Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming Steel

Diunggah oleh

Hugo RodriguezJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming Steel

Diunggah oleh

Hugo RodriguezHak Cipta:

Format Tersedia

05-04-01 GB8420Domex

Domex 650 MC

Hot rolled, extra high strength,

cold forming steel

Product Applications

Domex cold forming steels are The extra high strength steel

thermo-mechanically rolled in grades are used in applications

modern plants where the such as truck chassis, cranes

heating, rolling and cooling and earthmoving machines. In

processes are carefully these applications, the high

controlled. strength of the steels is used to

The chemical analysis, save weight and/or to increase

consisting of low levels of the payload.

carbon and manganese has As a result of this and the Chemical composition

precise addition of grain refiners good formability of the steels, C Si Mn P S Al Nb V Ti

such as niobium, titanium or the total costs can be reduced. % % % % % % % % %

vanadium. This together with a max max max max max min max max max

clean structure, makes Domex Dimension range 0,12 0,101) 2,00 0,025 0,010 0,015 0,092 0,202 0,152

Steels the most competitive

Domex 650 MC is available in 1) If the material is to be hot-dip galvanized, this must be specified in the order.

alternative for cold formed and 2) Sum of Nb, V and Ti = 0.22% max.

the range of sizes tabulated

welded products.

below in as rolled or pickled

Domex 650 MC with

condition with mill edge. Mechanical properties

designation D and E meet and

For material with trimmed

exceed the demands for steel Yield strength Tensile strength Elongation on failure

edges, the width is reduced by < 3 mm > 3 mm

S650 MC in EN-10149-2. ReH N/mm 2

Rm N/mm 2

A80 % A5 %

35 mm.

Some exceptions may occur. min min - max min min

650 700 - 880 12 14

Thickness (mm) Width (mm) Length (mm)

2,00 - (3,00) 1000 - 1035 1500 - 13000 Bendability

3,00 - (4,00) 885 - 1300 1500 - 13000

4,00 - (5,00) 885 - 1450 1500 - 13000 Nominal thickness, t

5,00 - (6,00) 885 - 1600 1500 - 13000 <3 mm 3 mm <t <6 mm >6 mm

6,00 - (7,00) 885 - 1550 1500 - 13000

Min. recommended 0,8 x t 1,2 x t 1,5 x t

7,00 - (8,00) 885 - 1500 1500 - 13000

bending radius (<90º)

8,00 - 10,00 885 - 1300 1500 - 13000

Impact strength Welding Tensile test pieces taken

The Charpy V-notch test is The low contents of carbon, across the weld can meet the

carried out according to phosphorus and sulphur enable same minimum tesile strength

EN 10045-1. all conventional welding requirements as the base metal.

methods to be readily used for If the stresses acting on the

Designation Test temperature Energy level

Domex 650 MC. No preheating weld are low also under-

is necessary. A narrow heat matching filler metals can be

B Not impact tested

D -20°C 40J affected zone with a somewhat used.

E -40°C 27J lower hardness is formed There are a large number of

immediately adjacent to the matching or over matching

1) Other test temperatures and impact strengths are available subject to special

weld.However, if normal welding filler metals that can be used

agreement.

parameters and methods are for welding of Domex 650 MC,

used, the heat affected zone is which gives a weld that can meet

of no practical significance. the same minimum tensile

strength requirements as the

base metal. Some examplesof

Examples of different matching and over matching filler metals

different filler metals that can

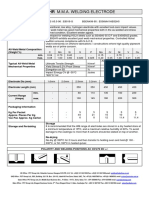

Manual metal arc welding Gas shielded metal arc welding Manufacturer be used are tabulated below.

coated electrode Cored electrode Wire electrode

OK 75.75 OK Tubrod 15.27 OK Autrod 13.13 ESAB Heat treatment

- - OK Autrod 13.29 -

Stress relief annealing should

- - OK Autrod 13.31 -

Filarc 118 PZ6132; PZ6148 - Filarc be carried out within the

P 110 MR Maxeta 110 - Elgamatic 135 ELGA temperature range of 530 -

Tenacito 75 Fluxofil 42 Carbofil NiMoCr Oerlikon 580°C. Heat treatment above

- - Spoolcord TD-T90 - this range, e.g. normalizing and

hot forming, reduces the strength

and should be avoided.

Technical service and

information

Knowledge Service Center will

be pleased to assist with

additional information

The particulars in this data sheet are correct at the time of going to print and are intended

concerning this product and

to give general guidance for the use of the product. Subject to changes arising from

continual product development. The information and data must not be regarded as other products from SSAB

guaranteed values, unless specially confirmed in writing. Tunnplåt.

SSAB Tunnplåt AB Denmark Great Britain Poland Brazil

SE-781 84 Borlänge SSAB Svensk Stål A/S SSAB Swedish Steel Ltd SSAB Swedish Steel Sp z o.o. SSAB Swedish Steel Ltda.

Sweden Tel +45 4320 5000 Tel +44 1905 795794 Tel +48 22 723 04 80 Tel + 55 41 3014 9070

Tel +46 243 700 00 ssab.dk swedishsteel.co.uk ssab.com.br

Fax +46 243 720 00 Portugal

office@ssabtunnplat.com Finland Italy SSAB Swedish Steel South Africa

ssabtunnplat.com OY SSAB Svenskt Stål Ab SSAB Swedish Steel S.p.A Tel +351 256 371 610 SSAB Swedish Steel Pty Ltd

ssabdirect.com Tel +358-9-686 6030 Tel +39 030 905 881 1 ssab.pt Tel +27 11 822 2570

ssab.fi ssab.it swedishsteel.co.za

Spain

France The Netherlands SSAB Swedish Steel S.L. China

SSAB Swedish Steel SA SSAB Swedish Steel BV Tel +34 91 300 5422 SSAB Swedish Steel

Tel +33 1 55 61 91 00 Tel +31 24 67 90 550 ssab.es Tel +86 10 6466 3441

ssab.fr ssab.nl swedishsteel.cn

USA

Germany Norway SSAB Swedish Steel Inc. Korea

SSAB Swedish Steel GmbH SSAB Svensk Stål A/S Tel +1 412-269 21 20 SSAB Swedish Steel Ltd

Tel +49 211 91 25-0 Tel +47 23 11 85 80 swedishsteel.us Tel +82 31 906 2770

Tel +49 711 6 8784-0 ssab.no

ssab.de

Anda mungkin juga menyukai

- Gb8417domex500mc PDFDokumen2 halamanGb8417domex500mc PDFMario MereniBelum ada peringkat

- Weld Like a Pro: Beginning to Advanced TechniquesDari EverandWeld Like a Pro: Beginning to Advanced TechniquesPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDokumen2 halamanDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangBelum ada peringkat

- DATA SHEET: Domex 700 MC steel specificationsDokumen2 halamanDATA SHEET: Domex 700 MC steel specificationsflorin_iacob2001Belum ada peringkat

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Domex 420 MCDokumen2 halamanDomex 420 MCHugo RodriguezBelum ada peringkat

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Dokumen4 halamanSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamBelum ada peringkat

- 421 - Domex 700 MCDokumen2 halaman421 - Domex 700 MClalamed21Belum ada peringkat

- CWC-BookletF1 24Dokumen1 halamanCWC-BookletF1 24Jagannath SahuBelum ada peringkat

- Datasheet BOHLER DCMS-IG TIGDokumen1 halamanDatasheet BOHLER DCMS-IG TIGDaniele DuarteBelum ada peringkat

- Tiginox 385: Classification: en Iso 14343-ADokumen1 halamanTiginox 385: Classification: en Iso 14343-AJagannath SahuBelum ada peringkat

- TDC 09 - R1 - S690 QL & Weldox 700Dokumen2 halamanTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreBelum ada peringkat

- High-Strength Steels For Cold-Forming, Thermomechanically-RolledDokumen2 halamanHigh-Strength Steels For Cold-Forming, Thermomechanically-RolledAshishkekreBelum ada peringkat

- Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Dokumen1 halamanAutomig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Jagannath SahuBelum ada peringkat

- SINOXX 4006 Steel: Designation by StandardsDokumen3 halamanSINOXX 4006 Steel: Designation by StandardsKiranBelum ada peringkat

- Data Sheet Strenx 650 MCDokumen3 halamanData Sheet Strenx 650 MCRoger BandeiraBelum ada peringkat

- Data Sheet Strenx 700 MCDokumen3 halamanData Sheet Strenx 700 MCRoger BandeiraBelum ada peringkat

- CWC-BookletF1 15Dokumen1 halamanCWC-BookletF1 15satnamBelum ada peringkat

- S 960 QDokumen2 halamanS 960 Qmohsen_267Belum ada peringkat

- High-Strength Steels For Cold-Forming, Thermomechanically-RolledDokumen2 halamanHigh-Strength Steels For Cold-Forming, Thermomechanically-RolledbenoiBelum ada peringkat

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Dokumen1 halamanTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamBelum ada peringkat

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADokumen1 halamanTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamBelum ada peringkat

- Strenx 700 MC: Advanced High Strength SteelDokumen2 halamanStrenx 700 MC: Advanced High Strength SteeldbaBelum ada peringkat

- WB56S M.M.A. welding electrode specificationsDokumen1 halamanWB56S M.M.A. welding electrode specificationslathasri78Belum ada peringkat

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Dokumen1 halamanAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamBelum ada peringkat

- 20Mncr5: Steel GradeDokumen4 halaman20Mncr5: Steel GradeAhmad ShujaBelum ada peringkat

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDokumen1 halamanAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuBelum ada peringkat

- Strenx 700MC D e 2017-04-20Dokumen2 halamanStrenx 700MC D e 2017-04-20Amandeep SinghBelum ada peringkat

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Dokumen5 halamanDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- S355MCDokumen2 halamanS355MCPankaj GuptaBelum ada peringkat

- Data Sheet A-10: Alloy TypeDokumen3 halamanData Sheet A-10: Alloy Typemohamed AdelBelum ada peringkat

- Rod - Union I Crmo 910Dokumen1 halamanRod - Union I Crmo 910Rushita SolankiBelum ada peringkat

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDokumen3 halamanAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sBelum ada peringkat

- WB9009E M.M.A. Welding Electrode Product InformationDokumen1 halamanWB9009E M.M.A. Welding Electrode Product Informationlathasri78Belum ada peringkat

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDokumen3 halamanLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanBelum ada peringkat

- Data Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFDokumen2 halamanData Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFangelokyoBelum ada peringkat

- Railrod: Data SheetDokumen1 halamanRailrod: Data Sheetmohamed AdelBelum ada peringkat

- LM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsDokumen3 halamanLM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsSohail ShaikhBelum ada peringkat

- 1 Ceramic Fiber BoardsDokumen2 halaman1 Ceramic Fiber BoardsMahesh MishraBelum ada peringkat

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Dokumen1 halamanAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuBelum ada peringkat

- 1 4501 Super Duplex TubesDokumen3 halaman1 4501 Super Duplex TubesAlma JakirovićBelum ada peringkat

- 1.4057 Aisi 431 Data Sheet PDFDokumen2 halaman1.4057 Aisi 431 Data Sheet PDFGagat GongatBelum ada peringkat

- Automig 80s G Tigfil 80s GDokumen1 halamanAutomig 80s G Tigfil 80s Gvijaysvm999Belum ada peringkat

- WB88SHR M.M.A. welding electrode propertiesDokumen1 halamanWB88SHR M.M.A. welding electrode propertieslathasri78Belum ada peringkat

- 1.4435 - C Stainless Steel DetailsDokumen3 halaman1.4435 - C Stainless Steel DetailsmeenakshiBelum ada peringkat

- Case Hardening Alloy Steel Bar 6587Dokumen3 halamanCase Hardening Alloy Steel Bar 6587CelsoBelum ada peringkat

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADokumen1 halamanAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamBelum ada peringkat

- Stainless SteelDokumen1 halamanStainless SteelSadashiva sahoo100% (1)

- Data Sheet 2008 Strenx 700 MC 20170420 254 371857150 enDokumen2 halamanData Sheet 2008 Strenx 700 MC 20170420 254 371857150 enmarkoBelum ada peringkat

- Grade c300Dokumen1 halamanGrade c300grezmosBelum ada peringkat

- CuZn33 CatalogueDokumen9 halamanCuZn33 CataloguefedericoBelum ada peringkat

- Cuzn37 Industrial RolledDokumen6 halamanCuzn37 Industrial RolledcvgfgBelum ada peringkat

- WA Applications For HydropowerDokumen6 halamanWA Applications For Hydropowersuharto ekoBelum ada peringkat

- 36NiCrMo16 10083 06 ENG 01Dokumen1 halaman36NiCrMo16 10083 06 ENG 01Guru Raj9739Belum ada peringkat

- Overhead Aluminium ConductorsDokumen23 halamanOverhead Aluminium ConductorsWayne KitchingBelum ada peringkat

- NB00550SWS04812GDokumen1 halamanNB00550SWS04812GHugo RodriguezBelum ada peringkat

- Beam Design Formulas With Shear and MomentDokumen20 halamanBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Engineering Bulletin 4-2002: Betts Industries, IncDokumen2 halamanEngineering Bulletin 4-2002: Betts Industries, IncHugo RodriguezBelum ada peringkat

- Engineering Bulletin 1-11 Page 1 of 1Dokumen1 halamanEngineering Bulletin 1-11 Page 1 of 1Hugo RodriguezBelum ada peringkat

- UEM Sol To ExercDokumen9 halamanUEM Sol To ExercHugo RodriguezBelum ada peringkat

- The Fabricator - Com Lean WeldingDokumen4 halamanThe Fabricator - Com Lean WeldingHugo RodriguezBelum ada peringkat

- Front View Left Side: Nozzle ScheduleDokumen1 halamanFront View Left Side: Nozzle ScheduleHugo RodriguezBelum ada peringkat

- NB00300DWS03812GDokumen1 halamanNB00300DWS03812GHugo RodriguezBelum ada peringkat

- Front View Left Side: A 2" A 2" A 2" A 2"Dokumen1 halamanFront View Left Side: A 2" A 2" A 2" A 2"Hugo RodriguezBelum ada peringkat

- Structural Steel Welded BeamsDokumen1 halamanStructural Steel Welded BeamsHugo RodriguezBelum ada peringkat

- Solicitation 3Dokumen27 halamanSolicitation 3Hugo RodriguezBelum ada peringkat

- UEM Sol To ExercDokumen9 halamanUEM Sol To ExercHugo RodriguezBelum ada peringkat

- Arcelormittal A514 and T-1Dokumen6 halamanArcelormittal A514 and T-1Hugo RodriguezBelum ada peringkat

- 3-Spec Lowboy TrailerDokumen9 halaman3-Spec Lowboy TrailerHugo RodriguezBelum ada peringkat

- MAG 51 Spec SheetDokumen1 halamanMAG 51 Spec SheetHugo RodriguezBelum ada peringkat

- Renegade LX40 DrawingDokumen1 halamanRenegade LX40 DrawingHugo RodriguezBelum ada peringkat

- EvoluciónDokumen28 halamanEvoluciónHugo RodriguezBelum ada peringkat

- TGS 8x4 Heavy Duty Tipper: Chassis SpecificationDokumen4 halamanTGS 8x4 Heavy Duty Tipper: Chassis SpecificationHugo RodriguezBelum ada peringkat

- Choosing the Correct Cross-Section Moment of Inertia I for Beam Bending AnalysisDokumen2 halamanChoosing the Correct Cross-Section Moment of Inertia I for Beam Bending AnalysisHugo RodriguezBelum ada peringkat

- Area MomentDokumen9 halamanArea MomentnnnnBelum ada peringkat

- EvoluciónDokumen28 halamanEvoluciónHugo RodriguezBelum ada peringkat

- Moments of Area PDFDokumen13 halamanMoments of Area PDFAlex LakeBelum ada peringkat

- Moment of Inertia Formulas and TheoremsDokumen45 halamanMoment of Inertia Formulas and Theoremsdccadar100% (1)

- HSLA Steels - Comparison of Cutting Techniques Effects on HardnessDokumen7 halamanHSLA Steels - Comparison of Cutting Techniques Effects on HardnessHugo RodriguezBelum ada peringkat

- Installation Instructions: 1520 Hoist W/ SubframeDokumen14 halamanInstallation Instructions: 1520 Hoist W/ SubframeHugo RodriguezBelum ada peringkat

- Order Your Spare Part With Just One !: ClickDokumen6 halamanOrder Your Spare Part With Just One !: ClickHugo RodriguezBelum ada peringkat

- Steel 650 MpaDokumen8 halamanSteel 650 MpaHugo RodriguezBelum ada peringkat

- Sinotruk Tipper 6x4Dokumen1 halamanSinotruk Tipper 6x4Hugo RodriguezBelum ada peringkat

- Transportation Permits Manual Chapter 8 - GlossaryDokumen16 halamanTransportation Permits Manual Chapter 8 - GlossaryHugo RodriguezBelum ada peringkat

- Cantar TipperDokumen4 halamanCantar TipperHugo RodriguezBelum ada peringkat

- DocuCentre IV C4470 3370 2270 BrochureDokumen8 halamanDocuCentre IV C4470 3370 2270 BrochureRumen StoychevBelum ada peringkat

- Contribution Sushruta AnatomyDokumen5 halamanContribution Sushruta AnatomyEmmanuelle Soni-DessaigneBelum ada peringkat

- Tony Bates DepressionDokumen7 halamanTony Bates DepressionNiamh WhiriskeyBelum ada peringkat

- Larry Dossey - HealingBeyondtheBodyDokumen2 halamanLarry Dossey - HealingBeyondtheBodypaulxeBelum ada peringkat

- Khin Thandar Myint EMPADokumen101 halamanKhin Thandar Myint EMPAAshin NandavamsaBelum ada peringkat

- Ocimum Species Ethnomedicinal Uses, Phytochemistry and Pharmacological ImportanceDokumen13 halamanOcimum Species Ethnomedicinal Uses, Phytochemistry and Pharmacological ImportanceManika ManikaBelum ada peringkat

- HexaflexDokumen10 halamanHexaflexCharlie Williams100% (1)

- Compiler Design Lab ManualDokumen24 halamanCompiler Design Lab ManualAbhi Kamate29% (7)

- Title Iii 1 30Dokumen3 halamanTitle Iii 1 30CheriferDahangCoBelum ada peringkat

- Sample Front Desk Receptionist ResumeDokumen5 halamanSample Front Desk Receptionist ResumeReyvie FabroBelum ada peringkat

- Elderly Suicide FactsDokumen2 halamanElderly Suicide FactsThe News-HeraldBelum ada peringkat

- IS-LM Model Analysis of Monetary and Fiscal PolicyDokumen23 halamanIS-LM Model Analysis of Monetary and Fiscal PolicyFatima mirzaBelum ada peringkat

- Red ProjectDokumen30 halamanRed ProjectApoorva SrivastavaBelum ada peringkat

- The ADDIE Instructional Design ModelDokumen2 halamanThe ADDIE Instructional Design ModelChristopher Pappas100% (1)

- Academic Transcript Of:: Issued To StudentDokumen3 halamanAcademic Transcript Of:: Issued To Studentjrex209Belum ada peringkat

- Jason A Brown: 1374 Cabin Creek Drive, Nicholson, GA 30565Dokumen3 halamanJason A Brown: 1374 Cabin Creek Drive, Nicholson, GA 30565Jason BrownBelum ada peringkat

- Rak Single DentureDokumen48 halamanRak Single Denturerakes0Belum ada peringkat

- Class 11 English Snapshots Chapter 1Dokumen2 halamanClass 11 English Snapshots Chapter 1Harsh彡Eagle彡Belum ada peringkat

- AP Biology 1st Semester Final Exam Review-2011.2012Dokumen13 halamanAP Biology 1st Semester Final Exam Review-2011.2012Jessica ShinBelum ada peringkat

- Planning Levels and Types for Organizational SuccessDokumen20 halamanPlanning Levels and Types for Organizational SuccessLala Ckee100% (1)

- What is a Literature ReviewDokumen21 halamanWhat is a Literature ReviewJSPBelum ada peringkat

- ATS - Contextual Theology SyllabusDokumen4 halamanATS - Contextual Theology SyllabusAts ConnectBelum ada peringkat

- Ardipithecus Ramidus Is A Hominin Species Dating To Between 4.5 and 4.2 Million Years AgoDokumen5 halamanArdipithecus Ramidus Is A Hominin Species Dating To Between 4.5 and 4.2 Million Years AgoBianca IrimieBelum ada peringkat

- Sample Essay: Qualities of A Good Neighbour 1Dokumen2 halamanSample Essay: Qualities of A Good Neighbour 1Simone Ng100% (1)

- Sample File: Official Game AccessoryDokumen6 halamanSample File: Official Game AccessoryJose L GarcíaBelum ada peringkat

- QHSE MANAGEMENT SYSTEM DOCUMENTATIONDokumen25 halamanQHSE MANAGEMENT SYSTEM DOCUMENTATIONherisb100% (1)

- Rhodes Solutions Ch4Dokumen19 halamanRhodes Solutions Ch4Joson Chai100% (4)

- Court Testimony-WpsDokumen3 halamanCourt Testimony-WpsCrisanto HernandezBelum ada peringkat

- Limitations For The Study: Celebrity ViewsDokumen3 halamanLimitations For The Study: Celebrity ViewsPakaya100% (2)

- Predict Y Scores Using Linear Regression EquationDokumen6 halamanPredict Y Scores Using Linear Regression EquationreebenthomasBelum ada peringkat