804 275 8638

uvinks@zeller-gmelin.com - www.zeller-gmelin.com Page 1 TechInfoLightfastPaper0109.doc

and weathering, there are two basic factors at

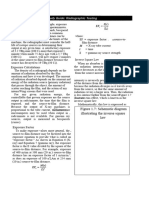

work; the number of daylight hours and the BLUE WOOL SCALE app. Days

intensity of the UV radiation. 1 3

2 6

The largest seasonal variations in energy output 3 13

occur in the far northern and southern 4 27

hemispheres. For example; in Chicago USA, a 5 58

print exposed in July may fade in 20 days, 6 117

whereas in November it would fade in 140 days, 7 250

all else being equal. These types of variations 8 500

serve to emphasize that product-testing results Blue Wool Scale vs. app. Days of Outdoor Exposure

are always specific to a region and necessitates (New York Latitude)

the reliance on light testing equipment when

establishing fade resistance standards. The testing of fastness to light is highly specified

within standard methods. But this sets a

Prints can be tested either in location, usually benchmark only as far as a mechanical test.

under glass, or by a testing device that artificially Here is a typical table of Blue Wool Scale

creates the spectral remission that a print would assessment in a simulation of direct intense

be exposed to under daylight conditions. Both sunlight.

these methods incorporate the use of the Blue

Wool Scale (BWS).

BLUE WOOL SCALE app. Hours in Xenon

Fadeometer

Within the printing ink industry, fade resistant inks

1 20

are typically formulated on the basis of figures

quoted by the pigment suppliers and checked 2 40

using laboratory fade testing equipment. The 3 80

basis of the Blue Wool Scale is a series of dyed 4 160

wool strips. These strips are dyed with various

5 350

dyes graded from 1 (very low) to 8 (very high).

6 700

Each grade of dyed wool is carefully

manufactured to fade at a predetermined rate; 7 1500

each grade fading under test conditions at twice 8 3000

the exposure time of the next lowest grade. The

Blue Wool Scale vs. Xenon Fadeometer

test is conducted by exposing the eight blue wool

ASTM D 3492 Specifications

samples alongside the test print samples. Both

sets of samples are half masked. When the test

A prediction can be made based on the number

period is complete, all samples are unmasked

of days a print can be expected to last at the

and the degree of fade compared against a grey st

average optimum sunlight condition (March 21

scale that numerically indicates a level of fade st

and September 21 ).

and therefore assigning a number to the result.

Other methods of evaluation are being examined

Please note that this estimate is an average,

but currently the Blue Wool Scale is by far the

and that real world results may vary greatly

most popular method.

according to seasons. For example, a print

exposed during July, may last 20 – 25 days while

the same print exposed in November could

theoretically last up to 140 days. Additionally, you

Corporate Headquarters – Zeller+Gmelin Corporation

4725 Jefferson Davis Highway – Richmond, Virginia 23234

Phone 800 84UV INK – 804 275 8486 – Fax 804 275 8638

uvinks@zeller-gmelin.com - www.zeller-gmelin.com Page 2 TechInfoLightfastPaper0109.doc

may want to subtract additional days for wants to choose the most inexpensive pigment

differences in latitude, altitude, location, exposure with adequate of fade resistance to meet

to air pollution and other chemicals, humidity and established end use specifications.

weathering effects. The bottom line is that, while

this estimate can be useful in choosing the right TECHNICAL HINTS

pigmentation for your product, you, as the

customer, must ultimately monitor and test your 1. The light fastness of a color is determined by

own results under your specific field conditions. the lowest value of any of the components in the

ink. Lightfast inks should contain lightfast

pigmentations top to bottom and bases used for

high fade conditions should be considered for the

160

entire ink.

140

120 2. In tints or pastels avoid use of heavy amounts

100 of transparent white and substitute with opaque

white, which substantially increases fade

80

resistance.

60

40 3. Avoid too-thin ink films. When properly cured,

20 the thicker film withstands light and weathering

0

better than a thinner film.

1 2 3 4 5 6 7 8 9 10 11 12

JAN M A R CH MAY J U LY S EP 4. Where possible utilize a protective overprint

Blue Wool 5 Pigmentation Fade Conditions at varnish with weather ability properties and

varying months (New York Latitude) blocking agents with ability to screen out UV light

in the suns spectrum.

PIGMENTATION CHOICES

5. Check with your ink manufacturer on the grade

There are a vast number of different pigmentation of pigmentation you are receiving in your

choices available to printing ink manufacturers. products.

Pigments that are the highest grade of fade

resistance are usually the most expensive and 6. Double check for any additional requirements

often these have much lower color intensity. For regarding chemicals that prints are subject to

these reasons, if the printer requires but does not come in contact and the ink/coatings ability to

request light fastness properties, the ink withstand that environment.

manufacturer will invariably supply inks based on

standard grade pigments. It is essential that if the 7. Adhesion of the ink/coating is highly related to

customer requires light fast pigmentation, he inks durability of outdoor exposure. Make sure

must inform the ink supplier of these adhesion is at its highest levels utilizing any

requirements! treatment or specialized inks necessary to

achieve those results.

Please note that many standard grades of blue

and black as well as some greens and violets

have excellent fade resistance, while the

standard grade of yellow, red and purple have

poor fade characteristics. Optimally, the customer

Corporate Headquarters – Zeller+Gmelin Corporation

4725 Jefferson Davis Highway – Richmond, Virginia 23234

Phone 800 84UV INK – 804 275 8486 – Fax 804 275 8638

uvinks@zeller-gmelin.com - www.zeller-gmelin.com Page 3 TechInfoLightfastPaper0109.doc

Anda mungkin juga menyukai

- Puma Diesel Engine Camshaft Removal & Installation GuideDokumen9 halamanPuma Diesel Engine Camshaft Removal & Installation GuideJam Bab100% (1)

- Acura TSX 2004 Electronic Throttle Control SystemDokumen89 halamanAcura TSX 2004 Electronic Throttle Control Systemjorge antonio guillen100% (1)

- Welding ProcessesDokumen51 halamanWelding ProcessesAtul100% (4)

- This Poster at WWW - Yourbias.isDokumen1 halamanThis Poster at WWW - Yourbias.isAstekMadden100% (1)

- Radiography LatestDokumen76 halamanRadiography LatestSavad Alwye100% (4)

- Sunglasses PDFDokumen6 halamanSunglasses PDFaliBelum ada peringkat

- Specifications and RequirementsDokumen22 halamanSpecifications and RequirementsMohammed AnasBelum ada peringkat

- Wiring Diagram - C3Dokumen3 halamanWiring Diagram - C3dardo100% (1)

- Building Code PDFDokumen227 halamanBuilding Code PDFBgee Lee100% (2)

- Waterborne Acrylic Elastomeric Roof Coatings: - September 2016Dokumen9 halamanWaterborne Acrylic Elastomeric Roof Coatings: - September 2016nanoBelum ada peringkat

- 8.4.4 - Radiographic Training ProgramDokumen31 halaman8.4.4 - Radiographic Training ProgramMaduabuchi Serge Enemuo100% (1)

- The Basics Of... Resin Technology: L A Fisher G R HaywardDokumen28 halamanThe Basics Of... Resin Technology: L A Fisher G R HaywardSerhan ÜnverBelum ada peringkat

- Wetting and DispersingDokumen16 halamanWetting and DispersingSerhan ÜnverBelum ada peringkat

- Quallity Control JPCLDokumen37 halamanQuallity Control JPCLSerhan ÜnverBelum ada peringkat

- Plastic UV Re KlyDokumen2 halamanPlastic UV Re KlybmsinghBelum ada peringkat

- AC Machinery Fundamentals ExplainedDokumen38 halamanAC Machinery Fundamentals ExplainedDicky Andra Irawan100% (1)

- ASTM C 1549 Determination-of-Solar-Re ectance-Near-Ambient-Temprature-using-aportable-solar-reflectometer PDFDokumen6 halamanASTM C 1549 Determination-of-Solar-Re ectance-Near-Ambient-Temprature-using-aportable-solar-reflectometer PDFSuraj RawatBelum ada peringkat

- Weymouth and Panhandle Equations For Gas PipelinesDokumen4 halamanWeymouth and Panhandle Equations For Gas PipelinessgrsthBelum ada peringkat

- ASTM Standard E1918-06 Medición de Reflectancia SolarDokumen4 halamanASTM Standard E1918-06 Medición de Reflectancia Solarvvallejo_1100% (1)

- Plea2006 Paper758 PDFDokumen6 halamanPlea2006 Paper758 PDFManuel GaldeanoBelum ada peringkat

- Measurement of Opacity and Particulate Emissions With An On Stack TransmissometerDokumen8 halamanMeasurement of Opacity and Particulate Emissions With An On Stack TransmissometerTU NGO THIENBelum ada peringkat

- The Blue Wool StandardsDokumen3 halamanThe Blue Wool StandardsWilli De Barros GonçalvesBelum ada peringkat

- Light Fastness Blue Wool ScaleDokumen4 halamanLight Fastness Blue Wool ScaleShaik DawoodBelum ada peringkat

- Astm D 904 - 99 - RdkwnaDokumen3 halamanAstm D 904 - 99 - RdkwnaSamuel Eduardo0% (1)

- Errors Using Joules To Time Out Test LenghtsDokumen8 halamanErrors Using Joules To Time Out Test Lenghtsnikopigni2Belum ada peringkat

- Measuring Solar Reflectance of Horizontal and Low-Sloped Surfaces in The FieldDokumen4 halamanMeasuring Solar Reflectance of Horizontal and Low-Sloped Surfaces in The FieldEric GozzerBelum ada peringkat

- Operating Light-And Water-Exposure Apparatus (Fluorescent UV-Condensation Type) For Exposure of Nonmetallic MaterialsDokumen9 halamanOperating Light-And Water-Exposure Apparatus (Fluorescent UV-Condensation Type) For Exposure of Nonmetallic MaterialsOrlando RojasBelum ada peringkat

- Comparison Between Models and Measurements of Direct and Diffuse Uv Erythemal Irradiance Under Clear Sky Conditions-Analysis of The Environmental Impacts On The MeasurementsDokumen4 halamanComparison Between Models and Measurements of Direct and Diffuse Uv Erythemal Irradiance Under Clear Sky Conditions-Analysis of The Environmental Impacts On The MeasurementsChrisBelum ada peringkat

- Results of Contamination Test of Silicone Rubber Polymer Insulators For The Round-Robin Test by CigreDokumen4 halamanResults of Contamination Test of Silicone Rubber Polymer Insulators For The Round-Robin Test by Cigreवसन्त गौतमBelum ada peringkat

- D 904 - 99 (2013)Dokumen3 halamanD 904 - 99 (2013)gt toniBelum ada peringkat

- D7897 15 Standard Practice For Laboratory Soiling and Weathering of Roofing Materials To Simulate Effects of Natural Exposure On Solar Reflectance and PDFDokumen10 halamanD7897 15 Standard Practice For Laboratory Soiling and Weathering of Roofing Materials To Simulate Effects of Natural Exposure On Solar Reflectance and PDFpractice rosBelum ada peringkat

- Uv Durability of Tencate Geosynthetics: Technical NoteDokumen8 halamanUv Durability of Tencate Geosynthetics: Technical NoteGerald TanBelum ada peringkat

- Exposure Meter PhotofactsDokumen48 halamanExposure Meter Photofactssabo6181Belum ada peringkat

- Optical PropertiesDokumen9 halamanOptical PropertiesShahab ShafiBelum ada peringkat

- The QUV Tester Compared To Sunshine Carbon ArcDokumen4 halamanThe QUV Tester Compared To Sunshine Carbon ArccsarmientoBelum ada peringkat

- Durability UV GeosyntheticsDokumen8 halamanDurability UV GeosyntheticsnknicoBelum ada peringkat

- Sensitometry and Characteristic CurveDokumen67 halamanSensitometry and Characteristic Curvesarose bhandari100% (2)

- Qsun and Quv ComparisonDokumen16 halamanQsun and Quv Comparisonnikopigni2Belum ada peringkat

- Handbook: E LightingDokumen1 halamanHandbook: E LightingreacharunkBelum ada peringkat

- Azocol Z 1Dokumen3 halamanAzocol Z 1Antonio EspiagoBelum ada peringkat

- A Quick, Practical Test Procedure To Evaluate The Performance of Instruments Used For UV Protection MeasurementsDokumen7 halamanA Quick, Practical Test Procedure To Evaluate The Performance of Instruments Used For UV Protection MeasurementsmimaBelum ada peringkat

- Filmproperties Testsanddetails 130422033931 Phpapp02Dokumen40 halamanFilmproperties Testsanddetails 130422033931 Phpapp02Hemant Kumar PathakBelum ada peringkat

- Uv 45Dokumen3 halamanUv 45Raghava TummalaBelum ada peringkat

- Elipsometrie Simpla PDFDokumen6 halamanElipsometrie Simpla PDFalexandruscribdBelum ada peringkat

- Astm E1918-21Dokumen5 halamanAstm E1918-21Bruno SilvaBelum ada peringkat

- Simulator Article (PV Tech) FINAL - July 2008Dokumen4 halamanSimulator Article (PV Tech) FINAL - July 2008PraveenBelum ada peringkat

- Asnt 3Dokumen6 halamanAsnt 3amin.adineh97Belum ada peringkat

- TR 17 A Low Cost Method of Measuring Solar IrradianceDokumen6 halamanTR 17 A Low Cost Method of Measuring Solar IrradianceAdekunle AdewoleBelum ada peringkat

- IR 820c IR 820c AURA: Representative of A New Generation of B&W Infrared FilmsDokumen19 halamanIR 820c IR 820c AURA: Representative of A New Generation of B&W Infrared FilmsTim HodgeBelum ada peringkat

- Optical Determination of Thickness and Gap of Semicondutors: September 7, 2016Dokumen5 halamanOptical Determination of Thickness and Gap of Semicondutors: September 7, 2016Matheus FagundesBelum ada peringkat

- Study Spectral DegradationDokumen7 halamanStudy Spectral DegradationnileshbagaleBelum ada peringkat

- Ao 44 005712 PDFDokumen11 halamanAo 44 005712 PDFDibakar RoyBelum ada peringkat

- Solar EnergyDokumen6 halamanSolar EnergyFawziah NasserBelum ada peringkat

- Experience With Optical Partial Discharge DetectionDokumen4 halamanExperience With Optical Partial Discharge DetectionDaniel Tamata SolorioBelum ada peringkat

- ASTM For Solar Reflectance-C1549Dokumen6 halamanASTM For Solar Reflectance-C1549Rahul GhoshBelum ada peringkat

- Effects of Woven Fabric Construction and Color On Ultraviolet ProtectionDokumen9 halamanEffects of Woven Fabric Construction and Color On Ultraviolet Protectionthelazyllama444Belum ada peringkat

- Africon04 WhsDokumen4 halamanAfricon04 WhsKambiz TaherkhaniBelum ada peringkat

- Bending LossDokumen6 halamanBending Lossesther lidiyaBelum ada peringkat

- Three Year Field Performance of Anti-Soiling Coatings at Multiple LocationsDokumen4 halamanThree Year Field Performance of Anti-Soiling Coatings at Multiple LocationsShubham KumarBelum ada peringkat

- Sunlight, UV, Accelerated Weathering: by Patrick Brennan & C. Fedor1Dokumen8 halamanSunlight, UV, Accelerated Weathering: by Patrick Brennan & C. Fedor1PaoloMMBelum ada peringkat

- High Irradiance UV/Condensation Testers Allow Faster Accelerated Weathering Test ResultsDokumen8 halamanHigh Irradiance UV/Condensation Testers Allow Faster Accelerated Weathering Test Resultsmhk665Belum ada peringkat

- Pintura y SugrosidadDokumen9 halamanPintura y Sugrosidadmartin sabusBelum ada peringkat

- c005 PDFDokumen10 halamanc005 PDFSamir ZaghloolBelum ada peringkat

- 1969 Jan 79-86Dokumen8 halaman1969 Jan 79-86Vaibhav DafaleBelum ada peringkat

- Measurement of Solar Extinction in Tower Plants With Digital CamerasDokumen8 halamanMeasurement of Solar Extinction in Tower Plants With Digital CamerasUmer JamalBelum ada peringkat

- UV190002 E Roof PaintDokumen1 halamanUV190002 E Roof PaintwidyaBelum ada peringkat

- Nonlinear Optical Responses in Organic Dye by Z-Scan MethodDokumen6 halamanNonlinear Optical Responses in Organic Dye by Z-Scan MethodAyari Gonzalez MariscalBelum ada peringkat

- Astm c1549Dokumen4 halamanAstm c1549arumaBelum ada peringkat

- Electrochemistry of NanomaterialsDari EverandElectrochemistry of NanomaterialsGary HodesBelum ada peringkat

- Handbook of Infrared Spectroscopy of Ultrathin FilmsDari EverandHandbook of Infrared Spectroscopy of Ultrathin FilmsBelum ada peringkat

- Cushion-Mount Plus Plate Mounting Tapes With Easy Mount AdhesiveDokumen6 halamanCushion-Mount Plus Plate Mounting Tapes With Easy Mount AdhesiveSerhan ÜnverBelum ada peringkat

- Oraflex: Solutions For The Flexographic Print IndustryDokumen6 halamanOraflex: Solutions For The Flexographic Print IndustrySerhan ÜnverBelum ada peringkat

- Tesa Softprint Plate Mounting Solutions For Flexographic PrintingDokumen5 halamanTesa Softprint Plate Mounting Solutions For Flexographic PrintingSerhan Ünver100% (1)

- Cushion-Mount Plus Plate Mounting Tapes With Easy Mount Adhesive High Plateside AdhesionDokumen6 halamanCushion-Mount Plus Plate Mounting Tapes With Easy Mount Adhesive High Plateside AdhesionSerhan ÜnverBelum ada peringkat

- 3M L Series Datapage-March2017-V3Dokumen5 halaman3M L Series Datapage-March2017-V3Serhan ÜnverBelum ada peringkat

- Treadmill CheatsheetDokumen2 halamanTreadmill CheatsheetCésar GonzálezBelum ada peringkat

- 3M Standart SeriesDokumen4 halaman3M Standart SeriesSerhan ÜnverBelum ada peringkat

- PIKE Catalog 2017 Vol-1Dokumen174 halamanPIKE Catalog 2017 Vol-1Serhan ÜnverBelum ada peringkat

- Test Code 28 Finalized ProofedDokumen37 halamanTest Code 28 Finalized Proofedmuneesa nisarBelum ada peringkat

- Advanced Characterisation of Surface AppearanceDokumen4 halamanAdvanced Characterisation of Surface AppearanceSerhan ÜnverBelum ada peringkat

- Organic ChemistryDokumen29 halamanOrganic ChemistrySerhan ÜnverBelum ada peringkat

- ResinDokumen47 halamanResinSerhan ÜnverBelum ada peringkat

- Bugs ModelDokumen23 halamanBugs ModelSerhan ÜnverBelum ada peringkat

- CH 01Dokumen21 halamanCH 01Jus ThomasBelum ada peringkat

- Industrial PaintingDokumen67 halamanIndustrial PaintingSerhan ÜnverBelum ada peringkat

- PCI Additive Definitions 2011Dokumen64 halamanPCI Additive Definitions 2011Serhan ÜnverBelum ada peringkat

- Coating TechnologyDokumen6 halamanCoating TechnologySerhan ÜnverBelum ada peringkat

- Quiz 7: Preparing A Document Using A Template and InstructionsDokumen1 halamanQuiz 7: Preparing A Document Using A Template and InstructionsSerhan ÜnverBelum ada peringkat

- The Present (With Religion)Dokumen335 halamanThe Present (With Religion)Buzgau Dan AdrianBelum ada peringkat

- Biochrom LTD Certificate No: 890333Dokumen5 halamanBiochrom LTD Certificate No: 890333Serhan ÜnverBelum ada peringkat

- Airwide International-China (A) Key Account SellingDokumen6 halamanAirwide International-China (A) Key Account SellingFahad ParvezBelum ada peringkat

- Operator Manual FurunoDokumen40 halamanOperator Manual FurunoJan JbaBelum ada peringkat

- 06 Transmision LineDokumen41 halaman06 Transmision LinebhargavBelum ada peringkat

- Steel Frame Wall Systems Installation GuideDokumen48 halamanSteel Frame Wall Systems Installation Guide陳宗煌Belum ada peringkat

- Narayana GT 5 QPDokumen17 halamanNarayana GT 5 QPGowri Shankar100% (1)

- Oq Faw1005Dokumen66 halamanOq Faw1005vijayns_250355172Belum ada peringkat

- Solar Generator ReportDokumen26 halamanSolar Generator ReportHasan HemaniBelum ada peringkat

- Installation Manual: X-POWER DC Inverter (K Series) Outdoor UnitDokumen30 halamanInstallation Manual: X-POWER DC Inverter (K Series) Outdoor UnitFred GarciaBelum ada peringkat

- Kingman Spyder 2008 Electra With Eye ManualDokumen35 halamanKingman Spyder 2008 Electra With Eye Manualshizim1Belum ada peringkat

- 08MAT1.5 Nickel and Nickel AlloysDokumen9 halaman08MAT1.5 Nickel and Nickel AlloysNdomaduBelum ada peringkat

- BRAZILIAN MIDRANGE COMBINE SCHEMATICDokumen75 halamanBRAZILIAN MIDRANGE COMBINE SCHEMATICRenato AssisBelum ada peringkat

- Miyachi - MA-627 Program Box ManualDokumen16 halamanMiyachi - MA-627 Program Box ManualcnmengineeringBelum ada peringkat

- Case Study Plant Harris Non Chemical DechlorinationDokumen1 halamanCase Study Plant Harris Non Chemical DechlorinationIrfan OmercausevicBelum ada peringkat

- MX 3100N PDFDokumen8 halamanMX 3100N PDFSanjay ArmarkarBelum ada peringkat

- Heat Pure 1500 Infrared Heater Owners ManualDokumen10 halamanHeat Pure 1500 Infrared Heater Owners ManualInfraredHeatStoreBelum ada peringkat

- PGT43C Product Sheet Pegasus A4 2016Dokumen1 halamanPGT43C Product Sheet Pegasus A4 2016unduhBelum ada peringkat

- IEEM 215 Manufacturing Processes Materials and PropertiesDokumen24 halamanIEEM 215 Manufacturing Processes Materials and PropertiesShaddab AliBelum ada peringkat

- Condair Gea Cairplus Gaisa Apstrades Iekartas Tehn Kat enDokumen36 halamanCondair Gea Cairplus Gaisa Apstrades Iekartas Tehn Kat enpolBelum ada peringkat

- 6th Sem Institution Electives_2023-24Dokumen3 halaman6th Sem Institution Electives_2023-24bhuvankumar3877Belum ada peringkat

- 4U - Physics Equations Formula SheetDokumen2 halaman4U - Physics Equations Formula Sheettrini_gangstaBelum ada peringkat

- 3 1/8" Ultra Slim MPR: Technical Data SheetDokumen2 halaman3 1/8" Ultra Slim MPR: Technical Data SheetMaximBelum ada peringkat

- Tufftride - Qpq-Process: Technical InformationDokumen19 halamanTufftride - Qpq-Process: Technical InformationmwasicBelum ada peringkat