Title 21 - Food and Drugs Chapter I - Food and Drug Adminis Tration Department of Health and Human Services

Diunggah oleh

Hk Hk0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

16 tayangan16 halamancGMP part C

Judul Asli

cGMP part C

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen InicGMP part C

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

16 tayangan16 halamanTitle 21 - Food and Drugs Chapter I - Food and Drug Adminis Tration Department of Health and Human Services

Diunggah oleh

Hk HkcGMP part C

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 16

TITLE 21--FOOD AND DRUGS

CHAPTER I--FOOD AND DRUG ADMINIS TRATION

DEPARTMENT OF HEALTH AND HUMAN SERVICES

SUBCHAPTER C--DRUGS: GENERAL

PART 211CURRENT GOOD MANUFACTURING PRACTICE FOR FINISHED

PHARMACEUTICALS

Subpart C--Buildings and Facilities

Subpart C--Buildings and Facilities

• 211.42 - Design and construction features.

• 211.44 - Lighting.

• 211.46 - Ventilation, air filtration, air heating and cooling.

• 211.48 - Plumbing.

• 211.50 - Sewage and refuse.

• 211.52 - Washing and toilet facilities.

• 211.56 - Sanitation.

• 211.58 - Maintenance.

Sec. 211.42 Design and construction

features.

• (a) Any building or buildings used in the manufacture, processing, packing, or

holding of a drug product shall be of suitable size, construction and location to

facilitate cleaning, maintenance, and proper operations.

• (b) Any such building shall have adequate space for the orderly placement of

equipment and materials to prevent mixups between different components, drug

product containers, closures, labeling, in-process materials, or drug products,

and to prevent contamination. The flow of components, drug product containers,

closures, labeling, in-process materials, and drug products through the building

or buildings shall be designed to prevent contamination.

Sec. 211.42 Design and construction

features. (Continue)

• (c) Operations shall be performed within specifically defined areas of adequate

size. There shall be separate or defined areas or such other control systems for

the firm's operations as are necessary to prevent contamination or mixups

during the course of the following procedures:

• (1) Receipt, identification, storage, and withholding from use of components,

drug product containers, closures, and labeling, pending the appropriate

sampling, testing, or examination by the quality control unit before release for

manufacturing or packaging;

• (2) Holding rejected components, drug product containers, closures, and labeling

before disposition;

• (3) Storage of released components, drug product containers, closures, and

labeling;

Sec. 211.42 Design and construction

features. (Continue)

• (4) Storage of in-process materials;

• (5) Manufacturing and processing operations;

• (6) Packaging and labeling operations;

• (7) Quarantine storage before release of drug products;

• (8) Storage of drug products after release;

• (9) Control and laboratory operations;

Sec. 211.42 Design and construction

features. (Continue)

• (10) Aseptic processing, which includes as appropriate:

• (i) Floors, walls, and ceilings of smooth, hard surfaces that are easily cleanable;

• (ii) Temperature and humidity controls;

• (iii) An air supply filtered through high-efficiency particulate air filters under

positive pressure, regardless of whether flow is laminar or nonlaminar;

• (iv) A system for monitoring environmental conditions;

• (v) A system for cleaning and disinfecting the room and equipment to produce

aseptic conditions;

• (vi) A system for maintaining any equipment used to control the aseptic

conditions.

Sec. 211.42 Design and construction

features. (Continue)

• (d) Operations relating to the manufacture, processing, and packing of penicillin

shall be performed in facilities separate from those used for other drug products

for human use.

Sec. 211.44 Lighting.

• Adequate lighting shall be provided in all areas.

Sec. 211.46 Ventilation, air filtration,

air heating and cooling.

• (a) Adequate ventilation shall be provided.

• (b) Equipment for adequate control over air pressure, micro-organisms, dust,

humidity, and temperature shall be provided when appropriate for the

manufacture, processing, packing, or holding of a drug product.

• (c) Air filtration systems, including prefilters and particulate matter air filters,

shall be used when appropriate on air supplies to production areas. If air is

recirculated to production areas, measures shall be taken to control recirculation

of dust from production. In areas where air contamination occurs during

production, there shall be adequate exhaust systems or other systems adequate

to control contaminants.

• (d) Air-handling systems for the manufacture, processing, and packing of

penicillin shall be completely separate from those for other drug products for

human use.

Sec. 211.48 Plumbing.

• (a) Potable water shall be supplied under continuous positive pressure in a

plumbing system free of defects that could contribute contamination to any drug

product. Potable water shall meet the standards prescribed in the

Environmental Protection Agency's Primary Drinking Water Regulations set

forth in 40 CFR part 141. Water not meeting such standards shall not be

permitted in the potable water system.

• (b) Drains shall be of adequate size and, where connected directly to a sewer,

shall be provided with an air break or other mechanical device to prevent back-

siphonage.

Sec. 211.50 Sewage and refuse.

• Sewage, trash, and other refuse in and from the building and immediate

premises shall be disposed of in a safe and sanitary manner.

Sec. 211.52 Washing and toilet

facilities.

• Adequate washing facilities shall be provided, including hot and cold water, soap

or detergent, air driers or single-service towels, and clean toilet facilities easily

accesible to working areas.

Sec. 211.56 Sanitation.

• (a) Any building used in the manufacture, processing, packing, or holding of a

drug product shall be maintained in a clean and sanitary condition, Any such

building shall be free of infestation by rodents, birds, insects, and other vermin

(other than laboratory animals). Trash and organic waste matter shall be held

and disposed of in a timely and sanitary manner.

• (b) There shall be written procedures assigning responsibility for sanitation and

describing in sufficient detail the cleaning schedules, methods, equipment, and

materials to be used in cleaning the buildings and facilities; such written

procedures shall be followed.

Sec. 211.56 Sanitation. (Continue)

• (c) There shall be written procedures for use of suitable rodenticides, insecticides,

fungicides, fumigating agents, and cleaning and sanitizing agents. Such written

procedures shall be designed to prevent the contamination of equipment,

components, drug product containers, closures, packaging, labeling materials, or

drug products and shall be followed. Rodenticides, insecticides, and fungicides

shall not be used unless registered and used in accordance with the Federal

Insecticide, Fungicide, and Rodenticide Act (7 U.S.C. 135).

• (d) Sanitation procedures shall apply to work performed by contractors or

temporary employees as well as work performed by full-time employees during

the ordinary course of operations.

Sec. 211.58 Maintenance.

• Any building used in the manufacture, processing, packing, or holding of a drug

product shall be maintained in a good state of repair.

Anda mungkin juga menyukai

- Food and Drug Administration, HHS 211.42: 211.28 Personnel ResponsibilitiesDokumen2 halamanFood and Drug Administration, HHS 211.42: 211.28 Personnel ResponsibilitiesJason WangBelum ada peringkat

- Design & Construction ServicesDokumen7 halamanDesign & Construction ServicesAashish GawriBelum ada peringkat

- 21 CFR Ch. I (4-1-12 Edition) 211.44: 211.50 Sewage and RefuseDokumen1 halaman21 CFR Ch. I (4-1-12 Edition) 211.44: 211.50 Sewage and RefuseJason WangBelum ada peringkat

- BuildingDokumen11 halamanBuildingA OmairaBelum ada peringkat

- Premises As Per GMPDokumen15 halamanPremises As Per GMPdivvelaBelum ada peringkat

- Current Good Manufaturing Procedures New OneDokumen22 halamanCurrent Good Manufaturing Procedures New OneSaicharan ReddyBelum ada peringkat

- Annexures Minutes of The 14th Meeting of Eec Held OnDokumen66 halamanAnnexures Minutes of The 14th Meeting of Eec Held OnTayyab TahirBelum ada peringkat

- Good Manufacturing FacilitiesDokumen8 halamanGood Manufacturing Facilitiessakumar5678Belum ada peringkat

- DDS BUILDINGS AND FACILITIEsDokumen11 halamanDDS BUILDINGS AND FACILITIEsrobertkani2004Belum ada peringkat

- Drugs and Cosmetics Act Schedule G and H RequirementsDokumen28 halamanDrugs and Cosmetics Act Schedule G and H RequirementsAmreen KhanBelum ada peringkat

- Drugs and Cosmetics Rules 1945 GMP RequirementsDokumen51 halamanDrugs and Cosmetics Rules 1945 GMP RequirementsregulatoryBelum ada peringkat

- FDA Drug Manufacturing Equipment GuidanceDokumen6 halamanFDA Drug Manufacturing Equipment GuidancepharmaxprojectsBelum ada peringkat

- Premises Design RequirementsDokumen10 halamanPremises Design Requirementsmohd ameerBelum ada peringkat

- Presented By, Rasika Walunj M.Pharm (Qat) : Modern College of Pharmacy (For Ladies), Moshi PuneDokumen46 halamanPresented By, Rasika Walunj M.Pharm (Qat) : Modern College of Pharmacy (For Ladies), Moshi PuneVivek PanchabhaiBelum ada peringkat

- TITLE 21 Part 111 Subpart CDokumen4 halamanTITLE 21 Part 111 Subpart Cbrarus05Belum ada peringkat

- Production Management in GMPDokumen7 halamanProduction Management in GMPRabbiiKhanBelum ada peringkat

- Dietary Supplement CFR Gap Analysis WorksheetDokumen18 halamanDietary Supplement CFR Gap Analysis WorksheetBrian Huff100% (3)

- FDA's Perspectives On Cross-Contamination in CMO Facilities, Considering High Risk ProductsDokumen41 halamanFDA's Perspectives On Cross-Contamination in CMO Facilities, Considering High Risk Productslina kharratBelum ada peringkat

- 21 CFR, Part 210 and 211 Current Good Manufacturing PracticeDokumen72 halaman21 CFR, Part 210 and 211 Current Good Manufacturing PracticeAKKAD PHARMABelum ada peringkat

- 21 CFR Part 225 (Up To Date As of 3-10-2023)Dokumen10 halaman21 CFR Part 225 (Up To Date As of 3-10-2023)ΧΡΗΣΤΟΣ ΜΠΑΡΤΖΟΣBelum ada peringkat

- C GMPDokumen12 halamanC GMPAbid Ali KhanBelum ada peringkat

- GMP Training Requirements for Manufacturing StaffDokumen14 halamanGMP Training Requirements for Manufacturing StaffPrince MoniBelum ada peringkat

- Schedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumDokumen77 halamanSchedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumVivek PanchabhaiBelum ada peringkat

- Effective Sanitation Practices for Food Safety ComplianceDokumen133 halamanEffective Sanitation Practices for Food Safety ComplianceYanuar Rufianti Wongi100% (1)

- Manufacture of Sterile Products Annex GuidanceDokumen52 halamanManufacture of Sterile Products Annex GuidanceLuis Gerardo Rendón BeltránBelum ada peringkat

- 9 GMP OkDokumen104 halaman9 GMP Okleonny slBelum ada peringkat

- GMP Slide ShareDokumen77 halamanGMP Slide SharePenmetsa Satyanarayana RajuBelum ada peringkat

- How To SanitationDokumen174 halamanHow To SanitationErick Moreira Valdez100% (1)

- PICs Annex1 Consultation Document Dec. 2017Dokumen50 halamanPICs Annex1 Consultation Document Dec. 2017DholakiaBelum ada peringkat

- 1 Location and SurroundingsDokumen10 halaman1 Location and SurroundingsNaveenbabu SoundararajanBelum ada peringkat

- Schedule T PDFDokumen10 halamanSchedule T PDFvikram chhabraBelum ada peringkat

- Enforcement+Regulation+of+the+Enforcement+Decree+on+the+Standards+of+Facilities+of+Manufacturers (No 1752) (Nov+19,2021)Dokumen10 halamanEnforcement+Regulation+of+the+Enforcement+Decree+on+the+Standards+of+Facilities+of+Manufacturers (No 1752) (Nov+19,2021)Mamangs BAPSSBelum ada peringkat

- 2.03.04 Manu Sites Vaccine Prod ControlDokumen11 halaman2.03.04 Manu Sites Vaccine Prod ControlPrabhu LancerBelum ada peringkat

- Yub Raj Neupane M.Pharma, Sem Ii Pharmaceutics Jamia Hamdard, New DelhiDokumen41 halamanYub Raj Neupane M.Pharma, Sem Ii Pharmaceutics Jamia Hamdard, New DelhiYub Raj NeupaneBelum ada peringkat

- GMP Checklist: Location and SurroundingsDokumen30 halamanGMP Checklist: Location and SurroundingsMv PatelBelum ada peringkat

- 21CFR Part 820: Basis For GMP RevisionDokumen37 halaman21CFR Part 820: Basis For GMP RevisionPhan ChaugiangBelum ada peringkat

- All You Never Wanted To Know About GLP and GMPDokumen55 halamanAll You Never Wanted To Know About GLP and GMPmuraliapBelum ada peringkat

- CFDA Good Manufacturing Practice (GMP) of Medical DevicesDokumen9 halamanCFDA Good Manufacturing Practice (GMP) of Medical DevicesAnonymous ihBB7CBelum ada peringkat

- Topic 2.1 Food Safety Requirement in Plant DesignDokumen54 halamanTopic 2.1 Food Safety Requirement in Plant DesignDorothy LimBelum ada peringkat

- 4.1 General: Chapter 4 - Facilities, Critical Systems and EquipmentDokumen20 halaman4.1 General: Chapter 4 - Facilities, Critical Systems and EquipmentDarlenis RodriguezBelum ada peringkat

- GMP Who GuidelineDokumen30 halamanGMP Who Guidelinedevang asherBelum ada peringkat

- CGMP, Production & Process ControlDokumen13 halamanCGMP, Production & Process ControlSayedul HamimBelum ada peringkat

- Guidelines Good Hygiene Practices For Small and Medium Scale Food Industries Towards HaccpDokumen14 halamanGuidelines Good Hygiene Practices For Small and Medium Scale Food Industries Towards HaccpSally Salina FarahBelum ada peringkat

- Session 2. Preparing For Cleaning ValidationDokumen49 halamanSession 2. Preparing For Cleaning Validationrizka_yiyisBelum ada peringkat

- The Good Manufacturing Practice For Pharmaceutical Products in Korea (KGMP)Dokumen29 halamanThe Good Manufacturing Practice For Pharmaceutical Products in Korea (KGMP)Rodrigo CenturionBelum ada peringkat

- Laundry Standards Codes of Practice 2012Dokumen19 halamanLaundry Standards Codes of Practice 2012Gino Paolo Andrade SalazarBelum ada peringkat

- CGMP Drinking WaterDokumen7 halamanCGMP Drinking Watererwan21Belum ada peringkat

- CGMP Regulations of Sterile ProductsDokumen33 halamanCGMP Regulations of Sterile ProductsSukesh Potla75% (4)

- SMF - Schedule M (20-22 Pages) PDFDokumen61 halamanSMF - Schedule M (20-22 Pages) PDFSrinivasBelum ada peringkat

- SASO 220 (GS 21E) Hygienic Regulations For Food Plants and Their PersonnelDokumen12 halamanSASO 220 (GS 21E) Hygienic Regulations For Food Plants and Their PersonnelAbdul RhmanBelum ada peringkat

- CDRHLearn ProductionandProcessControls Slides PDFDokumen53 halamanCDRHLearn ProductionandProcessControls Slides PDFmailtorubal2573Belum ada peringkat

- Food HandlingDokumen11 halamanFood Handlinginkpen56789Belum ada peringkat

- 3a CGMPDokumen73 halaman3a CGMPRICHELLE JIELEN QUEBEC100% (1)

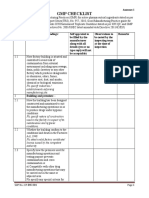

- GMP ChecklistDokumen10 halamanGMP Checklistkang adeBelum ada peringkat

- Introduction To Good Manufacturing Practices (GMP) : Presented by Mr. Sujit Kakade Assistant ProfessorDokumen31 halamanIntroduction To Good Manufacturing Practices (GMP) : Presented by Mr. Sujit Kakade Assistant ProfessorSujit KakadeBelum ada peringkat

- Cleanroom Technology: Fundamentals of Design, Testing and OperationDari EverandCleanroom Technology: Fundamentals of Design, Testing and OperationBelum ada peringkat

- Effective microbiological sampling of food processing environments (1999)Dari EverandEffective microbiological sampling of food processing environments (1999)Belum ada peringkat

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsDari EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsBelum ada peringkat

- Cleaning and disinfection of food factories: a practical guideDari EverandCleaning and disinfection of food factories: a practical guideBelum ada peringkat

- Energy Analysis of Closed Systems BreakdownDokumen31 halamanEnergy Analysis of Closed Systems Breakdownايات امجد امجدBelum ada peringkat

- Chefs at HomeDokumen4 halamanChefs at Homezbdv2kyzv7Belum ada peringkat

- Real Possibility of Future ConditionDokumen3 halamanReal Possibility of Future ConditionHusBelum ada peringkat

- PCB Table of Contents GuideDokumen3 halamanPCB Table of Contents GuidePreet ChahalBelum ada peringkat

- 32776Dokumen6 halaman32776Muqtar KhanBelum ada peringkat

- Surface Roughness Measurement - MitutoyoDokumen2 halamanSurface Roughness Measurement - MitutoyoSelvaraj BalasundramBelum ada peringkat

- General Science EnvironmentDokumen28 halamanGeneral Science EnvironmentHamza MujahidBelum ada peringkat

- Cambridge International AS & A Level: Mathematics 9709/13Dokumen20 halamanCambridge International AS & A Level: Mathematics 9709/13Justin OngBelum ada peringkat

- JJ309 Fluid Mechanics Unit 6Dokumen30 halamanJJ309 Fluid Mechanics Unit 6Adib AzharBelum ada peringkat

- Mastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesDokumen48 halamanMastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesSaul Saldana LoyaBelum ada peringkat

- Function and Definite Integrals ExplainedDokumen7 halamanFunction and Definite Integrals Explainedana maharaniBelum ada peringkat

- Cryptography 01092014Dokumen19 halamanCryptography 01092014Anshu MittalBelum ada peringkat

- A7670 Series Hardware Design v1.03Dokumen69 halamanA7670 Series Hardware Design v1.03Phạm NamBelum ada peringkat

- Briefing Paper No 4 CV Electrification 30 11 17 PDFDokumen5 halamanBriefing Paper No 4 CV Electrification 30 11 17 PDFAlex WoodrowBelum ada peringkat

- Organization Structure Training KAJARIADokumen30 halamanOrganization Structure Training KAJARIAViswanth GanaparthiBelum ada peringkat

- Balfour Relocation Feasibility StudyDokumen176 halamanBalfour Relocation Feasibility Studygreg32777Belum ada peringkat

- Project Cash FlowsDokumen2 halamanProject Cash FlowsAdarsh Chhajed20% (5)

- User Manual HDL 30 ADokumen36 halamanUser Manual HDL 30 AAgung KurniandraBelum ada peringkat

- Telemark PulloverDokumen2 halamanTelemark Pulloverkidknits100% (1)

- Answer Sheet FINAL LipidDokumen3 halamanAnswer Sheet FINAL LipidFaridah MagumparaBelum ada peringkat

- Indian War of Independence 1857 - Part 2Dokumen150 halamanIndian War of Independence 1857 - Part 2BISWAJIT MOHANTYBelum ada peringkat

- Unchained MelodeeDokumen93 halamanUnchained MelodeeRafael Cornholio RodriguezBelum ada peringkat

- Chem Tech South 2013 - ConferenceDokumen5 halamanChem Tech South 2013 - ConferenceAbirami PriyadharsiniBelum ada peringkat

- Multi Purpose StadiumDokumen130 halamanMulti Purpose StadiumEmmanuel SolomonBelum ada peringkat

- 3-Ph Induction MotorDokumen246 halaman3-Ph Induction MotorAn00pgadzillaBelum ada peringkat

- Macroeconomics II: Search and Matching: Luiz BrotherhoodDokumen18 halamanMacroeconomics II: Search and Matching: Luiz BrotherhoodMartin GutovskieBelum ada peringkat

- Calculator For SW Density Changes - Effect of List On Ships DraftDokumen3 halamanCalculator For SW Density Changes - Effect of List On Ships DraftHein Thurein KyawBelum ada peringkat

- 2023-05-11 St. Mary's County TimesDokumen40 halaman2023-05-11 St. Mary's County TimesSouthern Maryland OnlineBelum ada peringkat

- SEFT Islamic care effect on hypertension patients' blood pressureDokumen12 halamanSEFT Islamic care effect on hypertension patients' blood pressureSopian HadiBelum ada peringkat

- Personal Care Na Hair GuideDokumen8 halamanPersonal Care Na Hair GuideIsabellaBelum ada peringkat